欧洲药典8.0 buffer solutions

4.1.3.Buffer solutions EUROPEAN PHARMACOPOEIA

8.0

Sul?te standard solution (1.5ppm SO 2).5002900.Dissolve sodium metabisulfite R equivalent to 0.152g of Na 2S 2O 5in water R and dilute to 100.0mL with the same solvent.Dilute 5.0mL of this solution to 100.0mL with water R .To 3.0mL of the resulting solution,add 4.0mL of 0.1M sodium hydroxide and dilute to 100.0mL with water R .Thallium standard solution (10ppm Tl).5003000.

Dissolve thallous sulfate R equivalent to 0.1235g of Tl 2SO 4in a 9g/L solution of sodium chloride R and dilute to 1000.0mL with the same solution.Dilute 10.0mL of the solution to 100.0mL with the 9g/L solution of sodium chloride R .Tin liposoluble standard solution (1000ppm Sn).5005000.A tin (metal)organic compound in an oil.

Tin standard solution (5ppm Sn).5003100.Dissolve tin R equivalent to 0.500g of Sn in a mixture of 5mL of water R and 25mL of hydrochloric acid R and dilute to

1000.0mL with water R .Dilute the solution to 100times its

volume with a 2.5per cent V/V solution of hydrochloric acid R immediately before use.Tin standard solution (0.1ppm Sn).5003101.

Immediately before use,dilute tin standard solution (5ppm

Sn)R to 50times its volume with water R .Titanium standard solution (100ppm Ti).5003200.Dissolve 100.0mg of titanium R in 100mL of hydrochloric

acid R diluted to 150mL with water R ,heating if necessary.

Allow to cool and dilute to 1000mL with water R .Vanadium standard solution (1g/L V).5003300.Dissolve in water R ammonium vanadate R equivalent to

0.230g of NH 4VO 3and dilute to 100.0mL with the same

solvent.Zinc standard solution (5mg/mL Zn).5003400.Dissolve 3.15g of zinc oxide R in 15mL of hydrochloric acid R

and dilute to 500.0mL with water R .

Zinc standard solution (100ppm Zn).5003401.Immediately before use,dilute with water R to 10times its volume a solution containing zinc sulfate R equivalent to

0.440g of ZnSO 4,7H 2O and 1mL of acetic acid R in 100.0mL.Zinc standard solution (10ppm Zn).5003402.Immediately before use,dilute zinc standard solution (100ppm Zn)R to 10times its volume with water R .

Zinc standard solution (5ppm Zn).5003403.Immediately before use,dilute zinc standard solution (100ppm Zn)R to 20times its volume with water R .Zirconium standard solution (1g/L Zr).5003500.Dissolve zirconyl nitrate R equivalent to 0.293g of

ZrO(NO 3)2,2H 2O in a mixture of 2volumes of hydrochloric acid R and 8volumes of water R and dilute to 100.0mL with the same mixture of solvents.

01/2014:401034.1.3.BUFFER SOLUTIONS

Buffered acetone solution.4000100.

Dissolve 8.15g of sodium acetate R and 42g of sodium chloride R in water R ,add 68mL of 0.1M hydrochloric acid and 150mL of acetone R and dilute to 500mL with water R .Buffer solution pH 2.0.4000200.

Dissolve 6.57g of potassium chloride R in water R and add 119.0mL of 0.1M hydrochloric acid .Dilute to 1000.0mL with water R .Phosphate buffer solution pH 2.0.4007900.

Dissolve 8.95g of disodium hydrogen phosphate R and 3.40g of potassium dihydrogen phosphate R in water R and dilute to 1000.0mL with the same solvent.If necessary adjust the pH with phosphoric acid R .

Sulfate buffer solution pH 2.0.4008900.

Dissolve 132.1g of ammonium sulfate R in water R and dilute to 500.0mL with the same solvent (Solution A).Carefully and with constant cooling stir 14mL of sulfuric acid R into about 400mL of water R ;allow to cool and dilute to 500.0mL with water R (Solution B).Mix equal volumes of solutions A and B.Adjust the pH if necessary.

Buffer solution pH 2.2.4010500.

Mix 6.7mL of phosphoric acid R with 55.0mL of a 40g/L

solution of sodium hydroxide R and dilute to 1000.0mL with water R .Buffer solution pH 2.5.4000300.Dissolve 100g of potassium dihydrogen phosphate R in 800mL of water R ;adjust to pH 2.5with hydrochloric acid R and

dilute to 1000.0mL with water R .

Buffer solution pH 2.5R1.4000400.To 4.9g of dilute phosphoric acid R add 250mL of water R .

Adjust the pH with dilute sodium hydroxide solution R and

dilute to 500.0mL with water R .0.2M Phosphate buffer solution pH 2.5.4014100.Dissolve 27.2g of potassium dihydrogen phosphate R in about

900mL of water R ,adjust to pH 2.5with phosphoric acid R

and dilute to 1.0L with water R .Phosphate buffer solution pH 2.8.4010600.Dissolve 7.8g of sodium dihydrogen phosphate R in 900mL of

water R ,adjust to pH 2.8with phosphoric acid R and dilute to

1000mL with the same solvent.Buffer solution pH 3.0.4008000.Dissolve 21.0g of citric acid R in 200mL of 1M sodium

hydroxide and dilute to 1000mL with water R .Dilute 40.3mL of this solution to 100.0mL with 0.1M hydrochloric acid .0.25M Citrate buffer solution pH 3.0.4012600.

Dissolve 5.3g of citric acid R in 80mL of water R .Adjust the

pH with 1M sodium hydroxide and dilute to 100.0mL with water R .0.1M Phosphate buffer solution pH 3.0.4011500.

Dissolve 12.0g of anhydrous sodium dihydrogen phosphate R in water R ,adjust the pH with dilute phosphoric acid R1and dilute to 1000mL with water R .Phosphate buffer solution pH 3.0.4000500.

Mix 0.7mL of phosphoric acid R with 100mL of water R .Dilute to 900mL with the same solvent.Adjust to pH 3.0with strong sodium hydroxide solution R and dilute to 1000mL with water R .

Phosphate buffer solution pH 3.0R1.4010000.

Dissolve 3.40g of potassium dihydrogen phosphate R in

900mL of water R .Adjust to pH 3.0with phosphoric acid R and dilute to 1000.0mL with water R .

Phosphate buffer solution pH 3.2.4008100.

To 900mL of a 4g/L solution of sodium dihydrogen

phosphate R ,add 100mL of a 2.5g/L solution of phosphoric acid R .Adjust the pH if necessary.

Phosphate buffer solution pH 3.2R1.4008500.

Adjust a 35.8g/L solution of disodium hydrogen phosphate R to pH 3.2with dilute phosphoric acid R .Dilute 100.0mL of the solution to 2000.0mL with water R .

EUROPEAN PHARMACOPOEIA 8.0 4.1.3.Buffer

solutions

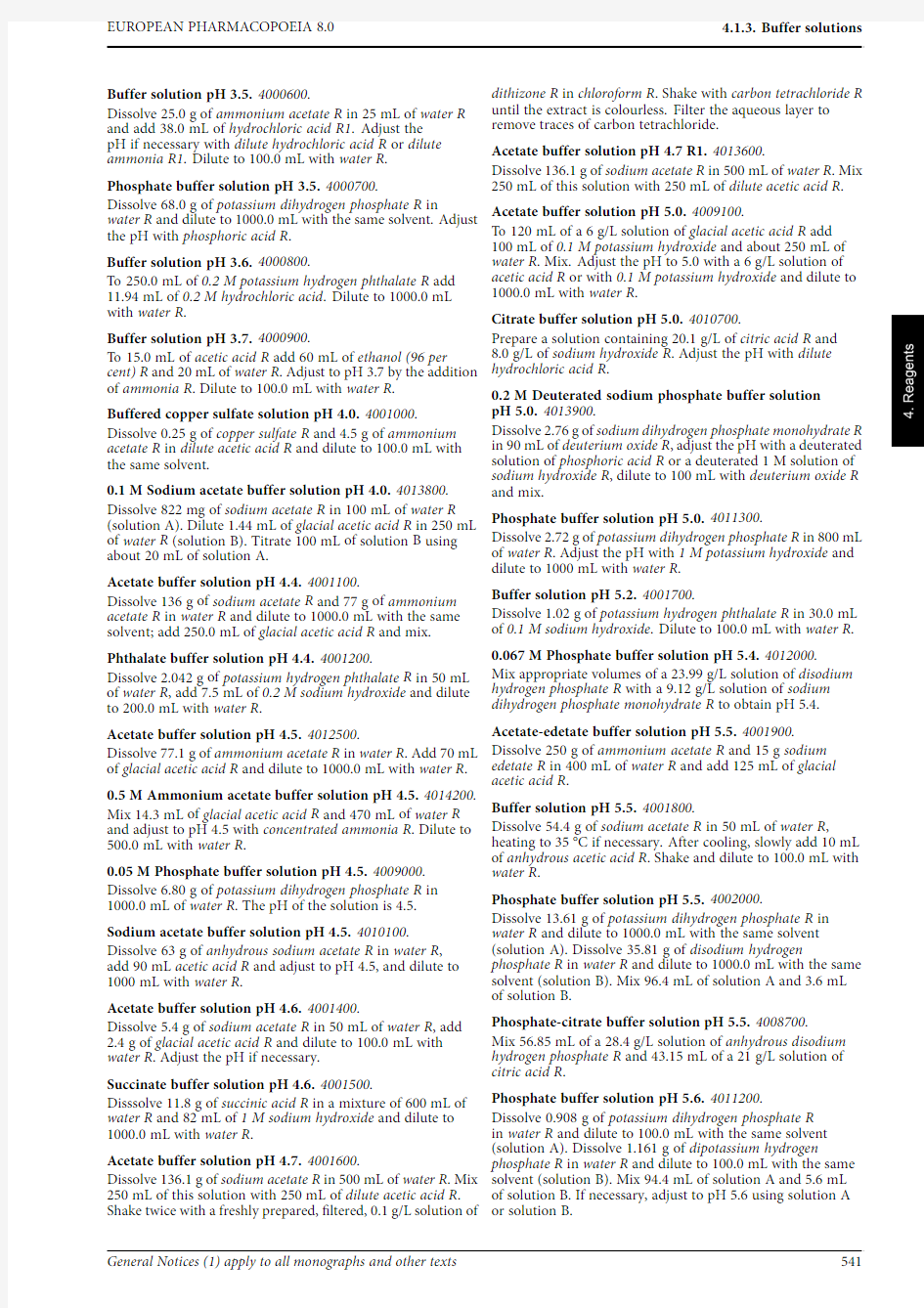

Buffer solution pH 3.5.4000600.

Dissolve 25.0g of ammonium acetate R in 25mL of water R and add 38.0mL of hydrochloric acid R1.Adjust the pH if necessary with dilute hydrochloric acid R or dilute ammonia R1.Dilute to 100.0mL with water R .

Phosphate buffer solution pH 3.5.4000700.

Dissolve 68.0g of potassium dihydrogen phosphate R in water R and dilute to 1000.0mL with the same solvent.Adjust

the pH with phosphoric acid R .

Buffer solution pH 3.6.4000800.To 250.0mL of 0.2M potassium hydrogen phthalate R add

11.94mL of 0.2M hydrochloric acid .Dilute to 1000.0mL

with water R .Buffer solution pH 3.7.4000900.

To 15.0mL of acetic acid R add 60mL of ethanol (96per

cent)R and 20mL of water R .Adjust to pH 3.7by the addition of ammonia R .Dilute to 100.0mL with water R .

Buffered copper sulfate solution pH 4.0.4001000.

Dissolve 0.25g of copper sulfate R and 4.5g of ammonium acetate R in dilute acetic acid R and dilute to 100.0mL with the same solvent.

0.1M Sodium acetate buffer solution pH 4.0.4013800.Dissolve 822mg of sodium acetate R in 100mL of water R (solution A).Dilute 1.44mL of glacial acetic acid R in 250mL of water R (solution B).Titrate 100mL of solution B using about 20mL of solution A.

Acetate buffer solution pH 4.4.4001100.

Dissolve 136g of sodium acetate R and 77g of ammonium acetate R in water R and dilute to 1000.0mL with the same solvent;add 250.0mL of glacial acetic acid R and mix.Phthalate buffer solution pH 4.4.4001200.

Dissolve 2.042g of potassium hydrogen phthalate R in 50mL of water R ,add 7.5mL of 0.2M sodium hydroxide and dilute to 200.0mL with water R .

Acetate buffer solution pH 4.5.4012500.

Dissolve 77.1g of ammonium acetate R in water R .Add 70mL of glacial acetic acid R and dilute to 1000.0mL with water R .

0.5M Ammonium acetate buffer solution pH 4.5.4014200.

Mix 14.3mL of glacial acetic acid R and 470mL of water R

and adjust to pH 4.5with concentrated ammonia R .Dilute to 500.0mL with water R .

0.05M Phosphate buffer solution pH 4.5.4009000.Dissolve 6.80g of potassium dihydrogen phosphate R in

1000.0mL of water R .The pH of the solution is 4.5.

Sodium acetate buffer solution pH 4.5.4010100.Dissolve 63g of anhydrous sodium acetate R in water R ,

add 90mL acetic acid R and adjust to pH 4.5,and dilute to

1000mL with water R .

Acetate buffer solution pH 4.6.4001400.

Dissolve 5.4g of sodium acetate R in 50mL of water R ,add

2.4g of glacial acetic acid R and dilute to 100.0mL with

water R .Adjust the pH if necessary.

Succinate buffer solution pH 4.6.4001500.

Disssolve 11.8g of succinic acid R in a mixture of 600mL of

water R and 82mL of 1M sodium hydroxide and dilute to

1000.0mL with water R .

Acetate buffer solution pH 4.7.4001600.Dissolve 136.1g of sodium acetate R in 500mL of water R .Mix 250mL of this solution with 250mL of dilute acetic acid R .Shake twice with a freshly prepared,?ltered,0.1g/L solution of dithizone R in chloroform R .Shake with carbon tetrachloride R until the extract is colourless.Filter the aqueous layer to remove traces of carbon tetrachloride.

Acetate buffer solution pH 4.7R1.4013600.

Dissolve 136.1g of sodium acetate R in 500mL of water R .Mix 250mL of this solution with 250mL of dilute acetic acid R .

Acetate buffer solution pH 5.0.4009100.To 120mL of a 6g/L solution of glacial acetic acid R add 100mL of 0.1M potassium hydroxide and about 250mL of

water R .Mix.Adjust the pH to 5.0with a 6g/L solution of

acetic acid R or with 0.1M potassium hydroxide and dilute to 1000.0mL with water R .Citrate buffer solution pH 5.0.4010700.Prepare a solution containing 20.1g/L of citric acid R and 8.0g/L of sodium hydroxide R .Adjust the pH with dilute hydrochloric acid R .

0.2M Deuterated sodium phosphate buffer solution pH 5.0.4013900.

Dissolve 2.76g of sodium dihydrogen phosphate monohydrate R in 90mL of deuterium oxide R ,adjust the pH with a deuterated solution of phosphoric acid R or a deuterated 1M solution of sodium hydroxide R ,dilute to 100mL with deuterium oxide R and mix.

Phosphate buffer solution pH 5.0.4011300.

Dissolve 2.72g of potassium dihydrogen phosphate R in 800mL of water R .Adjust the pH with 1M potassium hydroxide and dilute to 1000mL with water R .

Buffer solution pH 5.2.4001700.

Dissolve 1.02g of potassium hydrogen phthalate R in 30.0mL of 0.1M sodium hydroxide .Dilute to 100.0mL with water R .0.067M Phosphate buffer solution pH 5.4.4012000.

Mix appropriate volumes of a 23.99g/L solution of disodium hydrogen phosphate R with a 9.12g/L solution of sodium dihydrogen phosphate monohydrate R to obtain pH 5.4.

Acetate-edetate buffer solution pH 5.5.4001900.Dissolve 250g of ammonium acetate R and 15g sodium

edetate R in 400mL of water R and add 125mL of glacial acetic acid R .

Buffer solution pH 5.5.4001800.Dissolve 54.4g of sodium acetate R in 50mL of water R ,

heating to 35°C if necessary.After cooling,slowly add 10mL of anhydrous acetic acid R .Shake and dilute to 100.0mL with

water R .Phosphate buffer solution pH 5.5.4002000.Dissolve 13.61g of potassium dihydrogen phosphate R in

water R and dilute to 1000.0mL with the same solvent

(solution A).Dissolve 35.81g of disodium hydrogen phosphate R in water R and dilute to 1000.0mL with the same solvent (solution B).Mix 96.4mL of solution A and 3.6mL of solution B.

Phosphate-citrate buffer solution pH 5.5.4008700.Mix 56.85mL of a 28.4g/L solution of anhydrous disodium hydrogen phosphate R and 43.15mL of a 21g/L solution of citric acid R .

Phosphate buffer solution pH 5.6.4011200.Dissolve 0.908g of potassium dihydrogen phosphate R in water R and dilute to 100.0mL with the same solvent (solution A).Dissolve 1.161g of dipotassium hydrogen

phosphate R in water R and dilute to 100.0mL with the same solvent (solution B).Mix 94.4mL of solution A and 5.6mL of solution B.If necessary,adjust to pH 5.6using solution A or solution B.

4.1.3.Buffer solutions EUROPEAN PHARMACOPOEIA

8.0

Phosphate buffer solution pH5.8.4002100.

Dissolve1.19g of disodium hydrogen phosphate dihydrate R and8.25g of potassium dihydrogen phosphate R in water R and dilute to1000.0mL with the same solvent.

Acetate buffer solution pH6.0.4002200.

Dissolve100g of ammonium acetate R in300mL of water R, add4.1mL of glacial acetic acid R,adjust the pH if necessary using ammonia R or acetic acid R and dilute to500.0mL with water R.

Diethylammonium phosphate buffer solution pH6.0. 4002300.

Dilute68mL of phosphoric acid R to500mL with water R. To25mL of this solution add450mL of water R and6mL

of diethylamine R,adjust to pH6±0.05,if necessary,using diethylamine R or phosphoric acid R and dilute to500.0mL with water R.

Phosphate buffer solution pH6.0.4002400.

Mix63.2mL of a71.5g/L solution of disodium hydrogen phosphate R and36.8mL of a21g/L solution of citric acid R. Phosphate buffer solution pH6.0R1.4002500.

Dissolve6.8g of sodium dihydrogen phosphate R in water R and dilute to1000.0mL with water R.Adjust the pH with strong sodium hydroxide solution R.

Phosphate buffer solution pH6.0R2.4002600.

To250.0mL of0.2M potassium dihydrogen phosphate R add 28.5mL of0.2M sodium hydroxide and dilute to1000.0mL with water R.

Phosphate buffer solution pH6.4.4002800.

Dissolve2.5g of disodium hydrogen phosphate R,2.5g of sodium dihydrogen phosphate R and8.2g of sodium chloride R in950mL of water R.Adjust the pH of the solution to6.4with 1M sodium hydroxide or1M hydrochloric acid,if necessary. Dilute to1000.0mL with water R.

0.5M Phthalate buffer solution pH6.4.4009200. Dissolve100g of potassium hydrogen phthalate R in water R and dilute to1000.0mL with the same solvent.Adjust the pH if necessary,using strong sodium hydroxide solution R. Buffer solution pH6.5.4002900.

Dissolve60.5g of disodium hydrogen phosphate R and46g of potassium dihydrogen phosphate R in water R.Add100mL of 0.02M sodium edetate and20mg of mercuric chloride R and dilute to1000.0mL with water R.

Imidazole buffer solution pH6.5.4003000.

Dissolve6.81g of imidazole R,1.23g of magnesium sulfate R and0.73g of calcium sulfate R in752mL of0.1M hydrochloric acid.Adjust the pH if necessary and dilute to1000.0mL with water R.

0.1M phosphate buffer solution pH6.5.4010800. Dissolve13.80g of sodium dihydrogen phosphate monohydrate R in900mL of distilled water R.Adjust the pH using a400g/L solution of sodium hydroxide R.Dilute to 1000mL with distilled water R.

Phosphate buffer solution pH6.5.4012800.

Dissolve2.75g of sodium dihydrogen phosphate R and4.5g of sodium chloride R in500mL of water R.Adjust the pH with phosphate buffer solution pH8.5R.

Buffer solution pH6.6.4003100.

To250.0mL of0.2M potassium dihydrogen phosphate R add 89.0mL of0.2M sodium hydroxide.Dilute to1000.0mL with water R.0.1M Phosphate buffer solution pH6.7.4014300. Dissolve15.6g of sodium dihydrogen phosphate R in water R and dilute to1.0L with the same solvent.Dissolve17.8g of disodium hydrogen phosphate dihydrate R in water R and dilute to1.0L with the same solvent.Mix the solutions,check the pH and if necessary adjust to pH6.7.

Phosphate buffered saline pH6.8.4003200.

Dissolve1.0g of potassium dihydrogen phosphate R,2.0g

of dipotassium hydrogen phosphate R and8.5g of sodium chloride R in900mL of water R,adjust the pH if necessary and dilute to1000.0mL with the same solvent. Phosphate buffer solution pH6.8.4003300.

Mix77.3mL of a71.5g/L solution of disodium hydrogen phosphate R with22.7mL of a21g/L solution of citric acid R. Phosphate buffer solution pH6.8R1.4003400.

To51.0mL of a27.2g/L solution of potassium dihydrogen phosphate R add49.0mL of a71.6g/L solution of disodium hydrogen phosphate R.Adjust the pH if necessary. Storage:at2°C to8°C.

1M tris-hydrochloride buffer solution pH6.8.4009300. Dissolve60.6g of tris(hydroxymethyl)aminomethane R in 400mL of water R.Adjust the pH with hydrochloric acid R and dilute to500.0mL with water R.

Buffer solution pH7.0.4003500.

To1000mL of a solution containing18g/L of disodium hydrogen phosphate R and23g/L of sodium chloride R add suf?cient(about280mL)of a solution containing7.8g/L

of sodium dihydrogen phosphate R and23g/L of sodium chloride R to adjust the pH.Dissolve in the solution suf?cient sodium azide R to give a0.2g/L solution.

Maleate buffer solution pH7.0.4003600.

Dissolve10.0g of sodium chloride R,6.06g of

tris(hydroxymethyl)aminomethane R and4.90g of maleic anhydride R in900mL of water R.Adjust the pH using a 170g/L solution of sodium hydroxide R.Dilute to1000.0mL with water R.

Storage:at2°C to8°C;use within3days.

0.025M Phosphate buffer solution pH7.0.4009400.

Mix1volume of0.063M phosphate buffer solution pH7.0R with1.5volumes of water R.

0.03M Phosphate buffer solution pH7.0.4010300. Dissolve5.2g of dipotassium hydrogen phosphate R in

900mL of water for chromatography R.Adjust the solution to pH7.0±0.1using phosphoric acid R and dilute to1000mL with water for chromatography R.

0.05M Phosphate buffer solution pH7.0.4012400.

Mix34mL of water R and100mL of0.067M phosphate buffer solution pH7.0R.

0.063M Phosphate buffer solution pH7.0.4009500. Dissolve5.18g of anhydrous disodium hydrogen phosphate R and3.65g of sodium dihydrogen phosphate monohydrate R in 950mL of water R and adjust the pH with phosphoric acid R; dilute to1000.0mL with water R.

0.067M Phosphate buffer solution pH7.0.4003800. Dissolve0.908g of potassium dihydrogen phosphate R

in water R and dilute to100.0mL with the same solvent (solution A).Dissolve2.38g of disodium hydrogen phosphate R in water R and dilute to100.0mL with the same solvent (solution B).Mix38.9mL of solution A and61.1mL of solution B.Adjust the pH if necessary.

EUROPEAN PHARMACOPOEIA 8.0 4.1.3.Buffer

solutions

0.1M Phosphate buffer solution pH 7.0.4008200.Dissolve 1.361g of potassium dihydrogen phosphate R in water R and dilute to 100.0mL with the same solvent.

Adjust the pH using a 35g/L solution of disodium hydrogen phosphate R .

Phosphate buffer solution pH 7.0.4003700.

Mix 82.4mL of a 71.5g/L solution of disodium hydrogen phosphate R with 17.6mL of a 21g/L solution of citric acid R .Phosphate buffer solution pH 7.0R1.4003900.

Mix 250.0mL of 0.2M potassium dihydrogen phosphate R and 148.2mL of a 8g/L solution of sodium hydroxide R ,adjust the pH if necessary.Dilute to 1000.0mL with water R .

Phosphate buffer solution pH 7.0R2.4004000.

Mix 50.0mL of a 136g/L solution of potassium dihydrogen

phosphate R with 29.5mL of 1M sodium hydroxide and dilute to 100.0mL with water R .Adjust the pH to 7.0±0.1.Phosphate buffer solution pH 7.0R3.4008600.Dissolve 5g of potassium dihydrogen phosphate R and 11g

of dipotassium hydrogen phosphate R in 900mL of water R .

Adjust to pH 7.0with dilute phosphoric acid R or dilute sodium hydroxide solution R .Dilute to 1000mL with water R and mix.Phosphate buffer solution pH 7.0R4.4010200.

Dissolve 28.4g of anhydrous disodium hydrogen phosphate R and 18.2g of potassium dihydrogen phosphate R in water R and dilute to 500mL with the same solvent.

Phosphate buffer solution pH 7.0R5.4011400.

Dissolve 28.4g of anhydrous disodium hydrogen phosphate R in 800mL of water R .Adjust the pH using a 30per cent m/m solution of phosphoric acid R and dilute to 1000mL with water R .

Tetrabutylammonium buffer solution pH 7.0.4010900.Dissolve 6.16g of ammonium acetate R in a mixture of 15mL of tetrabutylammonium hydroxide solution (400g/L)R and 185mL of water R .Adjust the pH with nitric acid R .Buffered salt solution pH 7.2.4004300.

Dissolve in water R 8.0g of sodium chloride R ,0.2g of potassium chloride R ,0.1g of anhydrous calcium chloride R ,0.1g of magnesium chloride R ,3.18g of disodium hydrogen phosphate R and 0.2g of potassium dihydrogen phosphate R and dilute to 1000.0mL with water R .

Buffer solution pH 7.2.4004100.

To 250.0mL of 0.2M potassium dihydrogen phosphate R add 175.0mL of 0.2M sodium hydroxide .Dilute to 1000.0mL with water R .Adjust the pH if necessary.

Phosphate-albumin buffered saline pH 7.2.4004400.

Dissolve 10.75g of disodium hydrogen phosphate R ,7.6g of sodium chloride R and 10g of bovine albumin R in water R and dilute to 1000.0mL with the same solvent.Immediately before use adjust the pH using dilute sodium hydroxide solution R or dilute phosphoric acid R .

Phosphate-albumin buffered saline pH 7.2R1.4009600.Dissolve 10.75g of disodium hydrogen phosphate R ,7.6g of sodium chloride R and 1g of bovine albumin R in water R and dilute to 1000.0mL with the same solvent.Immediately before use adjust the pH using dilute sodium hydroxide solution R

or dilute phosphoric acid R .

Phosphate buffer solution pH 7.2.4004200.Mix 87.0mL of a 71.5g/L solution of disodium hydrogen

phosphate R with 13.0mL of a 21g/L solution of citric acid R .Imidazole buffer solution pH 7.3.4004500.

Dissolve 3.4g of imidazole R and 5.8g of sodium chloride R in water R ,add 18.6mL of 1M hydrochloric acid and dilute to 1000.0mL with water R .Adjust the pH if necessary.

Barbital buffer solution pH 7.4.4004700.

Mix 50mL of a solution in water R containing 19.44g/L of sodium acetate R and 29.46g/L of barbital sodium R with 50.5mL of 0.1M hydrochloric acid ,add 20mL of an 85g/L of sodium chloride R and dilute to 250mL with water R .Buffer solution pH 7.4.4004600.

Dissolve 0.6g of potassium dihydrogen phosphate R ,6.4g of disodium hydrogen phosphate R and 5.85g of sodium chloride R in water R ,and dilute to 1000.0mL with the same solvent.Adjust the pH if necessary.

Phosphate buffered saline pH 7.4.4005000.Dissolve 2.38g of disodium hydrogen phosphate R ,0.19g of potassium dihydrogen phosphate R and 8.0g of sodium

chloride R in water.Dilute to 1000.0mL with the same solvent.

Adjust the pH if necessary.Phosphate buffer solution pH 7.4.4004800.Add 250.0mL of 0.2M potassium dihydrogen phosphate R to 393.4mL of 0.1M sodium hydroxide .Tris(hydroxymethyl)aminomethane buffer solution pH 7.4.4012100.

Dissolve 30.3g of tris(hydroxymethyl)aminomethane R in approximately 200mL of water R .Add 183mL of 1M hydrochloric acid .Dilute to 500.0mL with water R .Note:the pH is 7.7-7.8at room temperature and 7.4at 37°C.This solution is stable for several months at 4°C.

Tris(hydroxymethyl)aminomethane sodium chloride buffer solution pH 7.4.4004900.

Dissolve 6.08g of tris(hydroxymethyl)aminomethane R ,8.77g of sodium chloride R in 500mL of distilled water R .Add 10.0g of bovine albumin R .Adjust the pH using hydrochloric acid R .Dilute to 1000.0mL with distilled water R .

Tris(hydroxymethyl)aminomethane sodium chloride buffer solution pH 7.4R1.4012200.

Dissolve 0.1g of bovine albumin R in a mixture containing 2mL of tris(hydroxymethyl)aminomethane buffer solution pH 7.4R and 50mL of a 5.84mg/mL solution of sodium chloride R .Dilute to 100.0mL with water R .

Tris-sodium acetate buffer solution pH 7.4.4012900.Dissolve 6.3g of tris(hydroxymethyl)aminomethane R and 4.9g of anhydrous sodium acetate R in 900mL of water R .Adjust to pH 7.4with sulfuric acid R and dilute to 1000mL with water R .

Tris-sodium acetate-sodium chloride buffer solution pH 7.4.4013000.

Dissolve 30.0g of tris(hydroxymethyl)aminomethane R ,14.5g

of anhydrous sodium acetate R and 14.6g of sodium chloride R in 900mL of water R .Add 0.50g of bovine albumin R .Adjust to pH 7.4with sulfuric acid R and dilute to 1000mL with water R .Borate buffer solution pH 7.5.4005200.

Dissolve 2.5g of sodium chloride R ,2.85g of disodium tetraborate R and 10.5g of boric acid R in water R and dilute to 1000.0mL with the same solvent.Adjust the pH if necessary.Storage :at 2°C to 8°C.Buffer (HEPES)solution pH 7.5.4009700.Dissolve 2.38g of 2-[4-(2-hydroxyethyl)piperazin-1-yl]ethanesulfonic acid R in about 90mL of water R .Adjust the

pH to 7.5with sodium hydroxide solution R .Dilute to 100mL with water R .

4.1.3.Buffer solutions EUROPEAN PHARMACOPOEIA

8.0

0.05M Phosphate buffer solution pH7.5.4014400. Dissolve0.89g of disodium hydrogen phosphate dihydrate R in about80mL of water R.Adjust to pH7.5with an8.5per cent V/V solution of phosphoric acid R and dilute to100.0mL with water R.

0.2M Phosphate buffer solution pH7.5.4005400. Dissolve27.22g of potassium dihydrogen phosphate R in

930mL of water R,adjust to pH7.5with a300g/L solution of potassium hydroxide R and dilute to1000.0mL with water R.

0.33M Phosphate buffer solution pH7.5.4005300. Dissolve119.31g of disodium hydrogen phosphate R in water R and dilute to1000.0mL with the same solvent(solution A). Dissolve45.36g of potassium dihydrogen phosphate R in water R and dilute to1000.0mL with the same solvent (solution B).Mix85mL of solution A and15mL of solution B. Adjust the pH if necessary.

0.05M Tris-hydrochloride buffer solution pH7.5.4005600. Dissolve6.057g of tris(hydroxymethyl)aminomethane R in water R and adjust the pH with hydrochloric acid R.Dilute to 1000.0mL with water R.

1M Tris-hydrochloride buffer solution pH7.5.4014500. Dissolve12.11g of tris(hydroxymethyl)aminomethane R in 90mL of water R,adjust to pH7.5with hydrochloric acid R and dilute to100.0mL with water R.

Tris(hydroxymethyl)aminomethane buffer solution pH7.5. 4005500.

Dissolve7.27g of tris(hydroxymethyl)aminomethane R and 5.27g of sodium chloride R in water R,and adjust the pH if necessary.Dilute to1000.0mL with water R.

Sodium citrate buffer solution pH7.8(0.034M sodium citrate,0.101M sodium chloride).4009800.

Dissolve10.0g of sodium citrate R and5.90g of sodium chloride R in900mL of water R.Adjust the pH by addition of hydrochloric acid R and dilute to1000mL with water R.

0.0015M Borate buffer solution pH8.0.4006000. Dissolve0.572g of disodium tetraborate R and2.94g of calcium chloride R in800mL of water R.Adjust the pH with 1M hydrochloric acid.Dilute to1000.0mL with water R. Buffer solution pH8.0.4005900.

To50.0mL of0.2M potassium dihydrogen phosphate R add 46.8mL of0.2M sodium hydroxide.Dilute to200.0mL with water R.

Buffer solution pH8.0R1.4010400.

Dissolve20g of dipotassium hydrogen phosphate R in900mL of water R.Adjust the pH with phosphoric acid R.Dilute to 1000mL with water R.

0.02M Phosphate buffer solution pH8.0.4006100.

To50.0mL of0.2M potassium dihydrogen phosphate R add 46.8mL of0.2M sodium hydroxide.Dilute to500.0mL with water R.

0.02M Sodium phosphate buffer solution pH8.0.4013700. Dissolve0.31g of sodium dihydrogen phosphate R in70mL of water R and adjust to pH8.0with1M sodium hydroxide,then dilute to100mL with water R.

0.1M Phosphate buffer solution pH8.0.4008400. Dissolve0.523g of potassium dihydrogen phosphate R and 16.73g of dipotassium hydrogen phosphate R in water R and dilute to1000.0mL with the same solvent.

1M Phosphate buffer solution pH8.0.4007800.

Dissolve136.1g of potassium dihydrogen phosphate R in water R,adjust the pH with1M sodium hydroxide.Dilute to 1000.0mL with water R.1M Tris-hydrochloride buffer solution pH8.0.4012700. Dissolve121.1g of tris(hydroxymethyl)aminomethane R and 1.47g of calcium chloride R in900mL of water R.Adjust the pH with hydrochloric acid R and dilute to1000.0mL with water R.

Tris-hydrochloride buffer solution pH8.0.4012300. Dissolve1.21g of tris(hydroxymethyl)aminomethane R and 29.4mg of calcium chloride R in water R.Adjust the pH with 1M hydrochloric acid and dilute to100.0mL with water R. Tris-sodium acetate buffer solution pH8.0.4013100. Dissolve6.3g of tris(hydroxymethyl)aminomethane R and 4.9g of anhydrous sodium acetate R in900mL of water R. Adjust to pH8.0with sulfuric acid R and dilute to1000mL with water R.

Tris-sodium acetate-sodium chloride buffer solution

pH8.0.4013200.

Dissolve30.0g of tris(hydroxymethyl)aminomethane R,14.5g of anhydrous sodium acetate R and14.6g of sodium chloride R in900mL of water R.Add0.50g of bovine albumin R.Adjust to pH8.0with sulfuric acid R and dilute to1000mL with water R.

Tris(hydroxymethyl)aminomethane buffer solution pH8.1. 4006200.

Dissolve0.294g of calcium chloride R in40mL of

tris(hydroxymethyl)aminomethane solution R and adjust the pH with1M hydrochloric acid.Dilute to100.0mL with water R.

Tris-glycine buffer solution pH8.3.4006300.

Dissolve6.0g of tris(hydroxymethyl)aminomethane R and 28.8g of glycine R in water R and dilute to1000.0mL with the same solvent.Dilute1volume to10volumes with water R immediately before use.

Tris-hydrochloride buffer solution pH8.3.4011800. Dissolve9.0g of tris(hydroxymethyl)aminomethane R in2.9L of water R.Adjust the pH with1M hydrochloric acid.Adjust the volume to3L with water R.

0.05M Tris-hydrochloride buffer solution pH9.0.4013500. Dissolve0.605g of tris(hydroxymethyl)aminomethane R in water R.Adjust the pH with1M hydrochloric acid and dilute to100.0mL with water R.

Barbital buffer solution pH8.4.4006400.

Dissolve8.25g of barbital sodium R in water R and dilute to 1000.0mL with the same solvent.

Tris-EDTA BSA buffer solution pH8.4.4006500. Dissolve6.1g of tris(hydroxymethyl)aminomethane R,2.8g of sodium edetate R,10.2g of sodium chloride R and10g

of bovine albumin R in water R,adjust to pH8.4using1M hydrochloric acid and dilute to1000.0mL with water R.

Tris(hydroxymethyl)aminomethane-EDTA buffer solution pH8.4.4006600.

Dissolve5.12g of sodium chloride R,3.03g of

tris(hydroxymethyl)aminomethane R and1.40g of sodium edetate R in250mL of distilled water R.Adjust the pH to8.4 using hydrochloric acid R.Dilute to500.0mL with distilled water R.

Guanidine-tris(hydroxymethyl)aminomethane-EDTA buffer solution pH8.5.4014600.

Dissolve1.0g of sodium edetate R,12.1g of

tris(hydroxymethyl)aminomethane R and57.0g of guanidine hydrochloride R in35mL of water R.Adjust to

pH8.5with hydrochloric acid R and dilute to100mL with water R.

EUROPEAN PHARMACOPOEIA 8.0 4.2.1.Primary standards for volumetric

solutions

Phosphate buffer solution pH 8.5.4013300.

Dissolve 3.5g of dipotassium hydrogen phosphate R and 4.5g of sodium chloride R in 500mL of water R .Adjust the pH with a mixture of equal volumes of dilute phosphoric acid R and water R .

Tris acetate buffer solution pH 8.5.4006700.

Dissolve 0.294g of calcium chloride R and 12.11g of

tris(hydroxymethyl)aminomethane R in water R .Adjust the pH with acetic acid R .Dilute to 1000.0mL with water R .Barbital buffer solution pH 8.6R1.4006900.

Dissolve in water R 1.38g of barbital R ,8.76g of barbital sodium R and 0.38g of calcium lactate R and dilute to 1000.0mL with the same solvent.

1.5M tris-hydrochloride buffer solution pH 8.8.4009900.

Dissolve 90.8g of tris(hydroxymethyl)aminomethane R in 400mL of water R .Adjust the pH with hydrochloric acid R and dilute to 500.0mL with water R .Buffer (phosphate)solution pH 9.0.4008300.

Dissolve 1.74g of potassium dihydrogen phosphate R in 80mL of water R ,adjust the pH with 1M potassium hydroxide and dilute to 100.0mL with water R .

Buffer solution pH 9.0.4007000.

Dissolve 6.18g of boric acid R in 0.1M potassium chloride R

and dilute to 1000.0mL with the same solvent.Mix 1000.0mL

of this solution and 420.0mL of 0.1M sodium hydroxide .Buffer solution pH 9.0R1.4007100.

Dissolve 6.20g of boric acid R in 500mL of water R and adjust the pH with 1M sodium hydroxide (about 41.5mL).Dilute to 1000.0mL with water R .

Ammonium chloride buffer solution pH 9.5.4007200.

Dissolve 33.5g of ammonium chloride R in 150mL of water R ,add 42.0mL of concentrated ammonia R and dilute to 250.0mL with water R .

Storage :in a polyethylene container.

Ammonium chloride buffer solution pH 10.0.4007300.Dissolve 5.4g of ammonium chloride R in 20mL of water R ,add 35.0mL of ammonia R and dilute to 100.0mL with water R .

Diethanolamine buffer solution pH 10.0.4007500.Dissolve 96.4g of diethanolamine R in water R and dilute to 400mL with the same solvent.Add 0.5mL of an 186g/L solution of magnesium chloride R and adjust the pH with 1M hydrochloric acid .Dilute to 500.0mL with water R .0.1M Ammonium carbonate buffer solution pH 10.3.4011900.

Dissolve 7.91g of ammonium carbonate R in 800mL of water R .Adjust the pH with dilute sodium hydroxide solution R .Dilute to 1000.0mL with water R .

Ammonium chloride buffer solution pH 10.4.4011000.Dissolve 70g of ammonium chloride R in 200mL of water R ,add 330mL of concentrated ammonia R and dilute to

1000.0mL with water R .If necessary,adjust to pH 10.4with ammonia R .

Borate buffer solution pH 10.4.4011100.

Dissolve 24.64g of boric acid R in 900mL of distilled water R .Adjust the pH using a 400g/L solution of sodium hydroxide R .Dilute to 1000mL with distilled water R .

Ammonium chloride buffer solution pH 10.7.4013400.Dissolve 67.5g of ammonium chloride R in water R ,add 570mL of concentrated ammonia R and dilute to 1000.0mL with water R .

Buffer solution pH 10.9.4007600.

Dissolve 6.75g of ammonium chloride R in ammonia R and dilute to 100.0mL with the same solvent.

Total-ionic-strength-adjustment buffer.4007700.Dissolve 58.5g of sodium chloride R ,57.0mL of glacial acetic acid R ,61.5g of sodium acetate R and 5.0g of

cyclohexylenedinitrilotetra-acetic acid R in water R and dilute to 500.0mL with the same solvent.Adjust to pH 5.0to 5.5with a 335g/L solution of sodium hydroxide R and dilute to 1000.0mL with distilled water R .

Total-ionic-strength-adjustment buffer R1.4008800.

Dissolve 210g of citric acid R in 400mL of distilled water R .Adjust to pH 7.0with concentrated ammonia R .Dilute to 1000.0mL with distilled water R (solution A).Dissolve 132g of ammonium phosphate R in distilled water R and

dilute to 1000.0mL with the same solvent (solution B).To a suspension of 292g of (ethylenedinitrilo)tetra-acetic acid R in about 500mL of distilled water R ,add about 200mL of

concentrated ammonia R to dissolve.Adjust the pH to 6to 7with concentrated ammonia R .Dilute to 1000.0mL with

distilled water R (solution C).Mix equal volumes of solution A,B,and C and adjust to pH 7.5with concentrated ammonia R .Buffer solution pH 11.4014000.

Dissolve 6.21g of boric acid R ,4.00g of sodium hydroxide R

and 3.70g of potassium chloride R in 500mL of water R and

dilute to 1000mL with the same solvent.

4.2.VOLUMETRIC ANALYSIS

04/2010:40201

4.2.1.PRIMARY STANDARDS FOR VOLUMETRIC SOLUTIONS

Primary standards for volumetric solutions are indicated by the suf?x RV .Primary standards of suitable quality may be obtained from commercial sources or prepared by the following methods.

Arsenious trioxide.As 2O 3.(M r 197.8).2000100.[1327-53-3].Sublime arsenious trioxide R in a suitable apparatus.Storage :over anhydrous silica gel R .

Benzoic acid.C 7H 6O 2.(M r 122.1).2000200.[65-85-0].Sublime benzoic acid R in a suitable apparatus.

Potassium bromate.KBrO 3.(M r 167.0).2000300.[7758-01-2].

Crystallise potassium bromate R from boiling water R .Collect the crystals and dry to constant mass at 180°C.

Potassium hydrogen phthalate.C 8H 5KO 4.(M r 204.2).2000400.[877-24-7].

Recrystallise potassium hydrogen phthalate R from boiling water R ,collect the crystals at a temperature above 35°C and dry to constant mass at 110°C.

Sodium carbonate.Na 2CO 3.(M r 106.0).2000500.[497-19-8].

Filter at room temperature a saturated solution of sodium carbonate R .Introduce slowly into the ?ltrate a stream of carbon dioxide R with constant cooling and stirring.After about 2h,collect the precipitate on a sintered-glass ?lter (2.1.2).Wash the ?lter with iced water R containing carbon dioxide.After drying at 100°C to 105°C,heat to constant mass at 270-300°C,stirring from time to time.

USP39 注射剂通则

tion as constituted for administration are not included in the individual monographs on sterile dry solids or liquid concentrates. However, in the interest of assuring the quality of injection preparations as they are actually administered, the following non-destructive tests are provided for demonstrating the suitability of constituted solutions when they are prepared just prior to use. Completeness and Clarity of Solution—Constitute the solution as directed in the labeling supplied by the manufacturer for the sterile dry dosage form. A:The solid dissolves completely, leaving no visible residue as undissolved matter. B:The constituted solution is not significantly less clear than an equal volume of the diluent or of Purified Water contained in a similar vessel and examined similarly. Particulate Matter—Constitute the solution as directed in the labeling supplied by the manufacturer for the sterile dry dos-age form: the solution is essentially free from particles of foreign matter that can be observed on visual inspection. á1? INJECTIONS AND IMPLANTED DRUG PRODUCTS (PARENTERALS)—PRODUCT QUALITY TESTS (Chapter to become official May 1, 2016) (Current chapter name is á1? Injections) INTRODUCTION Parenteral drug products include both injections and implanted drug products that are injected through the skin or other external boundary tissue, or implanted within the body to allow the direct administration of the active drug substance(s) into blood vessels, organs, tissues, or lesions. Injections may exist as either immediate- or extended-release dosage forms. Implan-ted parenteral drug products are long-acting dosage forms that provide continuous release of the active drug substance(s) of-ten for periods of months to years. For systemic delivery, they may be placed subcutaneously; for local delivery, they may be placed in a specific region of the body. Routes of administration for parenteral drug products include intravenous, intraventric-ular, intra-arterial, intra-articular, subcutaneous, intramuscular, intrathecal, intracisternal, and intraocular. Parenteral dosage forms include solutions, suspensions, emulsions, sterile powders for solutions and suspensions (including liposomes), implants (including microparticles), and products that consist of both a drug and a device such as drug-eluting stents. The reader is directed to Pharmaceutical Dosage Forms á1151?1 and to the later sections of this chapter for additional descriptions of dosage forms that fall into the general category of parenteral drug products. Nomenclature á1121?1 provides information on nomenclature used to establish USP names and monograph titles for parenteral drug products. Chapter á1? provides a framework to support the revision and the development of individual monographs, and is not meant to replace individual monographs. Chapter á1? provides lists of common product quality test requirements in a concise and a coherent fashion. The chapter is divided into four main sections: (1) universal product quality tests that are applicable to pa-rental dosage forms; (2) specific product quality tests, which are tests that should be considered in addition to Universal Tests; (3) product quality tests for specific dosage forms, which lists all the applicable tests (Universal and Specific) for the specific dosage form; and (4) product performance tests. If a monograph exists, it will reference á1? or indicated chapter parts. If a specific drug product monograph is missing (not in existence), the general chapters provide the quality tests that can be used by manufacturers until the dosage form monograph is developed by USP. The Pharmacopeial definitions for sterile preparations for parenteral use may not apply to some biologics because of their special nature and licensing requirements (see Biologics á1041?1). However, some biological finished drug products containing “Injection” in the monograph title must meet the requirements of á1? or indicated chapter subparts, where it is specified in the monograph. Drug Product Quality and Drug Product Performance Tests Procedures and acceptance criteria for testing parenteral drug products are divided into two categories: (1) those that assess product quality attributes, e.g., identification, sterility, and particulate matter, and are contained in this chapter and (2) those that assess product performance, e.g., in vitro release of the drug substance from the drug product. Whereas quality tests as-sess the integrity of the dosage form, the performance tests assess performance (bioavailability) after the product has been administered to the patient. A product performance test, i.e., drug release test for suspensions, emulsions, powder for suspen-sion (including microparticles and liposomes), and drug-eluting stents, should be carried out using appropriate test proce-dures. 1All listed chapters above á1000? are for information purposes only; they may be helpful but are not mandatory.

国内外药品包装体系及其包材相应试验

国内外药品包装体系及其包材相应试验(一) 药品包装是指直接接触药品的包装材料和容器,属于专用包装范畴,它具有包装的所有属性,并有其特殊性:1、能保护药品在贮藏、使用过程中不受环境的影响,保持药品原有属性2、药品包装材料自身在贮藏、使用过程中性质应有一定的稳定性3、药品包装材料在包裹药品时不能污染药品生产环境。4、药品包装材料不得带有在使用过程中不能消除的对所包装药物有影响的物质。5、药品包装材料与所包装的药品不能发生化学、生物意义上的反应。为了确认药品包装材料可被用于包裹药品,有必要对这些材料进行质量监控 一、药品包装分类 (一)按药品包装材料、容器所使用的成份可分为:塑料、橡胶(或弹性体)、玻璃、金属及其它类(如布类、陶瓷类、纸类、干燥剂类)等五类。 (二)按药品包装材料、容器的形状也可分为:容器(如口服固体药用高密度聚乙烯瓶等)、硬片或袋(如PVC固体药用硬片、药品包装用复合膜、袋等)、塞(如药用氯化丁基橡胶塞)、盖(如口服液瓶撕拉铝盖)、辅助用途(如输液接口)等五类。 二、药品包装材料标准体系 为确保药品的安全、有效使用,各国均对药品包装材料和容器进行质量控制,标准体系主要有 1、药典体系:各发达国家药典附录均收载有药品包装材料的技术要求 2、ISO体系:根据材料及形状制定标准(如铝盖、玻璃输液瓶) 3、各国工业标准体系:如英国工业标准BS等,已逐渐向ISO标准转化 4、国内标准体系:工业标准形式上与ISO标准相同,安全项目略少于先进国家药典。为有效控制药品包装材料的质量,国家食品药品监督管理局已于2002年始,制定并颁布相应的药品包装材料容器的质量标准,加强对材料的物理、机械性能、化学性能、安全性能的控制。 国际标准、各国药典都是药品包装国际市场共同遵循的技术依据,其中,药典侧重于材料、容器的安全性评价,国际标准侧重于产品使用性能的评价。 三、各国药品包装容器质量标准体系内容介绍 1、美国药典对玻璃产品控制的项目有:透光率试验、耐水性试验、砷浸出量试验等; 对PE或PET产品(适用于口服固体制剂)控制的项目有:红外测定、热分析、透光率试验、水蒸气透过量测定、重金属、不挥发物测定等。 2、日本药局方对注射剂用玻璃容器的检测项目有:封口要求、可溶性碱(耐水性)测定、铁测定(避光容器)、透光率测定;对塑料容器的特殊要求是(1)应考察容器的溶出或迁

美国及欧洲药典系统适应性要求

系统适应性——美国药典 系统适应性是气相和液相色谱分析方法的重要组成部分,用于证明色谱系统的分离度和重现性能满足样品的分析要求。 测试基于这样的原理:仪器、电路、方法和样品组成一个整体系统,我们可以对这个系统进行测试评估。 影响色谱系统的因素包括: 流动相的组成、离子强度、温度和pH值 柱子大小、流速、柱温和压力 固定相特点,包括填料类型,载体形状、粒径、孔 径、表面积等。 常用固定相为反相硅胶,以十八碳烷基健合硅胶 最常用,其它经过化学修饰 的硅胶也有使用。 分离度R s是理论塔板数n的函数(也叫柱效),α是分离因子,k 是容量因子(所有符号的意义见前文“色谱定义和说明”部分)。在规定的色谱条件下,n表示洗脱物中相邻化合物的分离程度,可作为衡量色谱系统柱效能的指标,但是不如直接测试的结果可靠。峰的尖锐程度部分反映柱效,这个参数对检查微量物质至关重要。 标准品或者标准溶液需要重复进样以确保精密度。除非个论中有规定, 系统适用性五针的数据的相对标准偏差不超过2.0%, 如果超过2.0%的话, 需要进样六针。 在含量测定中,如果纯品含

H是峰高,即峰最高点到基线的距离;h是噪音最大值和最小值之间的差值。 系统适应性测试的数据通过重复进样标准品或者特定文件中规定的对照溶液而得到, 此文件中对相关参数的定义同样适用于其它操作条件,以下情况可做相应调整: 标准品(包括参考物质) 对适应性测试中的所有化合 物均适用 在系统适应性测试中为改进色谱系统性能而作适 当调整 对色谱系统的调整不能弥补柱子和系统本身的缺陷。 为满足系统适应性要求而对分析方法调整时,除非另有规定,以下每个变量的最大值都应考虑;这些调整需要附加有效数据。为验证新方法的系统适应性,需要对改变条件后的分析方法重新评价。多处改动会对系统性能产生积累效果,在分析之前能仔细考虑。在梯度洗脱中不推荐改变流动性组成,如果必须改变,则只对溶剂体积或滞后体积改变。 流动相pH(HPLC):在配备

药典注射剂通则

附录ⅠB 注射剂 注射剂系指药物与适宜的溶剂或分散介质制成的供注入体内的溶液,乳状液或混悬液及供注入体内的溶液、乳状液或混悬液及供临用前配制或稀释成溶液或混悬液的粉末或浓溶液的无菌制剂。 注射剂可分为注射液、注射用无菌粉末与注射用浓溶液。 注射液包括溶液型、乳状液型或混悬型注射液,可用于肌内注射、静脉注射、静脉滴注等。其中,供静脉注射用的大体积(除另有规定外,一般不小于100ml)注射液也称静脉输液。 注射用无菌粉末系指药物制成的供临用前用适宜的无菌溶液配制成澄清溶液或均匀混悬液的无菌粉末或无菌块状物。可用适宜的注射用溶剂配制后注射,也可用静脉输液配制后静脉滴注。无菌粉末用溶剂结晶法、喷雾干燥法或冷冻干燥法等制得。 注射用浓溶液系指药物制成的供临用前稀释后静脉滴注用的无菌浓溶液。 注射液在生产与贮藏期间应符合下列有关规定。 一、溶液型注射液应澄明;除另有规定外,混悬型注射液中药物粒度应控制在15μm以下,含15~20μm (间有个别20~50μm)者,不得超过10%,若有可见沉淀,振摇时应容易分散均匀,混悬型注射液不得用于静脉注射或椎管注射;乳状液型注射液应稳定,不得有相分离现象,不得用于椎管注射。静脉用乳状液型注射液中乳滴的粒度90%应在1μm以下,不得有大于5μm的乳滴。除另有规定外,静脉输液应尽可能与血液等渗。 二、注射剂所用的原辅料应从来源及工艺等生产环节进行严格控制并应符合注射用的质量要求。注射剂所用溶剂必须安全无害,并不得影响疗效额质量。一般分为水性溶剂和非水性溶剂。 (1)水性溶剂最常用的为注射用水,也可用0.9%氯化钠溶液或其他适宜的水溶液。 (2)非水性溶剂常用的为植物油,主要为供注射用大豆油,其他还有乙醇、丙二醇和聚乙二醇等溶剂。供注射用的非水性溶剂,应严格限制其用量,并应在品种项下进行相应的检查。 三、配制注射剂时,可根据药物的性质加入适宜的附加剂。如渗透压调节剂、pH值调节剂、增溶剂、助溶剂、抗氧剂、抑菌剂、乳化剂、助悬剂等。所用附加剂应不影响药物疗效,避免对检验产生干扰,使用浓度不得引起毒性或明显的刺激。常用的抗氧剂有亚硫酸钠、亚硫酸氢钠和焦亚硫酸钠等,一般浓度为01.%~0.2%;常用的抑菌剂为0.5%苯酚、0.3%甲酚和0.5%三氯叔丁醇等。多剂量包装的注射液可加适宜的抑菌剂,,抑菌剂的用量应能抑制注射液中微生物的生长,加有抑菌剂的注射液,仍应采用适宜的方法灭菌。静脉输液与脑池内、硬膜外、椎管内用的注射液均不得加抑菌剂。除另有规定外,一次注射量超过15ml

小容量注射剂生产工艺规范通则

小容量注射剂生产工艺规程通则 目录 1.小容量注射剂生产工艺流程图、小容量注射剂车间概况(附图) 2.需要验证的关键工序及工艺验证(列表) 3.操作过程及工艺条件 4.技术安全、工艺卫生及劳动爱护 5.物料平衡及技经指标 6.设备一览表 7.岗位定员 8.附件目录(岗位操作、清洁规程)

1.可灭菌小容量注射剂的生产流程图 小容量注射剂车间概况(附图)讲明:由质监科按洁净厂房监操纵度SMP-ZL-014对洁净区进行监控,由工程设备科负责维修,车间应依照实际使用情况提出相应的建议,保证洁净厂房在使用中符合GMP的规定。 2.需要验证的关键工序及工艺验证(列表)

讲明:每年需按验证治理制度SMP-ZL-012对上述关键工序及工艺进行验证(再验证或回忆性验证)。若系统、设备设施 发生变更则必须进行相应的验证。 验证由厂验证小组负责。车间应依照情况及时提出相应的申请。 3.操作过程及工艺条件 3.1 工艺用水: 3.1.1 操作过程: 3.1.1.1 原水为符合国家饮用水的标准自来水。 3.1.1.2 纯化水由原水经石英砂过滤→精滤(PE棒)→阴床 →阳床→混床→紫外灯灭菌→进入贮罐。

3.1.1.3 注射用水由纯化水经多效蒸馏水机通过蒸馏而得。 3.1.2 工艺条件: 3.1.2.1 原水应符合国家饮用水标准。 3.1.2.2 原水的预处理的进水流量应≤3m3/h。 3.1.2.3 温床的流量为3m3/h。 3.1.2.4 多放蒸馏水机蒸气压力应在0.30~0.4Mpa之间,压 缩空气压力应在0.3~0.4MPa之间。 3.1.2.5 纯化水的电导率应≤2us/cm,离子检查符合?中 国药典?2005版二部“纯化水”的标准。 注射用水的电导率≤2us/cm,离子检查符合?中国药典?2005版二部“注射用水”的标准。 3.2 理瓶工序 3.2.1 本公司可灭菌小容量注射剂所选用直接接触药品的 容器为低硼硅玻璃安瓿,执行国家药品监督治理局国家药用 包装容器(材料)标准(试行)YBB00332002,以下均可简 称安瓿。 3.2.2 操作过程: 按批生产指令领取安瓿并除去外包装,烧字安瓿要核对批号、品名、规格、数量。在理瓶间逐盘理好后送入联动机 清洗或送入粗洗间用纯化水粗洗后送入精洗间超声,注射用 水甩干并检查清洁符合规定后送隧道烘房。

欧洲药典 10.0 5.1.8 50108 口服草药医疗产品及其制剂用提取物的微生物质量

04/2019:50108 5.1.8. 口服草药医疗产品及其制剂用提取物的微生物质量(MICROBIOLOGICAL QUALITY OF HERBAL MEDICINAL PRODUCTS FOR ORAL USE AND EXTRACTS USED IN THEIR PERPARATION) 该章节为草药医疗产品及其制剂用提取物提供推荐可接受标准。 非无菌产品的微生物检测按通用章节2.6.12、2.6.13和2.6.31给出的方法执行。下面给出了总需氧活菌计数(TAMC)和总酵母/霉菌计数(TYMC)的可接受标准。 可接受标准是基于单个结果或在进行了重复计数时重复计数结果的平均数。(例:直接平板计数法)。 某些特定微生物的可接受标准可见下表。该列表没有必要是详尽无遗的,对于给定的制剂需根据起始原料的性质、生产工艺及其使用目的进行必要的其他微生物测试。 含有活酵母菌药品的(活的生物治疗制品)不在此通论范围内。 草药医疗产品 A. 包含草药物质,含有或不含有赋形剂,意欲使用沸水制备浸剂和汤药的草药医疗产品(例如含有或不含有调味剂的草药茶) B. 含有例如提取物和/或草药物质,包含或不包含赋形剂,加工方法(例如,萃取),或者,如果合适的话,在这种情况下,草药物质的预处理能使微生物水平降低至下表列出的数目以下的草药医疗产品

C. 含有例如提取物和/或草药物质,包含或不包含赋形剂,加工方法(例如,使用低强度的乙醇或未沸腾的水进行萃取或低温度下制得的的浓缩液),或者在这种情况下,草药物质的预处理不能充分降低微生物水平至B下面要求的标准的草药医疗产品 提取物 提取物应符合类别B草药医疗产品的可接受标准。但是,当能够证明工艺方法不能使得微生物充分地减少到类别B的水平时,提取物应符合类别C草药医疗产品的要求。 该推荐可接受标准应用于意欲混合入口服草药医疗产品中的提取物。为了满足特定路径管理的可接受标准,对于意欲混合入通过其他路径管理的药用制剂的提取物,可提出更严格的可接受标准。 经认定,对于有些草药医疗产品和用于其制剂的提取物,由于微生物污染的典型水平,并不能满足上文所给TAMC, TYMC 和胆汁耐受革兰氏阴性菌的标准。可使用稍微宽松一些的可接受标准,前提是考虑到包括微生物污染的定性、定量特性和该草药医疗产品或提取物预期用途在内经过风险评估。如果指定的草药医疗产品或提取物方法不能在指定的微生物水平上有效计数,则可使用尽可能接近指定的可接受标准限度的经过验证的方法。

美国药典USP31 71 无菌检查法中文版

美国药典USP31-NF26无菌检查法《71》.doc 71 STERILITY TESTS 无菌检查法 此通则的各部分已经与欧洲药典和/或日本药典的对应部分做了协调。不一致的部分用符号()来标明。 下面这些步骤适用于测定是否某个用于无菌用途的药品是否符合其具体的各论中关于无菌 检查的要求。只要其性质许可,这些药品将使用供试产品无菌检查法项下的膜过滤法来检测。如果膜过滤技术是不适合的,则使用在供试产品无菌检查法项下的培养基直接接种法。除了具有标记为无菌通道的设备之外,所有的设备均须使用培养基直接接种法进行检测。在结果的观测与理解项下包含了复验的规定。 由于无菌检查法是一个非常精确的程序,在此过程中程序的无菌状态必须得到确保以实现对结果的正确理解,因此人员经过适当的培训并取得资质是非常重要的。无菌检查在无菌条件下进行。为了实现这样的条件,试验环境必须调整到适合进行无菌检查的方式。为避免污染而采取的特定预防措施应不会对任何试图在检查中发现的微生物产生影响。通过在工作区域作适当取样并进行适当控制,来定期监测进行此试验的工作条件。 这些药典规定程序自身的设计不能确保一批产品无菌或已经灭菌。这主要是通过灭菌工艺或者无菌操作程序的验证来完成。 当通过适当的药典方法获得了某物品中微生物污染的证据,这样获得的结果是该物品未能达到无菌检验要求的结论性证据,即便使用替代程序得到了不同的结果也无法否定此结果。如要获得关于无菌检验的其他信息,见药品的灭菌和无菌保证<1211> 按照下面描述的方法配制实验用培养基;或者使用脱水培养基,只要根据其制造商或者分销商说明进行恢复之后,其能够符合好氧菌、厌氧菌、霉菌生长促进试验的要求即可。使用经过验证的工艺对培养基进行灭菌操作。 下面的培养基已经被证实适合进行无菌检查。巯基醋酸盐液体培养基主要用于厌氧菌的培养。但其也用于检测好氧菌。大豆酪蛋白消化物培养基适合于培养霉菌和好氧菌。 Fluid Thioglycollate Medium 巯基醋酸盐液体培养基

中国药典》2015年版通则目录及增修订内容

《中国药典》2015年版通则目录及增修订内容 0100 制剂通则 0101 片剂 0102 注射剂 0103 胶囊剂 0104 颗粒剂 0105 眼用制剂 0106 鼻用制剂 0107 栓剂 0108 软膏剂 0109 乳膏剂 0110 糊剂 0111 吸入制剂 0112 喷雾剂 0113 气雾剂 0114 凝胶剂 0115 散剂 0116 滴丸剂 0117 糖丸 0118 糖浆剂

0120 涂剂 0121 涂膜剂 0122 酊剂 0123 贴剂 0124 贴膏剂 0125 口服溶液剂口服混悬剂口服乳剂 0126 植入剂 0127 膜剂 0128 耳用制剂 0129 洗剂 0130 冲洗剂 0131 灌肠剂 0181 丸剂 0182 合剂 0183 锭剂 0184 煎膏剂(膏滋) 0185 胶剂 0186 酒剂 0187 流浸膏剂与浸膏剂

0189 露剂 0190 茶剂 0200 其他通则 0211 药材和饮片取样法(未修订) 0212 药材和饮片检定通则(第二增补本) 0213 炮制通则(未修订) 0251 药用辅料通则 0261 制药用水 0271 药包材通则(待定) 0272 玻璃容器(待定) 0291 国家药品标准物质通则(第二增补本) 0300 0301 一般鉴别试验(第二增补本) 0400 光谱法 0401 紫外-可见分光光度法 0402 红外分光光度法 0405 荧光分光光度法 0406 原子吸收分光光度法 0407 火焰光度法 0411 电感耦合等离子体原子发射光谱法 0412 电感耦合等离子体质谱法(增订) 0421 拉曼光谱法(新增) 0431 质谱法 0441 核磁共振波谱法

最全的 关于 药品 炽灼残渣检查方法(中国药典、美国药典、欧洲药典)

药品的炽灼残渣检测方法(欧洲药典、美国药典) 1 原理:药品(多为有机化合物)经高温加热分解或挥发后遗留下的不挥发无机物(多为金属的氧化物,碳酸盐,磷酸盐,硅酸盐和氯化物等)。 2 仪器与用具:高温炉、坩埚、坩埚钳、通风柜 3 试剂与试液:硫酸分析纯 4 操作步骤 中国药典检测方法 空坩埚恒重:取坩埚置于高温炉内,将盖子斜盖在坩埚上,经700~800℃炽灼约30~60分钟,取出坩埚,稍冷片刻,移置干燥器内并盖上盖子,放冷至室温,精密称定坩埚重量。再在上述条件下炽灼约30分钟,取出,置干燥器内,放冷,称重;重复数次,直至恒重,备用。如无特殊情况,空坩埚在700~800℃(或500~600℃)炽灼二小时即可恒重。 称取供试品:取供试品~或各该药品项下规定的重量,置已炽灼至恒重的坩埚内,精密称定。 炭化:将盛有供试品的坩埚斜置电炉,炽灼至供试品全部炭化呈黑色,并不冒浓烟,放冷至室温。“炭化”操作应在通风柜内进行。 灰化:除另有规定外,滴加硫酸~,使炭化物全部湿润,继续在电炉上加热至硫酸蒸气除尽,白烟完全消失(以上操作应在通风柜内进行),将坩埚移置高温炉内,盖子斜盖于坩埚上,在700~800℃炽灼,约60分钟,使供试品完全灰化,(如供试品要做重金属试验,则灰化温度应在500~600℃)。 恒重:按操作方法5.4.4,依法操作炽灼30分钟,直至恒重。如无特殊情况,在700~800℃(或500~600℃)炽灼二小时即可恒重。

如需将残渣留作重金属检查,则炽灼温度控制在500~600℃。 5 欧洲药典检测方法 在600±50℃灼烧一个白金、瓷或石英坩埚30分钟,干燥器内冷却后称重。加入规定量的样品于上述坩埚内,称重。 用1mL的硫酸湿润样品,在低温上加热直至样品完全炭化。冷却后,用少量的硫酸湿润残渣,加热直至白烟不再产生。 在600±50℃的高温炉内灼烧,直至残渣完全灰化(在操作过程不应有火焰出现),干燥器内冷却后称重,并计算残渣的量。 除非另有规定,假如残渣的量超过规定的限量,重复用硫酸湿润和灼烧,与前面操作相同,直至恒重。 6 美国药典方法 称取1~2g样品或规定量的样品于已经灼烧,冷却和称重的合适坩埚(600℃±50℃炽灼30分钟),用少量(1mL)的硫酸湿润样品,在低温上加热直至样品完全炭化。 冷却后,除非另有规定,用少量(1mL)的硫酸湿润残渣,加热直至白烟不再产生。 在600℃±50℃的高温炉内灼烧,或者其它规定的温度,直至完全灰化,在干燥器内冷却后称重,计算残渣的量。 假如残渣的量超过规定的限量,再用1ml硫酸湿润残渣,继续低温加热和灼烧(与前面操作相同),并计算残渣的量。除非另有规定,继续烧烧直至恒重或残渣的量符合规定的限量。

9301 注射剂安全性检查法应用指导原则]

9301 注射剂安全性检查法应用指导原则

本指导原则为化药及中药注射剂临床使用的安全性和制剂质量可控性而 定。 注射剂安全性检查包括异常毒性、细菌内毒素(或热原) 、降压物质(包括 组胺类物质) 、过敏反应、溶血与凝聚等项。根据处方、工艺、用法及用量等设 定相应的检查项目并进行适用性研究。 其中, 细菌内毒素检查与热原检查项目间、 降压物质检查与组胺类物质检查项目间,可以根据适用性研究结果相互替代,选 择两者之一作为检查项目。 一、注射剂安全性检查项目的设定 1.静脉用注射剂 静脉用注射剂,均应设细菌内毒素(或热原)检查项。其中,化药注射剂一 般首选细菌内毒素检查项;中药注射剂一般首选热原检查项,若该药本身的药理 作用或对家兔的毒性反应影响热原检测,可选择细菌内毒素检查项。 所用原料系动植物来源或微生物发酵液提取物, 组分结构不清晰或有可能污 染毒性杂质且又缺乏有效的理化分析方法的静脉用注射剂, 应考虑设立异常毒性 检查项。 所用原料系动植物来源或微生物发酵液提取物时,组分结构不清晰且有可能 污染异源蛋白或未知过敏反应物质的静脉用注射剂, 如缺乏相关的理化分析方法 且临床发现过敏反应,应考虑设立过敏反应检查项。 所用原料系动植物来源或微生物发酵液提取物时, 组分结构不清晰或有可能 污染组胺、类组胺样降血压物质的静脉用注射剂,特别是中药注射剂,如缺乏相 关的理化分析方法且临床发现类过敏反应, 应考虑设立降压物质或组胺类物质检 查项。 检查项目一般首选降压物质检查项,但若降血压药理作用与该药具有的功能 主治有关,或对猫的反应干扰血压检测,可选择组胺类物质检查项替代。 中药注射剂应考虑设溶血与凝聚检查项。 2.肌内注射用注射剂 所用原料系动植物来源或微生物发酵液提取物时, 组分结构不清晰或有可能 污染毒性杂质且又缺乏有效的理化分析方法的肌内注射用注射剂, 应考虑设立异

欧洲药物管理基本介绍

欧洲药物管理EDMF&CTD基本介绍 EDMF文件简介: 欧洲药物管理档案(EDMF,即European Drug Master File)是药品制剂的制造商为取得上市许可而必须向注册当局提交的关于在制剂产品中所使用的原料药的基本情况的支持性技术文件。它的申请必须与使用该原料药的制剂的上市许可申请同时进行。当原料药物的生产厂家(ASM,即The Active Substance Manufacturer)不是药品制剂上市许可证的申请人时,也就是说当制剂生产厂家使用其它厂家生产的原料药物生产制剂时,为了保护原料药物的生产及质量管理等方面有价值的技术机密而由原料药物的生产厂家提交给欧洲官方机构的文件。分为公开部分和保密部分。与美国FDA的DMF涵概药品生产的全过程CMC(Chemistry, Manufacturing and Control)不同,欧洲DMF则主要强调第一个C,即Chemistry。具体的说,EDMF 的主要内容是药物及其相关杂质的化学,包括化学结构及结构解析、化学性质、杂质及其限度、杂质检查等等。 EDMF的适用范围: EDMF适用于以下三类原料药的申请: --仍由专利保护的新的原料药,并且这种原料药没有包括在欧洲药典或任何一个成员国的药典之中; --已过专利保护期的原料药,并且这种原料药没有包括在欧洲药典或任何一个成员国的药典之中; --包括在欧洲药典或任何一个成员国的药典之中的原料药,当这种原料药使用一个可能留下药典专论没有提到的杂质并且药典专论不能足够控制其质量的方法生产时。EDMF的变动和更新 如果EDMF持有人需要对EDMF的公开部分和保密部分做出变动,则任何变动均要向主管当局或EMEA上报,并通知所有申请人。若仅是修改EDMF的保密部分,并且生产采用的质量标准和杂质范围均没有发生改变,修改信息只需提供给主管当局;如果需要修改EDMF的公开部分,此信息必须提供给其他申请人和使用此EDMF的药品上市许可证的持有人,所有涉及到的申请人将通过适当的变更程序修改他们的上市许可证申请文档。 EDMF持有人应对EDMF文件在现行的生产工艺,质量控制,技术发展法规和科研要求方面保持内容更新。如果没有任何改变,在欧盟内使用此EDMF的第一个五年后,EDMF持有人应正式声明EDMF文件的内容仍然是不变和适用的,并提交一份更新的申请人或制剂生产厂家的名单。 EDMF的递交程序: 根据欧洲药物管理档案程序的要求,EDMF只能在递交制剂药品上市许可证申请时递交,并且只有欧洲的制剂生产厂家及其授权的代表(如,进口商)才能递交EDMF。

usp美国药典结构梳理

USP35-NF-30结构整理 vivi2010-10-02 USP总目录: 1 New Official Text修订文件 加快修订过程包括勘误表,临时修订声明(IRAS),修订公告。勘误表,临时修订声明,修订公告在USP网站上New Official Text部分刊出,勘误表,临时修订公告也会在PF上刊出2front matter前言 药典与处方集增补删减情况,审核人员,辅料收录情况 3凡例

药典, 1标题和修订 2 药典地位和法律认可 3标准复合性 4专论和通则 5 专论组成 6 检验规范和检验方法 7 测试结果 8 术语和定义 9 处方和配药 10 包装存储与标签 4通则 4.1章节列表 4.2一般检查和含量测定(章节编号小于1000)

检查和含量分析的一般要求 检查和含量分析的仪器, 微生物检查,生物检查和含量测定, 化学检查和含量测定, 物理检查和测定 4.3一般信息(章节号大于1000) 5食物补充剂通则 6试剂(试剂,指示剂,溶液等) 7参考表 性状描述和溶解性查询表(按字母顺序) 8食品补充剂各论(字母顺序) 9NF各论(辅料标准) 10 USP各论 11术语 附件:通则的章节中文目录(使用起来比较方便,直接找对应章节号即可)一、通用试验和检定 (1)试验和检定的总要求 1 注射剂 11 参比标准物 (2)试验和检定的装置 16 自动分析方法 21 测温仪 31 容量装置,如容量瓶、移液管、滴定管,各种规格的误差限度

41 砝码和天平 (3)微生物学试验 51 抗菌效力试验 55 生物指示剂:耐受性能试验 61 微生物限度试验 61 非灭菌制品的微生物检查:计数试验 62 非灭菌制品的特定菌检查,如大肠杆菌、金葡菌、沙门氏菌等 71 无菌试验 (4)生物学试验和检定 81 抗生素微生物检定 85 细菌内毒素试验 87 体外生物反应性试验:检查合成橡胶、塑料、高聚物对哺乳类细胞培养的影响 88 体内生物反应性试验:检查上述物质对小鼠、兔iv、ip或肌内植入的影响 91 泛酸钙检定 111 生物检定法的设计和分析 115 右泛醇检定 121 胰岛素检定 141 蛋白质——生物适应试验,用缺蛋白饲料大鼠,观察水解蛋白注射液和氨基酸混合物的作用 151 热原检查法 161 输血、输液器及类似医疗装置的内毒素、热原、无菌检查 171 维生素B12 活性检定 (5)化学试验和检定 A 鉴别试验 181 有机含氮碱的鉴别 191 一般鉴别试验 193 四环素类鉴别 197 分光光度法鉴别试验 201 薄层色谱鉴别试验 B 限量试验

中药天然药物注射剂基本技术要求

中药天然药物注射剂基本技术要求 【公布文号】国食药监注[2007]743号 【公布日期】2007-12-06 【生效日期】2007-12-06 【失效日期】----------- 【所属类别】政策参考 【文件来源】国家食品药品监督治理局 中药、天然药物注射剂差不多技术要求 (国食药监注[2007]743号) 各省、自治区、直辖市食品药品监督治理局(药品监督治理局): 为科学规范和指导中药、天然药物注射剂的研究工作,保证药品安全、有效、质量可控,国家局组织制定了《中药、天然药物注射剂差不多技术要求》,现予印发,请参照执行。 附件:中药、天然药物注射剂差不多技术要求 国家食品药品监督治理局 二○○七年十二月六日 附件: 中药、天然药物注射剂差不多技术要求 为促进中药、天然药物研制工作进一步规范化、科学化和标准化,加强中药、天然药物注射剂的质量治理,依照《中华人民共和国药品治理法》、《中华人民共和国药品治理法实施条例》、《药品注册治理方法》等有关规定,特制定本技术要求。 第一部分新的中药、天然药物注射剂 一、概述 中药、天然药物注射剂的给药途径不同于传统剂型,大多数情形下,传统用药体会对注射剂处方组成的配伍及配比的指导作用有限。中药、天然药物注射剂的开发需要通过研究充分说明其安全性、有效性及必要性,并保证其质量的可控性。 二、立题依据 中药、天然药物注射剂的处方(配伍及配比)及临床使用方法的确定,需要有相关的药效学及毒理学、药代动力学等研究结果的支持。同时,依照临床用药安全、有效、方便的原则,注射给药途径应该是解决口服等其他非注射给药途径不能有效发挥作用时的剂型选择,并应符合以下要求: 1.中药、天然药物注射剂的研发应符合临床治疗和药物性质的需要。应该提供充分的依据说明注射给药优于其他非注射给药途径,应在有效性或安全性方面表达出明显优势。 2.应与已上市的其他同一给药途径、同类功能主治(适应症)的注射剂进行比较,在有效性或安全性等方面具有一定优势或特色。 3.有效成份(注册分类1)制成的注射剂需要提供药代动力学的依据;多成份(注册分类2-6)制成的注射剂需要进行药代动力学探干脆研究。 4.有效成份制成的复方注射剂及多成份制成的注射剂需进行各组分组方合理性的相关研究。来自同一药

国外药典

药典(pharmacopoeia)是一个国家记载药品标准、规格的法典,一般由国家药品监督管理局主持编纂、颁布实施,国际性药典则由公认的国际组织或有关国家协商编订。制定药品标准对加强药品质量的监督管理、保证质量、保障用药安全有效、维护人民健康起着十分重要的作用。药品标准是药品现代化生产和质量管理的重要组成部分,是药品生产、供应、使用和监督管理部门共同遵循的法定依据。药品质量的内涵包括三方面:真伪、纯度、品质优良度。三者的集中表现是使用中的有效性和安全性。因此,药品标准一般包括以下内容:法定名称、来源、性状、鉴别、纯度检查、含量(效价或活性)测定、类别、剂量、规格、贮藏、制剂等等。 药典是从本草学、药物学以及处方集的编著演化而来。药典的重要特点是它的法定性和体例的规范化。中国最早的药物典籍,比较公认的是公元 659年唐代李淳风、苏敬等22人奉命编纂的《新修本草》。全书54卷,收载药物844种,堪称世界上最早的一部法定药典。15世纪印刷术的进步促进了欧洲近代药典编纂的发展。许多国家都相继制订各自的药典。1498年由佛罗伦萨学院出版的《佛罗伦萨处方集》,一般视为欧洲第一部法定药典。其后有不少城市纷纷编订具有法律约束性的药典。其中纽伦堡的瓦莱利乌斯医生编著的《药方书》赢得了很高的声誉,被纽伦堡当局承认,被定为第一本《纽伦堡药典》于1546年出版。在《纽伦堡药典》的影响下,在奥格斯堡、安特卫普、里昂、巴塞尔、巴伦西亚、科隆、巴黎和阿姆斯特丹等地也相继有药典问世。这一进展标志着欧洲各地区性药典向法定性国家药典转化的新阶段。 到20世纪90年代初,世界上至少已有38个国家编订了国家药典。另外,尚有区域性药典3种及世界卫生组织(WHO)编订的《国际药典》。下面简介几部著名药典。 英国药典(BP) 《英国药典》(British Pharmacopoeia,简称BP)是由英国药典委员会(British Pharmacopoeia Commission)编制,是英国制药标准的重要来源。英国药典不仅为读者提供了药用和成药配方标准以及公式配药标准,而且也向读者展示了许多明确分类并可参照的欧洲药典专著。

中国、美国、欧洲药典比较

:徐涛学号:专业:中药生物技术学 《中国药典》、《美国药典》、《欧洲药典》比较 1、各国药典概况 1.1 历史沿革 《中国药典》 英文名称Pharmacopoeia of The People’s Republic of China;简称Ch .P。 1950年4月,成立了第一届中国药典编纂委员会,药典委员会分设名词、化学药、制剂、植物药、生物制品、动物药、药理、剂量8个小组,第一版《中国药典》于1953年由卫生部编印发行。1957年出版《中国药典》1953年增补本。1953年药典共收载药品531中,其中化学药215种,植物药与油脂类65种,动物药13种,抗生素2种,生物制品25种,各类制剂211种。 1965年1月26日卫生部颁布《中国药典》1963年版(第二版)发行通知和实施办法。本版药典收载药品1310种,分一、二部,各有凡例和有关的目录,一部收载中医常用的中药材446种和中药成方制剂197;二部收载化学药品667种。此外,一部记载药品的“功能主治”,二部增加了药品的“作用与用途”。 1979年10月4日卫生部颁布《中国药典》1977年版(第三版),自1980年1月1日起执行。本版药典共收载药品1925种,其中一部收载中草药材(包括少数民族药材)、中草药提取物、植物油脂以及单味药材制剂等882种,成方制剂(包括少数民族药成方)270种,共1152种;二部收载化学药品、生物制品等773种。 1985年9月出版《中国药典》1985年版(第四版),1986年4月1日起执行。本版收载药品1489种,其中一部收载中药材、植物油脂及单味制剂506种,成方制剂207种,共713种,二部收载化学药品、生物制品等776种。 1990年12月3日卫生部颁布《中国药典》1990年版(第五版),自1991年7月1日起执行。1990年版的第一、第二增补本先后于1992、1993年出版,英文版于1993年7月出版。本版共收载药品1751种,一部收载784种,其中中药材、植物油脂等509种,中药成方及单味制剂275种;二部收载化学制品、生物制品等967种。与1985年版药典收载品种相比,一部新增80种,二部新增213种,删去25种。药典二部项下规定的“作用与用途”和“用法与用量”分别改为“类别”和“剂量”。有关品种的红外光谱吸收图谱,收入《药品红外光谱集》另行出版,该版药典附录不在刊印。 1995年卫生部颁布《中国药典》1995版(第六版),自1996年4月1日起正式执行。本版药典收载药品2375种,一部收载920种,其中中药材、植物油脂522种,中药成方及单味制剂398种;二部收载1455种,包括化学药、抗生素、生化药、放射性药品、生物制品及辅料等。一部新增142种,二