粘度的对性能的影响

In?uence of Melt Viscosity on the Structure and Properties of Electrically Conductive Nanocomposites Produced by Masterbatch Process

Stefano Besco,Alessandra Lorenzetti,Denis Hrelja,Carlo Boaretti,Martina Roso,Dino Ferri,Michele Modesti*

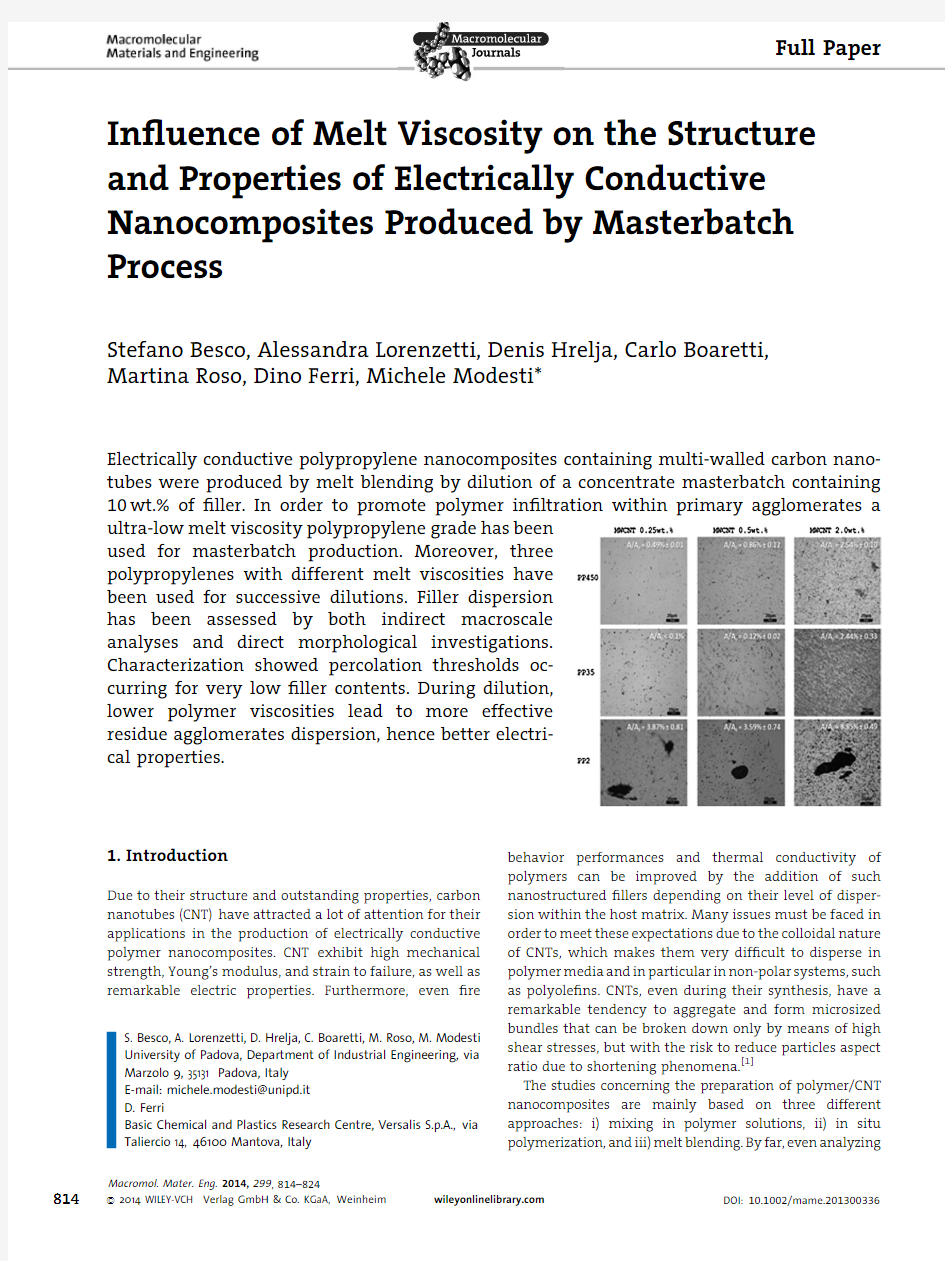

Electrically conductive polypropylene nanocomposites containing multi-walled carbon nano-tubes were produced by melt blending by dilution of a concentrate masterbatch containing 10wt.%of ?ller.In order to promote polymer in?ltration within primary agglomerates a ultra-low melt viscosity polypropylene grade has been used for masterbatch production.Moreover,three polypropylenes with different melt viscosities have been used for successive dilutions.Filler dispersion has been assessed by both indirect macroscale analyses and direct morphological investigations.Characterization showed percolation thresholds oc-curring for very low ?ller contents.During dilution,lower polymer viscosities lead to more effective residue agglomerates dispersion,hence better electri-cal

properties.

1.Introduction

Due to their structure and outstanding properties,carbon nanotubes (CNT)have attracted a lot of attention for their applications in the production of electrically conductive polymer https://www.360docs.net/doc/269310362.html,T exhibit high mechanical strength,Young’s modulus,and strain to failure,as well as remarkable electric properties.Furthermore,even ?re

behavior performances and thermal conductivity of polymers can be improved by the addition of such nanostructured ?llers depending on their level of disper-sion within the host matrix.Many issues must be faced in order to meet these expectations due to the colloidal nature of CNTs,which makes them very dif?cult to disperse in polymer media and in particular in non-polar systems,such as polyole?https://www.360docs.net/doc/269310362.html,Ts,even during their synthesis,have a remarkable tendency to aggregate and form microsized bundles that can be broken down only by means of high shear stresses,but with the risk to reduce particles aspect ratio due to shortening phenomena.[1]

The studies concerning the preparation of polymer/CNT nanocomposites are mainly based on three different approaches:i)mixing in polymer solutions,ii)in situ polymerization,and iii)melt blending.By far,even analyzing

S.Besco,A.Lorenzetti,D.Hrelja,C.Boaretti,M.Roso,M.Modesti University of Padova,Department of Industrial Engineering,via Marzolo 9,35131Padova,Italy E-mail:michele.modesti@unipd.it D.Ferri

Basic Chemical and Plastics Research Centre,Versalis S.p.A.,via Taliercio 14,46100Mantova,

Italy

Full

Paper

814

?2014WILEY-VCH Verlag GmbH &Co.KGaA,Weinheim

DOI:10.1002/mame.201300336

Macromol.Mater.Eng.2014,299,814–824

https://www.360docs.net/doc/269310362.html,

scienti?c literature,one of the most used techniques to produce thermoplastic-based polymer/CNT nanocomposites is the melt-compounding method due to its ?exibility,cost-effectiveness,safety,and scalability up to industrial level.[2]

The investigation of polypropylene (PP)/CNT-based sys-tems obtained by melt blending has been considered a focus for the present work.PP is a typical non-polar and partially crystalline polymer.Hence,due to the low interactions between PP and CNT,dispersion is very dif?cult,and usually leads to high percolation concentrations.

In their work,Tjong et al.[3]prepared several PP/multi-wall carbon nanotubes (MWCNT)nanocomposites by melt-compounding using two different mixing devices;they found that the best dispersion can be achieved in the presence of intensive shearing.PP/MWCNT nanocompo-sites prepared at high shear rates in fact exhibited remarkably lower percolation thresholds than the ones produced using low shear rates.

Pan et al.[4]investigated instead the improvement of the dispersion of MWCNT in a PP matrix by means of chemical modi?cation of the ?ller together with the addition of a masterbatch as a compatibilizer.The relationship between the dispersion of MWCNTs and the electrical conductivity of the composites has been investigated by controlling several parameters,such as CNTs modi?cation,compatibilization,melt mixing conditions,and post-heat treatments.The authors reported that the enhanced interfa-cial adhesion between the polymer and the ?ller could improve the dispersion of CNT.On the other hand,the electrical conductivity of the composites results reduced.

M €u

ller et al.[5]reported about the in?uence of feeding conditions of different MWCNT grades on ?ller dispersion,electrical conductivity,and mechanical properties of PP-based composites.MWCNTs were fed at selected concen-trations either from the main hopper of a twin-screw extruder (TSE;Berstorff ZE 25)or by using a side-feeding unit under the same processing conditions (rotation speed,throughput,and temperature pro?le).The results indicate that,depending on the packing of pristine MWCNT agglomerates,the more compact MWCNT grade should be added from the main hopper,whereas for the more loosely packed MWCNT grade the addition using the side feeder leads to better dispersion,lower electrical resistivity,and higher improvements for mechanical properties.

Several others examples can be reported about papers that were focused on the effects of processing route and parameters on the properties of polymer/CNT composites,mainly prepared by masterbatch dilution technique,[6–13]but only few works investigated the speci?c effects of the melt viscosity during the melt-compounding process.

In order to study the in?uence of melt viscosity and molecular weight on nanotube dispersion and electrical resistivity,Kasaliwal et al.[14]used three different poly carbonate grades (PCs)varying in molecular weights.PCs were melt-compounded with MWCNT using a small-scale compounder and working at constant temperature but varying mixing speed,thereby applying different magnitudes of shear stress.The composites based on the lowest molecular weight matrix showed smaller sized un-dispersed primary agglomerates compared with com-posites that have higher molecular weight matrices,highlighting the role of matrix in?ltration into primary nanotube agglomerates as the ?rst step of dispersion.In a study recently reported by Socher et al.,[15]polymer/MWCNT composites were produced using ?ve different matrices each having three different levels of viscosity,in order to identify the general in?uence of matrix polarity and viscosity on the electrical properties and the state of MWCNT dispersion.The results shown as the lowest percolation thresholds were always found for the compo-sites based on the lowest viscosity grades.The effect of nanotube shortening was quanti?ed as well,showing that the phenomenon became more pronounced with high viscosity matrices,hence partially explaining their higher percolation thresholds.Together with dispersion,in fact,CNT length shortening is also affected by melt viscosity and can remarkably in?uence electric properties,as investigat-ed,for example,by Krause et al.[16]and Castillo et al.[17]

A recent study by Mi c u 9s ?k et al.[18]is particularly interesting,considering the aim of the present https://www.360docs.net/doc/269310362.html,parative experiments regarding the electrical and mechanical behavior of composites prepared using a commercially available PP/MWCNT masterbatch contain-ing 20wt%MWCNT are reported.The concentrate was diluted with various grades of PP characterized by different melt ?ow index values (MFI)and maleic anhydride (MA)grafting levels.The results demonstrate that the grade and viscosity of the diluting polymer plays an important role on the dispersion of CNT.In the presence of MA grafting,the best results were achieved in terms of interaction between polymer and ?ller but improvement of the dispersion was prevented by the incompatibility between modi?ed PP used for dilution and the PP/MWCNT pristine masterbatch.The authors also concluded that lower-molecular-weight chains can better penetrate inside the masterbatch and lead to better dispersion of the masterbatch particles as compared to longer chains.The increase of polydispersity index could be a further reason for inappropriate dispersion of CNT.

Regarding the CNT dispersion mechanism,during melt compounding several progressive steps are involved that also relate to processing conditions and material properties.According with Alig et al.,[19]the initial wetting of the micron-sized agglomerates depends mainly on the interfa-cial energy between CNT and polymer.Then the polymer in?ltration into the primary agglomerates occurs,and it represents a key phenomenon for the successive dispersion and distribution steps by means of erosion mechanism.

Influence of Melt Viscosity on the Structure and Properties ...

www.mme-journal.de

Macromol.Mater.Eng.2014,299,814–824

?2014WILEY-VCH Verlag GmbH &Co.KGaA,Weinheim

815

https://www.360docs.net/doc/269310362.html,

In?ltration depends both on interface properties and on polymer viscosity.

The formation of secondary agglomerates,mostly during forming processing,has also been recognized as a further important step in?uencing composites ?nal properties in terms of electric conductivity.

In this paper,a comparative study between different PP-based CNT composites prepared by melt blending with a masterbatch route is reported.Considering in particular the discussion reported by Mi c u 9s ?k et al.[18]about the effects of melt viscosity on MWCNT dispersion in PP,the idea of the authors was to further investigate the possibility to maximize the polymer in?ltration mecha-nism at masterbatch level by using a particular ultra-low viscosity PP and without using chemical modi?cations or compatibilizers to improve polymer–?ller interactions.Moreover,the in?uence of polymer melt viscosity on the dispersion and properties of PP-CNT nanocomposites has been evaluated by using different standard PP grades (characterized by different MFI values)for masterbatch dilution in order to produce nanocomposites with compo-sitions varying between 0.25and 4wt%MWCNT.An extensive characterization has been done by means of electric,mechanical,thermal,and morphological analyses,in order to correlate materials structures and properties.

2.Experimental Section

2.1.Raw Materials

For the preparation of MWCNT masterbatch a high-?uidity PP from Basell Polyole?ns Company N.V.,Metocene MF650Y (MFI 1800g/10min at 2308C and 2.16kg),was used and labeled PP 1800.Three grades of PP homopolymer were considered for masterbatch dilution and labeled PP 450(MFI 450g/10min at 2308C and 2.16kg,Bor?ow HL504FB from Borealis Polyole?ne GmbH),PP 35(MFI 35g/10min at 2308C and 2.16kg,from Sigma–Aldrich Co.LLC)and PP 2(MFI 2g/10min at 2308C and 2.16kg,Hostalen PP N2122from Basell Polyole?ns Company N.V.).Commercial MWCNT (NC7000)produced by CCVD technique has been supplied by Nanocyl S.A.(Belgium).According to previous investigations,[16]NC7000nanotubes have an average diameter and length,respectively of 10.0and about 1300nm,and a purity of about

90%measured by means of thermal gravimetric analysis as declared by the producer.[20]

An estimation of the average molecular weights of the different PP grades has been done on the basis of the results reported by Bremner and Rudin.[21]The following equation has been purposed to correlate the MFI values of several commercial linear PPs with their average molecular weights (M w ):

k

MFI

?eM w Tx e1T

where k is a constant value depending on physical parameters such as polymer viscosity,and the mass used for MFI test and x varies between 3.4and 3.7.In Table 1,a comparison between the MFI values and the calculated average molecular weights for the different PP used in the study has been reported.

https://www.360docs.net/doc/269310362.html,posites Preparation

A co-rotating TSE (Dr.Collin Gmbh.Mod.ZK25)with a screw diameter of 25mm and a L /D ratio of 27has been used for masterbatch production and dilution.The extruder was equipped with one main volumetric feeding hopper and with a vacuum venting system in order to remove the vapors and gases during melt mixing.Experimental set-up and screw design are shown in Figure 1.

A ?xed masterbatch composition was chosen (MWCNT 10wt%and PP 180090wt%).The polymer was ?rst grounded to ?ne powder and then dry mixed with MWCNT (both dried overnight at 808C with a SGW Industry Owen by Crase s.r.l.,Italy).A temperature pro?le ranging from 150to 1608C was used together with 50rpm screws speed (25%of maximum value)and with a feeding throughput of about 2kg h à1.

Polymer-MWCNT composites containing 0.25–0.5–1–2–4wt%MWCNT have been then obtained by dilution of the masterbatch with three different grades of PP (PP 2,PP 35,and PP 450,respectively).Polymer and masterbatch in pellet form have been dried overnight at 808C (SGW Industry Owen by Crase s.r.l.)and dry premixed before being fed to TSE.The temperature pro?les ranged from 150to 1758C and the screw speed has been set up to 50rpm (25%of maximum screws speed).The amount of shear rate during dilution compounding was evaluated by means of the following equation:[14]

_g

?p eD à2d TN

e2

T

Polymer MFI (2308C/2.16kg)

[g/600s]

M w

[g mol à1]eh ?M =h ?

PP Tg _?10eh ?M =h ?

PP Tg _?100eh ?M =h ?

PP Tg

_?250PP 1800180072552–––PP 4504501054891903014PP 35352102203062PP 2

2

455297

14

4

2

www.mme-journal.de

S.Besco et al.

Macromol.Mater.Eng.2014,299,814–824

?2014WILEY-VCH Verlag GmbH &Co.KGaA,Weinheim

816

https://www.360docs.net/doc/269310362.html,

where D is the diameter of the screw (25mm),d is the screw-barrel clearance (ranging from 200to 300m m),and N is the screws speed in revolutions per second.Considering these data together with the screw speed conditions reported above,theoretical shear rate values ranging from 200to 300s à1have been calculated.This estimation will be useful for the evaluation of melt viscosities values during compounding conditions.

A compression molding device (Dr.Collin Gmbh.Mod.P200)has been used for the production of samples (mainly for electrical and mechanical characterization)working at a temperature of 2008C and with a maximum pressure of 15bar and a cycle time of 840s (240s for heating/molding,600s for cooling to room temperature at about 158C min à1).

https://www.360docs.net/doc/269310362.html,posites Characterization

Sinusoidal measurements were performed in shear with a Rheometrics Mechanical Spectrometer (RMS)model 800.The linear viscoelastic functions were measured using the 25mm parallel plate geometry (gaps ranging between 0.8and 0.9mm)at 1808C in a frequency range between 0.1and 300rad s à1.Round disks with a diameter of 20mm were cut from compression molded samples.The temperature was stable within 0.28C in the range of measure.Strain sweeps were previously performed to ensure a linear viscoelastic response and strain values between 3and 150%were chosen.All tests were done under a N 2atmosphere in order to prevent polymer degradation.

According to the method recently reported by Socher et al.,[15]the state of CNT dispersion at micron scale in the composites was studied using light transmission microscopy (LM)technique.Thin sections of a few microns in thickness were cut from compression-molded samples using a LKB 2088Ultrotome V.The samples were then observed with a Leica DMR microscope combined with a Leica DFC480R2camera.The software LAS Version 3.8.0has then been used for image acquisition.

The agglomerate area ratio A /A 0was determined from the light micrographs by calculating the ratio of the total area A of remaining agglomerates to the total area of the micrograph A 0using the software ImageJ Version 1.46r.Agglomerates larger than 5m m were taken into account for the calculation.[15]Several cuts were investigated for each sample and an average value together with the experimental standard deviation was considered.

The morphology of the composites at nanoscale has been assessed by transmission electron microscopy (TEM).Thin slices with a thickness of about 100nm have been obtained with a LKB Ultratome V from compression molded samples and observed with a TEM model FEI Tecnai 12.In order to estimate MWCNT average lengths,the software ImageJ Version 1.46r has been used to measure CNT lengths from TEM images using the full visible length of each separate nanotube.The collected data were then analyzed in order to obtain the average values together with the standard deviations.

The electric volume resistivity was measured on compression-molded samples (thin disks with diameter 60mm and thickness 0.4–0.6mm).For low-conductivity samples (i.e.,with volume resistivity higher than 108V cm),a Keithley 8009Resistivity Test Fixture combined with a Keithley electrometer Model 6517were used.For conductive samples (i.e.,with volume resistivity lower than 107V cm),strips 50mm long and 10mm wide were connected with silver contacts to a DMM 2000Keithley multimeter.

Polymer crystallization properties were investigated by means of standard differential scanning calorimetry (DSC Q200;TA Instruments,USA).Specimens were cyclically heated and cooled from 40to 2208C in hermetic pans,using heating/cooling ramps and working at 108C min à1in nitrogen atmosphere.

Dynamic-mechanical measurements (DMA Q800;TA Instru-ments)were carried out on compression molded samples (width 10mm,thickness 4mm,and length 20mm)in order to analyze the amorphous phase behavior of the composites in dynamic and non-isothermal conditions.Temperature ramp measurements were performed using a single cantilever ?xture at a frequency

of

Figure https://www.360docs.net/doc/269310362.html,yout of the melt processing apparatus with the details of screws con?guration.

Influence of Melt Viscosity on the Structure and Properties ...

www.mme-journal.de

Macromol.Mater.Eng.2014,299,814–824

?2014WILEY-VCH Verlag GmbH &Co.KGaA,

Weinheim

817

https://www.360docs.net/doc/269310362.html,

1Hz (amplitude 15m m)and at an heating rate of 38C min à1from à100to 1208C.

The real MWCNT contents in polymer/MWCNT composites were assessed with a Q600analyzer (TA Instruments)operating in nitrogen from ambient temperature to 10008C at a heating rate of 208C min à1,and the residue was analyzed after thermal degrada-tion at 8008C.The average weight of the analyzed samples was about 10mg.

Flexural modulus and deformation under maximum load were measured using a universal testing machine (Sun 2500,Galdabini,Italy)operating with a crosshead speed of 2mm min à1according to UNI ISO 128,with specimens having dimensions of 10,4,and 80mm for width,thickness,and length,respectively.All test specimens were conditioned in air at 238C and 40%R.H.for at least 48h before being analyzed.

3.Results and Discussion

3.1.Rheological Characterization

Viscosity curves have been obtained for all the pristine PP and for the concentrate masterbatch by means of a rotational rheometer in plate-plate geometry operating at 1808C.The results in terms of complex viscosity (Eta ?)versus frequency are reported in Figure 2.Remarkable differences can be observed between the three PP grades,and as expected,the complex viscosity of PP 2is higher than the one of PP 35(and both are higher than the one of PP 450)in the whole analysis range.On the other hand,the peculiar trend of the masterbatch,with a non-Newtonian behavior even at low frequencies,is typical of percolated systems containing high amounts of CNT.

According to the results obtained with Equation (2)and considering the frequency-shear rate equivalence stated by Cox–Mertz rule,the complex viscosity values (Eta ?)at the

higher frequencies (200–300rad s à1)have to be considered in order to estimate the relative melt behavior of the different matrices during melt mixing.

The viscosity ratios have been calculated as the ratios between masterbatch and pristine PP complex viscosities at speci?c shear rates considering three different frequencies below (10and 100rad s à1)and close (250rad s à1)to processing conditions.The results have been reported in Table 1.While for the lowest frequency value complex viscosities ratios higher than 1000have been be obtained,considering the frequencies in the range of melt compounding (250rad s à1)these values drop down in a range of between 2and 14.As a simple indication,in a shear ?ow and considering a Newtonian behavior of the ?uid,the critical capillary number indicating particle breakup is typically reached with viscosity ratios ranging from 0.1and 2.[22]Hence,based on this criteria and assuming the Cox–Merz law is applicable at these high shear rates,PP 2and PP 35likely can theoretically show droplet breakup.

The issue is in fact much more complex and the differences in melt viscosities for pristine PP 1800and diluting PP grades have to be considered as well.

The high difference in average molecular weights (Table 1),in particular between PP 1800and PP 2,could remarkably in?uence polymers miscibility in the molten state and therefore the morphology and properties of ?nal compounds.As previously reported by Mi c u 9s ?k [18]an excessive difference for masterbatch and diluting PP M w ,leading to an increase of polydispersity index,can be identi?ed a reason for inappropriate dispersion of the ?ller.3.2.Evaluation of MWCNT Content

The real amount of MWCNT with respect to the 10wt%MWCNT nominal value has been measured by means of TGA using Equation (3)and considering the residues of pure components after thermal degradation in nitrogen at 8008C.Considering the residue of the composite (R C ),of pristine MWCNT (R MWCNT ,96.6wt%),and of pristine polymer (R PP1800,0.69wt%),the weight fraction of MWCNT (v )can be calculated as follows:R C ?v R MWCNT te1àv TR PP1800

e3T

An experimental value of (10.3?0.16)wt%has been found,with a low standard deviation value that indicates a good homogeneity of the masterbatch.The comparison between nominal and real CNTs contents (calculated by Equation 3)for the different composites indicates that the real values are in good according with the nominal ones (see Figure 3),within experimental error.Regarding MWCNT 0.25wt%composites,due to the low amount of residue produced after thermal degradation,a reliable value

could

Figure https://www.360docs.net/doc/269310362.html,plex melt viscosity versus frequency plot for the different pristine polypropylenes and for the PP 1800/MWCNT 10wt%

masterbatch.

www.mme-journal.de

S.Besco et al.

Macromol.Mater.Eng.2014,299,814–824

?2014WILEY-VCH Verlag GmbH &Co.KGaA,Weinheim

818

https://www.360docs.net/doc/269310362.html,

not be obtained due to the in?uence of instrument sensitivity on experimental https://www.360docs.net/doc/269310362.html,posites Morphology

A simple but effective approach to evaluate composites morphology is light microscopy.In order to quantify the dispersion of primary agglomerates,the agglomerate area ratio A /A 0has been evaluated analyzing thin cuts from the composites at different MWCNT contents above and below percolation (see Figure 7about percolation behavior).

In Figure 4,a comparison between the composites obtained by dilution with PP 2,PP 35,and PP 450at different CNT contents has been reported.In a qualitative way,for PP 35-and PP 450-based composites,the particles dispersions are very similar and homogeneous.Moreover,considering A /A 0ratio,the calculated values are very low,hence indicating an effective dispersion during melt mixing with a very small amount of residue agglomerates with dimensions higher than the set up threshold.On the other hand,for PP 2-based composites,a generalized presence of large residue aggregates with dimensions varying from 20up to 100m m (not reported here)can be observed.In this case,the agglomerate area ratio can only con?rm the qualitative observation,with average values that are about one order greater than the ones obtained for PP 35and PP 450composites.Due to their shape and dimensions these agglomerates,apparently due to masterbatch drop-lets not in?ltrated by the polymer,can be only related to the uneffective mixing during dilution with PP 2.Hence,even if in presence of a favorable masterbatch/diluting PP viscosity ratio value (see Table 1),the worst results in terms of dispersion have been obtained.This may indicate that,even if pristine PP 1800rheological properties are remarkably in?uenced by 10wt%CNT content,when dealing with highly ?lled systems a prevision based on the comparison between the melt rheology of masterbatch and diluting polymer (Figure 4)may bring to improper hypothesis.

Beside dispersion,also MWCNT shortening must be considered due to its potential effects on the physical properties of the composites.This issue has been recently investigated by Socher et al.[15]and by Krause et al.[16,23]In order to assess the effects of the different melt viscosities of PP 2,PP 35,and PP 450on CNT lengths reduction,the determination of an average CNT length has been done.Several methods to compare length distribution of as-grown tubes and of CNT recovered from the composites by dissolution has been recently described.[24]

A statistic estimation of the average CNT length of the composites based on PP 35(low percolation threshold,see Figure 7)and on PP 2(high percolation threshold,see Figure 5)has been done by analyzing their

TEM

Figure 3.TGA estimation of the real MWCNT content for the composites obtained varying dilution PP grade (a:PP 450,b:PP 35,and c:PP 2)and ?ller

amount.

Influence of Melt Viscosity on the Structure and Properties ...

www.mme-journal.de

Macromol.Mater.Eng.2014,299,814–824

?2014WILEY-VCH Verlag GmbH &Co.KGaA,

Weinheim

819

https://www.360docs.net/doc/269310362.html,

micrographs,with the only aim to compare the average lengths of the particles in the two situations (hence without consider the obtained values as absolute values).The analysis of 2D TEM images of 3D particles,together with shortening effects due to nanotubes cutting during samples

microtoming,leads in fact to estimation errors that,even being the same in the two cases,on the other hand cannot allow an accurate and absolute value of particles length.The results show an average length of 431?131nm for PP 35base composites and of 425?120nm for PP 2-based ones.Considering the standard deviation,indicate a measured average length value that is almost the same for both composites (both containing 0.5wt%MWCNT for compari-son),hence with no peculiar effects on MWCNT lengths due to different polymer viscosities.3.4.Electrical Properties

The data regarding electrical characterization of the composites obtained diluting PP 1800-based masterbatch with several different PP grades are reported in Figure 5.The best results in terms of percolation performances were achieved with PP 35-and PP 450-based composites,as indicated by the sharp drop of electrical resistivity between 0.25and 0.5wt%MWCNT corresponding approximately to 0.13–0.25vol%if a density of 1.8g cm à3is considered for the ?ller.[18]PP 2-based composites show instead a different behavior with a remarkable shift of percolation threshold up to above MWCNT 1wt%.

Considering the evidences from the discussion of the morphological characterization (evaluation of

CNT

Figure 4.Light microscopy images of composites containing different amounts of MWCNT (below and above percolation,see also Figure 7)and obtained by dilution using different PP grades.Agglomerate area ratios A /A 0are indicated for each

sample.

Figure 5.Electrical properties measured for PP-MWCNT nanocomposites based on different PPs and with different MWCNT

contents.

www.mme-journal.de

S.Besco et al.

Macromol.Mater.Eng.2014,299,814–824

?2014WILEY-VCH Verlag GmbH &Co.KGaA,Weinheim

820

https://www.360docs.net/doc/269310362.html,

dispersion and shortening),the low percolation threshold obtained for PP 35and PP 450composites is de?nitely due to an effective dispersion during melt mixing,with a very low fraction of residue primary agglomerates in the ?nal composites (Figure 4).When using low viscosity PP for masterbatch production and dilution,effective in?ltration and consequently an effective CNT dispersion can be achieved,hence remarkably low percolation thresholds have been found with respect to the results reported in previous studies about similar systems.[18]The higher value of percolation achieved with PP 2-based composites,as already indicated when discussing compounds morpholo-gy,is probably due to an excessive difference of the molecular weights (hence of the rheological properties)of PP 2and PP 1800.This is also in accordance with what was reported by other authors about similar systems,[18]indicating that mixing polymers with the same chemical structure but remarkably different macromolecular lengths leads to worse dispersion of the ?ller in the ?nal composites and hence to less effective improvements of electrical conductivity.Moreover,considering the similar magnitude of CNT shortening for PP 35-and PP 2-based composites,the phenomenon of length reduction cannot be addressed to investigate whether it is responsible for the worse electrical behavior of the latter.3.5.Thermal Properties

Observing Figure 6,the temperature of crystallization of pristine PP 1800is intermediate between the ones of pristine PP 2and PP 450and very close to that of pure PP 35.An increase of the crystallization temperature for all the analyzed composites can be highlighted regardless of the type of PP used for dilution.Regarding PP 1800possible effects on the crystallization temperatures of the composites,it has recently been reported that,for similar systems,the lowest is the molecular weight of the polymer,the highest is the number of free chain ends increasing the nucleation density.[18]Moreover,regarding MWCNT effects,other authors already emphasized their action in promoting PP heterogeneous crystallization together with a nucleation effect regarding a -crystalline form.[18,24]

As the degree of crystallinity can in?uence the mechani-cal properties,the melting enthalpies of the composites have been compared.In Figure 7,the normalized speci?c melting enthalpies (with respect to pristine PPs values)have been evaluated by integration of melting peaks during second heating step and have been plotted as a function of MWCNT content and of the different PP grades.Moreover,the speci?c enthalpies have been evaluated considering the real amount of crystallizable polymer in the composites,hence rescaling the weight of the samples with the real MWCNT contents evaluated by TGA using Equation 3(see also Figure 3).

Two opposite experimental trends can be observed for PP 35composites at one side and for PP 450and PP 2composites on the other.In the ?rst case,a maximum increase up to 40%(4wt%MWCNT)for the normalized melting enthalpy value can be observed while for PP 450-and PP 2-based composites a maximum reduction of about 20%(4wt%MWCNT)can be evidenced.

A resonable explanation for this behavior can be related to a melt plasticizing effect of PP 1800for PP 35due to the effective melt mixing of the two PP grades.On the other hand,due to the remarkable difference of their

molecular

Figure 6.Crystallization temperatures measured by DSC for pristine PPs and relative MWCNT-based composites at different

compositions.

Figure 7.Melting enthalpies measured by DSC for pristine PPs and relative MWCNT-based composites at different compositions.Values normalized with pristine PPs

ones.

Influence of Melt Viscosity on the Structure and Properties ...

www.mme-journal.de

Macromol.Mater.Eng.2014,299,814–824

?2014WILEY-VCH Verlag GmbH &Co.KGaA,

Weinheim

821

https://www.360docs.net/doc/269310362.html,

weights,only little mixing probably occurred between PP1800and PP2melts,hence preventing melt plasticization phenomena.

Analyzing separately the three situations,for PP450-based composites the crystallization process can be hypothesized to be thermodynamically controlled,with the defects of PP1800leading to a decrease of the PP450 crystallinity due to the mixing occurring between the melts.Regarding PP35-based composites and assuming a mixing between the melts as well,the reduction of crystallinity induced by PP1800defects is probably compen-sated and overcome by a kinetic control,hence with the result of a global increase of PP35crystallinity that is proportional with PP1800content.

Following this hypothesis,the decrease of PP2crystallin-ity can only be explained with an absence of melt mixing (or a very limited degree of melt mixing)between PP2and PP1800,hence with the two PP crystallizing separately and causing a reduction of PP2crystallinity.

The amorphous phase of PP composites has been investigated by means of dynamic-mechanical tests evaluating the behavior of glass transition temperatures (T g),which are directly related to the cohesive energy and packing density of the polymer.In Figure8,T g variation versus MWCNT content has been reported(measured as the maximum of loss modulus function)as a function of dilution PP grades.Regarding pristine PPs,it has been found that their T g vary from3to58C above08C for PP450, PP35,and PP1800,whereas only PP2has a glass transition below08C.

Even if in every case a single and well-de?ned loss modulus peak has been identi?ed,due to the slight differences between the different PP grades T g values,no considerations can be made about their miscibility. However,an effect of PP1800can be clearly evidenced on the decrease of the T g for PP450-and PP35-based composites and on the increase of the same for PP2-based ones.

3.6.Mechanical Properties

The reinforcing effect of nanoparticles can be considered as a further indirect index of the magnitude of?ller dispersion: the higher is polymer–?ller contact interface area,the higher is the reinforcing effect without remarkable losses in ductility,due to effective MWCNT–macromolecules interactions at nanoscale.On the other hand,it has been reported that the addition of MWCNT can lead to an increase of elastic moduli followed by decreases in elongation and ductility due to ductile–brittle behavior transitions,[24,25]together with the presence of residue MWCNT agglomerates acting as stress concentrators. The behavior of?exural elastic modulus has been investigated as a function of MWCNT content for the nanocomposites obtained by dilution with the three different PP grades.The resulting values,normalized with respect to pristine matrices,are reported in Figure9.Even considering the experimental error,remarkable increases have been observed as a function of MWCNT content, independently from the polymer used for dilution and with similar trends for all the three cases considered. The considered systems have been obtained by dilution of a masterbatch containing about10wt%of MWCNT and 90wt%PP1800.Therefore,a considerable amount of PP1800 has been melt mixed with PP2,PP35,and PP450

during Figure8.Glass transition temperatures measured by DMA(peak

of loss modulus function)for pristine polypropylenes and relative

MWCNT-based nanocomposites at different compositions and

compared with theoretical behavior described by Fox

equation.

Figure9.Flexural elastic moduli for the different composites

obtained by dilution with PP450,PP35,and PP2.Values normalized

on respective pristine PPs

ones.

www.mme-journal.de

S.Besco et al.

Macromol.Mater.Eng.2014,299,814–824

?2014WILEY-VCH Verlag GmbH&Co.KGaA,Weinheim

822

https://www.360docs.net/doc/269310362.html,

dilution step.Hence,for a correct evaluation of the net MWCNT effects on the ?exural modulus of the composites,the contribution of PP 1800must be considered as well.Considering that PP 1800modulus is remarkably higher than the one of PP 450(1.2times),PP 35(1.4times),and PP 2(1.3times),its contribution to the increase of the overall ?exural moduli has been evaluated by means of a classic linear rule of mixing (even considering the partial miscibility of the polymers,see thermal characterization for details).A reinforcing effect due to PP 1800has been estimated,with an average contribution to the overall moduli increases ranging from 10%for PP 450-based composites up to about 25%for PP 2-based ones.

A further factor partially affecting the mechanical behavior is the amount of PP crystalline phase.The degree of crystallinity in?uences Young’s modulus due to the high stiffness of crystalline phase if compared to amorphous one.Considering the results of thermal properties characteriza-tion by DSC (Figure 7),the amount of crystalline phase increases only for PP 35-based composites,with a possible contribution to the overall moduli increase (not estimated here)while for PP 450-and PP 2-based composites the decrease of melting enthalpies seems to indicate that the increase of ?exural elastic moduli is completely due to CNT and PP 1800reinforcing effects.

In Figure 10,the values of ?exural deformation under maximum load (coinciding with deformation at break for brittle samples,indicated with a cross)for the different composites have been compared with respect to pristine PPs properties (normalized data).It is important to observe that,whereas for pristine PP 450the deformation at

break and deformation at maximum load coincide,for PP 35-based composites the fragile failure is reached only for MWCNT contents above 1wt%(MWCNT 4wt%for PP 2-based ones).

Hence PP 450composites,because of the intrinsic brittle-ness of pristine PP matrix,are only partially affected by the negative effects on ductility caused by MWCNT,with a maximum reduction of deformation at break (correspond-ing with deformation at maximum load)of 20%at 4wt%MWCNT content.On the other hand,PP 2-based composites maintain a ductility similar the one of pristine PP 2until 4wt %MWCNT content,where a drop of 50%can be observed.PP 35-based composites have an intermediate behavior,with a remarkable reduction of deformation under maxi-mum load that can be observed already for 1wt%MWCNT content and decreasing progressively way with the increase of ?ller content until a drop of 75%at 4wt%MWCNT.A complementary effect is of course due to the characteristic brittleness of PP 1800.

4.Conclusions

In this paper,PP/MWCNT nanocomposites have been produced by melt compounding using a 2-step masterbatch route.In order to maximize polymer in?ltration and hence to facilitate the dispersion of the ?ller during dilution step,an ultra-low viscosity PP grade has been used as polymer matrix for masterbatch,without adding compatibilizers or chemical modi?cations for CNT.Moreover three different PP grades have been considered for masterbatch dilution,in order to assess the in?uence of melt viscosity during this step as well.

The possibility to obtain very low percolation thresholds by taking advantage from the promoted polymer in?ltra-tion at masterbatch level has been con?rmed by the results obtained with morphological and electrical characteriza-tion.It can be concluded that,when ultra-low molecular weight polymer is used for masterbatch production,then to get the optimal dispersion in the ?nal compound the molecular weight of the diluting polymer cannot be too high as to not mix effectively with the lower M w master-batch resin.

Even if masterbatch and diluting PP grades can show a certain matching level regarding their rheological proper-ties,due to the complexity of melt mixing process the properties of pristine masterbatch carrier polymer must be considered as well,possibly avoiding excessive polydisper-sity indices (hence possible miscibility gaps)in the ?nal compounds.

The low degree of mixing between PP 2and PP 1800has been deduced also from melting enthalpy data analysis.In particular,it has been observed that when melt mixing occurs a plasticization effect due to PP 1800

ultra-low

Figure 10.Deformation under maximum load for the different composites obtained by dilution with PP 450,PP 35,and PP 2.Values normalized on respective pristine PPs ones.The ‘x’symbols indicate the samples with brittle behavior (deformation under maximum load coincides with deformation at

break).

Influence of Melt Viscosity on the Structure and Properties ...

www.mme-journal.de

Macromol.Mater.Eng.2014,299,814–824

?2014WILEY-VCH Verlag GmbH &Co.KGaA,

Weinheim

823

https://www.360docs.net/doc/269310362.html,

molecular weight can induce an increase of the degree of crystallinity due to a kinetically driven crystallization mechanism.In the absence of melt mixing,plasticization does not occur,with the result of a decrease in diluting PP crystalline content as in the case of PP2-based https://www.360docs.net/doc/269310362.html,T shortening has also been evaluated in order to investigate possible correlations with diluting PPs melt viscosities.It has been observed that the CNT shortening phenomena,often worsening electrical properties,in this case is independent from matrix viscosity but mainly affected by processing conditions.

Acknowledgements:The authors acknowledge Dr.Federico Caicci and Dr.Francesco Boldrin of Electron Microscopy Service of Department of Biology at University of Padova (Italy).This study was ?nanced by University of Padova under the PRAT project CPDA115982/11.

Received:August 28,2013;Revised:November 5,2013;Published online:January 20,2014;DOI:10.1002/mame.201300336Keywords:carbon nanotubes;melt mixing;nanocomposites;poly(propylene);processing

[1]D.Tasis,Carbon Nanotube-Polymer Composites ,RSC Pubs.,

London,UK 2013.

[2]T.McNally,P.P €o

tschke,Polymer Carbon Nanotube Compo-sites:Synthesis,Properties and Applications ,Woodhead Publishing,Cambridge,UK 2011.

[3]S.C.Tjong,G.D.Liang,S.P.Bao,Scr.Mater.2007,57,461.[4]Y.Pan,L.Li,S.H.Chan,https://www.360docs.net/doc/269310362.html,pos.A 2010,41,419.

[5]M.M €u

ller,B.Krause,B.Kretzschmar,P.P €o tschke,Compos.Sci.Technol.2011,71,1535.

[6]P.P €o

tschke,A.R.Bhattacharyya,A.Janke,H.Goering,Comp.Interface 2003,10,389.

[7]P.P €o tschke,T. D.Fornes, D.R.Paul,Polymer 2002,43,3247.

[8]O.Meincke, D.Kaempfer,H.Weickmann, C.Friedrich,

M.Vathauer,H.Warth,Polymer 2004,45,739.

[9]B.Lin,U.Sundararaj,P.P €o

tschke,Macromol.Mater.Eng.2006,291,227.

[10]I.Alig,D.Lellinger,S.M.Dudkin,P.P €o

tschke,Polymer 2007,48,1020.

[11]V.Peoglos,E.Logakis,C.H.Pandis,P.Pissis,J.Pionteck,P.

P €o tschke,M.Mi c u 9s ?k,M.J.Om a stov a ,Nanostruct.Polym.Nanocompos.2007,3,116.

[12]S.H.Lee,M.W.Kim,S.H.Kim,J.R.Youn,Eur.Polym.J.2008,

44,1620.

[13]P.P €o

tschke,S.Pegel, A.Janke, B.Kretzschmar,Carbon Nanotube Filled Thermoplastic Polymers for Conductive and Antistatic Applications ,VDI-Berichte Nr.1920,Nanofair 2005,S.209–212,ISBN 3-18-091920-5.

[14]G.Kasaliwal,A.G €o

ldel,P.P €o tschke,G.Heinrich,Polymer 2011,52,1027.

[15]R.Socher,B.Krause,M.M €u

ller,R.Boldt,P.P €o tschke,Polymer 2012,53,495.

[16]B.Krause,R.Boldt,P.P €o

tschke,Carbon 2011,49,1243.[17]F.Castillo,R.Socher,B.Krause,R.Headrick,B.P.Grady,

R.Prada-Silvy,P.P €o

tschke,Polymer 2011,52,3835.[18]M.Mi c u 9s ?k,M.Om a stov a ,I.Krupa,J.Proke 9s ,P.Pissis,E.Logakis,C.Pandis,P.P €o

tschke,J.Pionteck,J.Appl.Polym.Sci.2009,113,2536.

[19]I.Alig,P.P €o

tschke,D.Lellinger,T.Skipa,S.Pegel,G.Kasaliwal,T.Willmow,Polymer 2012,53,4.

[20]Nanocyl.Data sheet Nanocyl NC7000.Edition 2010-12-04.

Sambreville,Belgium;2010.

[21]T.Bremner,A.Rudin,J.Appl.Polym.Sci.1990,41,1617.[22]B.A.Morris,in:Multilayer Flexible Packaging:Technology

and Applications for the Food,Personal Care,and Over-the-Counter Pharmaceutical Industries (Ed.,J.R.Wagner),William Andrew Pubs.,Burlington 2009.

[23]B.Krause,T.Villmow,R.Boldt,M.Mende,G.Petzold,P.P €o

tschke,Compos.Sci.Technol.2011,71,1145.

[24]M.Gan ,B.Satapathy,M.Thunga,R.Weidisch,P.P €o

tschke,D.Jehnichen,Acta Mater.2008,56,2247.

[25]B.Satapathy,R.Weidisch,P.P €o

tschke,A.Janke,Compos.Sci.Technol.2007,67,867.

www.mme-journal.de

S.Besco et al.

Macromol.Mater.Eng.2014,299,814–824

?2014WILEY-VCH Verlag GmbH &Co.KGaA,Weinheim

824

https://www.360docs.net/doc/269310362.html,

煤灰粘度的影响因素

煤灰的黏度的影响因素 煤灰的黏度是指煤灰在熔融状态下的内摩擦系数,表征煤灰在高温熔融状态下流动时的物理特征。以符号η表示: f=η.s.du/dx f ——内摩擦系数n s——液面面积s du/dx——液面层之间的速度梯度 η——液体内摩擦系数或叫动力黏度。Pa.s 测定黏度的方法,一般采用钢丝扭矩式高温黏度计 1.影响因素: 煤灰的黏度大小主要取决于煤灰的组成以及各组分间的相互作用,煤灰的黏度大小于温度的高低有着极其密切的关系。 根据煤灰黏度的大小以及煤灰的化学组成,就可以选择合适的煤源,或者采用添加助熔剂,或者采用配煤的方法来改善煤灰的流动性,使其符合液态排渣炉的要求。对于液态排渣气化炉,正常排渣黏度一般为50——100Pa.s,最高不超过250Pa.s。 煤的灰熔点在一定程度上可以粗略的判断煤灰的流动性。一般的对于大多数煤来说,灰熔点高的煤,其灰的流动性也差,灰熔点相近的煤,不一定具有相同的流动性。 煤灰的化学组成对黏度的影响,SiO2、Al2O3增大煤灰黏度,Fe2O3、CaO、MgO降低煤灰黏度;若灰中Fe2O3含量高而SiO2含量低时,则在一定的范围内SiO2增大反而可以降低黏度;KNaO只会降低黏度。利用煤灰的组成可以预测其流动性。目前,差不多利用当量SiO2和碱酸比来预测煤灰的流动性。 a、当量SiO2= SiO2/ SiO2+ CaO+MgO+(Fe2O3+1.11FeO+1.43Fe)当量SiO2在40—90%内,一定黏度下的温度随当量SiO2的升高而升高。如有研究结果发现当量SiO2小于75%的灰渣,在1600℃下有较好的流动性(黏度小于250Pa.s)对于黏度大于75%的灰渣,要达到相同的流动性,则温度要在1600℃以上。 b、碱酸比=Fe2O3+CaO+MgO+KNaO/ SiO2+Al2O3+TiO2碱酸比有小变大时,指定黏度下的温度就会降低。 通常情况下,在高黏度的灰渣中添加助熔剂或低黏度的灰渣,可以降低其黏度来满足工业使用的要求。

粘度,色差影响因素及其控制方法

粘度、色差影响因素及控制方法 番茄酱质量有霉菌、浓度、粘度、色差(色值)、番茄红素、PH值、黑斑、总酸、析水度(仅对热破),感观事项指标。其中感观、霉菌及浓度直接决定产品是否合格。而粘度、色差(色差值)、析水度则反映产品的优劣,这对热破产品尤为明显。众多客户往往对粘度及色差更重视,愿意购买高粘度并且深红色而不是泛黄的热破酱。这有以下两点原因: 1、使用高粘度原酱做番茄沙司可节省原酱,因此可降低成本,其他许多产品也类似。即相同 量高粘度原酱较低粘酱可做更多的直接食用的产品,因此客户希望原酱越粘越好 2、消费者对直接食用的番茄制品的鲜红程度有较高要求。而原酱的色差(色值)直接决定了 成品外观的好坏。因此客户希望原酱色差(色值)越高越好。。新疆气候干燥少雨,日照长阳光充足,并且昼夜温差大。这一独特的气候和环境使新疆番茄原料的固形物含量高,番茄红素含量高,亩产高,并且不易腐烂,适宜运输,加工期长,同时霉菌指标低。这一大优势就使新疆番茄酱在国际市场上有很强的竞争力。(当然价格优势也同等重要)。要使质量优势充分发挥,还需加强生产过程控制才能达到高粘度色差。下面我们就对这一问题详述。 首先我们必须对粘度、色差有关知识有个大体了解。粘度指数样品酱稀释至一定程度(常规12.5%皮籽酱12%浓度),20℃30秒钟酱体流过的长度。其单位是cm/12.5%、30秒。它定量的反映了酱的粘性。测量仪器是确定的粘度仪。所以应该这样理解:粘度越大,值越小:值越大,酱就不粘。粘度与粘度值相反。色差即a/b值,红比黄。确切的说是酱体中番茄红素与番茄素含量的比值,它反映的是酱体红的程度,同时反映原料的成熟度。它没有单位。色差越大酱体越红,外观也越好。 其次,我们还要对番茄粘度产生机理、番茄物料在加工过程中发生的生化反应及色差降低原因有个大体的了解。酱体之所以有粘性是因为存在果胶物质包括原果胶、果胶及果胶酸三种状态。原果胶不溶于水,它与纤维素结合存在于细胞壁中,有粘性。果胶可溶于水,它存在于细中,有粘性。果胶酸可溶于水,存在于细胞中,无粘性。未成熟的果实细胞间含有大量原果胶,因而组织坚硬。随着成熟的进程,原果胶在果胶酶的作用下水解与纤维素分离成为果胶,并渗入细胞液内,果实变软有弹性,此时果实成熟。果胶在果胶酶的作用下水解成果胶酸,果实变成软塌状态,粘性逐渐降低。原果胶酶及果胶对完整的得番茄作用很慢,但对于破碎受伤的番茄作用迅速。这两种酶对热很敏感,77℃其活性完全钝化,为使产品达到一定粘度就要通过物料预热钝化酶的活性,保存有粘性的果胶物质,因此冷破酱预热(60℃-72℃)只是部分钝化其活性,而且要通过预热的作用,使果胶同纤维素分离,得到更多粘性

常用塑料基本性能和用途(经典)

工程塑料总概 热性质: 玻璃转移温度(Tg)及熔点(Tm);热变形温度(HDT)高;长期使用温度高(UL-746B);使用温度范围大;热膨胀系数小。 机械性质: 高强度,高机械模数,低潜变性,强耐磨损及耐疲劳性。其它耐化学药品性、抗电性、耐燃性、耐候性、尺寸安定性佳。 主要品种: 工程塑料是指一类可以作为结构材料,在较宽的温度范围内承受机械应力,在较为苛刻的化学物理环境中使用的高性能的高分子材料。一般指能承受一定的外力作用,并有良好的机械性能和尺寸稳定性,在高、低温下仍能保持其优良性能,可以作为工程结构件的塑料。如ABS、尼龙、聚矾等。 被当做通用性塑胶者包括聚碳酸酯(Polycarbonate, PC)、聚酰胺(尼龙, Polyamide, PA)、聚缩醛(Polyacetal, Polyoxy Methylene, POM)、变性聚苯醚(Poly Phenylene Oxide, 变性PPE)、聚酯(PETP,PBTP)、聚苯硫醚(Polyphenylene Sulfide, PPS)、聚芳基酯,而热硬化性塑胶则有不饱和聚酯、酚塑胶、环氧塑胶等。 拉伸强度均超过50MPa,抗拉强度在500kg/cm2以上,耐冲击性超过50J/m,弯曲弹性率在24000kg/cm2,负载挠曲温度超过100℃,其硬度、老化性优。聚丙烯若改善硬度及耐寒性,则亦可列入工程塑胶的范围。此外,较特殊者为强度弱、耐热、耐药品性优的氟素塑胶,耐热性优的矽溶融化合物、聚醯胺醯亚胺、聚醯亚胺、Polybismaleimide、Polysufone(PSF)、PES、丙烯塑胶、变性蜜胺塑胶、BT Resin、PEEK、PEI、液晶塑胶等。因为化学构造不同,故耐药品性、摩擦特性、电机特性等也有若干差异。且因成形性的不同,故有适用于任何成形方式者,亦有只能以某种成形方式加工者,造成应用上的受限。热硬化型的工程塑胶,其耐冲击性较差,因此大多添加玻璃纤维。工程塑胶除了聚碳酸酯等耐冲击性大者外,通常具有延伸率小、硬、脆的性质,但若添加20~30%的玻璃纤维,则可有所改善。

常用塑料特性一览表塑料材料特性

常用塑料特性一览表塑料材料特性 【--培训工作总结】 塑料材料特性工程部培训教材 什麼是塑料? 塑料是在一定條件下,一類具有可塑性的高分子材料的通稱,一般按照它的熱熔性把它們分成:熱固性塑料和熱塑性塑料。它是世界三大有機高分子材料之一(三大高分子材料是塑料,橡膠,纖維)。 塑料的英文名是plastic,俗稱:塑膠。 塑料的種類繁多,工藝繁多,本材料只介紹一點注塑用的塑料材料。 為什麼有人稱塑料為樹脂? 人類最早認識的高分子材料都是樹皮割破後流出的液體的提取物,呈粘稠狀,也就是說它是樹中提取的脂。因此,目前仍然有很多人把這種高分子材料叫樹脂。但隨著現代化工工業的發展,現在所

用的高分子材料都是石油化工產品或石油化工的副產品或石油合成 產品。現代的塑料已經不是樹中提取物了,而是石化產品。 塑料的本色和牌號 一般的塑料合成以後,從合成塔出來,都是麵粉狀的粉末,不能用來直接生產產品,這就是人們常說的從樹汁中提取出脂的成份是一樣的,也稱為樹脂,也叫粉料,這是一種純淨的塑料,它流動性差,熱穩定性低,易老化分解,不耐環境老化;因此,人們為了改善以上缺陷,在樹脂粉中加入熱穩定劑,抗老化劑,抗紫外光劑,加入增塑劑增加它的流動性,生產出適應各種加工工藝的,有特殊性能的,不同牌號的塑料品種。所以,同一種塑料品種有很多牌號,如:ABS 就有注塑級的,有擠出級的,有電鍍級的,有高剛性的,有很大柔韌性的,等,這才是目前人們普遍所使用的塑料,它們都經過造粒,都是顆粒料。目一種牌號的塑料,適應目一種工藝,或注塑,或擠出,或壓延,或吸塑等 塑料的分子結構 一般塑料的分子結構,都是線性的高分子鏈或帶支鏈的高分子鏈段,有結晶和非結晶兩種,塑料材料的性能與其結晶性能有很大的關係,與其分子結構有很大的關係,也與其組成的元素有很大的關係,

影响黏度的因素

影响黏度的因素:1 温度一般来说,温度升高粘度下降 2 时间在玻璃转变区域内,形成的玻璃液体的黏度与时间有关 3 组成硅酸盐材料的黏度总是随着不同改性阳离子的加入而变化粘弹性:在一些特定的情况下,一些非晶体和多晶体在受到比较小的应力作用时可以同时表现出弹性和粘性. 滞弹性:无机固体和金属表现出的这种与时间有关的弹性 影响蠕变的因素:1 温度温度升高,稳态蠕变速率增大2应力稳态蠕变速率随应力增加而增大3显微结构随着气孔率增加,稳态蠕变速率也增大; 晶粒愈小,稳态蠕变速率愈大; 当温度升高时,玻璃相的黏度下降,因而变形速率增大,蠕变速率增大4组成组成不同的材料其蠕变行为不同 5 晶体结构随着共价键结构程度增加,扩散及位错运动降低,蠕变就小材料的理论断裂强度与弹性模量,表面能和晶格常数的有关 影响材料断裂强度的因素:1内在因素材料的物理性能,如弹性模量,热膨胀系,导热性,断裂能等 2 显微结构有相组成,气孔,晶界和微裂纹 3 外界因素温度,应力,气氛及试样的形状大小和表面能 4 工艺原料的纯度粒度形状成型方法等 材料的断裂强度不是取决于裂纹的数量,而是取决于裂纹的大小 防止裂纹扩展的措施:·1 应使作用应力不超过临界应力 2 在材料中设置吸收能量的机构3 人为地在材料中造成大量极微细的裂纹也能吸收能量,阻止裂纹扩展 陶瓷材料显微结构的两个参数是晶粒尺寸和气孔率 提高无机材料强度改进韧性的途径:1 微晶高纯度和高密度(消除缺陷)2提高抗裂能力和预加应力(热韧化技术)3化学强度改变化学组成(大离子换小离子)4相变增韧5弥散增韧6复合材料 影响热容的因素:1温度对热容的影响高于德拜温度时,热容趋于常数;低于时,与(T/θ)3成正比2 化学键弹性模量熔点的影响原子越轻,原子间的作用力越大3无机材料的热容对材料的结构不敏感4相变由于热量不连续变化,热容出现突变 热膨胀系数:物体的体积或长度随温度的升高而增大的现象 影响热导率的因素:1温度的影响声子的自由程随温度升高而降低2显微结构的影响

常用塑料特性及其基本知

常用塑料特性及基本知识 为了进一步提高各品管人员对塑料的理解和更有效控制,现对常用塑料作以下简单阐述: 1、什么叫塑料: 塑料从其组成来讲,有些塑料单纯地由一种合成树脂组成,由这种树脂所制成的材料叫塑料。 2、塑料分类:以其受热行为分类,大体分为两类:“热固性塑料”和“热 塑性塑料”。 2.1 什么叫热固性塑料:热固性塑料是指在一定的温度和压力等条件下保持一定时间而固化、硬化后成为不熔不溶性物质的塑料,该种塑料不具备重复受热可塑性,如:酚醛、电木粉、环氧塑料等。 2.2 什么叫热塑性塑料:热塑性塑料是指在特定温度范围内能够反复加热软化和冷却定型的塑料,该种塑料具有可以重复使用和啤塑性能,如:ABS、PP、PC、PE等。 2.3 以塑料使用特点分类,可分为三种:通用塑料、工程塑料、特种塑料。2.3.1 通用塑料是指常用塑料,这类塑料产量大、用途广、价钱平/聚乙烯(PE)、聚丙烯(PP)、聚氯乙稀(PVC)、聚苯乙烯(PS)。ABS等。 2.3.2 工程塑料是指可以作为结构部件使用的塑料,具有类似金属的特性,能代替各种金属作为工程结构件使用,聚酰氨(PA),聚碳酸酯(PC), 聚甲醛(POM/赛钢),聚酯(PET),聚苯醚(PPO)等。2.3.3 特种塑料是指有某一方面特殊性能的塑料,具有较高耐热性、电绝缘性、耐腐蚀性等。 2.4 按用途分类塑胶分为工程塑胶和普通塑胶 一.按照受热性能,可分为热固性塑料和热塑性塑料. 热固性塑料—是经加热固化后不再在热的作用下变软而重复成型的塑料. 特点—质地坚硬,耐热性好,尺寸稳定,不溶于剂. 常见的有:酚醛塑料.环氧树脂.不饱和聚脂.脲甲醛.聚氯酯. 热塑性塑料—是指可以多次重复加热变软冷却结硬成型.主要由分子结构为线状或链状的聚合树脂构成. 常见的有:PE.PP.PS.ABS.PA.PMMA.PC.聚酯酸纤维等. 模具简介 1.两板模

各种塑胶材质的特性(精)

各种塑膠材质的特性~~申请加精 一.ABS:丙烯睛—丁二烯—苯聚合物- t0 t e+ }5 Y& \ 1.三种成份的作用 1 O" ]+ X2 w- [$ q6 Z/ `/ N 丙烯晴(A)——使制品较高硬度,提高耐磨性耐热性。 丁二烯(B)——加强柔顺性,保持材料韧性、弹性及耐冲击强度。 苯乙烯(S)——保持良好成型性(流动性着色性)及保持材料刚性(注根据组分不同派生 出多种规格牌号)。: C9 U\9 E! g# }7 Y 2.ABS具有良好的电镀性,是所有塑料中电镀性最好的。 3.ABS较GPPS抗冲击强度显著提高。- U4 b* x( C4 O- a3 @- B8 P; g: 4.ABS原料浅黄色不透明,制品表面光洁度好。 5.ABS收缩率小,尺寸稳定。6 P}, {7 t/ \ 6.不耐有机溶剂:如溶于酮、醛、酯、及氧化烃而形成乳浊流(ABS胶浆)。 7.材料共混性能:1 Y- U6 I- O. e4 h- j# U ABS+PVC~~~提高韧性,耐燃性,抗老化。' x1 p L: K( k8 F7 ^. [ ABS+PC~~~提高抗冲击强度,耐热性。 ABS 的成型工艺 1.成型加工前需充分干燥,使含水率< 0.1%,干燥条件温度 85℃,时间3HRS以上。 2.ABS流动性较好,易产生啤塑披锋,注射压力在70~~100MPa,不可太大。9 z* C( Y/ a0 b8 b7 h( u 3.料筒温度不易超过250℃ 前料筒 160~~~210℃、中料筒170~~~190℃、后料筒 160~~~180℃过高温会引起 塑胶成份分解、使流动性降低。 4.模温40~~80℃,外观要求高,模温也要高。$ W) T6 T* |5 N% s 5.注射速度取中、低速为主。注射力80~~130MPa。 6.ABS内应力检验:以制品浸入煤油中2分钟不出现裂纹为准。 二.MBS—透明ABS、聚甲基丙烯酸酯—丁二烯—苯乙烯共聚物。 主要性质:透明、韧性好、耐酸碱、流动性好、易于成型着色、尺寸稳定。 三.SBS—K料(透明)。丁二烯与本乙烯聚合物(KR01、KR03)。 主要性质:透明、较好弹性、方便成型。! N$ F6 R- @% Z$ 四.PS料:聚苯乙烯(GPPS硬胶、HIPS改性聚本乙烯 GPPS—硬 HIPS——不碎。$ V! n% u/ F8 M" ~0 m6 }6 } A)在GPPS中加于适量(5~~20%)丁二烯橡胶改性、从而改善了硬胶的抗冲击性。3 |" F6 `4 r5 Y! }7 u' D B)颜色:GPPS--透明度高性碎,HIPS--不透明之乳白色或略显黄色。 C)HIPS与GPPS根据需要可混合啤塑,GPPS成份越多制品表面光泽越好、流动性& `9 |8 d* e U* A+ A. y+ j7 u& m 越好。HIPS:GPPS=7:3或8:2可保持足够强度及表面质量。3 m$ O' T" h0 Z) K- O *聚本乙烯的成型工艺

常用塑料特性

尼龙1010特性 尼龙1010是一种半透明白色或微黄色坚韧固体,具有一般尼龙的共性。密度在1.04~1.05g/cm3之间,对霉菌的作用非常稳定,无毒,对光的作用也很稳定。它的机械性能、热和电性能列人表2-30。从表中看出:尼龙1010的最大特点是具有高度延展性,不可逆拉伸能力高,在拉力的作用下,可牵伸至原长的3~4倍,同时,还具有优良冲击性能和低温冲击性能,-60℃下不脆。但是,在高于100℃下,长期与氧接触逐渐变黄机械强度下降,特别是在熔融状态下,极易热氧化降解。 尼龙(Nylon,Polyamide,简称PA)是指由聚酰胺类树脂构成的塑料。此类树脂可由二元胺与二元酸通过缩聚制得,也可由氨基酸脱水后形成的内酰胺通过开环聚合制得,分子式为:[ NH(CH2)m NHCO (CH2)n-2 CO ] n [ NH(CH2)n-1 CO ] n PA主要用于家用电器元件、电子及机电工业产品如插头、线等,亦用于生产汽车及仪表中的零部件、体育用品、输送管道、医疗器材、尼龙带、尼龙薄膜及织物等。

与PS、PE、PP等不同,PA不随受热温度的升高而逐渐软化,而是在一个靠近熔点的窄 的温度范围内软化,熔点很明显,温度一旦达到就出现流动。 一、PA性能的主要优点有: 1. 机械强度高,韧性好,有较高的抗拉、抗压强度。抗拉强度接近于屈服强度,比ABS高一倍多。对冲击、应力振动的吸收能力强,冲击强度比一般塑料高了许多,并优于缩醛树脂。 2. 耐疲劳性能突出,制件经多次反复屈折仍能保持原有机械强度。常见的自动扶梯扶手、新型的自行车塑料轮圈等周期性疲劳作用极明显的场合经常应用PA。 3. 表面光滑,摩擦系数小,耐磨。作活动机械构件时有自润滑性,噪声低,在摩擦作用不太高时可不加润滑剂使用;如果确实需要用润滑剂以减轻摩擦或帮助散热,则水油、油脂等都可选择。 4. 耐腐蚀,十分耐碱和大多数盐液,还耐弱酸、机油、汽油等溶剂,对芳香族化合物呈惰性,可作润滑油、燃料等的包装材料。 5. 对生物侵蚀呈惰性,有良好的抗菌、抗霉能力。 6. 耐热,使用温度范围宽,可在-450C至+1000C下长期使用,短时耐受温度达120-1500C。 7. 有优良的电气性能。在干燥环境下,可作工频绝缘材料,即使在高湿环境下仍具有较好的电绝缘性。 8. 制件重量轻、易染色、易成型。因有较低的熔融粘度,能快速流动。易于充模,充模后凝固点高,能快速定型,故成型周期短,生产效率高。 二、PA性能的主要缺点; 1. 易吸水。吸水会在一定程度上影响制件尺寸和精度,特别是薄壁件增厚影响较大;吸水亦会大大降低塑料的机械强度。在选材时,应顾及使用环境及与别的元件的配合精度的影响。 2. 耐光性较差。在长期偏高温环境下会与空气中的氧发生氧化作用,开始时颜色变褐,继面破碎开裂。 3. 注塑技术要求较严:微量水分的存在都会对成型质量造成很大损害;因热膨胀作用使制品尺寸稳定性较难控制;制品中尖角的存在会导致应力集中而降低机械强度;壁厚如果不均匀会导致制件的扭曲、变形;制件后加工时设备精度要求高。 4. 会吸收水、醇而溶胀,不耐强酸及氧化剂,不能作耐酸材料使用。 PA的品种很多,如今已有几十种,以PA6、PA66、PA610最为常用。 PA6{ [ NH ( CN2)5 CO ]n} PA6熔融温度较PA66低,加工性能比其他PA好。制件有较高冲击强率,载荷分散性、弹性比PA66大,柔软性好,工作温度80-1000C,低温脆化温度-20至-300C,适于轻载荷条件下使用,可作机器仪表、仪器零件、电线电缆的绝缘;用玻纤增强后可制作齿轮、泵叶。但PA6吸水性很大,饱和吸水率高达10%左右,影响性能;又因介电常数较大,不宜用作高频低损耗材料。 PA66{ [ NH ( CN2)6 NH CO(CH2)4 CO ] n} PA66是PA系列中机械强度最高、应用最广的品种。其结晶度高,故刚性、硬度、耐热性都高,屈服强度较PA6和PA66大,摩擦系数小,耐应力开裂性良好,尤其是抗蠕变性是热塑性塑料中最强的品种之一;吸水率为7%,工作温度100-1200C。适于在中等载荷条件下使用,可制作盛载化学药物的瓶、管,其他用途类似于PA6。 PA610{ [ NH ( CN2)6 NH CO(CH2)8 CO ]n} PA610易于成型,性能介于PA6和PA66之间,硬度较高,耐磨性比PA6稍差。最大特点是吸水变化很小,尺寸较稳定,可代替PA6和PA66制作精密尺寸制件。

聚酰胺酸粘度的影响因素

聚酰胺酸粘度的影响因素 聚合物的分子量对聚合物的机械强度影响较大。聚酰胺酸作为聚酰亚胺的前躯体,其分子量的大小直接影响聚酰亚胺的机械强度。只有合成了高分子量的聚酰胺酸才能得到性能优良的聚酰亚胺。聚合物的分子量可以由聚合物的粘度进行表征,因此合成高粘度的聚酰胺酸溶液是制备高强度聚酰亚胺的第一步。影响聚酰胺酸分子量的因素很多,本实验通过对聚酰胺酸粘度的测定,讨论分析了加料顺序、单体摩尔比、反应温度、反应体系质量分数、反应时间,贮存条件六个因素对聚酰胺酸粘度的影响,确定了聚酰胺酸合成的较优的工艺条件,为制备聚酰亚胺材料奠定基础。 1、加料顺序对聚酰胺酸粘度的影响 合成聚酰胺酸溶液的加料方式按单体加料顺序分为二种: (1)正加料法(二胺溶于溶剂中,向反应混合物中加入二酐); (2)反加料法(二酐溶于溶剂中,向反应混合物中加入二胺)。 为了确定正加料法和反加料法对本实验聚酰胺酸溶液粘度的影响,在反应条件相同,采用此两种加料法,测定其各自粘度,通常情况下是正加料法得到的聚酰胺酸粘度较大,因为二酐容易与水反应,防止溶剂中水对实验的影响先溶解二胺,再加入二酐后其能优先于二胺反应,能减小水对于实验的影响,故通常正加料法得到聚合物的粘度较大。 加料方式确实对聚酰胺酸溶液分子量有着很大的影响。在相同反应条件下,正加料所得聚酸胺酸溶液的粘度η大于反加料法所得聚酸胺酸溶液的粘度η。这主要是因为在反加料法中,由于二酐过量,聚酰胺酸溶液中带有孤对电子的N 有向二酐中的电子吸收体C 进攻的趋势,这样会使聚酰胺酸溶液分子链发生断裂,得不到高分子量的聚酰胺酸溶液。其过程如图3-1所示:

2、单体摩尔比对聚酰胺酸粘度的影响 在合成聚酰胺酸溶液的反应中,必须严格的保证单体的等当量,才能得到高分子量的聚合物,任何因素引起的单体当量的偏离必然会导致聚合物分子量的降低。引起单体当量偏离的原因有单体的纯度、实验的精度、及体系中存在的副反应。在这几个因素中前两个可以通过单体提纯和提高实验精度来加以避免。而体系中存在以下几个副反应,如图3-2所示,以及二酐和溶剂络合的副反应。这些副反应的存在破坏了单体的等当量。 合成条件相同的情况下:反应初始温度-15℃,反应时间4 h,质量分数13%进行缩聚反应,二酐与二胺的摩尔配比分别为0.97,0.98,0.99,1.00,1.01,1.02,1.03,进行缩聚反应测得的二酐与二胺摩尔配比与聚酰胺酸溶液粘度η的关系如图3-3所示。结果表明,当二酐与二胺摩尔比为1时得到聚酰胺酸的粘度最大。

常用塑料特性及加工工艺

常用塑料特性及加工工艺 PEI 聚乙醚 典型应用范围: 汽车工业(发动机配件如温度传感器、燃料和空气处理器等),电器及电子设备(电气联结器、 印刷电路板、芯片外壳、防爆盒等),产品包装,飞机内部设备,医药行业(外科器械、工具壳 体、非植入器械)。 注塑模工艺条件: 干燥处理:PEI具有吸湿特性并可导致材料降解。要求湿度值应小于0.02%。建议干燥条件为 150C、4小时的干燥处理。 熔化温度:普通类型材料为340~400C;增强类型材料为340~415C。 模具温度:107~175C,建议模具温度为140C。 注射压力:700~1500bar。 注射速度:使用尽可能高的注射速度。 化学和物理特性: PEI具有很强的高温稳定性,既使是非增强型的PEI,仍具有很好的韧性和强度。因此利用PEI 优越的热稳定性可用来制作高温耐热器件。 PEI还有良好的阻燃性、 抗化学反应以及电绝缘特性。 玻璃化转化温度很高,达215C。PEI还具有很低的收缩率及良好的等方向机械特性。 PE-LD 低密度聚乙烯 典型应用范围: 碗,箱柜,管道联接器 注塑模工艺条件: 干燥:一般不需要

熔化温度:180~280C 模具温度:20~40C 为了实现冷却均匀以及较为经济的去热,建议冷却腔道直径至少为8mm,并且从冷却腔道到 模具表面的距离不要超过冷却腔道直径的1.5倍。 注射压力:最大可到1500bar。 保压压力:最大可到750bar。 注射速度:建议使用快速注射速度。 流道和浇口: 可以使用各种类型的流道和浇口。PE-LD特别适合于使用热流道模具。 化学和物理特性: 商业用的PE-LD材料的密度为0.91~0.94 g/cm3。PE-LD对气体和水蒸汽具有渗透性。PE-LD 的热膨胀系数很高不适合于加工长期使用的制品。 如果PE-LD的密度在0.91~0.925 g/cm3之间,那么其收缩率在2%~5%之间;如果密度在 0.926~0.94 g/cm3之间,那么其收缩率在1.5%~4%之间。当前实际的收缩率还要取决于注塑工艺 参数。 PE-LD在室温下可以抵抗多种溶剂, 但是芳香烃和氯化烃溶剂可使其膨胀。 同PE-HD类似, PE-LD 容易发生环境应力开裂现象。 PE-HD 高密度聚乙烯 典型应用范围: 电冰箱容器、存储容器、家用厨具、密封盖等。 注塑模工艺条件:

塑料的种类和主要特性

塑料的种类和主要特性及家具中的应用一热塑性塑料 1,聚乙烯(PE) A,主要特性 高压聚乙烯柔软、透明、无毒;低压聚乙烯刚硬、耐磨、耐蚀,电绝缘性较好 B,用途举例 :高压聚乙烯:薄膜、软管、塑料瓶;低压聚乙烯:化工设备、管道、承载不高的齿轮、轴承等 2, 聚丙烯(PP) A,主要特性 :强度、硬度、弹性均高于聚乙烯,密度小,耐热性良好,电绝缘性能和耐蚀性能优良,韧性差,不耐磨,易老化 B,用途举例 :法兰、齿轮、风扇叶轮、泵叶轮、把手、电视机(收录机) 壳体以及化工管道、容器、医疗器械等 3, 聚氯乙烯(PVC) A,主要特性

:较高的强度和较好的耐蚀性。软质聚氯乙烯,其伸长率高,制品柔软,耐蚀性和电绝缘性良好 B,用途举例 废气排污排毒塔、气体液体输送管,离心泵、通风机、接头;软质PVC薄膜、雨衣、耐酸碱软管、电缆 包皮、绝缘层等 4, 聚苯乙烯(PS) A,主要特性 :耐蚀性、电绝缘性、透明性好,强度、刚度较大,耐热性、耐磨性不高,抗冲击性差,易燃、易脆裂 B,用途举例 :纱管、纱绽、线轴;仪表零件、设备外壳;储槽、管道、弯头;灯罩、透明窗;电工绝缘材料等 5, 丙烯腈─丁二烯─苯乙烯共聚合物(ABS) A,主要特性 :较高强度和冲击韧度,良好的耐磨性和耐热性,较高的化学稳定性和绝缘性,易成形,机械加工性好,耐高、低温性能差,易燃,不透明 B,用途举例

齿轮、轴承、仪表盘壳、冰箱衬里以及各种容器、管道、飞机舱内装饰板、窗框、隔音板等,也可制作 小轿车车身及档泥板、扶手、热空气调节导管等汽车零件6, 聚酰胺(PA)尼龙或锦纶 A,主要特性 强度、韧性、耐磨性、耐蚀性、吸振性、自润滑性良好,成形性好,无毒、无味。蠕变值较大,导热性 较差,吸水性高,成形收缩率大 B,用途举例 尼龙610、66、6等,制造小型零件(齿轮、蜗轮等);芳香尼龙制作高温下耐磨的零件,绝缘材料和宇宙 服等。应注意,尼龙吸水后性能及尺寸发生很大变化 7, 聚碳酸酯(PC) A,主要特性 抗拉、抗弯强度高,冲击韧度及抗蠕变性能好,耐热性、耐寒性及尺寸稳定性较高,透明度高,吸水性 小,良好的绝缘性和加工成形性,化学稳定性差 B,用途举例

粘度影响因素

影响橡胶粘度的因素分析 发布日期:2010-06-28 一切增大液体内摩擦的因素都会使粘度增加,一切减小内摩擦的因素都会使粘度降低。影响胶料粘度的因素很多,一般来说,主要有化学结构、分子量、分子量分布、剪切速率、压力、温度、时间、填充补强剂和软化剂等,其中尤以分子量、温度和剪切速率影响最为重要。 1、化学结构 一般的说,极性橡胶的分子间力比非极性的大,前者粘度比后者大,流动性也较差。分子间力小,链柔顺性大(玻璃化温度Tg低)的橡胶,粘度就低,流动性好。例如顺丁胶,结构简单,取代基均为氢,链段柔顺性大,Tg较低(-100℃),流动性良好,甚至室温下会出现“冷流”。 2、分子量 分子量越大,粘度越高。因为分子量越大,分子链越长,分子间力越大,流动越困难。 3、分子量分布 分子量分布的影响比较复杂。一般说来,分子量分布窄的橡胶,分子链发生相对位移温度范围较窄,粘流温度Tf较高,而分子量分布宽者,分子链发生相对位移的温度范围较宽,同时低分子量级分有增塑作用,Tf较低,工艺性能较好。 4、支链 生胶一般由直链型分子所组成,但有时也有支链,支链的存在,对橡胶的粘度有一定的影响。 通过对多链聚合物的研究,表明多链聚合物对粘度的影响有两种情况,当支链相当短时,则粘度比同等分子量的直连分子低得多,易于流动;如果支链很长,则粘度比同等分子量的直连分子高很多。

短支链分子对降低胶料粘度效果很大,利用这一特性,在胶料中加入少量再生胶就能获得很好的流动性,易压出,膨胀率小。这是由于再生胶大多由带不太长的支链的大分子所组成。 5、温度 温度对橡胶的粘度影响很大,温度增高,粘度下降。不同橡胶在温度升高时,粘度下降的幅度并不一样。 6、剪切速率 橡胶作为非牛顿流体,其粘度随剪切速率的提高而下降。 7、压力 高聚物具有长链结构,容易产生较多空洞,在加工温度下的压缩性比普通液体大得多。在较高压力下,体积收缩较大,自由体积减小,分子间力增大,粘度随之增大。对高聚物来说,压力增大相当于降低温度,两者对粘度的影响可以看作是等效的。 8、时间 橡胶的粘度对时间有依赖性,这种现象称为触变性。它是指橡胶流体形变所需外力随时间而减小的一种可逆现象。橡胶塑炼后,在停放过程中可塑度会随时间而下降,加入活性炭黑或白炭黑会使胶料的触变性表现的更为明显。 9、配合剂 配合剂对粘度影响很大,其中以炭黑’填充剂和软化剂(增塑剂)等尤为显著。 炭黑会与橡胶产生某些物理或化学结合,阻碍橡胶分子链的运动和滑动,所以增加粘度。炭黑用量越大,粒径越小,结构性越高胶料的粘度越大。 软化剂能降低胶料的粘度和弹性,降低脆性温度,因而能显著改善胶料流动性能,使胶料柔软、压出膨胀率减小和压出速度的提高等。因为软化剂能减少橡胶分子间的作用力,又起稀释作用。在一定范围内,软化剂用量越多,胶

常用塑料材料的特性简介

常用塑料材料的特性简介 一、聚乙烯类塑料 聚乙烯是指由乙烯单体自由基聚合而成的聚合物,英文名简称PE。PE的合成原料来自石油,自1965年以来一直高居世界塑料树脂产量第一位。目前,聚乙烯的主要品种有: 低密度聚乙烯(LDPE),高密度聚乙烯(HDPE),线性低密度聚乙烯(LLDPE),(超)高分子量聚乙烯(UHMWPE),茂金属聚乙烯(m-PE) 还有其改性品种: 乙烯—乙酸乙烯酯(EVA)氯化聚乙烯(CPE)。 1、聚乙烯类塑料的结构性能 PE为线性聚合物,属于高分子长链脂肪烃;分子对称无极性,分子间作用力小,力学性能不高、电绝缘性好、熔点低、印刷性缓谩 E的结构规整,线性度高,因而易于结晶。结晶度从高到低排序:HDPE,LLDPE,LDPE。随结晶度的提高,PE制品的密度、刚性、硬度和强度等性能提高,但冲击性能下降。 (1)一般性能 PE树脂为无味、无毒的白色粉末或颗粒,外观呈乳白色,有似腊的手感;吸水率低,小于0.01%。PE膜透明,透明度随结晶度提高而下降。PE 膜的透水率低但透气性较大,不适于保鲜包装而适于防潮包装。PE易燃,氧指数仅为17?4,燃烧时低烟,有少量熔融滴落,火焰上黄下蓝,有石蜡气味。PE的耐水性较好。制品表面无极性,难以粘合和印刷,须经表面处理才可改善。 (2)力学性能 PE的力学性能一般,其拉伸强度较低,抗蠕变性不好,耐冲击性能较好。PE的耐环境应力开裂性不好,但随分子量增大而改善。PE的耐穿刺性好,并以LLDPE最好。 (3)热学性能 PE的耐热性不高,随分子量和结晶度的提高而改善。PE的耐低温性好,脆化温度一般可达-50℃以下;随分子量的增大,最低可达-140℃。PE 的线膨胀系数大,在塑料中属较大者。PE的热导率属塑料中较高者。 (4)电学性能 PE无极性,因此电性能十分优异。介电损耗很低,且随温度和频率变化极小。PE是少数耐电晕性好的塑料品种,介电强度又高,因而可用做高压绝缘材料。 (5)环境性能 PE具有良好的化学稳定性。在常温下可耐酸、碱、盐类水溶液的腐蚀,具体有稀硫酸、稀硝酸、任何浓度的盐酸、氢氟酸、磷酸、甲酸及乙酸等,但不耐强氧化剂如发烟硫酸、、浓硫酸和铬酸等。PE在60℃以下不溶于一般溶剂,但与脂肪烃、芳香烃、卤代烃等长期接触会溶胀或龟裂。温度超过60℃后,可少量溶于甲苯、乙酸戊酯、三氯乙烯、松节油、矿物油及石蜡中;温度超过100℃后,可溶于四氢化萘。 PE耐候性不好,日晒、雨淋都会引起老化,需加入抗氧剂和光稳定剂改善。2、聚乙烯类塑料的应用范围 (1)薄膜类制品 薄膜类制品是PE的最主要用途。LDPE树脂用于膜类制品可占50%以上,可用于食品、日用品、蔬菜、收缩、自粘、垃圾袋等轻质包装膜及农业用地膜、棚膜等。HDPE树脂用于膜类制品可占10%以上。因其薄膜强度高,主要用于重包装膜、撕裂膜及背心

影响粘度的几个因素

影响粘度的几个因素 粘度是聚乙烯加工性最重要的基本概念之一,是对流动性的定量表示,影响粘度的因素有熔体温度、压力、剪切速率以及相对分子质量等,下面分别叙述。 (1)温度的影响 由前面的分析已经知道,聚乙烯的粘度是剪切速率的函数,但是,聚乙烯的粘度同时也受到温度的影响。所以,只有剪切速率恒定时,研究温度对粘度的影响才有实际意义。一般说,聚乙烯熔体粘度的敏感性要比对剪切作用敏感强。研究表明,随着温度的升高,聚乙烯熔体的粘度呈指数函数方式下降。这是因为,温度升高,必然使得分子间,分子链间的运动加快,从而使得聚乙烯分子链之间的缠绕降低,分子之间的距离增大,从而导致粘度降低。易于成型,但制品收缩率大,还会引起分解,温度太低,熔体粘度大,流动困难,成型性差,并且弹性大,也会使制品的形状稳定性差。 但是不同的聚乙烯粘度对于温度的程度不同。聚甲醛对温度的变化最不敏感,其次是聚乙烯、聚丙烯、聚苯乙烯,最敏感的要数乙酸纤维素,表1中列出了一些常用聚乙烯对于温度的敏感程度。非常敏感的聚乙烯,温控十分重要,否则粘度较大变化,使操作不稳定,影响产品质量。

在实用中,对于温度敏感性好的熔体,可以考虑在成型过程中提高聚乙烯的成型温度来改善聚乙烯的流动性能,如PMMA、PC、CA、PA。但是对于敏感性差的聚乙烯,提高温度对于改善流动性能并不明显,所以一般不采用提高温度的办法来改进其流动特性。如POM和PE、PP等非极性聚乙烯,即使温度升幅度很大,粘度却降低很小。还有,提高温度必须受到一定条件的限制,就是成型温度必须在聚乙烯允许的成型温度范围之内,否则,聚乙烯就会发生降解。成型设备损耗大,工作条件恶化,得不偿失。利用活化能的大小来表达物料的粘度和温度的关系,有定量意义。表 2 为一些聚乙烯在低剪切速率下的活化能。 (2)压力的影响 聚乙烯熔体内部的分子之间、分子链之间具有微小的空间,即所谓的自由体积。因此聚乙烯是可以压缩的。注射过程中,聚乙烯受到的外部压力最大可以达到几十甚至几百MPa 。在此压力作用下,大分子之间的距离减小,链段活动范围减小,分子间距离缩小,分子间的作用力增加,致使链间的错动则更为困难,表现为整体粘度增大。但是不同聚乙烯在同样的压力下,粘度的增大程度并不相同。聚苯乙烯(PS)对于压力的敏感程度最高,即增加压力时,粘度增加得很快。高密度聚乙烯与低密度聚乙烯相比,压力对粘度的影响较小,聚丙烯受压力的影响相当于中等程度的聚乙烯。 增加压力引起粘度增加这一事实表明,单纯通过增加压力去提高

影响PA6切片粘度的因素和分析方法1

交通职业技术学院工业分析与检验专业2013届毕业论文影响PA6切片粘度的因素及其分析方法 ——以力恒化验室为例 学生:梁丽雯 学号: 0 专业:工业分析与检验 年级班级: 10(33)班 指导教师: 2012年9月 工业分析与检验

写作提纲引言 1总论 1.1不同粘度PA6切片的应用 2力恒化验室的常规检测项目简介2.1切片的可萃取物含量 2.1.1原理 2.1.2装置 2.1.3步骤 2.1.4备注 2.2切片的水含量(KF电位滴定法)2.2.1原理 2.2.2卡菲试剂 2.2.3步骤 2.3切片的灰分含量 2.3.1原理 2.3.2用具 2.3.3步骤 2.4切片的氨基含量 2.4.1原理 2.4.2试剂和材料 2.4.3步骤

2.4.4备注 2.5切片外观 2.5.1切片外观分类 3力恒化验室PA6切片黏度测定的具体介绍3.1黏度的定义 3.1.1粘度 3.1.2粘度分类 3.1.2.1绝对粘度 3.1.2.2运动粘度 3.1.2.3条件粘度 3.1.2.4相对粘度 3.1.3粘度的测定方法 3.1.4影响黏度的因素 3.2乌氏粘度计的测量 3.2.2乌氏粘度计测量实验用具 3.2.3乌氏粘度计测量仪器组成 3.2.4乌氏粘度计测量化学试剂 3.2.5乌氏粘度计测量硫酸浓度测定 3.2.6乌氏粘度计测量粘度计的校准 3.2.7乌氏粘度计测量分析步骤 3..2.8乌贝洛德毛细管粘度计使用注意事项 4.0 DVS系列自动粘度仪测定粘度

4.1上位机软件 参考文献 影响PA6切片粘度的因素及其分析方法 梁丽雯 摘要:聚酰胺(PA,俗称尼龙)是美国DuPont公司最先开发用于纤维的树脂,于1939年实现工业化。20世纪50年代开始开发和生产注塑制品,以取代金属满足下游工业制品轻量化、降低成本的要求。聚酰胺主链上含有许多重复的酰胺基,用作塑料时称尼龙,用作合成纤维时我们称为锦纶。本研究是用己酰胺来合成PA6锦纶切片。锦纶-PA6是合成纤维的第三大化纤,所以不管是在民用还是在工业用上都占着举足轻重的地位。切片的粘度是锦纶的重要测定指标及判等依据,不同粘度的切片应用的的领域也不同。在PA6切片的生产及测定过程中有许多原因导致相对粘度发生改变。所以,研究影响PA6切片粘度的因素及其分析方法有重要意义。 关键词:PA6切片;相对粘度;分析 引言 聚酰胺简称PA(Polyomide),聚酰胺纤维是指分子主链由酰胺键连接起来的一类合成纤维,各国的商品名称各不相同, 聚酰胺6纤维在中国称做“锦纶”,英美称尼龙6,德国称贝纶(Perlon),苏联称卡普纶(Капрон),日本称阿米纶(Amilan)。 1938年,聚酰胺66纤维以中间实验室规模开始生产,聚酰胺6纤维也于1941年开始工业化生产。接着其他类型的聚酰胺纤维也相继问世。由于聚酰胺纤维具有优良的物理性能和纺织性能,发展速度很快,在合成纤维产量中一直居首位,但从1972年开始为涤纶所超过而退居第二位。由于新纤维和新品种的开发以及老品种的改性,估计今后聚酰胺纤维的绝对产量仍会不断增长。聚酰胺纤维一般可分为两大类。一类是由二元胺和二元酸缩聚而得,另一类由w-氨基酸或由酰胺开环聚合制得。1938年1月28日德国PaulSchlack(1897-1987)以己酰胺(CPL)为原料

常用工程塑料的种类及主要特性

常用工程塑料的种类及主要特性

热固性塑料 塑料是以树脂(天然的或合成的)为主要组分,加入一些用来改善使用性能和工艺性能的添加剂而制成的。因其通常在加热、加压条件下塑制成型,故称为塑料。 塑料的分类 1.按树脂的性质分类 热塑性塑料:在特定温度范围内能反复加热软化和冷却硬化的塑料。如聚乙烯 塑料、聚氯乙烯塑料。 热固性塑料:因受热或其它条件能固化成不熔不溶性物料的塑料。如酚醛塑料 (PE、环氧塑料(EP等。 2.按塑料使用范围分类 通用塑料:指产量大、用途广、成型性好、价廉的塑料。如聚乙烯、聚丙烯、聚氯乙烯等。 工程塑料:指能承受一定的外力作用,并有良好的机械性能和尺寸稳定性,在 高、低温下仍能保持其优良性能,可以作为工程结构件的塑料。如ABS尼龙、聚矶等。 特种塑料:般指具有特种功能(如耐热、自润滑等),应用于特殊要求的塑料。 如氟塑料、有机硅等。 塑料的基本性能 1.质轻、比强度高。塑料质轻,一般塑料的密度都在0.9~ 2.3克/厘米 3 之间,只有钢铁的1/8~1/4、铝的1/2左右,而各种泡沫塑料的密度更低,约在0.01~0.5 克/厘米3之间。按单位质量计算的强度称为比强度,有些增强塑料的比强度接近甚至超过钢材。例如合金钢材,其单位质量的拉伸强度为160兆帕,而用玻璃纤维增强的塑 料可达到170~400兆帕。 2.优异的电绝缘性能。几乎所有的塑料都具有优异的电绝缘性能,如极小的介电损耗和优良的耐电弧特性,这些性能可与陶瓷媲美。 3.优良的化学稳定性能。一般塑料对酸碱等化学药品均有良好的耐腐蚀能力,特别是聚四氟乙烯的耐化学腐蚀性能比黄金还要好,甚至能耐"王水"等强腐蚀性电解质 的腐蚀,被称为"塑料王" 4.减摩、耐磨性能好。大多数塑料具有优良的减摩、耐磨和自润滑特性。许多工程塑

各种塑料的特性介绍

一、聚乙烯类塑料 聚乙烯是指由乙烯单体自由基聚合而成的聚合物,英文名简称PE。PE的合成原料来自石油,自1965年以来一直高居世界塑料树脂产量第一位。目前,聚乙烯的主要品种有: 低密度聚乙烯(LDPE), 高密度聚乙烯(HDPE), 线性低密度聚乙烯(LLDPE), (超)高分子量聚乙烯(UHMWPE), 茂金属聚乙烯(m-PE) 还有其改性品种:乙烯—乙酸乙烯酯(EVA)?氯化聚乙烯(CPE)。?1、聚乙烯类塑料的结构性能 PE为线性聚合物,属于高分子长链脂肪烃;分子对称无极性,分子间作用力小,力学性能不高、电绝缘性好、熔点低、印刷性不好。PE的结构规整,线性度高,因而易于结晶。结晶度从高到低排序:HDPE,LLDPE,LDPE。随结晶度的提高,PE制品的密度、刚性、硬度和强度等性能提高,但冲击性能下降。 (1)一般性能 PE树脂为无味、无毒的白色粉末或颗粒,外观呈乳白色,有似腊的手感;吸水率低,小于0?01%。PE膜透明,透明度随结晶度提高而下降。PE膜的透水率低但透气性较大,不适于保鲜包装而适于防潮包装。PE易燃,氧指数仅为17?4,燃烧时低烟,有少量熔融滴落,火焰上黄下蓝,有石蜡气味。PE的耐水性较好。制品表面无极性,难以粘合和印刷,须经表面处理才可改善。 (2)力学性能 PE的力学性能一般,其拉伸强度较低,抗蠕变性不好,耐冲击性能较好。PE的耐环境应力开裂性不好,但随分子量增大而改善。PE的耐穿刺性好,并以LLDPE最好。?(3)热学性能 PE的耐热性不高,随分子量和结晶度的提高而改善。PE的耐低温性好,脆化温度一般可达-50℃以下;随分子量的增大,最低可达-140℃。PE的线膨胀系数大,在塑料中属较大者。PE的热导率属塑料中较高者。 (4)电学性能 PE无极性,因此电性能十分优异。介电损耗很低,且随温度和频率变化极小。PE是少数耐电晕性好的塑料品种,介电强度又高,因而可用做高压绝缘材料。 (5)环境性能 PE具有良好的化学稳定性。在常温下可耐酸、碱、盐类水溶液的腐蚀,具体有稀硫酸、稀硝酸、任何浓度的盐酸、氢氟酸、磷酸、甲酸及乙酸等,但不耐强氧化剂如发烟硫酸、、浓硫酸和铬酸等。PE在60℃以下不溶于一般溶剂,但与脂肪烃、芳香烃、卤代烃等长期接触会溶胀或龟裂。温度超过60℃后,可少量溶于甲苯、乙酸戊酯、三氯乙烯、松节油、矿物油及石蜡中;温度超过100℃后,可溶于四氢化萘。?PE耐候性不好,日晒、雨淋都会引起老化,需加入抗氧剂和光稳定剂改善。?2、聚乙烯类塑料的应用范围 (1)薄膜类制品 薄膜类制品是PE的最主要用途。LDPE树脂用于膜类制品可占50%以上,可用于食品、日用品、蔬菜、收缩、自粘、垃圾袋等轻质包装膜及农业用地膜、棚膜等。HDPE树脂用于膜类制品可占10%以上。因其薄膜强度高,主要用于重包装膜、撕裂膜及背心袋等。LLDPE树脂用于膜类制品的比重比L DPE还要大,可占树脂的70%以上。LLDPE膜具有延伸性好、较高的拉伸强度、耐穿刺、耐环境应力开裂及低温冲击性好、可制成超薄膜等优点,主要用于包装膜、垃圾袋、保鲜膜、自粘膜及超薄地膜等。?(2)注塑制品 PE因加工性好而广泛用于注塑制品,其中HDPE占30%以上,LDPE和LLDPE各占10%以上。主要生产:日用品如盆、桶、盒、暖瓶壳、杯、玩具等,周转箱、瓦楞箱。 (3)中空制品 以HDPE树脂为主,可占树脂用量的20%。其制品具有耐应力开裂性好、耐油性好、耐低温冲击性好等优点,可用于食品油、酒类、汽油及化学制剂等液体的包装。此外还有中空玩具等。?(4)管材类制品 以HDPE树脂为主,主要用于生活给水、燃气输送、农业排灌、电缆穿线管、液体吸管及圆珠笔芯等。LDPE管还可用于化妆品、药品、牙膏、鞋油等的包装。? (5)丝类制品 圆丝用HDPE为原料,主要用于编织渔网、缆绳、工业滤网及民用纱窗网等。扁丝以HDPE和LLDP E为原料,主要用于编织袋、编织布及撕裂膜等。 (6)电缆制品 PE广泛用于中、高压电缆的绝缘和护套材料,其中以LDPE为主,最高耐压可达220kV。 (7)其它制品