Simulink Model of a Lithium-Ion Battery

Michael Knauff, Jeffrey McLaughlin, Dr. Chris Dafis,

Dr. Dagmar Niebur, Dr. Pritpal Singh , Dr. Harry Kwatny, and Dr. Chika Nwankpa Simulink Model of a Lithium-Ion Battery for the

Hybrid Power System Testbed

ABSTRACT

This paper investigates the identification of model parameters for a Simulink model of the 60Ah Lithium Technology Corporation Lithium-ion battery used in the hybrid power systems testbed. Two experimental tests of the battery are presented, along with a method for deriving battery model parameters using these tests. A comparison between test data and simulation results shows a high degree of accuracy in the model.

1.INTRODUCTION

The Hybrid Power System Testbed is a small scale hardware demonstration currently being assembled at NAVSEA Philadelphia, that will combines several emerging technologies, and provides a means to experiment with advanced power management schemes, such as that described in (Kwatny et al. 2005).

The testbed consists of a variety of power sources and loads interconnected via a DC bus. The power sources include a Lithium-ion (Li-ion) battery and a diesel generator, with additional sources being considered for future implementation (ex. fuel cell). The loads consist of a rim-driven propulsion motor, a power processing unit capable of emulating a wide variety of loads, and two permanent magnet machines in a motor/generator configuration used to dissipate excessive power beyond the capabilities of the other two loads. The sources and loads are connected to the DC bus via several power electronic building block modules (Ericsen, Hingorani, and Khersonsky 2006).

In order to gauge the physical interaction of the developmental components during operation, a model of the testbed was created in Matlab/Simulink. The overall Simulink model of the testbed is described in greater detail in (Knauff et al. 2007). This paper provides a detailed look at the model of the testbed’s Li-ion battery. It also discusses in detail the derivation of the model parameters via testing of the physical device.

2.BATTERY MODEL

A variety of models exist that predict battery behavior to varying degrees of accuracy. A good overview of the different model types available is presented by Singh and Nallanchakravarthula (2005) The available models differ in both complexity and in the nature of the tests necessary to implement the models. The model selected for the testbed was proposed by Chen and Rincon-Mora (2006). It was chosen for its relative simplicity, including the advantage that a straightforward test is given to derive the associated model parameters.

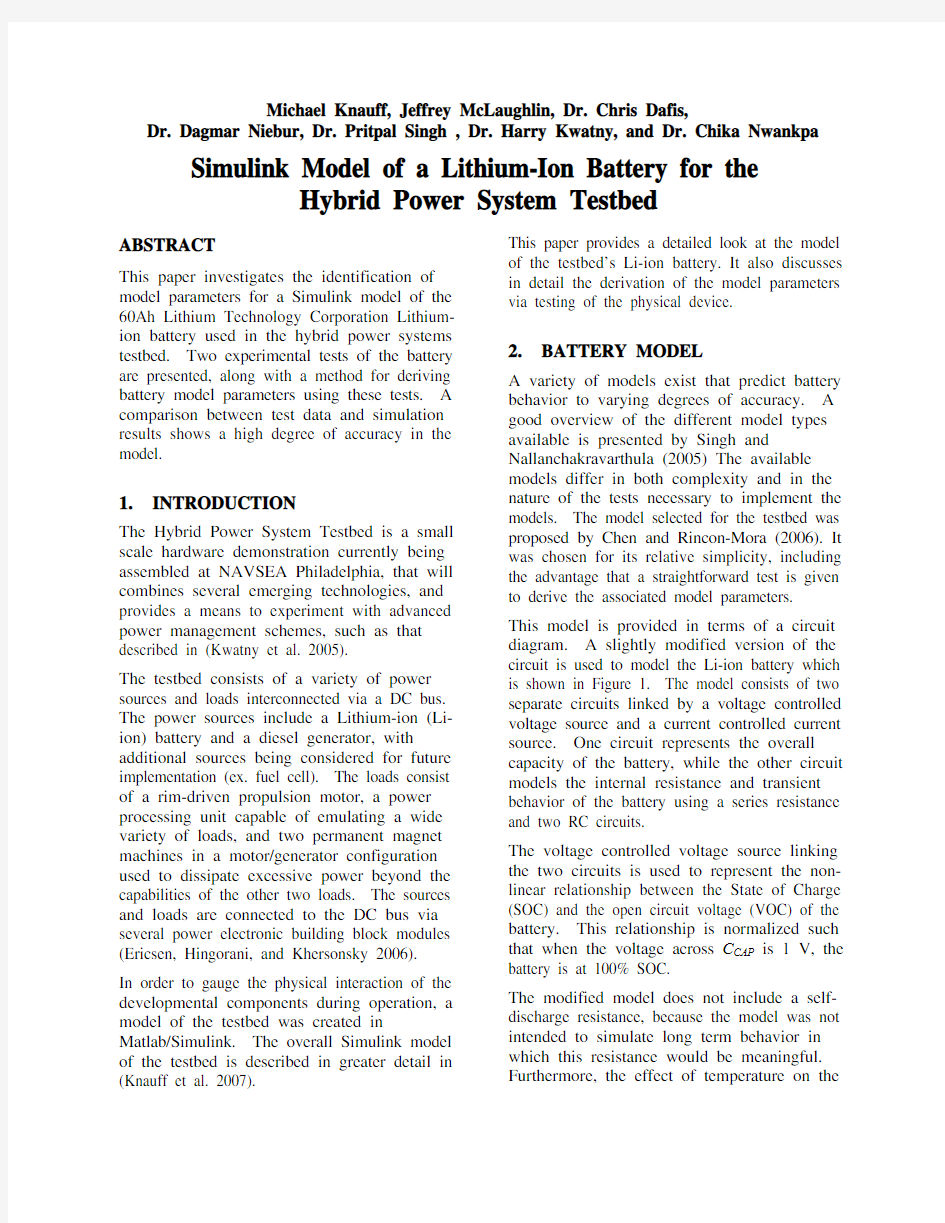

This model is provided in terms of a circuit diagram. A slightly modified version of the circuit is used to model the Li-ion battery which is shown in Figure 1. The model consists of two separate circuits linked by a voltage controlled voltage source and a current controlled current source. One circuit represents the overall capacity of the battery, while the other circuit models the internal resistance and transient behavior of the battery using a series resistance and two RC circuits.

The voltage controlled voltage source linking the two circuits is used to represent the non-linear relationship between the State of Charge (SOC) and the open circuit voltage (VOC) of the battery. This relationship is normalized such that when the voltage across C CAP is 1 V, the battery is at 100% SOC.

The modified model does not include a self-discharge resistance, because the model was not intended to simulate long term behavior in which this resistance would be meaningful. Furthermore, the effect of temperature on the

battery performance has not been accounted for in this version of the model due to the fact that the battery is expected to operate in a relatively narrow range of temperature conditions.

The circuit diagram in Figure 1 was implemented in Simulink by first finding an equivalent ordinary differential equation (ODE) describing the above circuit. The equation

1

1

1

1

1

1230

00

0()0

00()()CAP

TS

TS

TS TL

TL

TL

S C

R C C R C C

g x x x R ??????=?+???=+++??

???????????????

???

x

x u

y u

(1) describes the circuit diagram of Figure 1, where

R TS and C TS are the resistance and capacitance in the shorter time constant RC circuit, R TL and C TL are the resistance and capacitance in the longer time constant RC circuit, C CAP represents the overall capacitance of the battery, R S is the series resistance, and g (x ) is the non-linear function which maps SOC to VOC. The state vector x represents the voltages across C CAP , C TS , and C TL . The input u is the current entering the battery, and the output y is the voltage across the battery terminals. As noted above SOC is represented by the voltage v SOC across C CAP which ranges from 0 to 1 V, representing 0% to 100% battery capacity respectively.

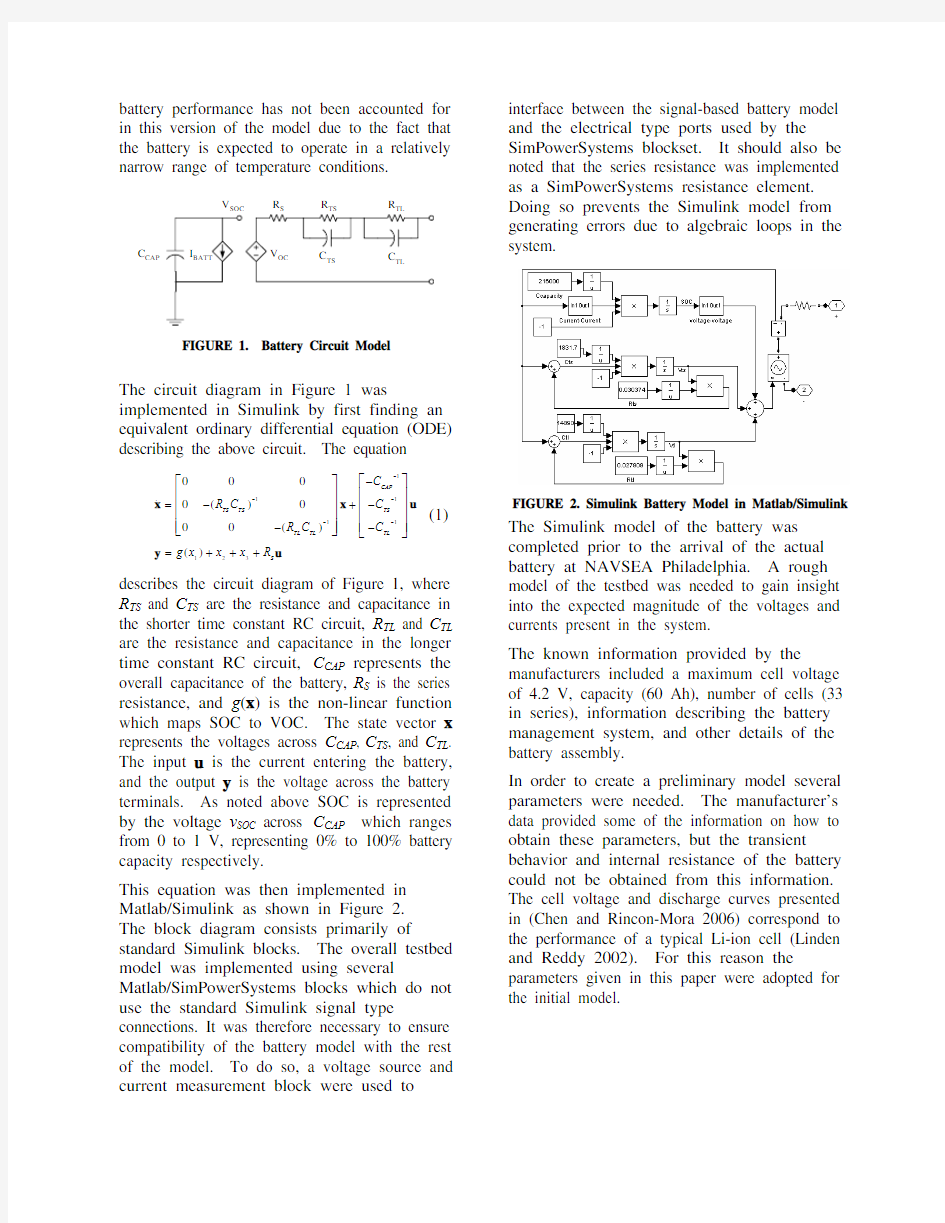

This equation was then implemented in Matlab/Simulink as shown in Figure 2. The block diagram consists primarily of standard Simulink blocks. The overall testbed model was implemented using several Matlab/SimPowerSystems blocks which do not use the standard Simulink signal type connections. It was therefore necessary to ensure compatibility of the battery model with the rest of the model. To do so, a voltage source and current measurement block were used to

interface between the signal-based battery model and the electrical type ports used by the SimPowerSystems blockset. It should also be noted that the series resistance was implemented as a SimPowerSystems resistance element. Doing so prevents the Simulink model from generating errors due to algebraic loops in the system.

The Simulink model of the battery was completed prior to the arrival of the actual battery at NAVSEA Philadelphia. A rough model of the testbed was needed to gain insight into the expected magnitude of the voltages and currents present in the system.

The known information provided by the manufacturers included a maximum cell voltage of 4.2 V, capacity (60 Ah), number of cells (33 in series), information describing the battery management system, and other details of the battery assembly.

In order to create a preliminary model several parameters were needed. The manufacturer’s data provided some of the information on how to obtain these parameters, but the transient behavior and internal resistance of the battery could not be obtained from this information. The cell voltage and discharge curves presented in (Chen and Rincon-Mora 2006) correspond to the performance of a typical Li-ion cell (Linden and Reddy 2002). For this reason the parameters given in this paper were adopted for

the initial model.

FIGURE 2. Simulink Battery Model in Matlab/Simulink

R R C CAP R V FIGURE 1. Battery Circuit Model

3.DERIVATION OF VOC–SOC

RELATIONSHIP

Once the actual battery arrived at NAVSEA Philadelphia, explicit model parameters had to be derived and employed in the model from battery tests. The first characteristic of the model to be experimentally derived was the non-linear function relating SOC to VOC.

To find an approximation for this function, a constant resistance discharge of the battery over

a safe discharge cycle was conducted. The battery is equipped with a battery management system (BMS) which, among other functionalities, automatically disconnects the battery terminals when the battery’s cell voltages are below a critical voltage level. This ensures that no permanent damage is inflicted on the battery. The discharge was executed until the point at which this mechanism triggers.

The setup used for this test is shown in Figure 3. Voltage and current at the battery terminals were monitored internally by the battery management system (BMS). This data is sampled once per second, and is made available via an RS232 port on the front of the battery assembly. Data was acquired using a serial connection and was stored as a text file for later analysis.

Upon completion of the test, the state of charge over the entire test period was found using the current data obtained from the test. Equation (2) was obtained from (1) and used to perform this calculation.

1

()(0)()

SOC SOC

CAP

v t v i d

C

τ

ττ

=?∫ (2)

Note that v SOC (0) should theoretically begin at 1 V for a fully charged battery. However, the measured voltage in each battery cell was roughly 4.09 V, while the manufacturer’s specifications listed a maximum cell voltage of 4.2 V. For this reason v SOC(0) was calibrated to be 0.9 V rather than 1 V.

The discharge-current data was numerically integrated (trapezoid rule) according to equation (2) yielding the SOC for each data point in the test. This data was then implemented in the model using an 11 point lookup table providing the corresponding values of VOC at the SOC values 0.0, 0.1, 0.2,…,1.0. A VOC value of 0 V was used for the 0.0 SOC value since the battery was not discharged to this point. Similarly a value of 138.6 V was used for 1.0 SOC corresponding to the manufacturer’s data for a fully charged cell multiplied by 33 cells.

After implementing this lookup table in the model, a simulation was used to demonstrate the improvement in this model compared with the initial model described above. Figure 4 shows a comparison between the actual data recorded during the discharge test, simulation results using the initial model, and simulation results for the refined model.

FIGURE 4. Battery Discharge Model Comparison

Blue – Experimental Data, Green – Initial Model

Red – Refined Model

FIGURE 3. Battery Test Setup

4.ESTIMATION OF RC AND SERIES

RESISTANCE PARAMETERS

After the SOC-VOC relationship had been derived the remaining model parameters were identified. A practical test for deriving these parameters is discussed in (Chen and Rincon-Mora 2006). The test involves a series of constant current discharge periods interspersed by a series of rest periods in which no current is drawn from the battery. Transient behavior of the battery is observed during these rest periods. This allows the model parameters to be derived at several points throughout the discharge cycle.

A similar test was conducted with one slight modification. Rather than using a set time interval for each pulse, the battery was discharged during the nine separate discharge cycles until a specific voltage v SOC was reached. Specified values were 0.9, 0.8, 0.7, …, 0.1 SOC. In the test setup shown in Figure 3 the resistive load was replaced by a programmable load capable of discharging the battery by drawing constant current. The rating of the available programmable load significantly limited the magnitude of the discharge current that could be applied in this test. The battery was therefore discharged for a significantly longer period of time compared to the test using the resistive load.

The load was programmed to toggle the current between 3.6 and 0 A based on a user trigger command. Each time the terminal voltage reached one of the predefined levels, the load was toggled and allowed to rest for approximately 25 minutes.

The battery was discharged down to a level of about 0.1 SOC and allowed to rest for one last transient period. Again, the battery was not fully discharged to avoid any potential damage to the battery. Throughout this process the current and terminal voltage of the battery were obtained via the RS232 output of the battery’s BMS.

After obtaining the test data the nine rest periods were separated and individually analyzed to obtain the model parameters. A technique for deriving these parameters is described by Schweighofer, Raab, and Brasseur (2003). However this technique is not completely automated because it requires some guidance in

selecting the two transient periods corresponding to the two RC circuits.

An alternative approach was instead taken which

utilized the Matlab Curve Fitting Toolbox.

Looking at the end of one discharge period at

the instant when the discharge current is turned

off, R S can be found by making the assumption

that the state vector remains constant in the

vicinity around this time instant. Equation (1) is

used to derive the equation

123

123

(()

(()

)

)

S C

t g x x x R

t g x x x

i

?

+

=+++

=++

y

y

(3)

where y(t-) is the terminal voltage prior to

turning off the discharge current and y(t +) is the

terminal voltage at the beginning of the rest

period. Then R S is given by

()()

S

C

y t y t

R

i

?+

?

= (4)

After finding R S the rest period can be analyzed.

Given that u in equation (1) is zero during this

period, the equation

1

12

1

3

()((0))(0)

(0)

TS TS

TL TL

R C

R C

y t g x x e

x e

?

?

=+

+

(5)

describes the terminal voltage during this interval.

To find x2(0) and x3(0) we consider the constant discharge period prior to the rest period. Using

equation (1) yields

()

()

1

()

22

1

()

33

()()

()()

TS TS

TL TL

t

R C

TS C TS C

t

R C

TL C TL C

x t x R i e R i

x t x R i e R i

τ

τ

τ

τ

?+

?+

=?+?

=?+?

(6)

where –τ is the time point at the beginning of the discharge period. Given that τ is sufficiently

large, the exponential components in equation

(6) are negligibly small at time t=0. Then Equation (6) reduces to

23(0)(0)TS C TL C

x R i x R i =?=?. (7)

Equation (5) is of the generic form

()bt dt y t k a e c e =+?+? (8)

The generic parameters k , a, b, c , and d were determined based on measurements of y (t ) and applying the Trust-Region algorithm of Matlab’s Curve Fitting Toolbox. Constraints on the parameters enforced positive values for k and negative values for a, b, c , and d . The battery model parameters were then derived from equations (5), (7), and (8) as

11TS C TL C TS TS TL TL a

R i c R i C R b C R d

=?

=?

=?=?

, (9) This method was used for each discharge period in the test. The resulting parameters are shown in Figures 5-9.

Rts as a function of SOC

SOC

R t s

FIGURE 8. R TS as a function of SOC

4

SOC

C t l

Ctl as a function of SOC

FIGURE 7. C TL as a function of SOC

Rtl as a function of SOC

SOC

R t l

FIGURE 6. R TL as a function of SOC

SOC

R s

Rs as a function of SOC

FIGURE 5. R S as a function of SOC

As noted in (Barsali and Ceraolo 2002), the RC circuit parameters are functions of the battery SOC. However, it should be noted that based on Figures 5-9 this variation is within an order of magnitude. Potentially, this parameter variation could be implemented in the Simulink model by replacing the parameter constant blocks with lookup tables.

Since it was desirable to keep the Simulink model as simple as possible, these parameters were instead implemented using the average of the parameters over the nine discharge cycles. A comparison of the resulting model with the test data is shown in Figures 10 and 11.

Figures 10 and 11 show a close match between the test data and simulation results (mean absolute percent error of 0.19 %), despite the fact that the averaged parameters were constant rather than functions of the SOC. Figure 11 presents a more detailed view of Figure 10, focusing on the time interval [3.75, 4]×104s and demonstrates that even when some steady state error is present the transient behavior of the model follows an almost identical path, only offset slightly from the actual system.

5. CONCLUSION

This paper investigates modeling and parameter identification of Li-ion batteries for use in numerical simulation in the Matlab/Simulink environment. A comparison of simulation and hardware testing results shows a high degree of accuracy with the selected battery model. In contrast to the technique proposed by Schweighofer, Raab, and Brasseur (2003) and utilized by Chen and Rincon-Mora (2006), where portions of the transient curve have to be identified manually, the technique investigated in this paper is completely automated. 6. ACKNOWLEDGMENTS

This work was supported in part by the Office of Naval Research Contract Number N00014-06-C-0041, the NSF-Navy Civilian Service (NNCS) Fellowship-Scholarship Program (NSF Aaward number #0549139), and ONR Contract #N65540-05-C-0028.

The authors would like to thank Lynn Petersen of ONR and John Metzer of NAVSEA-Philadelphia for their support and guidance during this effort.

x 10

4

Time (s)

V o l t a g e (V )

FIGURE 11. Comparison between simulation and test

data – detailed view

x 10

4

Time (s)

V o l t a g e (V )

FIGURE 10. Comparison between

simulation and test data

SOC

C t s

Cts as a function of SOC

FIGURE 9. C TS as a function of SOC

7.REFERENCES

Barsali, S., and M. Ceraolo. 2002. Dynamical models of lead-acid batteries: implementation issues. IEEE Transaction on Energy Conversion 17 (1):16-23.

Chen, Min, and G. A. Rincon-Mora. 2006. Accurate electrical battery model capable of predicting runtime and I-V performance. IEEE Transactions on Energy Conversion 21 (2):504-511.

Ericsen, T., N. Hingorani, and Y. Khersonsky. 2006. Power electronics and future marine electrical systems. IEEE Transactions on Industry Applications 42 (1):155-163.

Knauff, M. C., C. J. Dafis, D. Niebur, H. G. Kwatny, and C. O. Nwankpa. 2007. Simulink Model for Hybrid Power System Test-bed. Paper Accepted for Publication in Proceedings of IEEE Electric Ship Technologies Symposium, Arlington, VA, May 2007.

Kwatny, H. G., E. Mensah, D. Niebur, and C. Teolis. 2005. Optimal shipboard power system management via mixed integer dynamic programming. Proceedings of the IEEE Electric Ship Technologies Symposium, Philadelphia, PA, July 2005.

Linden, David, and Thomas B. Reddy. 2002. Handbook of batteries. 3rd ed. New York: McGraw-Hill.

Schweighofer, B., K. M. Raab, and G. Brasseur. 2003. Modeling of high power automotive batteries by the use of an automated test system. IEEE Transactions on Instrumentation and Measurement 52 (4):1087-1091.

Singh, P., and A. Nallanchakravarthula. 2005. Fuzzy logic modeling of unmanned surface vehicle (USV) hybrid power system. Proceedings of the 2005 Intelligent Systems Application to Power Systems, Arlington, VA, November 2005.

8.BIOGRAPHIES

Michael Knauff received the B.S.E. from the University of Hartford, Hartford, CT in 2003. He is currently pursuing his Ph.D. degree in electrical engineering at Drexel University, Philadelphia, PA. He is a student member of IEEE.Jeffrey McLaughlin received his B.E.E. at Villanova University in 2005, where he is currently in his last year of MSEE studies with a focus in power systems. While completing his graduate studies he has also held a research assistantship position funded by the Office of Naval Research. His research involves the construction and testing of an H-I-L hybrid power system testbed for unmanned surface vehicles. He is a member of Eta Kappa Nu, Tau Beta Pi, and a student member of IEEE.

Dr. Chris Dafis is an employee of NAVSEA-Philadelphia working in the Advanced Machinery Systems Integration branch (986). He received his B.S., M.S. and Ph.D. in Electrical Engineering and M.S. in Mathematics from Drexel University, in 1996, 1998, 2005, and 2002 respectively. His research interests are

in the areas of power systems protection, control, observability and stability as they apply to future Navy combatants. He is a member of IEEE, Eta Kappa Nu, and ASNE.

Dagmar Niebur received her Diploma in Mathematics and Physics from the University of Dortmund, Germany in 1984. She received her Diploma in Computer Science (1987) and her Ph.D. in Electrical Engineering (1994) from the Swiss Federal Institute of Technology, Lausanne, (EPFL) Switzerland. In 1997 she joined Drexel University's Electrical and Computer Engineering Department where she is currently an associate professor. Prior engagements included research positions at the Jet Propulsion Laboratory and EPFL. Her research focuses on intelligent information processing techniques for power system monitoring and control. In 2000, she received the NSF Career Award.

Pritpal Singh is Professor and Chairperson of the ECE Department, Villanova University. Dr. Singh received his B.Sc. from the University of Birmingham, U.K., and his Ph.D. from the University of Delaware. His research is focused on the SOC/SOH of batteries and fuel cells, photovoltaic devices and systems, and alternative energy sources.

Harry G. Kwatny received the B.S.M.E. degree, the M.S. degree in Aeronautics and

Astronautics, and the Ph.D. degree in Electrical Engineering from Drexel Institute of Technology, Philadelphia, PA, the Massachusetts Institute of Technology, Cambridge, and the University of Pennsylvania, Philadelphia, in 1961, 1962, and 1967, respectively. He joined the Department of Mechanical Engineering and Mechanics, Drexel University, Philadelphia, PA in 1966, where he

is currently the S. Herbert Raynes Professor of Mechanical Engineering. His research interests include modeling, analysis and control of nonlinear, parameter-dependent systems with specific applications to electric power systems and power plants, aircraft, spacecraft and ground vehicles. He has coauthored over 100 papers and

a monograph on non-linear control. He is also a coauthor of the software package TSi ProPac and a Mathematica package for nonlinear control system design and multibody mechanical system modeling.

Chika O. Nwankpa received the Magistr Diploma in Electric Power Ssystems from Leningrad Polytechnical Institute, USSR, in 1986, and the Ph.D. degree in the Electrical and Computer Engineering from the Illinois Institute of Technology, Chicago, in 1990. He is currently a Professor of Electrical and Computer Engineering and director of the Center for Electric Power Engineering (CEPE) at Drexel University, Philadelphia, PA. His research interests are in the areas of power systems and power electronics. Dr. Nwankpa is a recipient of the 1994 Presidential Faculty Fellow Award and the 1991 NSF Engineering Research Initiation Award.

汽车模型的背景、现状与前景

汽车模型的背景、现状与前景 1927年美国通用汽车公司将油泥应用到汽车设计开发模型上,1955年日本首次使用工业油泥进行汽车模型的设计开发,我国则在70年代初开始应用这一技术。汽车模型工是在80年代初期形成的,目前从业人员大约有1000多人,分布在全国20多个省100多家汽车生产企业。 汽车模型工是设计师与工程师之间的桥梁,没有这个桥梁汽车设计将无法进行。由于汽车车身设计程序要经过汽车效果图、小比例模型制作、1:1模型制作、模型数据采集、修线修面、结构设计等设计过程,因此汽车模型工水平的高低将直接影响到汽车产品开发的进度和质量。一个1:1的汽车油泥模型需要四人同时制作,制作周期为3-4个月,1:1内饰模型需要两人同时制作,制作周期为2-3个月,小比例模型制作周期为2个月。一般规模的汽车生产企业一年能开发2个或更多个新产品。 在欧美国家,汽车模型工可在专门的职业培训机构进行系统培训,在日本也有一些职业培训学校开设了汽车模型工的专业课程。国内目前没有专门的汽车模型工职业培训学校,汽车模型工都是各汽车厂内部自己培养的技术工人。一些有条件的汽车厂,如:解放汽车公司、东风汽车公司只能将该厂的汽车模型工送到国外进行培训,或通过国外代理商组织的专业培训班来提高技术水平。如,日本在中国的汽车模型工代理商每年在上海举办一次汽车模型工培训班,为国内汽车厂家培训了大批的汽车模型工。一方面,企业不可能大批量的培养人才,导致了汽车模型工人才的紧缺,使得国内很多的汽车生产企业无自主产品开发能力;另一方面,国内的汽车模型工与国外的汽车模型工的技术水平相比较还有很大的差距,从而限制了我国汽车工业的发展。

动态矩阵和模型预测控制的半自动驾驶汽车(自动控制论文)

Dhaval Shroff1, Harsh Nangalia1, Akash Metawala1, Mayur Parulekar1, Viraj Padte1 Research and Innovation Center Dwarkadas J. Sanghvi College of Engineering Mumbai, India. dhaval92shroff@https://www.360docs.net/doc/2011683220.html,; mvparulekar@https://www.360docs.net/doc/2011683220.html, Abstract—Dynamic matrix and model predictive control in a car aims at vehicle localization in order to avoid collisions by providing computational control for driver assistance whichprevents car crashes by taking control of the car away from the driver on incidences of driver’s negligence or distraction. This paper provides ways in which the vehicle’s position with reference to the surrounding objects and the vehicle’s dynamic movement parameters are synchronized and stored in dynamic matrices with samples at regular instants and hence predict the behavior of the car’s surrounding to provide the drivers and the passengers with a driving experience that eliminates any reflex braking or steering reactions and tedious driving in traffic conditions or at junctions.It aims at taking corrective action based on the feedback available from the closed loop system which is recursively accessed by the central controller of the car and it controls the propulsion and steeringand provides a greater restoring force to move the vehicle to a safer region.Our work is towards the development of an application for the DSRC framework (Dedicated Short Range Communication for Inter-Vehicular Communication) by US Department of Traffic (DoT) and DARPA (Defense Advanced Research Projects Agency) and European Commission- funded Project SAVE-U (Sensors and System Architecture for Vulnerable road Users Protection) and is a step towards Intelligent Transportation Systems such as Autonomous Unmanned Ground and Aerial Vehicular systems. Keywords-Driver assist, Model predictive control, Multi-vehicle co-operation, Dynamic matrix control, Self-mapping I.INTRODUCTION Driver assist technologies aim at reducing the driver stress and fatigue, enhance his/her vigilance, and perception of the environment around the vehicle. It compensates for the driver’s ability to react [6].In this paper, we present experimental results obtained in the process of developing a consumer car based on the initiative of US DoT for the need for safe vehicular movement to reduce fatalities due to accidents [5]. We aim at developing computational assist for the car using the surrounding map data obtained by the LiDAR (Light Detection and Ranging) sensors which is evaluated and specific commands are issued to the vehicle’s propellers to avoid static and dynamic obstacles. This is also an initiative by the Volvo car company [1] where they plan to drive some of these control systems in their cars and trucks by 2020 and by General Motors, which aims to implement semi-autonomous control in cars for consumers by the end of this decade [18].Developments in wireless and mobile communication technologies are advancing methods for ex- changing driving information between vehicles and roadside infrastructures to improve driving safety and efficiency [3]. We attempt to implement multi-vehicle co-operative communication using the principle of swarm robotics, which will not only prevent collisions but also define specific patterns, which the nearby cars can form and pass through any patch of road without causing traffic jams. The position of the car and the position of the obstacles in its path, static or moving, will be updated in real time for every sampling point and stored in constantly updated matrices using the algorithm of dynamic matrix control. Comparing the sequence of previous outputs available with change in time and the inputs given to the car, we can predict its non-linear behavior with the help of model predictive control. One of the advantages of predictive control is that if the future evolution of the reference is known priori, the system can react before the change has effectively been made, thus avoiding the effects of delay in the process response [16]. We propose an approach in which human driving behavior is modeled as a hybrid automation, in which the mode is unknown and represents primitive driving dynamics such as braking and acceleration. On the basis of this hybrid model, the vehicles equipped with the cooperative active safety system estimate in real-time the current driving mode of non-communicating human-driven vehicles and exploit this information to establish least restrictive safe control actions [13].For each current mode uncertainty, a mode dependent dynamic matrix is constructed, which determines the set of all continuous states that lead to an unsafe configuration for the given mode uncertainty. Then a feedback is obtained for different uncertainties and corrective action is applied accordingly [7].This ITS (Intelligent Transport System) -equipped car engages in a sort of game-theoretic decision, in which it uses information from its onboard sensors as well as roadside and traffic-light sensors to try to predict what the other car will do, reacting accordingly to prevent a crash.When both cars are ITS-equipped, the “game” becomes a cooperative one, with both cars communicating their positions and working together to avoid a collision [19]. The focus is to improve the reaction time and the speed of communication along with more accurate vehicle localization. In this paper, we concentrate on improving vehicle localization using model predictive control and dynamic matrix control algorithm by sampling inputs of the car such as velocity, steering frame angle, self-created maps Dynamic Matrix and Model Predictive Control for a Semi-Auto Pilot Car

汽车ABS系统的建模与仿真设计

基于Matlab/Simulink的汽车建模与仿真 摘要 本文所研究的是基于Matlab/Simulink的汽车防抱死刹车系统(ABS)的仿真方法,本方法是利用了Simulink所提供的模块建立了整车的动力学模型,轮胎模型,制动系统的模型和滑移率的计算模型,采用的控制方法是PID控制器,对建立的ABS的数学模型进行了仿真研究,得到了仿真的曲线,将仿真曲线与与没有安装ABS系统的制动效果进行对比。根据建立的数学模型分析,得到ABS系统可靠,能达到预期的效果。 关键词 ABS 仿真建模防抱死系统PID

Modeling and Simulation of ABS System of Automobiles Based on Matlab/Simulink Abstract A method for building a Simulator of ABS base on Matlab/Simulink is presented in this paper.The single wheel vehicle model was adopted as a research object in the paper. Mathematical models for an entire car, a bilinear tire model, a hydraulic brake model and a slip ratio calculation model were established in the Matlab/Simulink environment. The PID controller was designed. The established ABS mathematical model was simulated and researched and the simulation curves were obtained. The simulation results were compared with the results without ABS. The results show that established models were reliable and could achieve desirable brake control effects. Key words ABS; control; modeling; simulation;Anti-lock Braking System; PID

模型预测控制

云南大学信息学院学生实验报告 课程名称:现代控制理论 实验题目:预测控制 小组成员:李博(12018000748) 金蒋彪(12018000747) 专业:2018级检测技术与自动化专业

1、实验目的 (3) 2、实验原理 (3) 2.1、预测控制特点 (3) 2.2、预测控制模型 (4) 2.3、在线滚动优化 (5) 2.4、反馈校正 (5) 2.5、预测控制分类 (6) 2.6、动态矩阵控制 (7) 3、MATLAB仿真实现 (9) 3.1、对比预测控制与PID控制效果 (9) 3.2、P的变化对控制效果的影响 (12) 3.3、M的变化对控制效果的影响 (13) 3.4、模型失配与未失配时的控制效果对比 (14) 4、总结 (15) 5、附录 (16) 5.1、预测控制与PID控制对比仿真代码 (16) 5.1.1、预测控制代码 (16) 5.1.2、PID控制代码 (17) 5.2、不同P值对比控制效果代码 (19) 5.3、不同M值对比控制效果代码 (20) 5.4、模型失配与未失配对比代码 (20)

1、实验目的 (1)、通过对预测控制原理的学习,掌握预测控制的知识点。 (2)、通过对动态矩阵控制(DMC)的MATLAB仿真,发现其对直接处理具有纯滞后、大惯性的对象,有良好的跟踪性和较强的鲁棒性,输入已 知的控制模型,通过对参数的选择,来获得较好的控制效果。 (3)、了解matlab编程。 2、实验原理 模型预测控制(Model Predictive Control,MPC)是20世纪70年代提出的一种计算机控制算法,最早应用于工业过程控制领域。预测控制的优点是对数学模型要求不高,能直接处理具有纯滞后的过程,具有良好的跟踪性能和较强的抗干扰能力,对模型误差具有较强的鲁棒性。因此,预测控制目前已在多个行业得以应用,如炼油、石化、造纸、冶金、汽车制造、航空和食品加工等,尤其是在复杂工业过程中得到了广泛的应用。在分类上,模型预测控制(MPC)属于先进过程控制,其基本出发点与传统PID控制不同。传统PID控制,是根据过程当前的和过去的输出测量值与设定值之间的偏差来确定当前的控制输入,以达到所要求的性能指标。而预测控制不但利用当前时刻的和过去时刻的偏差值,而且还利用预测模型来预估过程未来的偏差值,以滚动优化确定当前的最优输入策略。因此,从基本思想看,预测控制优于PID控制。 2.1、预测控制特点 首先,对于复杂的工业对象。由于辨识其最小化模型要花费很大的代价,往往给基于传递函数或状态方程的控制算法带来困难,多变量高维度复杂系统难以建立精确的数学模型工业过程的结构、参数以及环境具有不确定性、时变性、非线性、强耦合,最优控制难以实现。而预测控制所需要的模型只强调其预测功能,不苛求其结构形式,从而为系统建模带来了方便。在许多场合下,只需测定对象的阶跃或脉冲响应,便可直接得到预测模型,而不必进一步导出其传递函数或状

实验四 SIMULINK仿真模型的建立及仿真(完整资料).doc

【最新整理,下载后即可编辑】 实验四SIMULINK仿真模型的建立及仿真(一) 一、实验目的: 1、熟悉SIMULINK模型文件的操作。 2、熟悉SIMULINK建模的有关库及示波器的使用。 3、熟悉Simulink仿真模型的建立。 4、掌握用不同的输入、不同的算法、不同的仿真时间的系统仿真。 二、实验内容: 1、设计SIMULINK仿真模型。 2、建立SIMULINK结构图仿真模型。 3、了解各模块参数的设定。 4、了解示波器的使用方法。 5、了解参数、算法、仿真时间的设定方法。 例7.1-1 已知质量m=1kg,阻尼b=2N.s/m。弹簧系数k=100N/m,且质量块的初始位移x(0)=0.05m,其初始速度x’(0)=0m/s,要求创建该系统的SIMULINK模型,并进行仿真运行。 步骤: 1、打开SIMULINK模块库,在MATLAB工作界面的工具条单击SIMULINK图标,或在MATLAB指令窗口中运行simulink,就可引出如图一所示的SIMULINK模块浏览器。

图一:SIMULINK模块浏览器 2、新建模型窗,单击SIMULINK模块库浏览器工具条山的新建图标,引出如图二所示的空白模型窗。 图二:已经复制进库模块的新建模型窗 3、从模块库复制所需模块到新建模型窗,分别在模块子库中

找到所需模块,然后拖进空白模型窗中,如图二。 4、新建模型窗中的模型再复制:按住Ctrl键,用鼠标“点亮并拖拉”积分模块到适当位置,便完成了积分模块的再复制。 5、模块间信号线的连接,使光标靠近模块输出口;待光标变为“单线十字叉”时,按下鼠标左键;移动十字叉,拖出一根“虚连线”;光标与另一个模块输入口靠近到一定程度,单十字变为双十字;放开鼠标左键,“虚连线”变变为带箭头的信号连线。如图三所示: 图三:已构建完成的新模型窗 6、根据理论数学模型设置模块参数: ①设置增益模块

FrontiArt汽车模型的保养方法

汽车保养指仿真汽车模型的保管和养护,这个问题又与汽车模型的陈列有关。关于汽车模型的陈列可以参考仿真汽车模型的陈列有关方面。当汽车模型收藏者的藏品数量增大后,日常保养就显得日益重要起来,有人做过统计,当藏品超过1000个后,收藏者玩汽车模型的时间中起码有三分之一以上花在保养上,汽车模型保养分永久性保养,陈列性保养,非陈列性保养三大类,三大类保养都有一些共性问题。 第一,无论采取哪一种保养类型,防尘都是首要的。灰尘无孔不入,放在陈列架里的汽车模型可以避开95%以上的灰尘颗粒,但还有5%的灰尘会透过玻璃门的缝隙,入侵到汽车模型架里去,去除汽车模型里的灰尘不能用吸尘器,因为吸尘器的吸力太大,会吸坏汽车模型上

的小零件(前反光镜,天线等)但可以用女同胞吹头发用的吹风机,使用自然风档,风力大小可用距离来调整,注意千万不可大意调在暖风档,用这种方法可以方便地吹去附在汽车模型表面的灰尘,去除灰尘的另一种方法:用一支旧的大楷毛笔,越旧,毛越软,越好,使用前要彻底洗干净,用这种旧毛笔能方便地扫去灰尘且不会损坏车模。 第二个共性问题是拿汽车模型必须戴手套,即使洗过手,手指也会在汽车模型光亮的油漆表面留下指纹或汗迹,这些指纹,汗迹时间长了,在一定的温度下就会产生霉斑,手套宜用汗衫布类的白手套,不能用棉纱的否则纱线会钩住汽车模型上的零件。还有,手套必须保持干净,脏手套反而会污染车模。千万不要轻视戴手套,要防微污染。

第三个共性问题是防潮。在危害汽车模型的诸多因素里,潮湿是首恶。无论汽车模型陈列与否,都要注意。可在陈列架及非陈列的放汽车模型的箱子里摆放防潮剂,防潮剂要注意及时更换。江南地区黄梅天气成应注意防潮,可在梅雨天后的高温干燥天气里适当开启陈列架的门,让高温干燥的微风吹进。

收藏什么样的汽车模型

应该收藏什么品牌的汽车模型? 对于一个初入门的模型爱好者来说,选择一个适合自己的汽车车模型品牌,相对是比较重要的.一般而言,市场上主流的适合收藏的车模型品牌有下面这些. 一.高端品牌,价格2000左右或3000加 1.德国CMC模型 2.意大利MR模型 3.意大利BBR模型 4.意大利Looksmart模型 5.美国依珂索托Exoto模型 6.美国富兰克林Franklin模型 7.美国戴保尼MBI模型 美国富兰克林模型在国内的价格已经逐步攀升,尤其在2011年以后,由于国内工厂的倒闭,为数不多的商家水涨船高,很多少有的停产的模型已经趋于天价.作为在国内少有的老爷车品牌,富兰克林的倒闭对车迷来说是个很悲哀的事情. 二.中端品牌,也是市场主流品牌,价位不等,一般在2000以内. 1.德国奥拓AutoArt模型 2.德国迷你切Minichamps模型 3.德国舒克Schuco模型 4.日本京商KyoSho模型 5.美国Highway61模型 6.美国TrueScaleMiniature 7.澳门Spark模型 8.法国诺威尔Norev模型 9.香港IXO模型 另外有模型市场上流行的称为国产原厂或进口原厂包装的模型,占据了市场很大的份额.也是相对受欢迎度比较高的模型品牌. 三.中低端品牌,价位比较便宜,做工相对粗燥价位集中在2~300,少有超过400元的. 1.意大利布拉格Bburago模型 2.泰国玛莎图MaiSto模型 3.香港太阳星SunSatr模型 4.香港风火轮Hotwheels模型 5.香港威利Welly模型 这几个品牌里面,其中风火轮的Elitei系列做工有很大提高,价位一般集中在600-500左右,威利FX系列和旗下的GTA系列,做工也很大进步,很多车型都是值得收藏和入手的.

车辆悬架模型的仿真与分析

车辆悬架模型的仿真与分析 目前,关于汽车模型的研究很多。詹长书等人研究了二自由度懸架模型的频域响应特性。李俊等人模拟了不同车速和路况下二自由度车辆模型的动力学。郑兆明研究了二自由度车轮动载荷的均方值。基于Matlab建立了更加复杂的悬架模型,分析了其在模拟路面作用下的响应,分析了系统阻尼参数和刚度参数变化对车身动态响应的影响。 标签:汽车悬架;模型;模拟 据公安部交通管理局统计,截至2019年3月底,全国机动车保有量达3.3亿辆,其中汽车达2.46亿辆,驾驶人达4.1亿,机动车、驾驶人总量及增量均居世界第一。随着汽车数量的迅速增加,人们开始越来越重视汽车的乘坐舒适性,平顺性是舒适性的重要组成部分。振动是影响平顺性的主要因素,因此车身系统参数的合理设计对提高汽车的舒适性和安全性具有重要意义。 1车辆悬架模型 传统的悬架系统一般由弹性元件和参数固定的阻尼元件组成。本文选择汽车后轮的任意悬架系统建立四分之一模型。该模型的简图如下图1所示。其中,1是螺旋弹簧,2是纵向推力杆,3是减震器,4是横向稳定器,5是定向推力杆。 2悬架刚度分析 2.1悬架垂直刚度分析 悬架系统的垂直刚度可以通过分析悬架两个车轮在同一方向上的运行情况来获得。因为装有发动机的车辆的前轴载荷变化很大,所以前悬架通过调节螺旋弹簧的刚度和自由长度来确保车身姿态。后悬架的轴重变化不大,只有螺旋弹簧的自由长度略有调整,后悬架螺旋弹簧的刚度没有调整。这导致带有发动机的B 车型前悬架刚度略有增加。 除了悬架结构和参数的匹配外,前后悬架固有频率的正确匹配是降低车辆振动耦合度、有效提高车辆乘坐舒适性的重要方法之一。由于B型前悬架的轴重变化很大,通过调整前悬架螺旋弹簧的刚度,前悬架和后悬架的偏置频率比几乎不变。 2.2悬架倾角的刚度分析 一般来说,乘用车的前后侧倾刚度比要求在1.4和2.6之间,以满足略微不足的转向特性的要求。B车型前悬架的侧倾刚度略高于C车型,这是由前悬架刚度的增加引起的。前悬架侧倾刚度的增加有助于减小侧倾角度,但变化很小。

实验四-SIMULINK仿真模型建立及仿真

实验四 SIMULINK仿真模型的建立及仿真(一) 一、实验目的: 1、熟悉SIMULINK模型文件的操作。 2、熟悉SIMULINK建模的有关库及示波器的使用。 3、熟悉Simulink仿真模型的建立。 4、掌握用不同的输入、不同的算法、不同的仿真时间的系统 仿真。 二、实验内容: 1、设计SIMULINK仿真模型。 2、建立SIMULINK结构图仿真模型。 3、了解各模块参数的设定。 4、了解示波器的使用方法。 5、了解参数、算法、仿真时间的设定方法。 例7.1-1 已知质量m=1kg,阻尼b=2N.s/m。弹簧系数k=100N/m,且质量块的初始位移x(0)=0.05m,其初始速度x’(0)=0m/s,要求创建该系统的SIMULINK 模型,并进行仿真运行。 步骤: 1、打开SIMULINK模块库,在MATLAB工作界面的工具条单击SIMULINK图标,或在MATLAB指令窗口中运行simulink,就可引出如图一所示的SIMULINK模块浏览器。

图一:SIMULINK模块浏览器 2、新建模型窗,单击SIMULINK模块库浏览器工具条山的新建图标,引出如图二所示的空白模型窗。 图二:已经复制进库模块的新建模型窗 3、从模块库复制所需模块到新建模型窗,分别在模块子库中找到所需模块,然后拖进空白模型窗中,如图二。 4、新建模型窗中的模型再复制:按住Ctrl键,用鼠标“点亮并拖拉”积分模块到适当位置,便完成了积分模块的再复制。 5、模块间信号线的连接,使光标靠近模块输出口;待光标变为“单线十字叉”时,按下鼠标左键;移动十字叉,拖出一根“虚连线”;光标与另一个模块输入口靠近到一定程度,单十字变为双十字;放开鼠标左键,“虚连线”变变为带箭头的信号连线。如图三所示:

汽车模型的设计及数控加工

2012届本科毕业论文(设计)论文题目:汽车模型的设计及数控加工 学生姓名: 所在院系:机电学院 所学专业:机械设计制造及其自动化 导师姓名: 完成时间:2012年5月18日

摘要 数控机床是典型的机电相融合的机电一体化产品,CAD/CAM是计算机科学同机械工程交叉的结果。本课题主要是对汽车模型进行设计并用数控机床加工,在设计和加工过程中,用Solid Works进行造型设计, CAXA制造工程师来生成加工轨迹路线和加工代码,然后采用数控机床进行各个零件的加工,最终完成模型组装。 关键词:数控机床,造型设计,Solid Works ,CAXA制造工程师,数控加工 Abstract CNC machine tool is typical of combining electromechanical integration of the mechanical and electronic products,CAD/CAM is computer science with mechanical engineering cross results. This topic is mainly to the car model design and CNC machine tool processing, in the design and processing process, with Solid Works on model design, CAXA manufacturing engineers to generate processing track route and processing code, then the CNC machine tools for various pats processing ,finally complete assembly model. Keywords:CNC Machine Tool , Model Design ,Solid Works ,CAXA Manufacturing Engineers ,CNC Machining

制作简单汽车模型教学设计实施方案

目录 一、教学设计 课程名称汽车机械基础教学时间90课时 学习单元制作简单汽车模型教学时间45课时 学习目标(细化) 1、学生通过与顾客沟通,掌握与顾客沟通地技巧; 2、学生根据顾客地描述,确认顾客委托任务; 3、学生通过查找资料收集相关信息,制定出制作简单汽车模型地工作计划; 4、学生能够初步掌握常用工具、量具地操作方法与技能以及维护保养知识; 5、能正确解释汽车常用金属材料牌号地意义,知道汽车常用材料机械性能和适宜采用地工艺方法;能解释汽车零件地材料性能、牌号及加 工地方法. 1 / 21

6、学生能够掌握识读汽车基本地零件图和简单装配图、各种结构、工作示意图,对图地理解正确,并能说明结构、工作示意图所表达地意 思. 7、学生能够掌握钳工基础知识,钳工工艺加工地编程;钳工工艺基础理论知识; 8、合理选择和正确使用改锥及各类扳手等常用通用工具; 合理选择和正确使用外径千分尺、游标卡尺、百分表等通用量具,测量结果准确. 9、让学生在实践中培养安全和维护质量意识,并且认真履行工作安全和环境保护地规定; 10、学生对工作结果进行记录并对结果加以分析总结; 11、学生要对实习设备工具、车辆、仪器、环境、人身安全认真负责; 12、通过小组学习培养团队协作意识; 13、与顾客,上级和同事进行沟通并对工作情况进行说明; 14、提升环保和节约意识,对可重复利用材料合理使用; 15、严格遵守用电安全、生产条例,规范操作 工作任务工作过程导向教学突破点教学设备设施要求 情境模拟:机修工人从销售商处接受制作金属汽车模型地任务,加工后成品收购进行销售. 零件加工尺寸、加工余量 金属零件钳工加工 汽车维修钳工基本工具: 划线:划针、划线盘、高度游标卡尺、划规、 2 / 21

汽车模拟驾驶模型与仿真的研究

第36卷第3期2002年5月 浙 江 大 学 学 报(工学版) Jo ur nal o f Zhejiang U niv ersity(Eng ineer ing Science) Vol.36No.3May 2002 收稿日期:2001-05-13. 作者简介:蔡忠法(1969-),男,浙江温岭人,讲师,主要从事电子技术和系统仿真的研究.E-m ail:z fcai@m https://www.360docs.net/doc/2011683220.html, 汽车模拟驾驶模型与仿真的研究 蔡忠法,章安元 (浙江大学电气工程学院,浙江杭州310027) 摘 要:在主动型驾驶模拟训练系统中,模拟驾驶舱各个操纵机构存在着多输入、多耦合、非线性的控制作用,而驾驶模拟训练要求驾驶动力学模型适于快速实时仿真.本文使用拟合多项式描述汽车发动机负荷特性,提出结构简化的汽车速度和方向控制模型.对模拟驾驶的仿真结构和学员操作的逻辑判断进行了讨论,通过对操纵机构输入的线性化处理,得到汽车行驶的仿真模型并选择快速仿真算法实现了所建模型.实验结果表明,本文提出的理论模型和仿真算法是正确可行的.关键词:汽车驾驶;模拟器;模型;仿真 中图分类号:T P312 文献标识码:A 文章编号:1008-973X(2002)03-0327-04 Study of automobile emulated driving model and simulation CAI Zhong -fa ,ZHANG A n -yuan (College of Electr ical Eng ineer ing ,Zhej iang U niv er sity ,H angz hou 310027,China ) Abstract :In active automo bile driving training simulato r,the steering framewo rk in the simulated cabin has multi-input,m ulti-co upling and non-linear contro l effect.A driving training sim ulator r equires dynam ic model suitable for fast real -tim e simulation .T his paper uses poly nom ials to express the load characteristics of the automo bile engine ,and presents simplified -str ucture velocity and direction co ntro l models .T he sim ulation structure o f simulated driving and log ic alestimation o f driver oper ation are discussed,and illegal operation of driver and car backing state are judged cor rectly.T hr oug h the linearization process of the steering fr am ew or k input function ,sim ulation models for m ultiple driving cases w ere derived and effectiv e algo rithm w as selected to realize the models.Ex periment results show ed that the presented m odel and simulation alg orithm are corr ect and feasible. Key words :automo bile driving ;simulator ;model ;simulation 汽车驾驶模拟训练系统是通过模拟驾驶舱和计算机实时生成汽车行驶过程中虚拟的视境、音响等驾驶环境,训练正确的驾驶操作.它可取代实车训练中的部分科目和内容,有利于驾驶培训正规化、科学化和规范化,并具有节能、安全、经济、高效等优点,因此,开发适合我国交通国情和道路状况的汽车驾驶模拟训练系统具有重大的社会效益和经济效益.而建立并实现汽车模拟驾驶的动力学模型是研制汽车驾驶模拟训练系统的前提.以往的汽车动力学模型主要是通过汽车部件建模,因而结构复杂,计算时 间长[1] .在基于微机平台的主动型汽车驾驶模拟训练系统中,需建立适合快速实时仿真、结构简化的汽车行驶速度和方向控制模型,以确定汽车行驶的世界坐标位置,控制图形生成系统动态生成虚拟视景.在主动型汽车驾驶模拟训练系统中,图形实时生成系统占据了大部分CPU 时间,因此需要在模型的逼真度与复杂性之间作一折中.为了满足模拟训练的要求,简化模型结构和选择合适的快速仿真算法是实现驾驶实时仿真所必须首先考虑的问题.

锁相环Simulink仿真模型

锁相环学习总结 通过这段的学习,我对锁相环的一些基本概念、结构构成、工作原理、主要参数以及simulink 搭建仿真模型有了较清晰的把握与理解,同时,在仿真中也出现了一些实际问题,下面我将对这段学习中对锁相环的认识和理解、设计思路以及中间所遇到的问题作一下总结: 1. 概述 锁相环(PLL )是实现两个信号相位同步的自动控制系统,组成锁相环的基本部件有检相器(PD )、环路滤波器(LF )、压控振荡器(VCO ),其结构图如下所示: 2. 锁相环的基本概念和重要参数指标 锁相是相位锁定的简称,表示两个信号之间相位同步。若两正弦信号如下所示: 相位同步是指两个信号频率相等,相差为一固定值。 ) (sin )sin()()(sin )sin()('t U t U t u t U t U t u o o o o o i i i i i θθωθθω=+==+=

当i ω=o ω,两个信号之间的相位差 为一固定值, 不 随时间变化而变化,称两信号相位同步。 当i ω≠o ω,两个信号的相位差 ,不论i θ 是否等于o θ,只要时间有变化,那么相位差就会随时间变化而 变化,称此时两信号不同步。若这两个信号分别为锁相环的输入和输出,则此时环路出于失锁状态。 当环路工作时,且输入与输出信号频差在捕获带范围之内,通过环路的反馈控制,输出信号的瞬时角频率)(t v ω便由o ω向i ω方向变化,总会有一个时刻使得i ω=o ω,相位差等于0或一个非常小的常数,那么此时称为相位锁定,环路处于锁定状态。若达到锁定状态后,输入信号频率变化,通过环路控制,输出信号也继续变化 并向输入信号频率靠近,相位差保持在一个固定的常数之内,则称环路此时为跟踪状态。锁定状态可以认为是静态的相位同步,而跟踪状态则为动态的相位同步。 环路从失锁进入到锁定状态称为捕获状态。 其他几个环路工作时的重要概念: 快捕带:能使环路快捕入锁的最大频差称为环路的快捕带,记为 L ω?,两倍的快捕带为快捕范围。 捕获带:能使环路进入锁定的最大固有频差,用P ω?表示,两倍的捕获带为捕获范围。 同步带:环路在所定条件下,可缓慢增加固有频差,直到环路失锁,把能够维持环路锁定的最大固有频差成为同步带,用H ω?, o i t t θθθθ-=-)()('o i o i t t t θθωωθθ-+-=-)()()('

汽车动力学仿真模型的发展

!汽车动力学发展历史简介 汽车动力学是伴随着汽车的出现而发展起来的 一门专业学科。人们很早就认识到“$%&’()*+”转向和应用弹性悬架可使乘客感到更加舒适等基本原 理[,],但那只是一种感性的认识。在各国学者的不懈 努力下,这门学科逐渐发展成熟。-’.’/在,00#年1)’%23举行的题为“车辆平顺性和操纵稳定性”的会议上发表的论文,对,00"年以前汽车动力学的发 展做了较为全面的总结[ !],见表,。近年来汽车动力学又有了进一步发展,大量的高水平学术论文和经典的汽车动力学专著相继被发表,而且开发出许多专为汽车动力学研究建立模型的软件,如美国密西根大学开发的$456%*(、$45678)等商业软件。汽车是一复杂的连续体系统,要想对其进行动力特性的预测和优化需建立经合理简化的抽象汽车模型,以达到缩短产品开发周期、保证整车性能指标和降低产品成本的目的。 "汽车动力学模型的发展 汽车动力学从严格意义上来讲包括对一切与车 辆系统相关运动的研究,然而最为核心的是平顺性和操纵稳定性这两大领域,一般认为平顺性主要研究影响车身的垂向跳跃、俯仰、侧倾振动的因素,而操纵稳定性主要研究车辆的横向、横摆和侧倾运动。建模时一般假设平顺性和操纵稳定性之间无偶合关系。 "#!汽车平顺性模型 在汽车平顺性的早期研究阶段,限于当时数学、 力学理论、计算手段及试验方法,把系统简化成集中质量—弹簧—阻尼模型,如图,所示。 图,整车集中质量—弹簧—阻尼模型 此类模型一般先以函数的形式给出其动能!和势能"以及表达系统阻尼性质的物理量耗散能 !的表达式: 【摘要】汽车动力学包括对一切与车辆系统相关运动的研究,其最核心的是平顺性和操纵稳定性这两大领域。在简要说明了汽车动力学发展过程的基础上介绍了平顺性和操纵稳定性两大领域的模型发展过程。平顺性模型主要经过集中质量—弹簧—阻尼模型、有限元模型和动态子结构模型阶段;而操纵稳定性模型从低自由度线性模型、非线性多自由度模型发展到多体模型。最后提出了汽车动力学仿真模型的发展动向。 主题词:汽车动力学模型发展 中图分类号:9:;,<,文献标识码:$ 文章编号:,"""=#>"#(!""#)"!=""",=": $%&%’()*%+,(-.%/01’%$2+3*0140*5’3,0(+6(7%’ ?2*+.@’8A?2*+.B8+.2*8AC48D*8/8+AB8*D6+.E’8 (B8/8+9+8F’(785G ) 【89:,;31,】H’28%/’IG+*)8%7754I8’7*//)6F’)’+57(’/’F*+556F’28%/’7G75’)*+I 857%6(’8752’5J6E8’/I76E (8I’K *L8/85G *+I 2*+I/8+.75*L8/85G<1+52’M*M’(AI’F’/6M8+.M(6%’776E )6I’/76E F’28%/’(8I’*L8/85G *+I 2*+I/8+.75*L8/85G *(’8+K 5(6I4%’I *E5’(I’F’/6M)’+5%64(7’6E F’28%/’IG+*)8%78778)M/G 8+5(6I4%’I