SMT QPA check list

PCBA Quality Process Audit

Add a 'Y' to the Box if the Process Was Assessed

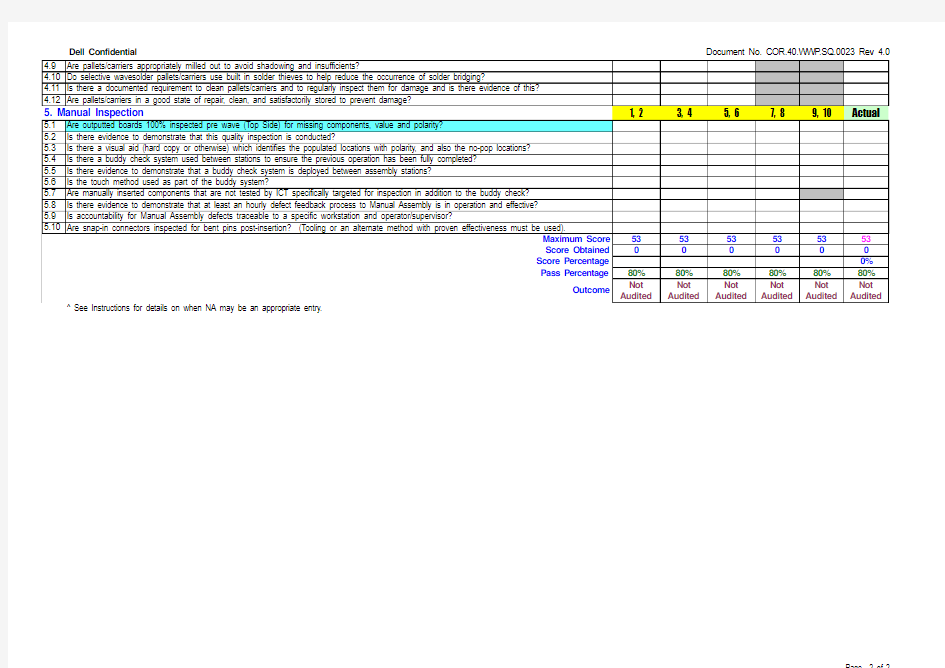

Manual Assembly

#Audit Criterion1, 23, 45, 67, 89, 10Actual 1. Work Instructions

1.1Are revision controlled Work Instructions displayed for the operator at each assembly station? (Score 0 if any unsigned/undated handwritten instructions or any handwritten instructions more than 48 hrs old)

1.2Are component part numbers and their descriptions specified on Work Instructions?

1.3Are component descriptions sufficiently detailed to ensure the correct component is being used?

1.4Are the reference designators and the quantity per part number specified on Work Instructions?

1.5Is component polarity or its non-existence consistently and unambiguously specified on Work Instructions?

1.6Are the components on the Work Instructions listed by the most appropriate order of insertion?

1.7Is the layout of lin bins/trays defined on Work Instructions for each assembly station?

1.8Are all lin bins/trays located in the correct position as per Work Instructions for each assembly station?

1.9Do Work instructions indicate if solder pallets/carriers or breakers must be used?

1.10Do Work instructions indicate if a top hat, separators, plugs, Kapton tape, finger protection, etc. must be used?

1.11Does the direction of build for the board align with the orientation of the board on the Work Instructions and Wave direction?

1.12Do Work Instructions not only indicate what components need to be inserted but also the buddy check components?

1.13Is the conveyor at entry to the wave, slower than the wave conveyor speed, and documented on Work Instructions?

1.14Is there a documented process for the identification and control of non-completed boards resulting from breaks, shift changes, etc.

1.15Is the PWB part number and Revision specified on the Work Instruction or line set-up instructions?

1.16Does the PWB part number and Revision cross-reference to the PCBA part number and Revision?

2. Station Breakout1, 23, 45, 67, 89, 10Actual 2.1Is there a document available which describes the guidelines for station breakout at Manual Assembly?

2.2Has the number of assembly stations required been determined scientifically in order to maximize throughput within constraints?

2.3Is there evidence that the line is evenly balanced with the defined number of stations and the defined station breakout?

2.4Is there evidence to demonstrate that the assembly operators follow the defined station breakout on the Work instructions?

2.5Is there evidence that sufficient time is allocated for component insertion at each station, as determined by the beat rate of the line?

2.6Does following the breakout ensure that the insertion of subsequent components is not restrictive or increased in difficulty?

2.7Does following the breakout ensure that 'snap-in' type components are inserted first or off-line?

2.8Does following the breakout ensure that components that 'look' alike are assembled at different and non-adjacent stations where possible?

2.9Does following the breakout ensure that components that 'fit' alike are assembled at different and non-adjacent stations, where possible?

3. Line Set-Up and Verification1, 23, 45, 67, 89, 10Actual 3.1Are all Manual Assembly station set-ups verified according to Work Instructions and a log signed prior to start-up & re-start?

3.2Are first-built boards verified against documentation for missing components, value, and for correct polarity pre Wave?

3.3Are the components supplied to Manual Assembly appropriately prepped with correct lead length, forming and pitch, etc.?

3.4Is it evident that lead snipping has been minimized through adequate component prep and/or pallet support design?

3.5Are all totes or tray locations identified with printed part numbers, descriptions, circuit designators, station number, and/or layout information?

3.6Are boards conveyed along the line automatically without the need to manually push the board forward or pull the board back?

4. Tooling1, 23, 45, 67, 89, 10Actual 4.1Is tooling used to provide underside support on all sides, to minimize flexing, for the insertion of components that require a force or snap-in fit?

4.2Is tooling used and is it adequate to prevent board flexing during all component insertion?

4.3Is tooling used for snap-in components prone to bent pins, to verify the pin straightness prior to their insertion?

4.4Is there a document available which describes the guidelines for pallet/carrier design?

4.5Are footprint, co-planarity, depth below datum, ID, clamping mechanisms, chamfering, direction of flow, criteria addressed?

4.6Are pallets/carriers identified by a name or tooling number which is traceable to the PCBA part number and revision?

4.7Is pallet/carrier orientation to the line specified or indicated and correct?

4.8Are pallets/carriers designed such a way that they support all non-snap-in components without the use of weights?

Menu