材料热物性参数

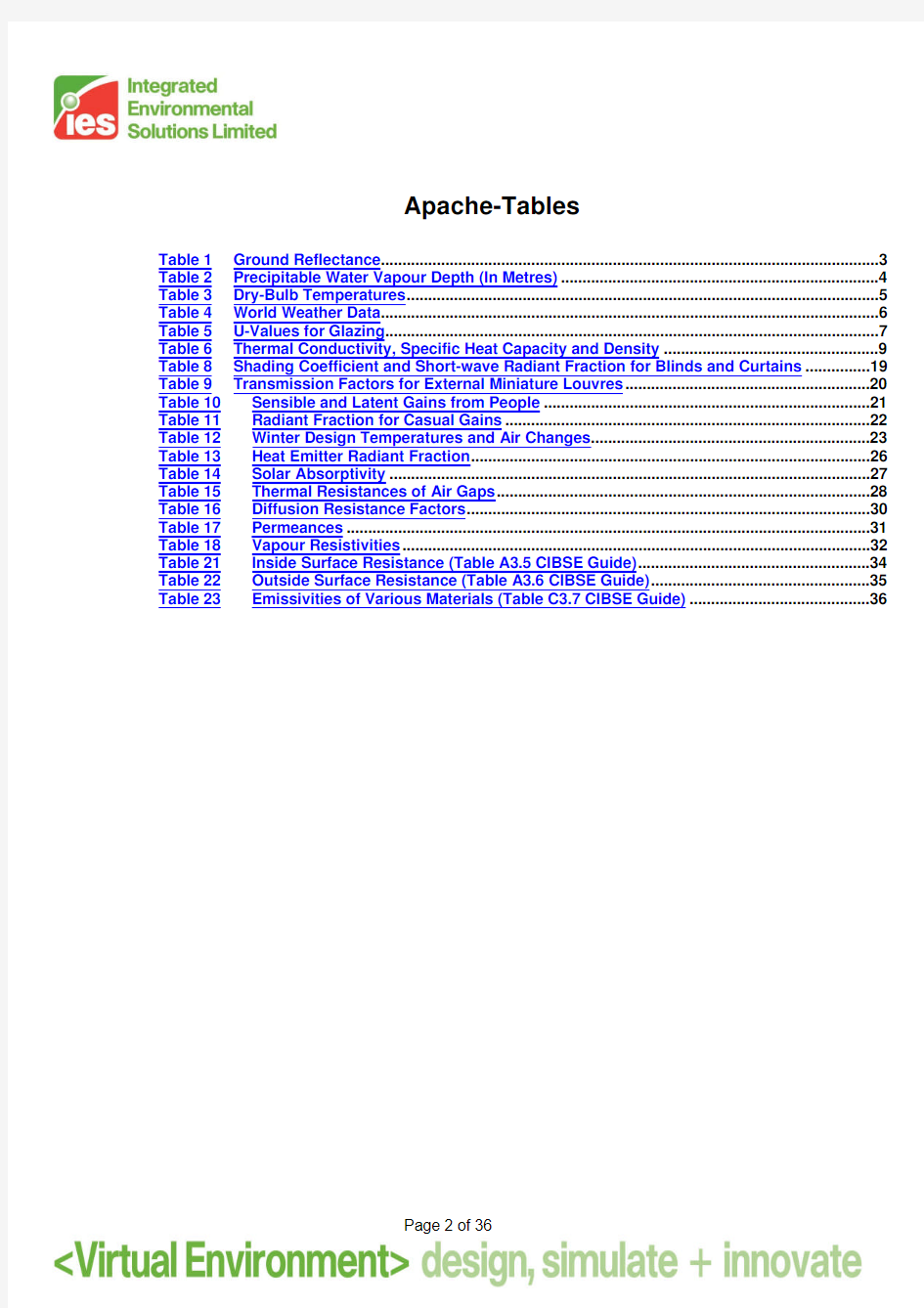

Apache-Tables

Apache-Tables

Table1Ground Reflectance (3)

Table2Precipitable Water Vapour Depth(In Metres) (4)

Table3Dry-Bulb Temperatures (5)

Table4World Weather Data (6)

Table5U-Values for Glazing (7)

Table6Thermal Conductivity,Specific Heat Capacity and Density (9)

Table8Shading Coefficient and Short-wave Radiant Fraction for Blinds and Curtains (19)

Table9Transmission Factors for External Miniature Louvres (20)

Table10Sensible and Latent Gains from People (21)

Table11Radiant Fraction for Casual Gains (22)

Table12Winter Design Temperatures and Air Changes (23)

Table13Heat Emitter Radiant Fraction (26)

Table14Solar Absorptivity (27)

Table15Thermal Resistances of Air Gaps (28)

Table16Diffusion Resistance Factors (30)

Table17Permeances (31)

Table18Vapour Resistivities (32)

Table21Inside Surface Resistance(Table A3.5CIBSE Guide) (34)

Table22Outside Surface Resistance(Table A3.6CIBSE Guide) (35)

Table23Emissivities of Various Materials(Table C3.7CIBSE Guide) (36)

Table1Ground Reflectance

General Situation Typical Kr

Temperate localities0.2

Tropical localities(humid)0.2

Tropical localities(arid)0.5 Source:CIBSE Guide

Environment Typical Kr

Snow(fresh)0.8-0.9

Snow(old)0.45-0.7

Water0.1-0.2

Ice0.7

Grass0.25

Crops&woodland0.2

Concrete0.3

Brick0.2-0.4

Asphalt0.15

Source:Climate in the UK by Page&Lebens.

Table2Precipitable Water Vapour Depth(In Metres)

Altitude Latitude

(air pressure)030456070 Warm or wet season

1000mb mean0.050.040.0250.020.018 min.0.020.020.010.0070.007 max.0.10.070.040.040.04

900mb mean0.030.0190.0160.01250.011 min.0.010.0070.0070.0040.004 max.0.070.040.040.020.02

800mb mean0.020.0150.010.0080.007 min.0.010.0070.0040.0040.002 max.0.040.040.020.020.02

700mb mean0.010.0080.0050.0040.0035 min.0.0040.0040.0020.0020.001 max.0.020.020.010.010.01

Cold or dry season

1000mb mean0.030.0150.0080.0050.003 min.0.010.0040.0040.0020.001 max.0.070.040.020.010.01

900mb mean0.020.010.0050.00350.002 min.0.0070.0040.0020.0020.001 max.0.040.020.010.010.007

800mb mean0.010.0060.0030.0020.001 min.0.0040.0020.0010.0010.0005 max.0.020.020.010.0070.002

700mb mean0.0060.0030.00150.0010.0005 min.0.0020.0010.0010.00050.0002 max.0.010.010.0040.0020.001

From'Solar Radiation',ed.by N.Robinson.Maps from Engineering Data Unit.

Table3Dry-Bulb Temperatures See CIBSE Guide A Table A2.28.

Table4World Weather Data See CIBSE Guide A Table A2.19.

Table5U-Values for Glazing

Without Frames

Construction Sheltered Normal Severe

Single window glazing5 5.6 6.7

Double window glazing with airspace

25mm or more 2.8 2.9 3.2

12mm 2.83 3.3

6mm 3.2 3.4 3.8

3mm 3.64 4.4

Triple window glazing with airspace

25mm or more 1.92 2.1

12mm2 2.1 2.2

6mm 2.3 2.5 2.6

3mm 2.83 3.3

Roof glazing skylight 5.7 6.67.9

Horizontal laylight with skylight

or lantern light over ventilated 3.5 3.8 4.2

unventilated 2.83 3.3 With Frames

Window type Fraction of area Sheltered Normal Severe

occupied by frame

SINGLE GLAZING

Wood frame10% 4.7 5.3 6.3

20% 4.55 5.9

30% 4.2 4.7 5.5 Aluminium frame

(no thermal break)10% 5.367.1

20% 5.6 6.47.5

30% 5.9 6.77.9 (with thermal break)10% 5.1 5.7 6.7

20% 5.2 5.8 6.8

30% 5.2 5.8 6.8 DOUBLE GLAZING

Wood frame10% 2.83 3.2

20% 2.7 2.9 3.2

30% 2.7 2.9 3.1 Aluminium frame

(no thermal break)10% 3.3 3.6 4.1

20% 3.9 4.3 4.8

30% 4.4 4.9 5.6 Aluminium frame

(with thermal break)10% 3.1 3.3 3.7

20% 3.4 3.74

30% 3.74 4.4

Table6Thermal Conductivity,Specific Heat Capacity and Density

System Material Database

Material Description Conductivity Sp.Heat Capacity Density

(W/mK)(J/kgK)(kg/m3) Asphalts&Other Roofing Finishes

Asbestos Cement Decking0.36010501500 Asbestos Cement Sheet0.3601050700 Asphalt0.50010001700 Felt/Bitumen Layers0.50010001700 Asphalt/Asbestos Tiles0.5508371900 Roofing Felt0.190837960 Asphalt Mastic Roofing 1.1508372325 Built-Up Roof–BR010.16214641121 Roof Gravel/Slag–RG01 1.4428811674

Boards,Sheets&Deckings

Asbestos Cement Decking0.36010501500 Asbestos Cement Sheet0.3601050700 Fibreboard0.0601000300 Gypsum Plasterboard0.160840950 Polyurethane Board0.025140030 Hardboard(Medium)0.0802000600 Hardboard(Standard)0.1302000900 Cork Board0.0401888160 Chipboard0.1502093800 Weatherboard0.1402000650 Perlite Plasterboard0.180837800 Cratherm Board0.050837176 Anti-Sun Glass Cladding 1.0507502500 Plate-Glass Cladding0.7608372710 4mm Clear Float Cladding 1.0507502500 Lightweight Metallic Cladding0.29010001250 Asbestos-Cement Board0.58010001900 Fibreboard–Tile&Lay-In Panel0.058600290 Paperboard–Laminated0.0721400480 Hardboard–Medium Density0.1051300800 Paperboard–Homogeneous From

Repulped Paper0.0721200480 Hardboard–High Density0.8201300880

Hardboard–Standard Tempered

Grade0.14413001010 Particleboard–Low Density0.1021300590 Particleboard–Medium Density0.1351300800 Particleboard–High Density0.17013001000 Asbestos-Cement Board–AB010.5978371922 Cement Mortar–CM010.7218371858 Particle Board Underlay–PB040.31112131202 Hard Board Medium Density Siding–

HB010.0941171641 Hard Board Medium Density Others–

HB020.1051297801 Hard Board High Density–HB030.1181381881 Hard Board High Density Standard

Service Tempered–HB040.14413811009

Brick&Block Work

Brickwork(Outer Leaf)0.8408001700 Brickwork(Inner Leaf)0.6208001700 Concrete Block(Heavyweight) 1.63010002300 Concrete Block(Medium)0.51010001400 Concrete Block(Lightweight)0.1901000600 Concrete Paviour0.9608402000 Foam Slag0.2509601040 Vermiculite Insulating Brick0.270837700 Aerated Concrete Block0.2401000750 Thermalite-High Strength0.1901050760 Thermalite'Turbo'0.1101050480 Thermalite'Shield'/'Smooth Face'0.1701050650 Glass Block0.7008372500 Common Brick–BK010.7218371922 Face Brick–BK04 1.3109212083 Face Brick–HF-A2 1.3319212083 Face Brick–HF-A7 1.3319212003 Common Brick–HF-C40.7278371922

Carpet

Wilton Carpet0.0601360186 Simulated Sheeps Wool0.0601360198 Wool Felt Underlay0.0401360160 Cellular Rubber Underlay0.1001360400 Synthetic Carpet0.0602500160

Concrete

Aerated Concrete Slab0.160840500 Cast Concrete(Dense) 1.4008402100 Cast Concrete(Lightweight)0.38010001200 Cast Concrete 1.130******** Concrete Block(Heavyweight) 1.63010002300 Concrete Block(Medium)0.51010001400 Concrete Block(Lightweight)0.1901000600 Concrete Paviour0.9608402000 Foam Slag0.2509601040 Aerated Concrete Block0.2401000750 Refactory Insulating Concrete0.2508371050 Vermiculite Aggregate0.170837450 Concrete Tiles 1.1008372100 Heavyweight Concrete Dried Aggregate

–CC01 1.3108372243 Heavyweight Concrete Undried

Aggregate–CC11 1.8028372243 Heavyweight Concrete Undried

Aggregate–HF-C12 1.7308372243 Lightweight Concrete–80Lbs–CC210.368371282 Lightweight Concrete–30Lbs–CC310.130837481 Lightweight Concrete–40Lbs–HF-

C140.173837641 Lightweight Concrete–HF-C20.380837609 Heavyweight Concrete Block-Hollow–

CB010.8128371618 Heavyweight Concrete Block-

Concrete-Filled–CB02 1.3108372234 Heavyweight Concrete Block-Perlite-

Filled–CB030.3848371650 Heavyweight Concrete Block–Part-

Filled Concrete–CB04 1.0118371826 Heavyweight Concrete Block–

Concrete and Perlite-Filled–CB050.8258371842 Mediumweight Concrete Block-Hollow

–CB210.5198371218 Mediumweight Concrete Block-

Concrete-Filled–CB220.7718371842 Mediumweight Concrete Block-Perlite-

Filled–CB230.2628371250 Mediumweight Concrete Block–Part-

Filled Concrete–CB240.5728371426 Mediumweight Concrete Block–

Concrete and Perlite-Filled–CB250.4318371442 Lightweight Concrete Block-Hollow–0.3848371041

CB41

Lightweight Concrete Block-Concrete-

Filled–CB420.6398371666 Lightweight Concrete Block-Perlite-

Filled–CB430.2208371073 Lightweight Concrete Block–Part-

Filled Concrete–CB440.4868371250 Lightweight Concrete Block–Concrete

and Perlite-Filled–CB450.3608371266

Gravels,Beddings Etc.

Stone Chippings0.96010001800 Gravel0.3608401840 Gravel-Based Soil0.5201842050 Tile Bedding 1.4006502100

Insulating Materials

Eps Slab0.035140025 Silicon0.1801004700 Glass-Fibre Quilt0.04084012 Glass-Fibre Slab0.035100025 Mineral Fibre Slab0.035100030 Phenolic Foam0.040140030 Polyurethane Board0.025140030 Uf Foam0.040140010 Wood Wool Slab0.1001000500 Vermiculite Insulating Brick0.270837700 Refactory Insulating Concrete0.2508371050 Glasswool0.040670200 Thermalite-High Strength0.1901050760 Thermalite'Turbo'0.1101050480 Thermalite'Shield'/'Smooth Face'0.1701050650 Siporex0.1201004550 P.V.C0.16010041379 Polystyrene0.030138025 Hard Rubber0.150******** Cratherm Board0.050837176 Uf Foam Two0.030176430 Uf Foam Two0.030176430 Lightweight Metallic Cladding0.29010001250 Dense Eps Slab Insulation(styrofoam)0.025140030 Cellular Glass0.050800136 Glass-Fibre–Organic Bonded0.0361000100

Expanded Perlite–Organic Bonded0.052130016 Expanded Rubber-Rigid0.032170072 Cellular Polyurethane0.023160024 Cellular Polyisocyanurate0.02390032 Cellular Phenolic–Mineral Fibre With

Resin Binder0.042700240 Cement Fibre Slab–Shredded Wood

With Magnesia Oxysulfide Cement

Binder0.0821300350 Vermiculite-Exfoliated0.0681300120 Felt&Membrane–Felt–HF-E30.19016741121 Felt&Membrane–Finish–HF-A60.41510881249 Mineral Wool/Fibre–Batt–IN010.04383710 Mineral Wool/Fibre–Fill–IN110.04683710 Mineral Wool/Fibre–Fill–IN120.04683711 Cellulose Fill–IN130.039138148 Insulation Board–HF-B20.043138148 Insulation Board–HF-B50.04383732 Preformed Mineral Board–IN210.042711240 Expanded Polystyrene–IN310.035121329 Expanded Polyurethane–IN410.023159024 Urea Formaldehyde–IN510.035125511 Insulation Board Sheathing–IN610.0551297288 Insulation Board Shingle Backer–IN630.0581297288 Insulation Board Nail Base Sheathing–

IN640.0641297400 Preformed Roof Insulation–IN710.052837256

Metal

Steel50.0004807800 Copper200.0004188900 Aluminium160.0008962800 Lightweight Metallic Cladding0.29010001250 Steel Siding–HF-A344.9704187690

Plaster

Plaster(Dense)0.50010001300 Plaster(Lightweight)0.1601000600 Gypsum Plasterboard0.160840950 Perlite Plasterboard0.180837800 Gypsum Plastering0.4208371200 Perlite Plastering0.080837400 Vermiculite Plastering0.200837720

Plaster Ceiling Tiles0.3808401120 Cement Plaster0.7208001860 Perlite Plaster0.2201300720 Perlite Plaster–Sand Aggregate0.8108001680 Cement Plaster–With Sand Aggregate

–CM030.7218371858 Gypsum/Plaster Board–HF-E10.160837801 Gypsum Plaster Lightweight

Aggregate–GP040.230837721 Gypsum Plaster–Sand Aggregate–

GP060.8198371682

Screeds And Renders

External Rendering0.50010001300 Screed0.4108401200 Granolithic Render/Screed0.8708372085 Stucco–HF-A10.7218372659

Sands,Stones And Soils

Stone Chippings0.96010001800 Gravel0.3608401840 Gravel-Based Soil0.5201842050 Sandstone 1.8307122200 Granite(Red) 2.9009002650 Marble(White) 2.7708022600 Cultivated Sandy Soil12.5%D.W.

Moisture 1.79011901800 Cultivated Sandy Soil25.0%D.W.

Moisture 2.22014802000 Cultivated Clay Soil12.5%D.W.

Moisture 1.180******** Cultivated Clay Soil25.0%D.W.

Moisture 1.59015502000 Cultivated Peat Soil133%D.W.

Moisture0.2903300700 Cultivated Peat Soil366%D.W.

Moisture0.50036501100 Dry Limestone Sub-Soil 1.4908402180 London Clay 1.41010001900 Soil 1.7298371842 Stone–ST01 1.8028372243 Stone–HF-A3 1.4351674881 Terrazzo–TZ01 1.8028372243

Tiles

Clay Tile0.8408001900 Concrete Tiles 1.1008372100 Slate Tiles 2.0007532700 Plastic Tiles0.5008371950 Rubber Tiles0.30020001600 Cork Tiles0.0801800530 Asphalt/Asbestos Tiles0.5508371900 P.V.C./Asbestos Tiles0.8508372000 Ceiling Tiles0.0561000380 Plaster Ceiling Tiles0.3808401120 Lightweight Metallic Cladding0.29010001250 Acoustical Tile–Mineral Fibreboard0.050800290 Acoustic Tile-AC010.0571339288 Acoustic Tile–HF-E50.0612142480 Hollow Clay Tile–1Cell–CT010.4988371121 Hollow Clay Tile–2Cells–CT030.5718371121 Hollow Clay Tile–3Cells–CT060.6928371121 Clay Tile–HF-C10.5718371121 Paver–Clay Tile–CT11 1.8028371922 Slate–SL01 1.44214641602

Timber

Timber Flooring0.1401200650 Plywood(Lightweight)0.1502500560 Plywood(Heavyweight)0.1501420700 Wood Blocks0.1401200650 Wood Wool Slab0.1001000500 Hardboard(Medium)0.0802000600 Hardboard(Standard)0.1302000900 Pine(20%Moist)0.1402720419 Cork Board0.0401888160 Chipboard0.1502093800 Weatherboard0.1402000650 Oak(Radial)0.1902390700 Cork Tiles0.0801800530 Plywood–PW010.1151213545 Soft Wood–WD010.1151381513 Hard Wood–WD110.1581255721 Wood–HF-B70.121837593 Plywood–Douglas Fir0.1201200540 Shingle Wood–WS010.1151255513

Table7Reflectance,Absorbtance and Transmittance of Glazing Materials

Description Refl Absorp Trans Refr

Clear Float4mm0.070.110.82 1.526

Clear Float6mm0.070.150.78 1.526

Clear Float10mm0.070.230.7 1.526

Clear Float12mm0.060.270.67 1.526

'Spectrafloat'6mm51/65(Bronze)0.10.360.54 1.526

'Antisun'Float6mm72/62(Green)0.050.490.46 1.526

'Antisun'Float4mm55/68(Grey)0.050.40.55 1.526

'Antisun'Float6mm42/60(Grey)0.050.530.42 1.526

'Antisun'Float10mm25/49(Grey)0.040.710.25 1.526

'Antisun'Float12mm19/45(Grey)0.040.770.19 1.526

'Antisun'Float4mm61/70(Bronze)0.060.360.58 1.526

'Antisun'Float6mm50/62(Bronze)0.050.490.46 1.526

'Antisun'Float10mm33/51(Bronze)0.040.670.29 1.526

'Antisun'Float12mm27/47(Bronze)0.040.730.23 1.526

'Antisun'Float6mm54/62(Blue)0.050.490.46 1.526

Reflectafloat6mm35/53(Silver)0.280.290.43 1.526

'Suncool'Classic6mm20/33(Blue)0.210.640.15 1.526

'Suncool'Classic6mm30/39(Blue)0.180.610.21 1.526

'Suncool'Classic6mm40/50(Blue)0.10.580.32 1.526

'Suncool'Classic6mm10/24(Bronze)0.210.730.06 1.526

'Suncool'Classic6mm10/23(Silver)0.320.60.08 1.526

'Suncool'Classic6mm20/34(Silver)0.180.660.16 1.526

'Suncool'Classic10mm10/33(Blue)0.190.660.15 1.526

'Suncool'Classic10mm30/38(Blue)0.170.630.2 1.526

'Suncool'Classic10mm40/49(Blue)0.090.60.31 1.526

'Suncool'Classic10mm10/24(Bronze)0.190.760.05 1.526

'Suncool'Classic10mm10/23(Silver)0.30.620.08 1.526

'Suncool'Classic10mm20/34(Silver)0.160.690.15 1.526

'Suncool'Classic6mm20/34(Silver)0.180.660.16 1.526

'Suncool'Classic10mm20/33(Blue)0.190.660.15 1.526

Stopsol4mm(Clear)0.250.220.53 1.526

Stopsol5mm(Clear)0.250.240.51 1.526

Stopsol6mm(Clear)0.250.250.5 1.526

Stopsol8mm(Clear)0.250.280.47 1.526

Stopsol10mm(Clear)0.240.310.45 1.526

Stopsol4mm(Bronze)0.270.380.35 1.526

Stopsol5mm(Bronze)0.270.410.32 1.526

Stopsol6mm(Bronze)0.260.450.29 1.526

Stopsol8mm(Bronze)0.260.510.23 1.526

Stopsol10mm(Bronze)0.260.560.18 1.526 Stopsol6mm(Silver)0.20.370.43 1.526 Kappafloat4mm(Champagne)0.170.220.61 1.526 Kappafloat4mm(Neutral)0.20.140.66 1.526 Kappafloat6mm(Champagne)0.160.260.58 1.526 Kappafloat6mm(Neutral)0.20.170.63 1.526 Saflex Blue-Green(Light)5.4mm0.070.190.74 1.526 Saflex Blue-Grey(Light)5.4mm0.060.40.54 1.526 Saflex Blue-Grey(Medium)6.2mm0.050.590.36 1.526 Saflex Bronze5.4mm0.060.410.53 1.526 Saflex Bronze(Light)5.4mm0.060.370.57 1.526 Saflex Bronze(Medium)5.7mm0.050.560.39 1.526 Saflex Green-Blue(Light)5.3mm0.070.180.75 1.526 Saflex Grey5.4mm0.050.510.44 1.526 Saflex Grey-Green(Light)5.4mm0.060.420.52 1.526 Saflex Marine Blue(Light)5.3mm0.060.350.59 1.526 Saflex Marine Blue(Medium)5.3mm0.050.560.39 1.526 Saflex Pink(Light)6.3mm0.060.310.63 1.526 Saflex Translucent White6.1mm0.060.370.57 1.526 Saflex Shadowlite Smoke Brown(L)5.4mm0.060.390.55 1.526 Saflex Shadowlite Smoke Brown(M)5.3mm0.050.670.28 1.526 Saflex Shadowlite Smoke Brown(D)6.3mm0.040.860.1 1.526 Polycarbonate3mm Clear0.090.090.82 1.6 Acrylic3mm Clear0.090.060.85 1.49 Luxguard6mm(Bright Silver)Cs-140.270.610.12 1.526 Luxguard6mm(Bright Silver)Cs-200.220.610.17 1.526 Luxguard6mm(Bright Silver)Cs-350.140.540.32 1.526 Luxguard6mm(Pewter)Cp-140.20.660.14 1.526 Luxguard6mm(Pewter)Cp-200.160.650.19 1.526 Luxguard6mm(Pewter)Cp-350.090.580.33 1.526 Luxguard6mm(Bronze)Cb-140.180.690.13 1.526 Luxguard6mm(Bronze)Cb-200.130.680.19 1.526 Luxguard6mm(Bronze)Cb-350.080.60.32 1.526 Luxguard6mm(Royal Blue)Cr-140.170.70.13 1.526 Luxguard6mm(Royal Blue)Cr-200.120.690.19 1.526 Luxguard6mm(Royal Blue)Cr-350.070.610.32 1.526 Thermoclear8mm Polycarbonate Sheeting0.050.80.15 1.59 Thermoclear16mm Polycarbonate Sheeting0.080.70.22 1.59 Perfectly Clear Glazing Material0011

Note:

1)The figures for Kappafloat are for viewing the glass from the coated side,i.e.when the

Kappafloat is the inside pane.If the Kappafloat is used as the outside pane then values should be obtained from another source.

2)The Saflex and Saflex Shadowlite glasses are laminated glass with a0.38mm interlayer

3)The refractive index for the plastic materials listed(GRP,PC)will NOT be the same as

for glass.

Sources of above data:

Pilkington,Transmission Properties of Windows July85Glaverbel,Reflective Glazing Monsanto, Solar Control J.Page and R.Lebens,Climate in the United Kingdom.

Table8Shading Coefficient and Short-wave Radiant Fraction for Blinds and Curtains

Shading device Shading

Coefficient Short-wave Radiant Fraction

Dark green open-weave plastic blind0.810.5

Venetian blind0.610.3

White cotton curtain0.540.3

Cream Holland linen blind0.400.3

Mid-pane Venetian blind0.440.4

(From BRE data)

Net curtain(fine)0.76

Net curtain(open weave)0.85

Venetian blind(open)0.83

Venetian blind(closed)0.56

Light curtain(closed)0.49

(From ETSU data for white room1987)

Note:A shading coefficient of0means full shading,and a coefficient of1means no shading.

Table9Transmission Factors for External Miniature Louvres

Vertical Shadow

Angle(°)

Transmisson

Standard Koolshade Low-Sun Angle KoolShade

00.650.5

150.40.2

300.20

4500

6000

7500

9000 From Colt KoolShade leaflet.

材料热物性测试的研究现状及发展需求

材料热物性测试的研究现状及发展需求 陈桂生,廖 艳,曾亚光,付志勇,邓丽娟 (中国测试技术研究院,四川成都610021) 摘 要:材料热物性是对特定热过程进行基础研究、分析计算和工程设计的关键参数,是材料最基本的性能之一,在 科学研究、工程设计、工业生产等领域应用十分广泛,也是各行业节能技术发展的基础。通过对材料热物性发展历史、国内外研究现状的分析,比较了我国与发达国家在防护热板法导热系数装置研究上的差距,阐明了热物性测试的重要意义及我国在材料热物性测试领域仍未建全量值传递体系的不足。 关键词:材料热物性;防护热板法;导热系数;热学微系统;标准物质;量值传递体系中图分类号:O551.3;TK121 文献标识码:A 文章编号:1674-5124(2010)05-0005-04 Development requirements and research status of thermal physical properties testing CHEN Gui-sheng ,LIAO Yan ,ZENG Ya-guang ,FU Zhi-yong ,DENG Li-juan (National Institute of Measurement and Testing Technology ,Chengdu 610021,China ) Abstract:Thermal physical properties of materials are the key parameters for study ,analysis and engineering design of special thermal process.As the most basic characteristics of materials ,thermal physical properties are widely used in scientific research ,engineer design and industrial production field.They are also the basis for developing energy-saving technology in industry.In this paper ,thermal properties ’development history and current research progress were introduced.The difference of research on the guarded hot -plate device for thermal conductivity measurement between developed countries and China was compared.The importance of thermal properties testing was clarified.Finally ,the necessity of our country to establish full value transfer system in thermal properties testing field was discussed. Key words:thermal physical properties of material ;guarded hot plate apparatus ;thermal conductivity ;thermal micro-system ;reference materials ;value transfer system 收稿日期:2010-04-11;收到修改稿日期:2010-06-22作者简介:陈桂生(1953-),男,副研究员,主要从事温度计量 测试研究工作。 1引言 材料科学是人类生产、生活,社会发展的支柱和科学研究、科技创新最重要的基础,国家经济建设、国防建设和高新技术的发展都离不开材料,材料日益成为国家重要的战略资源。 材料的热物性是材料的重要特征参量,它是指材料在热过程中所表现出来的反映各种热力学特性的参数的总称,包括材料的导热系数、热扩散率、比热容、热膨胀系数、发射率、热流密度等[1]。材料热物 性参量在航空航天、 新材料的研究和开发、能源的有效利用、国防技术、微电子技术等高新技术领域以及建筑节能、空调制冷、石油化工、生物工程、医学、冶金、电力等工业领域都具有明显的科学意义和重要的工程应用价值。 能源短缺是当今全球经济发展所面临的重大挑 战,这使节能技术研究及其推广应用被各国列为重 点发展对象。 随着我国国民经济的快速增长,一方面能源缺口逐年扩大,另一方面我国的能源利用率仍然偏低,节能及提高能源利用效率方面大有潜力可 挖。节能技术的研究, 首先从关注能量的耗散开始。能量的耗散主要集中在热力转换这一过程中,如 电力生产、 炼钢、化工产品的分解与合成、建筑采暖等都是通过热力转换过程完成。因此, 提高热力转换效率及降低转换过程中的能源损耗是节能的重要途径。要提高热力转换效率和降低能源的损耗,合理地控制热能的转移和传递方式,就必须对材料的热物性参数进行研究,建立测试体系为各行业降低能耗和节能技术的研究推广提供可靠的技术支撑。 2热物性测试技术的发展过程 早在18世纪,人类就开始对材料的热物性进行 第36卷第5期2010年9月中国测试 CHINA MEASUREMENT &TEST Vol.36No.5September ,2010

热分析技术在金属材料研究中的应用

研究生课程论文 (2014 -2015 学年第一学期) 热分析技术在金属材料研究中的应用 提交日期:2014年12月 1 日研究生签名: 学号学院材料科学与工程学院 课程编号课程名称材料的物性及其测试技术 学位类别硕士任课教师 教师评语: 成绩评定:分任课教师签名:年月日

热分析技术在金属材料研究中的应用 摘要:介绍了热分析技术的一些常用的热分析方法,如热重分析、差热分析、差示扫描量热分析、热膨胀等;同时阐述了热分析技术在金属材料中的应用,如测定金属材料的相变的临界温度以及对磁性材料居里温度的测量,及相变的热效应等。 关键词:热分析技术金属材料研究应用 Application of thermal analysis technique in the research of metallic materials Jing Deng School of Materials Science and Engineering, South China University of Technology Abstract: The application of the thermal analysis technique and some commonly methods were introduced, such as thermogravimetry analysis (TGA), differential thermal analysis (DTA), differential scanning calorimetry (DSC), thermodilatometry and so on. The application of the thermal analysis technology in metallic materials was introduced, for example, to measure phase transition critical temperature of the metallic materials and the Curie temperature of the magnetic material and the thermal effect of the phase transition. Keywords: thermal analysis technique; metallic materials; research; application 1、前言 热分析是在程序控制温度下测量物质的物理性质与温度之间对应关系的一项技术。主要包括如下三个方面的内容:一是物质要承受程序控温的作用,即以一定的速率等速升温或降温;二是要选择一观测的物理量P,该物理量可以是热学、磁学、力学、电学、声学和光学的等;三是测量物理量P随温度T的变化,往往不能直接给出两者之间的函数关系[1]。 热分析主要用于研究物理变化(晶型转变、熔融、升华和吸附等)和化学变化(脱水、分解、氧化和还原等)。热分析不仅提供热力学参数,而且还能给出有参考价值的动力学数据。因此,热分析在材料研究和选择上,在热力学和动力学的理论研究上都是很重要的分析手段[2]。 按照测量的物理性质,国际热分析协会(ICTA)将现有的热分析技术分类[3-4],具体见表1。热分析技术种类繁多,应用甚广,本文将介绍主要的热分析技术及其在金属材料研究中的主要应用。 表1 ICTA关于热分析技术的分类 测试性质方法名称英文全称缩名称质量热重法Thermogravimetry Analysis TGA 等压质量变化测定Isobaric Mass-change Determination 逸出气检测Evolved Gas Detection EGD 逸出气分析Evolved Gas Analysis EGA 放射热分析Emanation Thermal Analysis TEA

金属热物性参数

金属热物性参数

表1 各种金属的热物性值 金属温度? C 比热 cal/(g·?C) 导热系数 cal/(cm·s·?C) 密度ρ(g/cm3)液相 线、固相线温度(?C) 纯铁 25 200 400 769 800 1000 1500 0.107 0.124 0.145 0.358 0.230 0.148 0.180 0.192 0.152 0.120 0.074 0.071 0.070 0.032 ρ=7.88(20?C) =7.3(1500?C) =7.0(1600?C) 镇静钢(C0.08%) 200 400 800 1200 0.112 0.124 0.142 0.230 0.158 0.142 0.128 0.107 0.068 0.071 ρ=7.86(15?C) 软钢(C0.23%) 200 400 800 1200 0.112 0.124 0.142 0.228 0.158 0.124 0.116 0.102 0.062 0.071 ρ=7.86(15?C) 碳素结构钢(S35C) 25 200 400 800 0.111 0.125 0.134 0.285 0.103 0.095 0.079 0.078 中碳钢(C0.4%) 200 400 800 1200 0.112 0.122 0.140 0.148 0.156 0.124 0.115 0.100 0.059 0.071 ρ=7.85(15?C) 共析钢(C0.8%) 200 400 800 1200 0.108 0.128 0.144 0.146 0.160 0.119 0.108 0.091 0.058 0.072 ρ=7.85(15?C) 工具钢(C1.2%) 200 400 800 0.108 0.130 0.142 0.156 0.103 0.102 0.089 0.057 ρ=7.83(15?C)

水的物性参数表

温度t °C 密度p比热容 cp 热导率入运动黏度V动力黏度n 普朗特数Pr kg/m3 kJ/(kg .K) W/(m ?K) m2/s Pa - s 0 999.9 4.212 0.551 1.789E-06 1.788E-03 13.67 1 999.9 4.210 0.553 1.741E-06 1.740E-03 13.26 2 999.9 4.208 0.556 1.692E-06 1.692E-0 3 12.84 3 999.9 4.206 0.558 1.644E-06 1.643E-03 12.43 4 999.8 4.204 0.560 1.596E-06 1.595E-03 12.01 5 999.8 4.202 0.563 1.548E-0 6 1.547E-03 11.60 6 999.8 4.199 0.565 1.499E-06 1.499E-03 11.18 7 999.8 4.197 0.567 1.451E-06 1.451E-03 10.77 8 999.7 4.195 0.569 1.403E-06 1.402E-03 10.35 9 999.7 4.193 0.572 1.354E-06 1.354E-03 9.94 10 999.7 4.191 0.574 1.306E-06 1.306E-03 9.52 11 999.6 4.190 0.577 1.276E-06 1.276E-03 9.27 12 999.4 4.189 0.579 1.246E-06 1.246E-03 9.02 13 999.3 4.189 0.582 1.216E-06 1.215E-03 8.77 14 999.1 4.188 0.584 1.186E-06 1.185E-03 8.52 15 999.0 4.187 0.587 1.156E-06 1.155E-03 8.27 16 998.8 4.186 0.589 1.126E-06 1.125E-03 8.02 17 998.7 4.185 0.592 1.096E-06 1.095E-03 7.77 18 998.5 4.185 0.594 1.066E-06 1.064E-03 7.52 19 998.4 4.184 0.597 1.036E-06 1.034E-03 7.27 20 998.2 4.183 0.599 1.006E-06 1.004E-03 7.02 21 998.0 4.182 0.601 9.859E-07 9.838E-04 6.86 22 997.7 4.181 0.603 9.658E-07 9.635E-04 6.70 23 997.5 4.180 0.605 9.457E-07 9.433E-04 6.54 24 997.2 4.179 0.607 9.256E-07 9.230E-04 6.38 25 997.0 4.179 0.609 9.055E-07 9.028E-04 6.22 26 996.7 4.178 0.610 8.854E-07 8.825E-04 6.06 27 996.5 4.177 0.612 8.653E-07 8.623E-04 5.90 28 996.2 4.176 0.614 8.452E-07 8.420E-04 5.74 29 996.0 4.175 0.616 8.251E-07 8.218E-04 5.58 30 995.7 4.174 0.618 8.050E-07 8.015E-04 5.42 31 995.4 4.174 0.620 7.904E-07 7.867E-04 5.31 32 995.0 4.174 0.621 7.758E-07 7.719E-04 5.20 33 994.7 4.174 0.623 7.612E-07 7.570E-04 5.09 34 994.3 4.174 0.625 7.466E-07 7.422E-04 4.98 35 994.0 4.174 0.627 7.320E-07 7.274E-04 4.87 36 993.6 4.174 0.628 7.174E-07 7.126E-04 4.75 37 993.3 4.174 0.630 7.028E-07 6.978E-04 4.64 38 992.9 4.174 0.632 6.882E-07 6.829E-04 4.53 39 992.6 4.174 0.633 6.736E-07 6.681E-04 4.42 40 992.2 4.174 0.635 6.590E-07 6.533E-04 4.31 41 991.8 4.174 0.636 6.487E-07 6.429E-04 4.23

物性参数表

物性参数表

常用溶剂 一、乙醇(ethyl alcohol,ethanol)CAS No.:64-17-5 (1)分子式 C2H6O (2)相对分子质量 46.07 (3)结构式 CH3CH2OH , (4)外观与性状:无色液体,有酒香。(5)熔点(℃):-114.1 (6)沸点(℃):78.3 溶解性:与水混溶,可混溶于醚、氯仿、甘油等多数有机溶剂; 密度:相对密度(水=1)0.79;相对密度(空气=1)1.59; 稳定性:稳定;危险标记7(易燃液体); 主要用途:用于制酒工业、有机合成、消毒以用作溶剂

二、甲醇(methyl alcohol,Methanol)CAS No.:67-56-1 (1)分子式 CH4O (2)相对分子质量32.04 (3)结构式 CH3O, (4)外观与性状:无色澄清液体,有刺激性气味。 (5)熔点(℃):-97.8,凝固点 -97.49℃,沸点64.5℃.闪点(开口)16℃,燃点470℃,折射率1. 3285,表面张力22.55×10-3N/m (6)相对密度(20 ℃/4℃)0.7914 溶解度参数δ=14.8,能与水、乙醇、乙醚、丙酮、苯、氯仿等有机溶剂混溶,甲醇对金属特别是黄铜有轻微的腐蚀性。易燃,燃烧时有无光的谈蓝色火焰。蒸气能与空气形成爆炸混合物.爆炸极限6.0%-36.5%(vol)。纯品略带乙醇味,粗品刺鼻难闻。有毒可直接侵害人的肢体细胞组织.特别是侵害视觉神经网膜,致使失明。正常人一次饮用4一10g纯甲醉可产生严重中毒。饮用7-8g可导致失明,饮用

30-100g就会死亡。空气中甲酵蒸气最高容许浓度5mg/m3。

材料热物性参数

Apache-Tables

Apache-Tables Table1Ground Reflectance (3) Table2Precipitable Water Vapour Depth(In Metres) (4) Table3Dry-Bulb Temperatures (5) Table4World Weather Data (6) Table5U-Values for Glazing (7) Table6Thermal Conductivity,Specific Heat Capacity and Density (9) Table8Shading Coefficient and Short-wave Radiant Fraction for Blinds and Curtains (19) Table9Transmission Factors for External Miniature Louvres (20) Table10Sensible and Latent Gains from People (21) Table11Radiant Fraction for Casual Gains (22) Table12Winter Design Temperatures and Air Changes (23) Table13Heat Emitter Radiant Fraction (26) Table14Solar Absorptivity (27) Table15Thermal Resistances of Air Gaps (28) Table16Diffusion Resistance Factors (30) Table17Permeances (31) Table18Vapour Resistivities (32) Table21Inside Surface Resistance(Table A3.5CIBSE Guide) (34) Table22Outside Surface Resistance(Table A3.6CIBSE Guide) (35) Table23Emissivities of Various Materials(Table C3.7CIBSE Guide) (36)

常用材料的热物性参数

表1 各种金属的热物性值 温度 C 比热 cal/(g·C) 导热系数 cal/(cm·s· C) 密度(g/cm3)液相 线、固相线温度(C) =7.88(20C) =7.3(1500C) =7.0(1600C) =7.86(15C) =7.86(15C) =7.85(15C) =7.85(15C)

=7.83(15C)续表1 各种金属的热物性值 温度 C 比热 cal/(g·C) 导热系数 cal/(cm·s· C) 密度(g/cm3)液相 线、固相线温度(C) =7.73(15C) Ts=1488 T L=1497 =7.84(15C) T S=1420 T L=1520 =7.7(15C) 13.1Cr,0.5Ni T S=1399 T L=1454 =7.0(15C) 比热相对于 普通铸铁

=7.1(15C) 温度 C 比热 cal/(g·C) 导热系数 cal/(cm·s· C) 密度(g/cm3)液相 线、固相线温度(C) =7.5~7.8(15C) =8.92 T S=T L=1083

s=2.70(15C) T S=T M=660.2 温度 C 比热 cal/(g·C) 导热系数 cal/(cm·s· C) 密度(g/cm3)液相 线、固相线温度(C) s=1.74 T L=T S=651

s=6.09 T S=1395 T L=1427表2 铸型的热物性计算公式

硅砂,干型,呋喃铸型600C以下 0.385<<0.494 0.0058 互联网上的物性参数查询 1 化学工程师资源主页 该站点由西弗吉尼亚大学校友Christopher M.A.Haslego维护。该主页有非常丰富的化学工程方面的内容,其中包括一些查找物性数据比较好的站点:(https://www.360docs.net/doc/559934435.html,/physinternetzz.shtml) 1.1 物性数据((https://www.360docs.net/doc/559934435.html,/data.xls) 该数据库是浏览型数据库,含有470多种纯组分的物性数据,如分子量、冰点、沸点、临界温度、临界压力、临界体积、临界压缩、无中心参数、液体密度、偶极矩、气相热容、液相热容、液体粘度、反应标准热、蒸气压、蒸发热等。 1.2 聚合物和大分子的物理性质数据库(https://www.360docs.net/doc/559934435.html,/~athas/databank/intro.html) 该数据库是浏览型数据库。含有200多种线性大分子的物性数据,如熔融温度、玻璃转换温度、热容等。该站点不仅提供物理性质,还提供一些供估计物质物理性质的软件,如PhysProps from G&P Engineering、Prode's thermoPhysical Properties Generator(PPP)等。 1.3 https://www.360docs.net/doc/559934435.html,/~jrm/thermot.html 该站点可查294种组分的热力学性质,还可以根据Peng Robinson状态方程计算纯组分或混合物的性质:包括气液相图、液体与气体密度、焓、热容、临界值、分子量等数据。 1.4 https://www.360docs.net/doc/559934435.html,/ G&P Engineering是一个软件,提供物质的28种物理性质并估算其它18种物理性质。 2 由美国国家标准技术研究院开发的数据库 2.1 标准参考数据库化学网上工具书(https://www.360docs.net/doc/559934435.html,/chemistry/) 该数据库是一种检索型数据库,检索方法非常简单,可通过化学物质名称、分子式、部分分子式、CAS登记号、结构或部分结构、离子能性质、振动与电子能、分子量和作用进行检索,可检索到的数据包括分子式、分子量、化学结构、别名、CAS登记号、气相热化学数据、凝聚相热化学数据、液态常压热容、固态常压热容、相变数据、汽化焓、升华焓、燃烧焓、燃烧熵、各种反应的热化学数据、溶解数据、气相离子能数据、气相红外光谱、质谱、紫外/可见光谱、振动/电子能及其参考文献。 2.2 美国标准技术研究所物理网上工具书(https://www.360docs.net/doc/559934435.html,/) 该站点包括物性常数、原子光谱数据、分子光谱数据、离子化数据、χ-射线、γ-射线数据、放射性计量数据、核物理数据及其它数据库。 3 化学搜索器 温度t °C 密度p比热容cp 热导率入运动黏度V动力黏度n 普朗特数P r kg/m3 kJ/(kg .K) W/(m ? K) m2/s Pa - s 0 999.9 4.212 0.551 1.789E-06 1.788E-03 13.67 1 999.9 4.210 0.553 1.741E-06 1.740E-03 13.26 2 999.9 4.208 0.556 1.692E-06 1.692E-0 3 12.84 3 999.9 4.206 0.558 1.644E-06 1.643E-03 12.43 4 999.8 4.204 0.560 1.596E-06 1.595E-03 12.01 5 999.8 4.202 0.563 1.548E-0 6 1.547E-03 11.60 6 999.8 4.199 0.565 1.499E-06 1.499E-03 11.18 7 999.8 4.197 0.567 1.451E-06 1.451E-03 10.77 8 999.7 4.195 0.569 1.403E-06 1.402E-03 10.35 9 999.7 4.193 0.572 1.354E-06 1.354E-03 9.94 10 999.7 4.191 0.574 1.306E-06 1.306E-03 9.52 11 999.6 4.190 0.577 1.276E-06 1.276E-03 9.27 12 999.4 4.189 0.579 1.246E-06 1.246E-03 9.02 13 999.3 4.189 0.582 1.216E-06 1.215E-03 8.77 14 999.1 4.188 0.584 1.186E-06 1.185E-03 8.52 15 999.0 4.187 0.587 1.156E-06 1.155E-03 8.27 16 998.8 4.186 0.589 1.126E-06 1.125E-03 8.02 17 998.7 4.185 0.592 1.096E-06 1.095E-03 7.77 18 998.5 4.185 0.594 1.066E-06 1.064E-03 7.52 19 998.4 4.184 0.597 1.036E-06 1.034E-03 7.27 20 998.2 4.183 0.599 1.006E-06 1.004E-03 7.02 21 998.0 4.182 0.601 9.859E-07 9.838E-04 6.86 22 997.7 4.181 0.603 9.658E-07 9.635E-04 6.70 23 997.5 4.180 0.605 9.457E-07 9.433E-04 6.54 24 997.2 4.179 0.607 9.256E-07 9.230E-04 6.38 25 997.0 4.179 0.609 9.055E-07 9.028E-04 6.22 26 996.7 4.178 0.610 8.854E-07 8.825E-04 6.06 27 996.5 4.177 0.612 8.653E-07 8.623E-04 5.90 28 996.2 4.176 0.614 8.452E-07 8.420E-04 5.74 29 996.0 4.175 0.616 8.251E-07 8.218E-04 5.58 30 995.7 4.174 0.618 8.050E-07 8.015E-04 5.42 31 995.4 4.174 0.620 7.904E-07 7.867E-04 5.31 32 995.0 4.174 0.621 7.758E-07 7.719E-04 5.20 33 994.7 4.174 0.623 7.612E-07 7.570E-04 5.09 34 994.3 4.174 0.625 7.466E-07 7.422E-04 4.98 35 994.0 4.174 0.627 7.320E-07 7.274E-04 4.87 36 993.6 4.174 0.628 7.174E-07 7.126E-04 4.75 37 993.3 4.174 0.630 7.028E-07 6.978E-04 4.64 38 992.9 4.174 0.632 6.882E-07 6.829E-04 4.53 39 992.6 4.174 0.633 6.736E-07 6.681E-04 4.42 40 992.2 4.174 0.635 6.590E-07 6.533E-04 4.31 41 991.8 4.174 0.636 6.487E-07 6.429E-04 4.23 表1 各种金属的热物性值 温度 C 比热 cal/(g·C) 导热系数 cal/(cm·s· C) 密度(g/cm3)液相 线、固相线温度 (C) =7.88(20C) =7.3(1500C) =7.0(1600C) =7.86(15C) =7.86(15C) =7.85(15C) =7.85(15C) =7.83(15C) 续表1 各种金属的热物性值 温度 C 比热 cal/(g·C) 导热系数 cal/(cm·s· C) 密度(g/cm3)液相 线、固相线温度 (C) =7.73(15C) Ts=1488 T L=1497 =7.84(15C) T S=1420 T L=1520 =7.7(15C) 13.1Cr,0.5Ni T S=1399 T L=1454 =7.0(15C) 比热相对于 普通铸铁 =7.1(15C) 温度 C 比热 cal/(g·C) 导热系数 cal/(cm·s· C) 密度(g/cm3)液相 线、固相线温度 (C) =7.5~7.8(15C) =8.92 T S=T L=1083 s=2.70(15C) T S=T M=660.2 温度 C 比热 cal/(g·C) 导热系数 cal/(cm·s· C) 密度(g/cm3)液相 线、固相线温度 (C) s=1.74 T L=T S=651 s=6.09 T S=1395 T L=1427 表2 铸型的热物性计算公式 硅砂,干型,呋喃铸型600C以下 0.385<<0.494 0.0058 1.别名·xx 液氨;Ammonia、Liquid amlllorlia. 2.用途 氮肥、铵盐、硝酸、尿素、丙烯腈、三聚氰酰胺、丙烯酰胺、氢氰酸、无机试剂、药品、染料、酸性中和剂、橡胶氧化剂、金属表面氮化、制冷剂、半导体用气体、氧化、氮化膜、化学气相淀积、标准气、校正气、在线仪表标准气。 3.制法 氢和氮在高温高压时在催化剂的作用下合成而得氨。 4.理化性质 分子量: 17.031熔点( 101.325kPa):-77.7℃沸点( 101.325kPa):-33.4℃液体密度(- 73.15℃, 8.666kPa):729kg/m3 气体密度(0℃, 101.325kPa): 0.7708kg/m3 相对密度(气体,空气= 1.25℃, 101.325kPa): 0.597比容( 21.1℃, 101.325kPa): 1.4109m3/kg 气液容积比: (15℃,100kPa):947L/L 临界温度: 132.4℃临界压力:11277kPa临界密度:235kg/m3 压缩系数: 压缩系数 压力kPa 300K380K420K580K 101.330. 99060.99660. 99780.9997 506.630. 94630.97850.985l 0.9954 1013.250. 88600.95730. 97030.9911熔化热(- 77.74℃, 6.677kPa): 331.59kJ/kg 气化热(- 33.41℃, 101.325kPa): 1371.18kJ/kg 比热容( 101.33kPa,300K): Cp= 2159.97J/(kg·K) 比热比(气体, 46.8℃, 101.325kPa): CP/Cv= 1.307 蒸气压(-20℃): 186.4kPa(0℃): 410.4kPa(20℃):829,9kPa粘度(气体,20℃,101.325kPa): 0.00982mPa·s(液体,- 33.5℃): 1 纯组分物性常数的估算 1.1、乙基2-乙氧基乙醇物性的输入 由于Aspen Plus 软件自带的物性数据库中很难查乙基2-乙氧基乙醇的物性参数, 使模拟分离、确定工艺条件的过程中遇到困难, 所以采用物性估算的功能对乙基2-乙氧基乙醇计算。 已知: 最简式:(C6H14O3) 分子式:(CH3-CH2-O-CH2-CH2-O-CH2-CH2-OH) 沸点:195℃ 1.2、具体模拟计算过程 乙基2-乙氧基乙醇为非库组分,其临界温度、临界压力、临界体积和临界压缩因子及理想状态的标准吉布斯自由能、标准吉生成热、蒸汽压、偏心因子等一些参数都很难查询到,根据的已知标准沸点TB,可以使用aspen plus软件的Estimation Input Pure Component(估计输入纯组分) 对纯组分物性的这些参数进行估计。 为估计纯组分物性参数,则需 1. 在 Data (数据)菜单中选择Properties(性质) 2. 在 Data Browser Menu(数据浏览菜单)左屏选择Estimation(估计)然后选Input(输入) 3. 在 Setup(设置)表中选择Estimation(估计)选项,Identifying Parameters to be Estimated(识别估计参数) 4. 单击 Pure Component(纯组分)页 5. 在 Pure Component 页中选择要用Parameter(参数)列表框估计的参数 6. 在 Component(组分)列表框中选择要估计所选物性的组分如果要为多组分估计 选择物性可单独选择附加组分或选择All(所有)估计所有组分的物性 7. 在每个组分的 Method(方法)列表框中选择要使用的估计方法可以规定一个以上的方法。 具体操作过程如下: 1、打开一个新的运行,点击Date/Setup 2、在Setup/Specifications-Global页上改变Run Type位property Estimation 丙稀丙稀物性参数物性参数物性参数 (1) (1) 常规性质常规性质常规性质 中文名: 丙稀 英文名: PROPYLENE CAS 号: 115071 化学式: C3H6 结构简式: 所属族: 1-炔烃 分子量: 42.0806 kg/kmol 熔点: 87.89 K 沸点: 225.46 K 临界压力: 4665.003 kPa 临界温度: 365.57 K 临界体积: 1.884E-04 m3/mol 偏心因子: 0.13982 临界压缩因子: 0.289 偶极距: 0.36575 debye 标准焓: 19.7099872 kJ/mol 标准自由焓: 62.14997 kJ/mol 绝对熵: .2666 kJ/mol/K 熔化焓: 未知 kJ/mol 溶解参数: 6.43 (cal/cm3)1/2 折光率: 1.3625 等张比容: 140.014 (2) (2) 饱和蒸气压饱和蒸气压饱和蒸气压 系数(Y 单位:Pa) 使用温度范围:87.89 - 365.57K A= 57.263 B=-3382.4 C=-5.7707 D= .000010431 E= 2 (3) (3) 液体热容液体热容液体热容 系数(Y 单位:J/kmol/K) 使用温度范围:87.89 - 298.15K A= 117200 B=-386.32 C= 1.2348 D= 0 E= 0 (4) (4) 理想气体比热容理想气体比热容理想气体比热容 系数(Y 单位:J/mol/K) 使用温度范围:130 - 1500K A= 43390 B= 152000 C= 1425 D= 78600 E= 623.9 (5) (5) 液体粘度液体粘度液体粘度 系数(Y 单位:Pa·s) 使用温度范围:87.89 - 320K A=-9.1477 B= 500.87 C=-.31745 D= 0 E= 0 1 化学工程师资源主页 该站点由西弗吉尼亚大学校友Christopher M.A.Haslego维护。该主页有非常丰富的 化学工程方面的内容,其中包括一些查找物性数据比较好的站点:(https://www.360docs.net/doc/559934435.html,/physinternetzz.shtml) 1.1 物性数据((https://www.360docs.net/doc/559934435.html,/data.xls) 该数据库是浏览型数据库,含有470多种纯组分的物性数据,如分子量、冰点、沸点 、临界温度、临界压力、临界体积、临界压缩、无中心参数、液体密度、偶极矩、气相 热容、液相热容、液体粘度、反应标准热、蒸气压、蒸发热等。 1.2 聚合物和大分子的物理性质数据库(https://www.360docs.net/doc/559934435.html,/~athas/da tabank/intro.html) 该数据库是浏览型数据库。含有200多种线性大分子的物性数据,如熔融温度、玻璃 转换温度、热容等。该站点不仅提供物理性质,还提供一些供估计物质物理性质的软件 ,如PhysProps from G&P Engineering、Prode's thermoPhysical Properties Genera tor(PPP)等。 1.3 https://www.360docs.net/doc/559934435.html,/~jrm/thermot.html 该站点可查294种组分的热力学性质,还可以根据Peng Robinson状态方程计算纯组 分或混合物的性质:包括气液相图、液体与气体密度、焓、热容、临界值、分子量等数 据。 1.4 https://www.360docs.net/doc/559934435.html,/ G&P Engineering是一个软件,提供物质的28种物理性质并估算其它18种物理性质。 2 由美国国家标准技术研究院开发的数据库 2.1 标准参考数据库化学网上工具书(https://www.360docs.net/doc/559934435.html,/chemistry/) 该数据库是一种检索型数据库,检索方法非常简单,可通过化学物质名称、分子式 、部分分子式、CAS登记号、结构或部分结构、离子能性质、振动与电子能、分子量和作 用进行检索,可检索到的数据包括分子式、分子量、化学结构、别名、CAS登记号、气相 热化学数据、凝聚相热化学数据、液态常压热容、固态常压热容、相变数据、汽化焓、 升华焓、燃烧焓、燃烧熵、各种反应的热化学数据、溶解数据、气相离子能数据、气相 红外光谱、质谱、紫外/可见光谱、振动/电子能及其参考文献。 2.2 美国标准技术研究所物理网上工具书(https://www.360docs.net/doc/559934435.html,/) 该站点包括物性常数、原子光谱数据、分子光谱数据、离子化数据、χ-射线、γ- 射线数据、放射性计量数据、核物理数据及其它数据库。 3 化学搜索器(https://www.360docs.net/doc/559934435.html,/' target=_blank>https://www.360docs.net/doc/559934435.html,/) Chemfinder化学搜索器是免费注册使用的数据库,是目前网上化合物性质 资源]化工主要物性参数查询网站 1 化学工程师资源主页该站点由西弗吉尼亚大学校友Christopher M.A.Haslego维护。该主页有非常丰富的化学工程方面的内容,其中包括一些查找物性数据比较好的站点:(https://www.360docs.net/doc/559934435.html,/physinternetzz.shtml)1.1物性数据((https://www.360docs.net/doc/559934435.html,/data.xls) 该数据库是浏览型数据库,含有470多种纯组分的物性数据,如分子量、冰点、沸点、临界温度、临界压力、临界体积、临界压缩、无中心参数、液体密度、偶极矩、气相热容、液相热容、液体粘度、反应标准热、蒸气压、蒸发热等。1. 2 聚合物和大分子的物理性质数据库(https://www.360docs.net/doc/559934435.html,/~athas/databank/intro.html) 该数据库是浏览型数据库。含有200多种线性大分子的物性数据,如熔融温度、玻璃转换温度、热容等。该站点不仅提供物理性质,还提供一些供估计物质物理性质的软件,如PhysProps from G&P Engineering、Prode's thermoPhysical Properties Generator(PPP)等。1. 3 https://www.360docs.net/doc/559934435.html,/~jrm/thermot.html 该站点可查294种组分的热力学性质,还可以根据Peng Robinson状态方程计算纯组分或混合物的性质:包括气液相图、液体与气体密度、焓、热容、临界值、分子量等数据。1. 4 https://www.360docs.net/doc/559934435.html,/ G&P Engineering是一个软件,提供物质的28种物理性质并估算其它18种物理性质。2 由美国国家标准技术研究院开发的数据库2.1 标准参考数据库化学网上工具书(https://www.360docs.net/doc/559934435.html,/chemistry/) 该数据库是一种检索型数据库,检索方法非常简单,可通过化学物质名称、分子式、部分分子式、CAS登记号、结构或部分结构、离子能性质、振动与电子能、分子量和作用进行检索,可检索到的数据包括分子式、分子量、化学结构、别名、CAS登记号、气相热化学数据、凝聚相热化学数据、液态常压热容、固态常压热容、相变数据、汽化焓、升华焓、燃烧焓、燃烧熵、各种反应的热化学数据、溶解数据、气相离子能数据、气相红外光谱、质谱、紫外/可见光谱、振动/电子能及其参考文献。2.2美国标准技术研究所物理网上工具书(https://www.360docs.net/doc/559934435.html,/) 该站点包括物性常数、原子光谱数据、分子光谱数据、离子化数据、χ-射线、γ-射线数据、放射性计量数据、核物理数据及其它数据库。3 化学搜索器(https://www.360docs.net/doc/559934435.html,/' target=_blank>https://www.360docs.net/doc/559934435.html,/) Chemfinder 化学搜索器是免费注册使用的数据库,是目前网上化合物性质数据最全面的资源。可通过分子式、化学物质名称、分子量或化合物的结构片段来检索,检索结果包括化合物的同义词、结构图形及物理性质,如熔点、沸点、蒸发速率、闪点、折射率、CAS登记号、比重、蒸汽密度、水溶性质及特征等。该数据库目前含有7 5 000种化合物的数据,其中包括几千种最常见化合物的详细资料。使用起来方便、简单。4sigma-aldrich手册(https://www.360docs.net/doc/559934435.html,/saws.nsf/Pages/Custom+Bulk ?EditDocument) 该数据库是一种可检索数据库,可通过产品名称、全文、分子式、CAS登记号等进行检索,检索的结果包括产品名称、登记号、分子式、分子量、贮存温度、纯度、安全数据等。5 热化学性质估计(http:/https://www.360docs.net/doc/559934435.html,/chem/TCPEE/TCPE.htm) 有机化合物热化学性质预测,通过化学物质的结构来预测,可预测到沸点、蒸汽压、临界性质、密度、液相密度、溶解参数、粘度等数据。 6 化学同义词数据库(http://129.79.137.107/cfdocs/libchem/searchu.html) 通过化学物质缩写来检索化合物全称,所检索的缩写部分自动进行左右截词。如检索PVC,则系统检索到CPVC(critical pigment volume concentration、Chlorinated Polyvinyl Chloride)、PVC(pigment volume concentration、polyvinyl chloride)、UPVC(unplasticized poly(vinyl chloride))。7加拿大环境技术中心网(https://www.360docs.net/doc/559934435.html,/cgi-win/oil-prop-cgi.exe?Pat h=\Website\river\) 该数据库是检索型数据库,包含412种原油及油品的性质,包括油来源、含水量、比重、Reid 蒸汽压、非金属含量等。8 https://www.360docs.net/doc/559934435.html,/conversn/constant.htm 该互联网上的物性参数查询

水的物性参数表

常用材料的热物性参数

氨气物性参数

利用aspen-plus进行物性参数的估算

丙烯物性参数

物性参数网站大全

化工主要物性参数查询网站