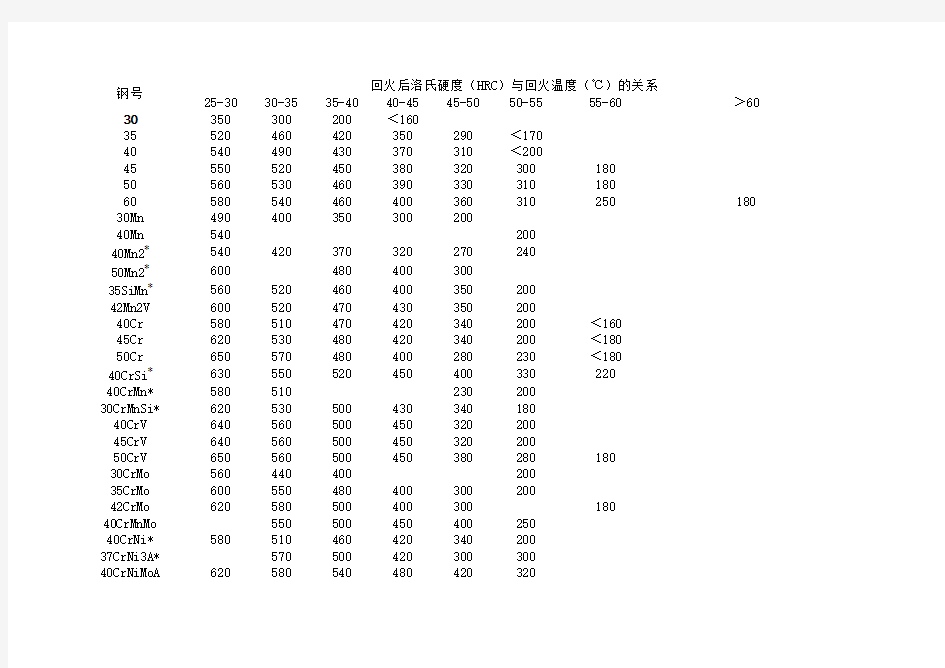

常用热处理参数及硬度对照表

25-3030-3535-4040-4545-5050-5555-60>60

30350300200<16035520460420350290<17040540490430370310<200455505204503803203001805056053046039033031018060580540460400360310250180

30Mn 490400350300200

40Mn 540200

40Mn2*54042037032027024050Mn2*60048040030035SiMn *56052046040035020042Mn2V 60052047043035020040Cr 580510470420340200<16045Cr 620530480420340200<18050Cr 650570480400280230<18040CrSi *630550520450400330220

40CrMn*580510230200

30CrMnSi*62053050043034018040CrV 64056050045032020045CrV 64056050045032020050CrV 65056050045038028018030CrMo 56044040020035CrMo 60055048040030020042CrMo 62058050040030018040CrMnMo 55050045040025040CrNi*58051046042034020037CrNi3A*57050042030030040CrNiMoA

620

580

540480420320

钢号回火后洛氏硬度(HRC)与回火温度(℃)的关系

35CrMoV640590500360300<200

38CrSi*630550520450400330

38CrMoAiA680630530430320200

45B550450

50B420?400360280

40MnB*650450

40MnVB600460

45CrNi*570500430360280230<160 65620550500450380300230

70620550500450380310230

85620550500450380330250

65Mn660600520440380300230<170 55SiMn550490

60Si2MnA620600550520470420380180 50CrMn580500450400330

60Si2CrV460420

30W4Cr2VA

GCr6550500460400300250<200 GCr9550500460410350270<180 GCr15680580530480420380270<180 GCr9SiMn420350280<200 GCr15SiMn480420350280<180 Cr6WV700650600540450250<180

T7(A)580530470420370320250 T8(A)580530470420370332250 T10(A)580540490430380340250 T12(A)580540490430380340250<160<200<200

550-650℃回火

9Mn2400340280

9Mn2V 500400320250Cr2600

5304804203202309Cr2Mo(W)9SiCr 670

6205805204503803001006SiCr 630590530450380280<200Cr 580530480420350280

<200SiCr 440370

<250CrMn 590540490430340280<180CrWMn 640

600540480420350280170Cr12650600520470250 750700650600550Cr12MoV

740670620570530380<180

700

710

650610

550(二次硬化峰值对应回火温度)

W 350

300240W?330280220CrW5620

550500450400320270<2009CrWMn 620570520470370250<180

6SiMnV 6005304704005CrMnMo 580520470380250<2005CrNiMo 700

640550450380280<2003Cr2W8V 700630540<2008Cr3610580510

440

330

200Cr4W2MoV 300220

W18Cr4V 720700

680650W9Cr4V2

670

640

W12Mo3Cr4V3Co5Si W12Mo9Cr4VCo8

<200

<180700±10,工频淬后,700系调质温度<160550±10℃(三次回火)570±10℃(三次回火)

W6Mo5Cr4V2W6Mo5Cr4V3Al W9Cr4V2Co10W10Cr4V5Co51Cr135805505002Cr13600560520450<4003Cr13620600570540<5004Cr13630

610

580

550

500<4009Cr185********<150Cr18560

300

250<200

1Cr17Ni2650-700550230-500

15/20渗碳后350280220<16015Cr/20Cr渗碳后380

330

240<18020CrMnTi渗碳后240<18020CrMnMo渗碳后240<18012CrNi4(A)渗碳后400310

24018Cr2Ni4W(A)渗碳后240<20020MnTiB渗碳后240<18030CrMnTi渗碳后240<180

35CrMnTi

<180

ZG35ZG45ZG55400340280

180

ZGMnB 600-650350-400500-550

450

ZG40Mn ZG40Cr

参看序号4参看序号6参看序号10

参看序号15

560±10℃(二次或三次回火)

570±10℃(三次回火)

注:

1)有“*”者表示回火脆性较大,通常不在250-400℃间回火;

2)回火温度依硬度要求的中值偏上而定;

3)80号钢的550±10℃二次回火系1030±10℃淬火作热冲模;中下限温度为冷冲模淬火,仅低温回火。

备注以下为碳素及低合金钢

水冷回火作弹簧回火以下为弹簧钢

以下为轴承钢以下为工具钢、模具钢

<1000℃淬火

>1000℃淬火

960-1030℃淬火1050-1130℃淬火

550±10二次作热冲模以下为高速钢

以下为不锈钢以下为渗碳钢以下为铸钢