机械类英文文献

Available online at https://www.360docs.net/doc/2b129247.html,

Physica A334(2004)243–254

https://www.360docs.net/doc/2b129247.html,/locate/physa

Stability and transition in

multiple production lines

Takashi Nagatani?

Department of Mechanical Engineering,Shizuoka University,Hamamatsu432-8561,Japan

Received28October2003

Abstract

We present the dynamical model of the multiple production lines composed of M parallel and u series machines.We extend the single-series production line model to the multiple production lines.We study the e ect of the multiple lines on the dynamical behavior of the production process.We apply the linear stability analysis to the production process in the multiple lines. The linear stability criterion is derived for the production system with the multiple lines.It is shown that the production process in the multiple lines is more unstable than that in the single line.The phase diagram(region map)is given for the multiple production lines.The nonlinear instability and dynamical transition are investigated by using computer simulation.It is shown that the dynamical transitions occur between the stable and oscillatory productions.

c 2003Elsevier B.V.All rights reserved.

PACS:05.90.+m;89.90.+m;89.40.+k

Keywords:Production process;Instability;Dynamical transition;Transportation;Multiple lines

1.Introduction

Concepts from statistical physics and nonlinear dynamics have been very successful in discovering and explaining dynamical phenomena in transportation systems[1–5]. Many of these phenomena are based on mechanisms such as delayed adaptation to changing conditions and competition for limited resources.The delayed adaptation is relevant for production systems as well[6–10].Mathematicians,physicists,tra c sci-entists,and economists have suggested that tra c dynamics has also implications for the dynamical behavior of production process.

?Fax:+81-53-478-1048.

E-mail address:tmtnaga@ipc.shizuoka.ac.jp(T.Nagatani).

0378-4371/$-see front matter c 2003Elsevier B.V.All rights reserved.

doi:10.1016/j.physa.2003.11.002

244T.Nagatani/Physica A334(2004)243–254

The recently proposed supply-chain model[6]is closely related to the tra c model. The stability of a linear supply chain has been investigated by using the linear stability method and computer simulation,which have been developed in the tra c dynamics [1,11].It has been found that the dynamical transition occurs between the stable and oscillatory productions by varying the adaptation time.The strength of the oscillation increases with the adaptation time.The dynamical transition is very similar to the jamming transition in tra c ow.

When the consumption rate is subject to perturbations,the perturbations may cause variations in the production of upstream producers.This is due to delays in their adaptation of the production speed.Under certain conditions,the oscillations in the production and in the resulting inventories(stock levels)of the generated products grow from one producer to the next upstream one.This is called the bullwhip e ect and known,for example,from the“beer distribution game”.

Until now,the production process composed of a series line of machines has been proposed and investigated by means of linear stability analysis and computer simula-tions[6,11].A control strategy of the production process has been developed to manage the process of bringing an unstable system into the stable regime.However,there are various production systems in real factories.Products are made through the production processes composed of complex networks.As a result,the products depend highly on the network structure of the production process.

In this paper,we consider the dynamical behavior of products produced through the multiple production lines.We present an extended dynamical model of the multiple supply chains to take into account the network structure of M parallel and u series production lines.We study the e ect of multiple lines on the production process.We show that the multiple production lines induce the instability of the production process easier than that of the single production line,and perturbations of consumption grow to higher oscillations of the products.We analyze the stability of multiple production lines using the linear stability analysis method.We show the stability,dynamical transition, and phase diagram(region map).

2.Model

We present the dynamical model of the multiple production lines to take into account the network structure of M parallel and u series machines.The model consists of M parallel chains in which each chain is composed of a series of u production units j, which receive products from the next upstream producer j?1and generate products for the next downstream producer j+1.

First,we describe the supply-chain model for late convenience.Recently,Helbing [6]has suggested the following model for the dynamics of supply chains:

d N j d t =

u

b=1

(f j b?n j b) b(t)min

1;

C0b N0(t)

c0b

;

V k b N k(t)

c k b

?Y j u+1(t);(1)

where N j denotes the inventory(stock level)of product j, b is the desired production speed of production unit(machine)b,f j b the number of products generated in each

T.Nagatani/Physica A334(2004)243–254245 production step,n j b the number of products(educts)needed,V k b a limitation of transport capacity in the delivery of the required educts,and Y j u+1the consumption rate of product j.Moreover,there is usually a considerable delay in the adaptation of the (desired)production speeds b,which may be modeled by

d b d t =

1

T

[W({N k(t)};{d N k(t)=d t})? b(t)]:(2)

Herein,W(···)denotes a control function re ecting the decisions of the production management as a function of the inventories N k(t),their temporal changes d N k=d t,and T is the delay or adaptation time.If we focus on a linear supply chain with f k b= bk and n j b= b;j+1,where b;j represents the Kronecker delta function,the above equations simplify considerably.For j∈{0;1;:::;u}they read

d N j

d t

= j(t)? j+1(t)(3) with

d j d t =

1

T

[W({N k(t)};{d N k(t)=d t})? j(t)];(4)

where we assume the boundary condition Y j u+1(t)= u+1(t) j;u.In the previous paper [11],we have investigated the stability of the linear supply chain assuming control function of the form

W(N)=1?[tanh(N?N c)+tanh(N c)]=2:(5) We have presented the criterion of the strategies to manage to bring into the stable production process.

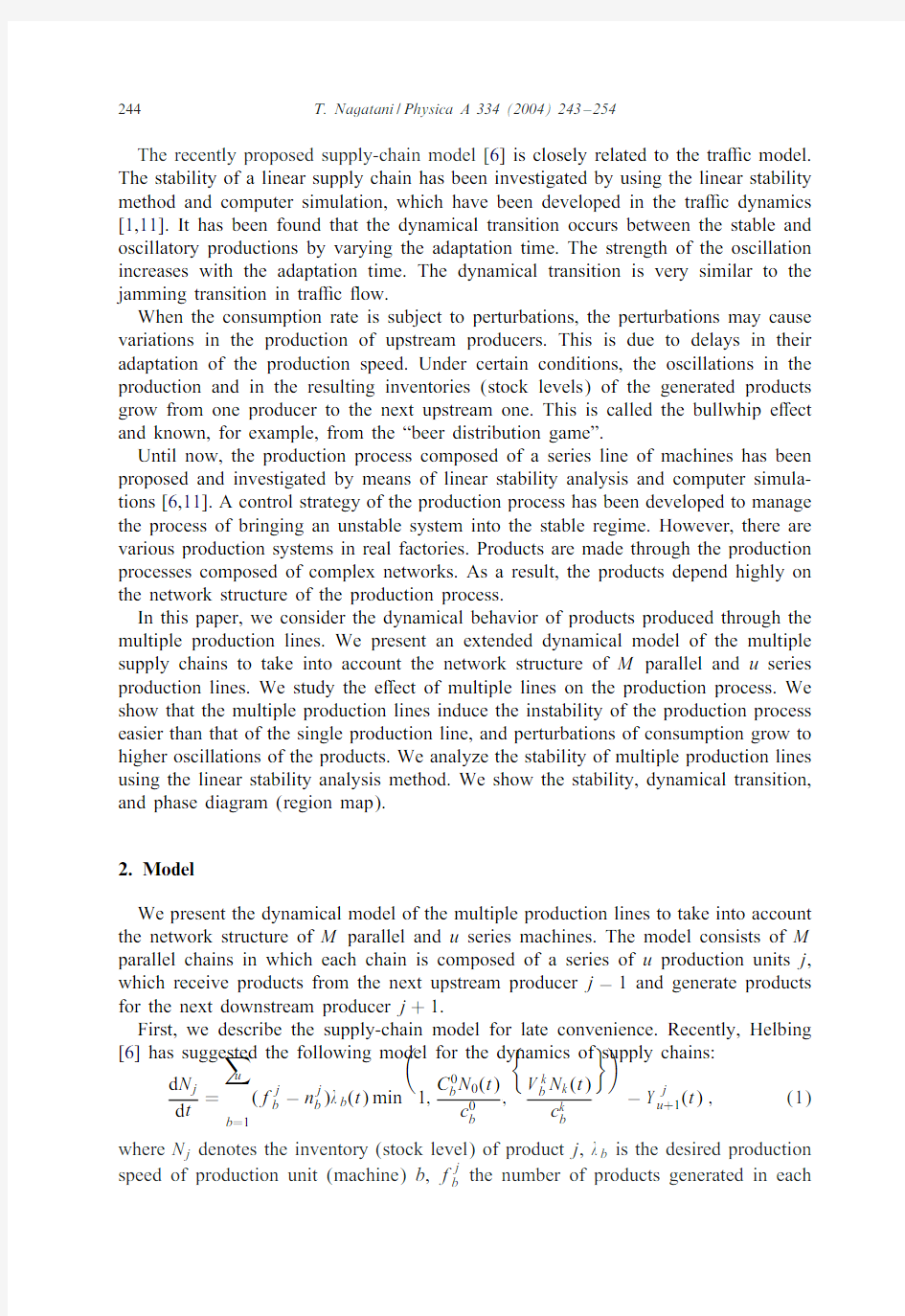

We extend the single linear supply-chain model to the multiple production lines. Fig.1shows the schematic illustration of the multiple production lines.The production system is composed of M parallel and u series machines.Fig.1shows the special case of M=3and u=4for illustration.At each production step,a bu er is set and all the products produced by all machines(i=1;2;:::;M,j)at step j are stocked,transiently,

j+1

j-1

(i-1, j)

(i+1, j)

Supply Demand

Fig.1.Schematic illustration of the production process.The system is composed of M(=3)parallel and u(=4)series machines.At each production step,a bu er is set and all the products produced by the machines at step j are stocked,transiently,into bu er j.Then,the products are supplied to the next machines at step j+1.The original materials are supplied on the left boundary.The?nal products are consumed on the right boundary.

246T.Nagatani/Physica A334(2004)243–254

into bu er j.Then,the products are supplied to the next machines(i=1;2;:::;M, j+1).The product N j(t)at bu er j and production rate i;j(t)of machine(i;j)are described by the following equations:

d N j d t =

M

i=1

i;j(t)?

M

i=1

i;j+1;(6)

d i;j d t =

1

T

[W i;j(N j(t))? i;j(t)]:(7)

Here,we assume that the control function W i;j(t)of machine(i;j)at time t depends only on the product N j(t)at bu er j and time t.The control function is given by W i;j(N j(t))=1? tanh(N j(t)?N c;i;j)+tanh(N c;i;j) =2;(8) where N c;i;j is the turning point at machine(i;j).We assume that the control function on line i is the same for any machine on the same line:W i;j(N j(t))=W i(N j(t)).

In the following sections,we study the dynamical behavior for the production sys-tem described by Eqs.(6)–(8),by using the linear stability analysis and computer simulation.

3.Linear stability analysis

Let us study the instability of the steady solution for Eqs.(6)–(8).The steady solutions are given by the uniform distribution.The steady solutions are set as N0and i;0,where i;0satis?es i;0=W i(N0).Let N i(t)and i;j(t)be small deviations from the steady solutions N0and i;0:

N j(t)=N0+ N j(t);(9) i;j(t)=W i(N0)+ i;j(t):(10) Then,the linearized equations are obtained from Eqs.(6)and(7)

d N j d t =

M

i=1

i;j(t)?

M

i=1

i;j+1(t);(11)

d i;j d t =

1

T

[W i(N0) N j(t)? i;j(t)];(12)

where W i(N0)is the derivative of control function on line i and at N=N0.

By expanding N j(t)=X exp(Ikj+zt)and i;j(t)=Y i exp(Ikj+zt),one obtains

zX=(1?e Ik)M

i=1

Y i;(13) zTY i=W i(N0)X?Y i;(14) where I is the imaginary unit.

T.Nagatani/Physica A334(2004)243–254247 By inserting Eq.(13)into Eq.(14),one obtains

Y i=W i(N0)

(1+zT)

X:(15)

By solving Eq.(15)with z,one?nds that the leading term of z is order of Ik.When Ik→0,z→0.Let us derive the long wave expansion of z,which is determined order by order around Ik≈0.By expanding z=z1(Ik)+z2(Ik)2+···,the?rst-and second-order terms of Ik are obtained:

z1=?M

i=1

W i(N0);(16)

z2=?Tz21?1

2

M

i=1

W i(N0):(17)

If z2is a negative value,the steady state becomes unstable for long wavelength modes. When z2is a positive value,the steady state is stable.Therefore,the linear stability condition is given by

T??

1

2(

M

i=1

W i(N0))

:(18)

When the adaptation time(delay)of the production lines satis?es the above rela-tion(18),the uctuation of consumption decays accordingly as going to the upstream machines.Otherwise,the production lines become unstable and the perturbation of consumption grows with time and accordingly as going to the upstream.The unstable production system results in the oscillating inventories.The neutral stability curve is given by

T=?

1

2(

M

i=1

W i(N0))

:(19)

The threshold between the stable and oscillating productions is given by the neutral stability curve.

We study the e ect of the multiple lines on the neutral stability curve.We compare the neutral stability curve of double production lines with that of the single production line.Fig.2shows the plot of the delay’s threshold T against inventory(product)N where M=2,u=200,N c;1=3,and N c;2=6.In the production system of double lines, the production rate on the?rst line is one until about N c;1=3and decreases to zero when the inventory is higher than about N c;1=3.While the production rate on the second line is one until about N c;2=6and decreases to zero when the inventory is higher than about N c;2=6.For comparison,we show the two neutral stability curves of the production systems of single and double lines.The solid line on the left-hand side indicates the neutral stability curve of the single production line.The region1 above the solid line represents the unstable state.The solid line on the right-hand side indicates the neutral stability curve of the double production lines.The regions1and 2above the solid line represents the unstable state.The neutral stability curve of the single line has a single valley.While the neutral stability curve of the double lines has two valleys and a mountain.Below each curve,the production system is stable and

248T.Nagatani/Physica A334(2004)243–254

Fig.2.Neutral stability curve and region map(phase diagram)of the production process with double series (M=2),where N c;1=3and N c;2=6.For comparison,the neutral stability curve of the single series(M=1) is also shown where N c;1=3.Region1above the neutral stability curve shows the unstable state for the single series.Regions1and2above the neutral stability curve show the unstable state for the double series. The stable region exits below each curve.

robust for the uctuating consumption.The production system of double lines is more unstable than that of the single line.

We study the e ect of the line’s number M on the neutral stability curve.We restrict ourselves to the multiple production lines with the same characteristics.Fig.3shows the plots of the delay’s threshold T against inventory N for M=1–4,where u=200 and N c;1=N c;2=N c;3=N c;4=3.Each curve has a single valley.The minimum value at the valley C1presents a critical threshold.The critical threshold decreases accordingly as the number M of production lines increases.The unstable region above the neutral curve extends with increasing M.Therefore,the production system of multiple lines becomes more unstable according as the line’s number M increases.

We study the e ect of the di erence between the two production lines on the in-stability of the production system.We consider the production system of double lines with di erent value of N c;i in the control function.Fig.4shows the neutral stability curves for N c;2=4,6,7where N c;1=3and M=2.Point C1on each curve indicates the ?rst minimum value of the delay’s threshold.Point C2indicates the maximum value. Point C3indicates the second minimum value.With increasing N c;2,point C3shifts to the right and the second minimum value does not change.While point C2shifts to the right and the maximum value increases with N c;2.Thus,the unstable region extends to higher values of inventory,but the stable region also extends below point C2.Therefore,the stable production process changes highly by varying N c;2in the control function.

T.Nagatani/Physica A334(2004)243–254249

Fig.3.Neutral stability curves for the line’s number M=1–4,where N c;1=N c;2=N c;3=N c;4=3.

Fig.4.Dependence of the neutral stability curve on N c;2for the double series(M=2),where N c;1=3. Three neutral stability curves are shown for N c;2=4,6,7.

We study the stability of the triple production lines.Fig.5shows the neutral stability curve in(N;T)parameter space for N c;1=3,N c;2=6,and N c;3=9.The solid line indicates the neutral stability curve of the triple series.The dotted line indicates the neutral stability curve of the double series with N c;1=3and N c;2=6.Points C1,C3, and C5indicate the?rst,second,and third minimum values,respectively.These points present the same value for the delay time,but the value of the corresponding inventory

250T.Nagatani/Physica A334(2004)243–254

Fig.5.Neutral stability curve of triple series(M=3)for N c;1=3,N c;2=6,and N c;3=9.Three local minimum values are indicated by points C1,C3,and C5.Two local maximum values are indicated by points C2and C4.

increases.Points C2and C4indicate the?rst and second maximum values.The neutral stability curve of triple series is consistent with that of double series until about N=7. When the inventory is higher than about N=7,the neutral stability curve of triple series deviates from that of double series.The unstable region of triple series extends to the higher values of inventory.Thus,the stability of production systems changes highly with number M of production line.

The neutral stability criterion presents the transition line(boundary)between the unstable and stable regions.However,by the linear stability analysis,it is unknown how the production process develops after the production system becomes unstable. In the following section,we carry out computer simulation.We study the dynamical behavior of the production system after the system becomes unstable.

4.Simulation

We have carried out computer simulations of Eqs.(6)–(8),using Euler integration with a time discretization of t=0:01,u=200production units,and N c;1=3.The boundary condition has been chosen as follows:

N u+1(t)=N0+ (t);(20) where (t)is a white noise with mean value (t) =0and time correlation (t) (t ) = tt =4.

We study the dynamical behavior of inventory N j(t)by varying the initial value N0. Fig.6shows the time evolution of the inventory distribution N j(t)of the double series (M=2)for adaptation time(delay)T=1:5at some values(a)N0=3,(b)N0=4,

T.Nagatani/Physica A334(2004)243–254251

Fig.6.Time evolution of the inventory distribution N j(t)of the double series(M=2)for adaptation time (delay)T=1:5at some values(a)N0=3,(b)N0=4,and(c)N0=6of initial inventory N0for t= 1800–2000,where u=200,N c;1=3and N c;2=6.

and(c)N0=6of initial inventory N0for t=1800–2000,where u=200,N c;1=3 and N c;2=6.For(a)initial value N0=3,when the production process starts from the initial uniform distribution,the process becomes unstable,the uctuating consumption propagates upstream,grows accordingly as going to the upstream,and the inventories oscillate highly in time.The oscillation has a constant period.For(b)initial value N0=4,when the production process starts from the initial uniform distribution,the process is stable,the uctuating consumption does not propagates upstream,decays accordingly as going to the upstream,and the inventory distribution remains to be the initial form.For(c)initial value N0=6,starting from the initial uniform distribution, the process becomes unstable,the perturbations of consumption propagate upstream, grow accordingly as going to the upstream,and the inventories oscillate periodically. The space–time pattern of(c)N0=6is consistent with that of(a)N0=3.This is due to the symmetry at N=4:5in the neutral stability curve of Fig.2.At two minimum points,the dynamical behavior of the double series is consistent with one another.The stable uniform distribution occurs below the neutral stability curve in Fig.2.

We study the dynamical behavior of oscillating inventories by varying the adaptation time for the production system of double series(M=2).Fig.7shows the plots of the inventory N j(2000)against bu er’s number j at initial value N0=3and t= 2000for adaptation times(a)T=2:5,(b)T=2:25,(c)T=1:75,and(d)T=1:5, where u=200,N c;1=3and N c;2=6.For(a)T=2:5,the inventory oscillates higher accordingly as going to the upstream.With high values of adaptation time T,the width of oscillation is large.Fig.8(a)shows the plot of the maximum and minimum values

252T.Nagatani/Physica A334(2004)243–254

Fig.7.Plots of the inventory N j(2000)against bu er’s number j at initial value N0=3and t=2000for adaptation times(a)T=2:5,(b)T=2:25,(c)T=1:75,and(d)T=1:5,where u=200,N c;1=3and N c;2=6.

(N max and N min)of oscillating inventories against adaptation time T for initial value N0=3where u=200,N c;1=3and N c;2=6.When the inventory distribution exhibits the uniform distribution,the maximum value agrees with the minimum value.The di erence between the maximum and minimum values is consistent with the maximum width of oscillating inventories.At T c;1=1:0,the?rst dynamical transition occurs. The stable production process changes to the oscillating production process at the?rst transition point.Furthermore,the second transition occurs at T c;2=2:0.At the second transition point,the oscillation width increases discontinuously and abruptly.Thus,we ?nd that there are the two transition points in the production process of double lines. The?rst transition point is consistent with the neutral stability point,but the second transition point cannot be predicted by the linear stability theory.

Fig.8(b)shows the plot of the maximum and minimum values(N max and N min)of oscillating inventories against adaptation time T for initial value N0=2:5,where u=200, N c;1=3and N c;2=6.At T c;1=1:5,the?rst dynamical transition occurs.The stable production process changes to the oscillating production process at the?rst transition point.Furthermore,the second transition occurs at T c;2=2:12.At the second transition

T.Nagatani/Physica A334(2004)243–254253

Fig.8.Plots of the maximum and minimum values(N max and N min)of oscillating inventories against adaptation time T,where u=200,N c;1=3and N c;2=6.(a)Initial value N0=3.(b)Initial value N0=2:5.

(c)Initial value N0=6.

point,the oscillation width increases discontinuously and abruptly.The transition points are de?nitely di erent from those in Fig.8(a).The?rst transition point agrees nearly with the neutral stability point.

Fig.8(c)shows the plot of the maximum and minimum values(N max and N min)of oscillating inventories against adaptation time T for initial value N0=6,where u=200, N c;1=3and N c;2=6.At T c;1=1:0,the?rst dynamical transition occurs.The stable production process changes to the oscillating production process at the?rst transition point.Furthermore,the second transition occurs at T c;2=2:0.At the second transition point,the oscillation width increases discontinuously and abruptly.The transition points agree with those in Fig.8(a).The curve re ected graph(c)at horizontal line N=6 is consistent with that re ected graph(a)at horizontal line N=3.This is due to the symmetry at N=4:5in the neutral stability curve of Fig.2.At two minimum points of the neutral stability curve,the dynamical behavior of the double series is consistent with one another.The stable uniform distribution appears below the neutral stability curve in Fig.2.

Thus,we?nd that the?rst dynamical transition point is determined by the linear stability theory.However,the second transition point cannot be estimated by the linear stability theory.Also,we are not able to determine the oscillation width analytically,

254T.Nagatani/Physica A334(2004)243–254

but can calculate the nonlinear dynamical behavior numerically.The production system of multiple series exhibits more complex behavior than that of the single series.It has richer physical context.

5.Summary

We have investigated the dynamical behavior of products in the production process of multiple series analytically and numerically.We have presented the extended dynamical model to take into account the production network composed of M parallel and u series machines.We have clari?ed the e ect of multiple lines on the dynamical characteristics of the production process.We have shown that the dynamical transition occurs between the stable and oscillating production states.We have found that the production process in the multiple series of machines becomes more unstable than that in the single series. We have presented the neutral stability criterion by using the linear stability analysis. We have shown that the neutral stability curve agrees with the dynamical transition line.

Acknowledgements

We would like to thank Professor Dirk Helbing for useful discussions. References

[1]T.Nagatani,Rep.Prog.Phys.65(2002)1331.

[2]D.Helbing,Rev.Mod.Phys.73(2001)1067.

[3]D.Chowdhury,L.Santen,A.Schadschneider,Phys.Rep.329(2000)199.

[4]B.S.Kerner,Netw.Spatial Econ.1(2001)35.

[5]L.A.Safonov,E.Tomer,V.V.Strygin,Y.Ashhkenazy,S.Havlin,Chaos12(2002)1006.

[6]D.Helbing,New J.Phys.5(2003)901.

[7]C.Daganzo,A Theory of Supply Chains,Springer,New York,2002.

[8]J.D.Sterman,Business Dynamics,McGraw-Hill,Boston,2000.

[9]J.A.Buzacott,J.G.Shanthikumar,Stochastic Models of Manufacturing Systems,Prentice-Hall,

Englewood Cli s,NJ,1993.

[10]D.Helbing,preprint,https://www.360docs.net/doc/2b129247.html,/abs/cond-mat/0301204,2003.

[11]T.Nagatani,D.Helbing,preprint,https://www.360docs.net/doc/2b129247.html,/abs/cond-mat/0304476,2003.

关于力的外文文献翻译、中英文翻译、外文翻译

五、外文资料翻译 Stress and Strain 1.Introduction to Mechanics of Materials Mechanics of materials is a branch of applied mechanics that deals with the behavior of solid bodies subjected to various types of loading. It is a field of study that i s known by a variety of names, including “strength of materials” and “mechanics of deformable bodies”. The solid bodies considered in this book include axially-loaded bars, shafts, beams, and columns, as well as structures that are assemblies of these components. Usually the objective of our analysis will be the determination of the stresses, strains, and deformations produced by the loads; if these quantities can be found for all values of load up to the failure load, then we will have obtained a complete picture of the mechanics behavior of the body. Theoretical analyses and experimental results have equally important roles in the study of mechanics of materials . On many occasion we will make logical derivations to obtain formulas and equations for predicting mechanics behavior, but at the same time we must recognize that these formulas cannot be used in a realistic way unless certain properties of the been made in the laboratory. Also , many problems of importance in engineering cannot be handled efficiently by theoretical means, and experimental measurements become a practical necessity. The historical development of mechanics of materials is a fascinating blend of both theory and experiment, with experiments pointing the way to useful results in some instances and with theory doing so in others①. Such famous men as Leonardo da Vinci(1452-1519) and Galileo Galilei (1564-1642) made experiments to adequate to determine the strength of wires , bars , and beams , although they did not develop any adequate theo ries (by today’s standards ) to explain their test results . By contrast , the famous mathematician Leonhard Euler(1707-1783) developed the mathematical theory any of columns and calculated the critical load of a column in 1744 , long before any experimental evidence existed to show the significance of his results ②. Thus , Euler’s theoretical results remained unused for many years, although today they form the basis of column theory. The importance of combining theoretical derivations with experimentally determined properties of materials will be evident theoretical derivations with experimentally determined properties of materials will be evident as we proceed with

机械论文的外文参考文献1

1、‘‘How can a bill of materials be de?ned so that all possible products can be built ef?ciently?’’ One way to answer it is to de?ne a set of components (called modules), each of which contains a set of primary functions. An individual product is then built by combining selected modules. 【1】Bruno Agard,Bernard Penz. A simulated annealing method based on a clustering approach to determine bills of materials for a large product family. Int. J. Production Economics 117 (2009) 389–401. 2、In this study, we propose a methodology for building a semantically annotated multi-faceted ontology for product family modelling that is able to automatically suggest semantically-related annotations based on the design and manufacturing repository. 【2】Soon Chong Johnson Lim,Ying Liu,Wing Bun Lee.A methodology for building a semantically annotated multi-faceted ontology for product family modelling. Advanced Engineering Informatics 25 (2011) 147–161. 3、The aim of this work is to establish a methodology for an effective work ing of Recon?gurable Manufacturing Systems (RMSs). These systems are the next step in manufacturing, allowing the production of any quantity of highly customised and complex products together with the bene?ts of mass production. 【3】R.Galan,J.Racero,I.Eguia,J.M.Garcia. A systematic approach for product families formation in Recon?gurable Manufacturing Systems.Robotics and Computer-Integrated Manufacturing 23 (2007) 489–502. 4、A mixed integer linear programming model is investigated that optimizes the operating cost of the resulting supply chain while choosing the product variants and can de?ne the product family and its supply chain simultaneously. 【4】Jacques Lamothe,Khaled Hadj-Hamou,Michel Aldanondo. An optimization model for selecting a product family and designing its supply chain. European Journal of Operational Research 169 (2006) 1030–1047. 5、This paper presents LCP-families, a concept to develop reference ranges for environmental impact of a new product. A new product can be catalogued as environmentally better or worse than a percentage of its competitors, depending on what position it occupies in its LCP-family.

平面设计中英文对照外文翻译文献

(文档含英文原文和中文翻译) 中英文翻译 平面设计 任何时期平面设计可以参照一些艺术和专业学科侧重于视觉传达和介绍。采用多种方式相结合,创造和符号,图像和语句创建一个代表性的想法和信息。平面设计师可以使用印刷,视觉艺术和排版技术产生的最终结果。平面设计常常提到的进程,其中沟通是创造和产品设计。 共同使用的平面设计包括杂志,广告,产品包装和网页设计。例如,可能包括产品包装的标志或其他艺术作品,举办文字和纯粹的设计元素,如形状和颜色统一件。组成的一个最重要的特点,尤其是平面设计在使用前现有材料或不同的元素。 平面设计涵盖了人类历史上诸多领域,在此漫长的历史和在相对最近爆炸视觉传达中的第20和21世纪,人们有时是模糊的区别和重叠的广告艺术,平面设计和美术。毕竟,他们有着许多相同的内容,理论,原则,做法和语言,有时同样的客人或客户。广告艺术的最终目标是出售的商品和服务。在平面

设计,“其实质是使以信息,形成以思想,言论和感觉的经验”。 在唐朝( 618-906 )之间的第4和第7世纪的木块被切断打印纺织品和后重现佛典。阿藏印在868是已知最早的印刷书籍。 在19世纪后期欧洲,尤其是在英国,平面设计开始以独立的运动从美术中分离出来。蒙德里安称为父亲的图形设计。他是一个很好的艺术家,但是他在现代广告中利用现代电网系统在广告、印刷和网络布局网格。 于1849年,在大不列颠亨利科尔成为的主要力量之一在设计教育界,该国政府通告设计在杂志设计和制造的重要性。他组织了大型的展览作为庆祝现代工业技术和维多利亚式的设计。 从1892年至1896年威廉?莫里斯凯尔姆斯科特出版社出版的书籍的一些最重要的平面设计产品和工艺美术运动,并提出了一个非常赚钱的商机就是出版伟大文本论的图书并以高价出售给富人。莫里斯证明了市场的存在使平面设计在他们自己拥有的权利,并帮助开拓者从生产和美术分离设计。这历史相对论是,然而,重要的,因为它为第一次重大的反应对于十九世纪的陈旧的平面设计。莫里斯的工作,以及与其他私营新闻运动,直接影响新艺术风格和间接负责20世纪初非专业性平面设计的事态发展。 谁创造了最初的“平面设计”似乎存在争议。这被归因于英国的设计师和大学教授Richard Guyatt,但另一消息来源于20世纪初美国图书设计师William Addison Dwiggins。 伦敦地铁的标志设计是爱德华约翰斯顿于1916年设计的一个经典的现代而且使用了系统字体设计。 在20世纪20年代,苏联的建构主义应用于“智能生产”在不同领域的生产。个性化的运动艺术在俄罗斯大革命是没有价值的,从而走向以创造物体的功利为目的。他们设计的建筑、剧院集、海报、面料、服装、家具、徽标、菜单等。 Jan Tschichold 在他的1928年书中编纂了新的现代印刷原则,他后来否认他在这本书的法西斯主义哲学主张,但它仍然是非常有影响力。 Tschichold ,包豪斯印刷专家如赫伯特拜耳和拉斯洛莫霍伊一纳吉,和El Lissitzky 是平面设计之父都被我们今天所知。 他们首创的生产技术和文体设备,主要用于整个二十世纪。随后的几年看到平面设计在现代风格获得广泛的接受和应用。第二次世界大战结束后,美国经济的建立更需要平面设计,主要是广告和包装等。移居国外的德国包豪斯设计学院于1937年到芝加哥带来了“大规模生产”极简到美国;引发野火的“现代”建筑和设计。值得注意的名称世纪中叶现代设计包括阿德里安Frutiger ,设计师和Frutiger字体大学;保兰德,从20世纪30年代后期,直到他去世于1996年,采取的原则和适用包豪斯他们受欢迎的广告和标志设计,帮助创造一个独特的办法,美国的欧洲简约而成为一个主要的先驱。平面设计称为企业形象;约瑟夫米勒,罗克曼,设计的海报严重尚未获取1950年代和1960年代时代典型。 从道路标志到技术图表,从备忘录到参考手册,增强了平面设计的知识转让。可读性增强了文字的视觉效果。 设计还可以通过理念或有效的视觉传播帮助销售产品。将它应用到产品和公司识别系统的要素像标志、颜色和文字。连同这些被定义为品牌。品牌已日益成为重要的提供的服务范围,许多平面设计师,企业形象和条件往往是同时交替使用。

机械手设计英文参考文献原文翻译

机械手设计英文参考文 献原文翻译 Company number:【WTUT-WT88Y-W8BBGB-BWYTT-19998】

翻译人:王墨墨山东科技大学 文献题目:Automated Calibration of Robot Coordinates for Reconfigurable Assembly Systems 翻译正文如下: 针对可重构装配系统的机器人协调性的自动校准 T.艾利,Y.米达,H.菊地,M.雪松 日本东京大学,机械研究院,精密工程部 摘要 为了实现流水工作线更高的可重构性,以必要设备如机器人的快速插入插出为研究目的。当一种新的设备被装配到流水工作线时,应使其具备校准系统。该研究使用两台电荷耦合摄像机,基于直接线性变换法,致力于研究一种相对位置/相对方位的自动化校准系统。摄像机被随机放置,然后对每一个机械手执行一组动作。通过摄像机检测机械手动作,就能捕捉到两台机器人的相对位置。最佳的结果精度为均方根值毫米。 关键词: 装配,校准,机器人 1 介绍 21世纪新的制造系统需要具备新的生产能力,如可重用性,可拓展性,敏捷性以及可重构性 [1]。系统配置的低成本转变,能够使系统应对可预见的以及不可预见的市场波动。关于组装系统,许多研究者提出了分散的方法来实现可重构性[2][3]。他们中的大多数都是基于主体的系统,主体逐一协同以建立一种新的

配置。然而,协同只是目的的一部分。在现实生产系统中,例如工作空间这类物理问题应当被有效解决。 为了实现更高的可重构性,一些研究人员不顾昂贵的造价,开发出了特殊的均匀单元[4][5][6]。作者为装配单元提出了一种自律分散型机器人系统,包含多样化的传统设备[7][8]。该系统可以从一个系统添加/删除装配设备,亦或是添加/删除装配设备到另一个系统;它通过协同作用,合理地解决了工作空间的冲突问题。我们可以把该功能称为“插入与生产”。 表1:合作所需的调节和量度 在重构过程中,校准的装配机器人是非常重要的。这是因为,需要用它们来测量相关主体的特征,以便在物理主体之间建立良好的协作关系。这一调整必须要达到表1中所列到的多种标准要求。受力单元和方向的调整是不可避免的,以便使良好的协同控制得以实现。从几何标准上看,位置校准是最基本的部分。一般来说,校准被理解为“绝对”,即,关于特定的领域框架;或者“相对”,即,关于另一个机器人的基本框架。后者被称为“机器人之间的校准”。 个体机器人的校准已被广泛研究过了。例如,运动参数的识别就非常受欢迎。然而,很少有对机器人之间校准的研究。玉木等人是用一种基于标记的方法,在一个可重构的装配单元内,校准机器人桌子和移动机械手之间的相互位置/方向联系。波尼兹和夏发表了一种校准方法。该方法通过两个机械手的机械接触来实现,实验非常耗时,并要求特别小心地操作。

英文文献及中文翻译

毕业设计说明书 英文文献及中文翻译 学院:专 2011年6月 电子与计算机科学技术软件工程

https://www.360docs.net/doc/2b129247.html, Overview https://www.360docs.net/doc/2b129247.html, is a unified Web development model that includes the services necessary for you to build enterprise-class Web applications with a minimum of https://www.360docs.net/doc/2b129247.html, is part of https://www.360docs.net/doc/2b129247.html, Framework,and when coding https://www.360docs.net/doc/2b129247.html, applications you have access to classes in https://www.360docs.net/doc/2b129247.html, Framework.You can code your applications in any language compatible with the common language runtime(CLR), including Microsoft Visual Basic and C#.These languages enable you to develop https://www.360docs.net/doc/2b129247.html, applications that benefit from the common language runtime,type safety, inheritance,and so on. If you want to try https://www.360docs.net/doc/2b129247.html,,you can install Visual Web Developer Express using the Microsoft Web Platform Installer,which is a free tool that makes it simple to download,install,and service components of the Microsoft Web Platform.These components include Visual Web Developer Express,Internet Information Services (IIS),SQL Server Express,and https://www.360docs.net/doc/2b129247.html, Framework.All of these are tools that you use to create https://www.360docs.net/doc/2b129247.html, Web applications.You can also use the Microsoft Web Platform Installer to install open-source https://www.360docs.net/doc/2b129247.html, and PHP Web applications. Visual Web Developer Visual Web Developer is a full-featured development environment for creating https://www.360docs.net/doc/2b129247.html, Web applications.Visual Web Developer provides an ideal environment in which to build Web sites and then publish them to a hosting https://www.360docs.net/doc/2b129247.html,ing the development tools in Visual Web Developer,you can develop https://www.360docs.net/doc/2b129247.html, Web pages on your own computer.Visual Web Developer includes a local Web server that provides all the features you need to test and debug https://www.360docs.net/doc/2b129247.html, Web pages,without requiring Internet Information Services(IIS)to be installed. Visual Web Developer provides an ideal environment in which to build Web sites and then publish them to a hosting https://www.360docs.net/doc/2b129247.html,ing the development tools in Visual Web Developer,you can develop https://www.360docs.net/doc/2b129247.html, Web pages on your own computer.

机床加工外文翻译参考文献

机床加工外文翻译参考文献(文档含中英文对照即英文原文和中文翻译) 基本加工工序和切削技术 基本加工的操作 机床是从早期的埃及人的脚踏动力车和约翰·威尔金森的镗床发展而来的。它们为工件和刀具提供刚性支撑并可以精确控制它们的相对位置和相对速度。基本上讲,金属切削是指一个磨尖的锲形工具从有韧性的工件表面上去除一条很窄的金属。切屑是被废弃的产品,与其它工件相比切屑较短,但对于未切削部分的厚度有一定的增加。工件表面的几何形状取决于刀具的形状以及加工操作过程中刀具的路径。 大多数加工工序产生不同几何形状的零件。如果一个粗糙的工件在中心轴上转动并且刀具平行于旋转中心切入工件表面,一个旋转表面就产生了,这种操作称为车削。如果一个空心的管子以同样的方式在内表面加工,这种操作称为镗孔。当均匀地改变直径时便产生了一个圆锥形的外表面,这称为锥度车削。如果刀具接触点以改变半径的方式运动,那么一个外轮廓像球的工件便产生了;或者如果工件足够的短并且支撑是十分刚硬的,那么成型刀具相对于旋转轴正常进给的一个外表面便可产生,短锥形或圆柱形的表面也可形成。

平坦的表面是经常需要的,它们可以由刀具接触点相对于旋转轴的径向车削产生。在刨削时对于较大的工件更容易将刀具固定并将工件置于刀具下面。刀具可以往复地进给。成形面可以通过成型刀具加工产生。 多刃刀具也能使用。使用双刃槽钻钻深度是钻孔直径5-10倍的孔。不管是钻头旋转还是工件旋转,切削刃与工件之间的相对运动是一个重要因数。在铣削时一个带有许多切削刃的旋转刀具与工件接触,工件相对刀具慢慢运动。平的或成形面根据刀具的几何形状和进给方式可能产生。可以产生横向或纵向轴旋转并且可以在任何三个坐标方向上进给。 基本机床 机床通过从塑性材料上去除屑片来产生出具有特别几何形状和精确尺寸的零件。后者是废弃物,是由塑性材料如钢的长而不断的带状物变化而来,从处理的角度来看,那是没有用处的。很容易处理不好由铸铁产生的破裂的屑片。机床执行五种基本的去除金属的过程:车削,刨削,钻孔,铣削。所有其他的去除金属的过程都是由这五个基本程序修改而来的,举例来说,镗孔是内部车削;铰孔,攻丝和扩孔是进一步加工钻过的孔;齿轮加工是基于铣削操作的。抛光和打磨是磨削和去除磨料工序的变形。因此,只有四种基本类型的机床,使用特别可控制几何形状的切削工具1.车床,2.钻床,3.铣床,4.磨床。磨削过程形成了屑片,但磨粒的几何形状是不可控制的。 通过各种加工工序去除材料的数量和速度是巨大的,正如在大型车削加工,或者是极小的如研磨和超精密加工中只有面的高点被除掉。一台机床履行三大职能:1.它支撑工件或夹具和刀具2.它为工件和刀具提供相对运动3.在每一种情况下提供一系列的进给量和一般可达4-32种的速度选择。 加工速度和进给 速度,进给量和切削深度是经济加工的三大变量。其他的量数是攻丝和刀具材料,冷却剂和刀具的几何形状,去除金属的速度和所需要的功率依赖于这些变量。 切削深度,进给量和切削速度是任何一个金属加工工序中必须建立的机械参量。它们都影响去除金属的力,功率和速度。切削速度可以定义为在旋转一周时

中英文翻译与文献

Monolithic integrated circuit history The monolithic integrated circuit was born in the late-1970s, has experienced SCM, MCU, the SOC three big stages. SCM namely monolithic microcomputer (Single Chip Microcomputer) the stage, mainly seeks the best monolithic shape embedded system's best architecture. “the innovation pattern” obtains successfully, has established SCM and the general-purpose calculator completely different development path. In founds on the embedded system independent development path, Intel Corporation has lasting achievements. MCU namely micro controller (Micro Controller Unit) the stage, the main technological development direction is: Expands unceasingly when satisfies the embedded application, the object system request's each kind of peripheral circuit and the interface circuit, underline its object intellectualization control. It involves the domain is related with the object system, therefore, develops the MCU heavy responsibility to fall inevitably on electrical, the electronic technology factory. Looking from this angle, Intel fades out the MCU development also to have its objective factor gradually. Is developing the MCU aspect, the most famous factory family belongings count Philips Corporation. Philips Corporation by it in embedded application aspect huge superiority, MCS-51 from monolithic microcomputer rapidly expand to micro controller. Therefore, when we review the embedded system development path, do not forget Intel and the Philips historical merit. Monolithic integrated circuit is the embedded system's road of independent development, to the MCU stage development's important attribute, seeks application system's on chip maximized solution;

机械类英文参考文献

Int J Interact Des Manuf(2011)5:103–117 DOI10.1007/s12008-011-0119-7 ORIGINAL PAPER Benchmarking of virtual reality performance in mechanics education Maura Mengoni·Michele Germani· Margherita Peruzzini Received:27April2011/Accepted:29April2011/Published online:27May2011 ?Springer-Verlag2011 Abstract The paper explores the potentialities of virtual reality(VR)to improve the learning process of mechanical product design.It is focused on the definition of a proper experimental VR-based set-up whose performance matches mechanical design learning purposes,such as assemblability and tolerances prescription.The method consists of two main activities:VR technologies benchmarking based on sensory feedback and evaluation of how VR tools impact on learning curves.In order to quantify the performance of the technol-ogy,an experimental protocol is de?ned and an testing plan is set.Evaluation parameters are divided into performance and usability metrics to distinguish between the cognitive and technical aspects of the learning process.The experi-mental VR-based set up is tested on students in mechanical engineering through the application of the protocol. Keywords Mechanical product design·Virtual reality·Experimental protocol·Learning curve· Mechanics education 1Introduction Modern society is dominated by continuous scienti?c and technical developments.Specialization has become one of the most important enablers for industrial improvement.As a result,nowadays education is more and more job-oriented and technical education is assuming greater importance.In this context both university and industry are collaborating to create high professional competencies.The?rst disseminates M.Mengoni(B)·M.Germani·M.Peruzzini Department of Mechanical Engineering, Polytechnic University of Marche, Via Brecce Bianche,60131Ancona,Italy e-mail:m.mengoni@univpm.it knowledge and innovative methods while the second pro-vides a practical background for general principles training. The main problem deals with the effort and time required to improve technical learning,while market competitiveness forces companies to demand young and high-quali?ed engi-neers in short time.Therefore,the entire educational process needs to be fast and ef?cient.Novel information technolo-gies(IT)and emerging virtual reality(VR)systems provide a possible answer to the above-mentioned questions.Some of the most important issues,in mechanical design?eld,are the investigation of such technologies potentialities and the evaluation of achievable bene?ts in terms of product design learning effectiveness and quality.While IT has been deeply explored in distance education,i.e.e-learning,VR still rep-resents a novelty. VR refers to an immersive environment that allows pow-erful visualization and direct manipulation of virtual objects. It is widely used for several engineering applications as it provides novel human computer interfaces to interact with digital mock-ups.The close connection between industry and education represents the starting point of this research. Instead of traditional teaching methods,virtual technolo-gies can simultaneously stimulate the senses of vision by providing stereoscopic imaging views and complex spatial effects,of touch,hearing and motion by respectively adopt-ing haptic,sound and motion devices.These can improve the learning process in respect with traditional teaching meth-ods and tools.The observation of students interpreting two-dimensional drawings highlighted several dif?culties:the impact evaluation of geometric and dimensional tolerances chains,the detection of functional and assembly errors,the recognition of right design solutions and the choice of the proper manufacturing operations.These limitations force tutors to seek for innovative technologies able to improve students’perception.

英文文献及中文翻译撰写格式

关于毕业设计说明书(论文)英文文献及中文翻译撰写格式 为提高我校毕业生毕业设计说明书(毕业论文)的撰写质量,做到毕业设计说明书(毕业论文)在内容和格式上的统一和规范,特规定如下: 一、装订顺序 论文(设计说明书)英文文献及中文翻译内容一般应由3个部分组成,严格按以下顺序装订。 1、封面 2、中文翻译 3、英文文献(原文) 二、书写格式要求 1、毕业设计(论文)英文文献及中文翻译分毕业设计说明书英文文献及中文翻译和毕业论文英文文献及中文翻译两种,所有出现相关字样之处请根据具体情况选择“毕业设计说明书” 或“毕业论文”字样。 2、毕业设计说明书(毕业论文)英文文献及中文翻译中的中文翻译用Word 软件编辑,英文文献用原文,一律打印在A4幅面白纸上,单面打印。 3、毕业设计说明书(毕业论文)英文文献及中文翻译的上边距:30mm;下边距:25mm;左边距:3Omm;右边距:2Omm;行间距1.5倍行距。 4、中文翻译页眉的文字为“中北大学2019届毕业设计说明书” 或“中北大学××××届毕业论文”,用小四号黑体字,页眉线的上边距为25mm;页脚的下边距为18mm。 5、中文翻译正文用小四号宋体,每章的大标题用小三号黑体,加粗,留出上下间距为:段前0.5行,段后0.5行;二级标题用小四号黑体,加粗;其余小标题用小四号黑体,不加粗。 6、文中的图、表、附注、公式一律采用阿拉伯数字分章编号。如图1.2,表2.3,附注3.2或式4.3。 7、图表应认真设计和绘制,不得徒手勾画。表格与插图中的文字一律用5号宋体。

每一插图和表格应有明确简短的图表名,图名置于图之下,表名置于表之上,图表号与图表名之间空一格。插图和表格应安排在正文中第一次提及该图表的文字的下方。当插图或表格不能安排在该页时,应安排在该页的下一页。 图表居中放置,表尽量采用三线表。每个表应尽量放在一页内,如有困难,要加“续表X.X”字样,并有标题栏。 图、表中若有附注时,附注各项的序号一律用阿拉伯数字加圆括号顺序排,如:注①。附注写在图、表的下方。 文中公式的编号用圆括号括起写在右边行末顶格,其间不加虚线。 8、文中所用的物理量和单位及符号一律采用国家标准,可参见国家标准《量和单位》(GB3100~3102-93)。 9、文中章节编号可参照《中华人民共和国国家标准文献著录总则》。

机械类方向的论文参考文献

机械类方向的论文参考文献 机械类方向的论文参考文献 在日常学习和工作中,大家最不陌生的就是论文了吧,通过论文写作可以培养我们的科学研究能力。那么你知道一篇好的论文该怎么写吗?下面是小编为大家收集的机械类方向的论文参考文献,希望对大家有所帮助。机械类论文参考文献1 [1] 王遐.随车起重机行业扫描[J].工程机械与维修,2006(3):68-71 [2] 王金诺,于兰峰.起重运输机金属结构[M].北京:中国铁道出版社,2002 [3] 卢章平,张艳.不同有限元分析网格的.转化[J].机械设计与研究,2009(6):10-14 [4] 朱秀娟.有限元分析网格划分的关键技巧[J].机械工程与自动化,2009(1):185-186 [5] 姚卫星.结构疲劳寿命分析[M].北京:国防工业出版社,2003.50-54 [6] 桥斌.国内外随车起重机的对比[J].工程机械与维修,2006(7):91-92 [7] 王欣,黄琳.起重机伸缩臂截面拓扑优化[J].大连理工大学学报,2009(3):374-379 机械类论文参考文献2 1 金会庆.驾驶适性.合肥:安徽人民出版社,1995. 2 蔡辉、张颖、倪宗瓒等.Delphi法中评价专家的筛选.中国卫生事业管理,1995,1:49~55. 3 侯定丕.管理科学定量分析引论.合肥:中国科技大学出版社,1993. 4 王有森.德尔菲法. 医学科研管理学(刘海林主编.第一版),北京:人民卫生出版社,1991:279~289. 5 安徽省劳动保护教育中心编.劳动安全、卫生国家标准及其编制说明汇编第三辑,1987. 6 Kaoru Ishikawa. Guide to Quality Control. Asian Productivity Organization.Tokyo. 1982:42~49 机械类论文参考文献3 [1]郑文纬,吴克坚 .机械原理[M] .北京:高等教育出版社,1997 [2]濮良贵.纪名刚.机械设计[M] .北京:高等机械出版社.2006 [3]杨家军.机械系统创新设计[M] .武汉:华中科技大学出版社.2000 [4]高志.黄纯颖. 机械创新设计[M] . 北京:高等机械出版社.2010 [5]王晶.第四届全国大学生机械创新设计大赛决赛作品选集. 北京:高等教育出版社,2011 [6]黄华梁、彭文生.创新思维与创造性技法. 北京:高等教育出版社,2007 [7]李学志.计算机辅助设计与绘图[M] .北京:清华大学出版社.2007 [8]吴宗泽.机械设计手册[M] .北京:机械工业出版社.2008 [9]颜鸿森.姚燕安.王玉新等译.机构装置的创造性设计(creative design of mechanical devices)[M] .北京:机械工业