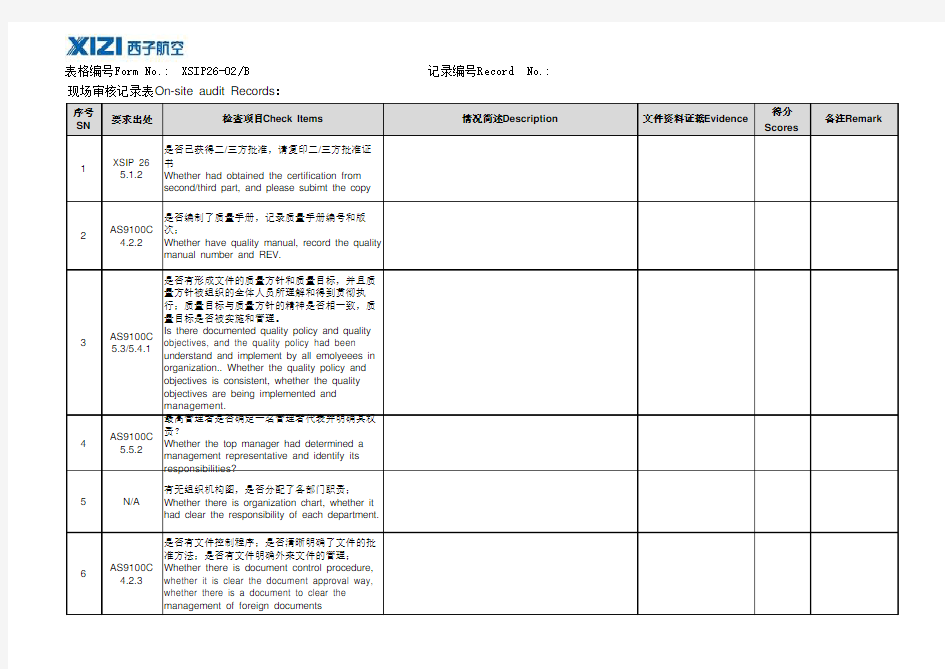

现场审核记录表

得分Scores

1XSIP 26

5.1.2

是否已获得二/三方批准,请复印二/三方批准证

书

Whether had obtained the certification from

second/third part, and please subimt the copy

2AS9100C

4.2.2

是否编制了质量手册,记录质量手册编号和版

次;

Whether have quality manual, record the quality

manual number and REV.

3AS9100C

5.3/5.4.1

是否有形成文件的质量方针和质量目标,并且质

量方针被组织的全体人员所理解和得到贯彻执

行;质量目标与质量方针的精神是否相一致,质

量目标是否被实施和管理。

Is there documented quality policy and quality

objectives, and the quality policy had been

understand and implement by all emolyeees in

organization.. Whether the quality policy and

objectives is consistent, whether the quality

objectives are being implemented and

management.

4AS9100C

5.5.2

最高管理者是否确定一名管理者代表并明确其权

责?

Whether the top manager had determined a

management representative and identify its

responsibilities?

5N/A 有无组织机构图,是否分配了各部门职责;Whether there is organization chart, whether it had clear the responsibility of each department.

6AS9100C

4.2.3

是否有文件控制程序;是否清晰明确了文件的批

准方法;是否有文件明确外来文件的管理;

Whether there is document control procedure,

whether it is clear the document approval way,

whether there is a document to clear the

management of foreign documents

备注Remark 要求出处

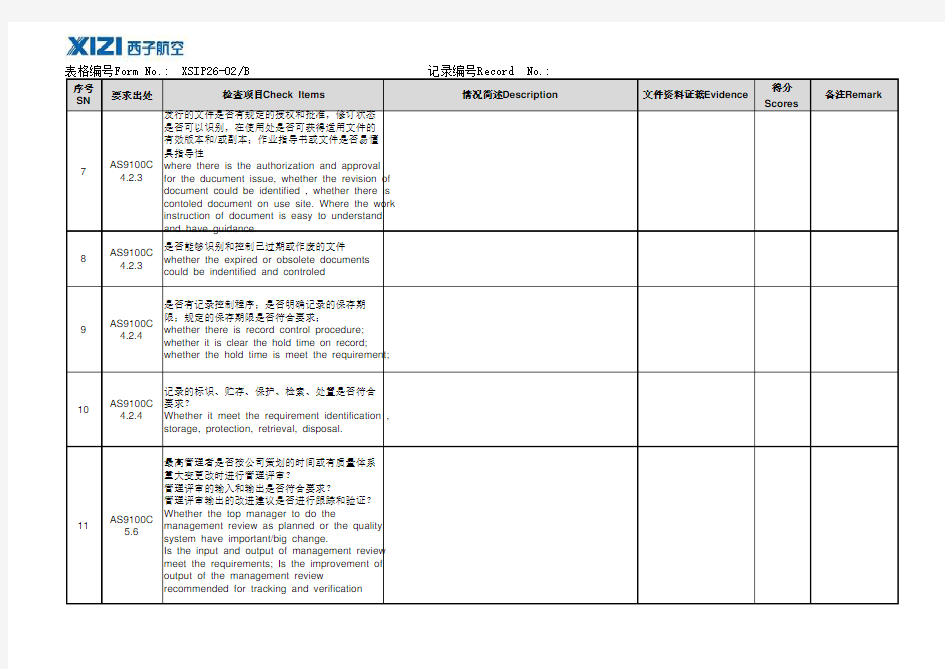

现场审核记录表On-site audit Records:

序号

SN

检查项目Check Items情况简述Description文件资料证据Evidence

得分Scores

7AS9100C

4.2.3

发行的文件是否有规定的授权和批准,修订状态

是否可以识别,在使用处是否可获得适用文件的

有效版本和/或副本;作业指导书或文件是否易懂

具指导性

where there is the authorization and approval

for the ducument issue, whether the revision of

document could be identified , whether there is

contoled document on use site. Where the work

instruction of document is easy to understand

and have guidance.

8AS9100C

4.2.3

是否能够识别和控制已过期或作废的文件

whether the expired or obsolete documents

could be indentified and controled

9AS9100C

4.2.4

是否有记录控制程序;是否明确记录的保存期

限;规定的保存期限是否符合要求;

whether there is record control procedure;

whether it is clear the hold time on record;

whether the hold time is meet the requirement;

10AS9100C

4.2.4

记录的标识、贮存、保护、检索、处置是否符合

要求?

Whether it meet the requirement identification ,

storage, protection, retrieval, disposal.

11AS9100C

5.6

最高管理者是否按公司策划的时间或有质量体系

重大变更改时进行管理评审?

管理评审的输入和输出是否符合要求?

管理评审输出的改进建议是否进行跟踪和验证?

Whether the top manager to do the

management review as planned or the quality

system have important/big change.

Is the input and output of management review

meet the requirements; Is the improvement of

output of the management review

recommended for tracking and verification

序号

SN

要求出处检查项目Check Items情况简述Description文件资料证据Evidence备注Remark

得分Scores

12AS9100C

8.2.2

是否编制内部审核程序文件?

是否制定内部审核计划,并按计划进行内审?

是否编制内部审核报告?

对于内审过程中发现的不符合项,是否组织进行

整改并跟踪其整改状态?

Is there the document about internal audit

procedure;

Is the internal audit plan developed , and

carried out according to the plan;

Is the internal audit report prepared?

For the findings from internal audit, whether to

carry out the improvent action and track the

status.

13AS9100C

7.2.2

是否进行合同或订单的评审,识别存在的风险并

采取相应的措施以降低风险?

Is there a review for contract or order to identify

the risk and take some action to reduce the risk.

14AS9100C

7.5.4

对于顾客提供的原料、文件、工装等是否进行验

证、保护、维护管理?

当顾客提供的财产出现丢失、损坏或不适用时是

否通知顾客?

For the material,document,toolings etc. provide

by customer, whether carry out the verification,

protection and maintenance.

15有无关于客户投诉的处置流程

whether there is deal process for customer complaints

16是否进行顾客满意度调查,是否针对客户提出的

改进建议制定了整改措施;

Whether the customer satisfaction survey is

carried out, whether the improvement action are

carried out for customer suggestions.

情况简述Description文件资料证据Evidence备注Remark

序号

SN

要求出处检查项目Check Items

得分Scores

17AS9100C

7.4.1

是否保持并维护一份批准供应商目录?

是否对供应商进行评价和再评价,评价过程中是

否形成报告,对于评价过程中存在的问题是否跟

踪?

Whether there is a approved suppliers list and

be maintained?

Whether to evaluation and re-evaluation for the

supplier, whether issue the evaluation report,

whether follow up the findings of evaluation.

18AS9100C

7.4.2

采购/外协合同中的质量要求和技术要求是否完

整?

是否把顾客的相关要求传递给次级供应商?

Is the quality and tachnical requirement is

completed in the procurement/outsourcing

contreact.

Whether sent the customer's requirement to the

sub suppliers.

19AS9100C

7.4.3

采购零件、材料有无实施恰当的进货检查;所有

采购的材料是否经过验证,以确保其满足要求后

才可以投入生产使用;是否保存了检查和验证的

而证据?

Whether there is appropriate incoming

inspection for the parts and materials of

procurement.whether all the procurement

material had been validated to ensure them

meet the requirement before used for

produceion. whether the evidence of inspection

20仓库保管条件是否恰当;是否执行先入先出管理;

Whether the storage conditions is appropriate; whether the management ruler is the first in the first out.

21AS9100C

6.4

如需要,是否对工作环境进行监控?

If necessary, whether to monitor the work

environment?

22AS9100C

6.3

是否设有设备台账及工装台账,工装是否定检定

查;

Whether there are equipments and toolings

lists, and whether do the regular inpection or

文件资料证据Evidence备注Remark

序号

SN

要求出处检查项目Check Items情况简述Description

得分Scores

23AS9100C

6.3

设备是否进行维护和保养以确保其处于完好状

态,并有相关记录?

Whether maintenance equipment to ensure that

the equipment is in good condition, and hold the

maintenance records?

24当发现设备不符合要求时,是否对以往产品的有效性进行了评价和记录

After the equipment isn't in confromity with the requirements, whether evaluate and record the effectiveness of the previous products.

25设备调整后,有无进行动作确认和产品品质确认的要求

After equipment adjustment, whether there is action to confirm and product quality requirement.

26有无异常情况处置流程,是否有改善措施;Is there exception handling process, whether there is improvement plan.

27AS9100C

7.6

是否有计量器具台账?

所有的监视和测量装置是否有定检标识并在有效

期内?

数控测量软件是否经过验证?

Is there a gage list?

Whether all monitoring and measuring devices

identified and in the period of validity?

Whether the software had been verified?

28AS9100C

7.5.3

是否对自进货、制造到出厂全过程的零件(产

品)进行标识管理;

现场是否对不同状态零件进行分区管理;

whether take the identify for the parts(products)

during the whole process from purchase,

manufacture to deliver.

29AS9100C

7.5.5

对产品的搬运方式是否作了规定并采取了适当的

防护措施;

是否有效地控制易变质材料的有效期?

Whether indefied the requirement for handing

and has taken some appropriate protection

action.

文件资料证据Evidence备注Remark

序号

SN

要求出处检查项目Check Items情况简述Description

得分Scores

30AS9100C

7.5.2

是否有特殊过程;

是否对特殊过程进行确认和再确认;

是否对关键和特殊过程及有可能造成污染的过程

实施连续监控和/或由具有资格的人员来完成.

Whether there are some special process?

Whether to confirm and re-confirm the special

processes?

Whether to do the continu monitoring and/or by

qualified personnel for the key and special

processes and processes that may cause

pollution.

31是否对过程进行了监视,当监视结果不符合要求时是否采取了适合的纠正和预防措施

Whether the processes are monitored, whether take some corrcetive and preventive action for the monitored result doesn't meet the requirement.

32是否有高温测量过程;高温测量的时间间隔是否符合规范要求;

Whether there is the process of high temperature measurement. Whether the frequency of high temperature measurement is in compliance with the specification requirements.

33AS9100C

8.2.4

是否编制产品的接收准则,并按准则进行检验?

Is the preparation of the product acceptance

criteria, and in according to it for inspection.

34AS9100C

8.2.4

产品的紧急放行是否经过批准?

The energency release had been approved.

35AS9100C

7.5.1

自进货、制造到出厂全过程有无制定标准作业文

件并按标准实施作业?

Whether there is the standard work document

for the process from the purchase,

manufacturing to deliver and taken.

序号

SN

要求出处检查项目Check Items情况简述Description文件资料证据Evidence备注Remark

得分Scores

36AS9100C

7.5.1

数控加工软件使用前是否经过确认?

数控程序的编制、使用、更改过程控制是否符合

要求?

Is the software of NC machining had been

approved before use?

Is the process of development, used and

change control of NC program meet the

requirement.

37AS9100C

7.5.1

生产过程中的工艺、设备、工装和软件程序的更

改是否进行控制?

工程更改或其他有影响的更改是否进行首件检

验?

Does the change of process, equipments,

toolings and softwave program is controled.

Whether do FAI for engeering change or

otherwise affected?

38是否编制了首件检验计划,是否有首件检验记录Whether issue the FAI plan , whether there is the FAI record?

39是否有能够维持提高作业现场为中心的日常性5S 活动 (整理、整顿、清洁、清扫、素养) Whether there is a daily 5S action to maintain the activity of the site as the center.

40AS9100C

8.3

有无不合格品控制的程序文件

Whethet there is the procedure for Nonconfirm

part control.

41AS9100C

8.3

有无返工、修理及报废处理流程返工、修理有

无记录,有无效果再确认

Is there flow for rework, repair and scrap

process; Is there the record for rework, repair ,

and re-confirm record for them.

42AS9100C

8.3

是否规定了存在质量问题的产品冻结和解冻的权

责

Whether defined the responsibility for holding

and releasing of have quality problem product .

43AS9100C

8.3

不符合要求的产品是否得到控制以防止其非预期

的使用和交付

Whether the nonconfirm product is controlled to

prevent its unintended use and delivery.

序号SN

情况简述Description文件资料证据Evidence备注Remark 要求出处检查项目Check Items

得分Scores

44AS9100C

8.5.2

是否形成了纠正措施的程序文件;是否按程序文

件管理和控制纠正措施

Is there documented for corrective action;

whether management and controled the actiong

according to procedure.

45AS9100C

8.5.3

是否形成了预防措施的程序文件;是否按程序文

件管理和控制预防措施

Is there documented for preventive action;

whether management and controled the actions

according to procedure.

46AS9100C

8.4

是否进行了质量信息的收集和分析,分析过程是

否使用了质量工具

Where collect and analysis the quality

information, whether use some quality tools

during analysis process.

47AS9100C

8.5.1

是否利用质量数据分析结果寻找质量管理体系持

续改进的机会,是否对质量分析结果采取必要的

改进措施

whether find the improve point by the quality

data analysis for quality management system,

whethere take some necessary improvement

action for the analysis result.

48是否有完善的人员培训及印章管理体制Whether there is a perfect procedure for personnel training and stemp management

49是否制定必要的教育训练步骤方面的文件并实施;关键岗位有无资格认定;是否保存了人员的培训资料

Documentation and implementation of necessary stemps of training process; whether there is qualified requirement of Key positions; whether save the records of training.

50是否有自己的实验室,实验过程是否符合标准要

求;

Whether there is its own laboratory, whether the

test process is meet with the standard

requirement.

陪审人员:

Entourage:

备注Remark

序号

SN

要求出处检查项目Check Items情况简述Description文件资料证据Evidence

审核人员:

Auditor