美标材料A36

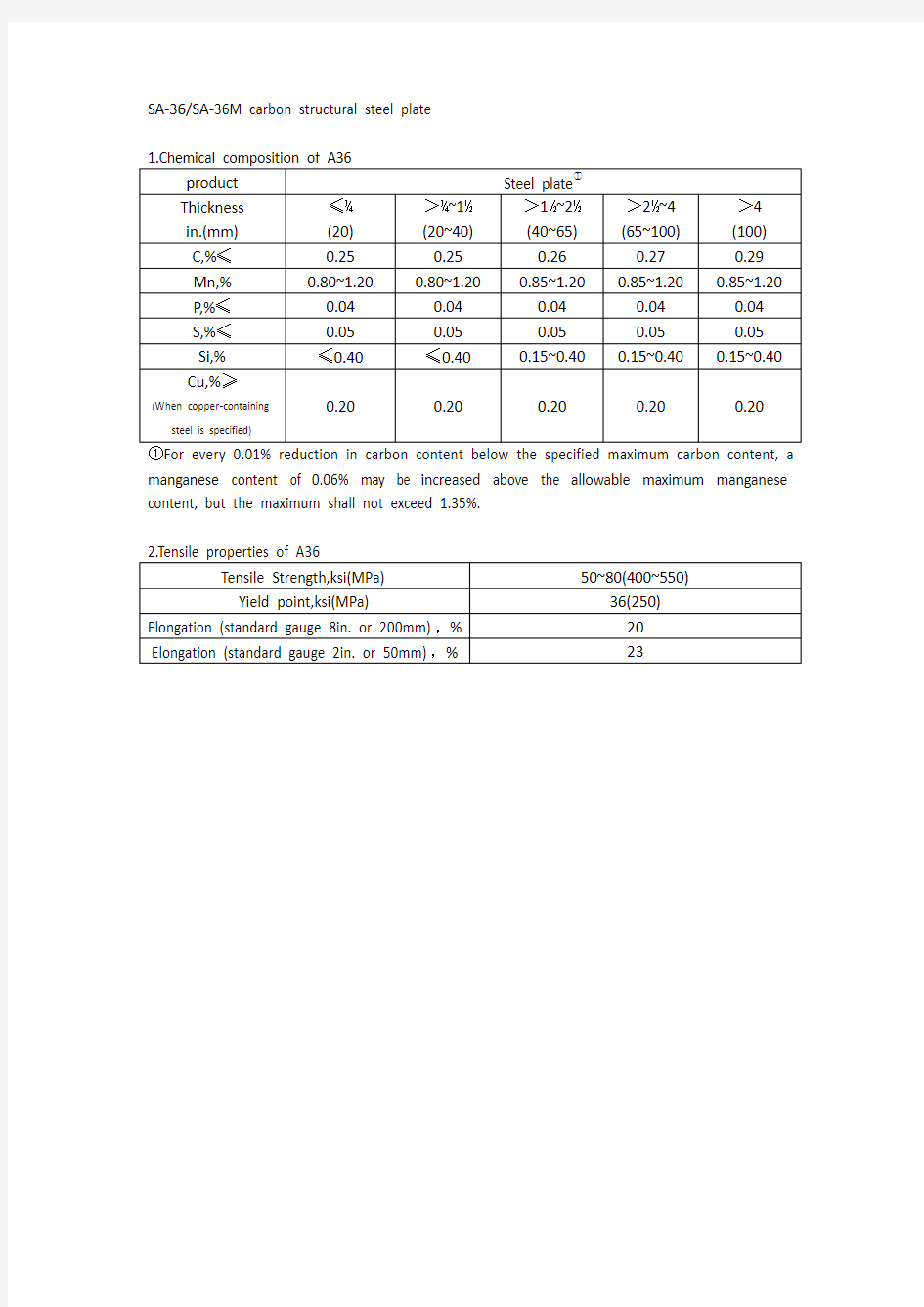

SA-36/SA-36M carbon structural steel plate

①For every 0.01% reduction in carbon content below the specified maximum carbon content, a manganese content of 0.06% may be increased above the allowable maximum manganese content, but the maximum shall not exceed 1.35%.

美标材料SA542

Quenched and tempered chromium-molybdenum and chromium-molybdenum-vanadium alloy steel plates for pressure vessels 1. SA542 is suitable for two 21?4Cr-1Mo and three Cr-Mo-V alloy steel plates used in quenching and tempering conditions to manufacture welded pressure vessels and components. 2. There are five types of steel supplied by SA542, codenamed “A”, “B”, “C”, “D”and “E”. Type B and Type A are identical except for the limited range of carbon, phosphorus, sulfur and nickel. Steel is also divided into five categories, the strengths of which are listed below. composition to meet the specified mechanical properties. The minimum thickness of the steel plate is limited to 3/16 in. (5 mm) 3, SA542 steelmaking method: SA542 steel must be killed steel, and must meet the A20/A20M standard fine austenite grain size requirements. 4, SA542 heat treatment 4.1 SA542 All steel plates are subjected to normalizing heat treatment. At this time, the steel plate may be heated to an appropriate austenitizing temperature for a sufficient time to make the temperature uniform throughout the thickness and quenched by spraying or immersion in a suitable liquid medium. The minimum austenitizing temperature of the D-type material should be 1650℉(900 ℃). The minimum austenitizing temperature of the E-type material should be 1850℉(1010 ℃). 4.2 After quenching, the tempering of the steel plate has obtained the specified tensile performance requirements. When tempering, the steel plate is heated to a suitable temperature and kept for a period of time, and the holding time is not less than 30 min/in. (1.2 min/mm), but 5、4.3 For steel plates with a thickness greater than 4 in. (100 mm), before the heat treatment according to 4.2, for A, B, C and D steel plates at 1650~1850℉(900~1010℃), for E steel at 1850~2050℉( Pre-normalizing treatment or water quenching at a temperature within the temperature range of 1010 to 1120℃). 6、4.4 Order steel plates not subjected to heat treatment in accordance with the requirements of Articles 4.1 to 4.3 shall be subjected to stress relief treatment or annealed condition, and the minimum stress relief treatment temperature of the steel plate shall be 1200℉(650℃) except for the E-shaped steel plate. , other models of steel should be 1050℉(565℃).

美标与国标压力、管径、法兰关系对照表

美标与国标压力、管径、法兰关系对照表 ANSI是美国国家标准学会(AMERICAN NATIONAL STANDARDS INSTITUTE: ANSI)的简称。 一、美标压力与公称压力关系 ANSI标准压力磅级与公称压力的关系表

1bf/in2=== 1kgf/cm2=in2= 1bar=in2=cm2 ASME标准压力磅级与公称压力的关系表 二、美标压力与公称压力关系 ANSI标准管径与国标管径比较

ANSI GB ANSI GB ANSI GB 1/2in4in100mm12in300mm 1in6in150mm14in350mm 2in50mm8in200mm16in400mm 3in80mm10in250mm18in450mm 20in500 mm24in600 mm30in 三、美标、日标、德标法兰尺寸表 法兰标准尺寸表 一、ANSI150、300、400、600、900、1500、2500RF法兰尺寸表(美標)

公称 通径外径 螺栓孔 中心圆 直径 连接凸 出部分 直径 内径 焊接处颈 部直径 颈根 部直 径 法兰 厚度 焊接法兰长度 连接凸 出部分 高度 螺栓 孔直 径 数 量 螺栓 直径 DN D D1D2A B C E F G J L1L2L3L d n M 209870432128202738135316 22915412 251085127352534514914561715412 321188935433242605916572115412 401277341504048676518622215412 5015292536250837819642519416 6517810563756573959124702919416 801901277891808910810824703019416 100229157102116100114140135247633 30519816 125254216186128144125141165164248937238M20 150279216154171150168197192258940238M20 2003432702032212002192482462910244238M20 25040636232425527625027330530530102492512M22 30048343238130532730032436536532114562512M22 表 2 ANSI 公称 通径外径 螺栓孔 中心圆 直径 连接凸 出部分 直径 内径 焊接处颈 部直径 颈根 部直 径 法兰 厚度 焊接法兰长度 连接凸 出部分 高度 螺栓 孔直 径 数 量 螺栓 直径

美标材质规格

ASTM A1-00(2005) 碳素钢T型钢轨规格 ASTM A1000-05 特种弹簧质量级碳钢丝及合金钢丝规格 ASTM A100-07 硅铁规格 ASTM A1001-01(2006) 硅铁规格 ASTM A1002-99(2003) 镍-铝有序合金铸件规格 ASTM A1003/A1003M-05 冷成形框式构件用金属和非金属镀层碳素钢薄板规格 ASTM A1004/A1004M-99(2004) 准备用作冷成形框架构件的金属、涂漆金属和非金属涂敷钢薄板规格 ASTM A1005/A1005M-00(2004) 平端纵焊缝和螺旋焊缝双重埋弧焊干线用黑钢管规格ASTM A1006/A1006M-00(2004) 平端激光束焊接干线用黑钢管规格 ASTM A1007-02(被ASTM A1007-07代替) 钢丝绳用碳素钢丝规格 ASTM A1008/A1008M-07(被ASTM A1008/A1008M-07a 代替) 高强度低合金冷轧碳素结构钢薄板以及可成型性、溶液硬化和可烘烤硬化性经改进的高强度低合金冷轧碳素结构钢薄板规格 ASTM A1008/A1008M-07a 高强度低合金冷轧碳素结构钢薄板以及可成型性、溶液硬化和可烘烤硬化性经改进的高强度低合金冷轧碳素结构钢薄板规格 ASTM A1009-05 高频(10kHz-1 MHz)电力变压器和滤波感应器用软磁MnZn铁芯材料标准规范 ASTM A1010/A1010M-01e1 更高强度马氏体不锈钢厚板、薄板和带材规格 ASTM A101-04 铬铁规格 ASTM A1011/A1011M-06b(被ASTM A1011/A1011M-07代替) 高强度低合金冷轧碳素结构钢薄板和带材、可成型性经改进的高强度低合金冷轧碳素结构钢薄板和带材以及具有超高强度的低合金冷轧碳素结构钢薄板和带材的规格 ASTM A1011/A1011M-07 高强度低合金冷轧碳素结构钢薄板和带材、可成型性经改进的高强度低合金冷轧碳素结构钢薄板和带材以及具有超高强度的低合金冷轧碳素结构钢薄板和带材的规格 ASTM A1012-02(2007) 带整体式散热片的铁素体、奥氏体和二相合金钢冷凝器与热交换器无缝管及焊接管的规格 ASTM A1013-00(2005) 用伏特计、安培计和瓦特计测定可控温度下软磁芯部件的高频(10 kHz-1 MHz)磁芯损耗的标准试验方法 ASTM A1014/A1014M-06 高温工作用沉淀硬化螺栓材料(UNS N07718)规格 ASTM A1015-01(2005) 卫生设施用管状产品管内图像检测指南 ASTM A1016/A1016M-04A 铁素体合金钢、奥素体合金钢和不锈钢管通用要求规格 ASTM A1017/A1017M-07 压力容器用铬钼钨合金钢中厚板规格 ASTM A1018/A1018M-06c(被ASTM A1018/A1018M-07代替) 碳素钢、市售钢、拉制钢、结构钢、高强度低合金钢、可成型性经改进的高强度低合金钢以及超高强度钢热轧薄板、带材和特厚卷材规格 ASTM A1018/A1018M-07 碳素钢、市售钢、拉制钢、结构钢、高强度低合金钢、可成型性经改进的高强度低合金钢以及超高强度钢热轧薄板、带材和特厚卷材规格 ASTM A1019/A1019M-01(2007) 下水道和排水管用聚合物预涂的直径为36英寸或不足36英寸[900 mm]的闭合肋钢管规格 ASTM A1019/A1019M-01(被ASTM A1019/A1019M-01(2007)代替) 下水道和排水管用聚合物预涂的直径为36英寸或不足36英寸[900 mm]的闭合肋钢管规格 ASTM A1020/A1020M-02 锅炉、过热器、热交换器和冷凝器设备用溶焊碳钢和碳锰钢管道规

美标标准尺寸及重量对照表

不锈钢按照ASME B36 10M-1996标准尺寸及重量 对照表 标准尺寸及重量对照表 SCH 是Schedule的缩写. SCH No. 为管壁厚度号! 管道壁厚的SCH表示 Sch就是"schedule" ,管道的壁厚等级 SCH是设计压力与设计温度下材料的许用应力的比值乘以1000,并经圆整的数值。即:SCH.=P/〔σ〕t×1000 式中:P——设计压力,MPa 〔σ〕t——设计温度下材料的许用应力,Mpa 管道表号(SCH.)并不是壁厚,是一壁厚系列。同一管径,不同的管道表号,其壁厚不同。SCH.愈大者管壁愈厚。 对于碳钢管壁厚系列有SCH.10,20,30,40,60,80,100,120,140,160 等10 个等级。 对于不锈钢管壁厚系列有SCH.5S,10S,40S,80S 4 级。 中国管道设计习惯,一般用ODxSn,即管道公称外径x壁厚。例OD108x4 每米公斤=(外径-壁厚)×壁厚×0.02491 每英尺磅=每米公斤×0.30481/0.4536 英寸毫米单位壁厚. 壁厚. 重量重量 . mm 英寸公斤/米. 磅/英尺 1/8” 10.3 10S 1.24 0. 9 0.28 0.19 1/8”10.3 STD-40 1.73 0.068 0.37 0.25 1/8” 10.3 XS-80 2.41 0.095 0.48 0.32 1/4” 13.7 10S 1.65 0.065 0.50 0.34 1/4” 13.7 STD-40 2.24 0.088 0.64 0.43 1/4” 13.7 XS-80 3.02 0.119 0.81 0.55 3/8” 17.1 10S 1.65 0.065 0.64 0.43 3/8”17.1 STD-40 2.31 0.091 0.85 0.57 3/8” 17.1 XS-80 3.20 0.126 1.11 0.75 1/2” 21.3 5S 1.05 0.042 0.53 0.36 1/2”21.3 10S 2.11 0.083 1.01 0.68 1/2” 21.3 STD-40 2.77 0.109 1.28 0.86 1/2” 21.3 XS-80 3.73 0.147 1.63 1.10

钢材材质国标与美标对照表

钢材材质国标与美标对照表 浏览字体:大中小 美国 中国GB 日本JIS 德国 钢种ASTM 牌号牌号标准号钢号钢号材料号标准号 (A53 钢 GGP G3452 (Q235 )种F) (St33) 1.0033 DIN1626 STPY41 G3457 A283-D A135-A STPG38 G3454 (St37) 1.0110 DIN1626 A53-A STPG38 G3456 A106-A St37-2 1.0112 DIN17175 St35.8 1.0305 STS38 G3455 DIN1629/4 St35.4 1.0309 碳素10 A179-C 钢管STB30 G3461 St35.8 1.0305 DIN17175 A214-C A192 STB33 G3461 St35.8 1.0305 DIN17175 A226 STB35 G3461 St35.8 1.0305 DIN17175 A315-B (St42) 1.0130 STPG42 G3454 DIN1626 A53-B St42-2 1.0132 20 STPT42 G3456 A106-B St45-8 1.0405 DIN17175 STB42 G3461 A106-B St45-8 1.0405 DIN17175

A178-C St45-4 1.0309 DIN1629/4 STS42 G3455 A210-A- 1 G345 1.083 STS49 5 St52.4 2 DIN1629/4 低合16Mn A210-C STPT49 G345 St52 1.083 DIN1629/3 金 6 1 钢管 G346 15MnV STBL39 4 G346 16Mn STPL39 A333-1.6 0 1.035 TT St35N SEW680 G346 6 15MnV STBL39 A334-1.6 4 低A333-7.9 1.035 SEW680 09Mn2V TT St35N 温A334-7.9 6 钢G346 SEW680 管STPL46 0 A333-3.4 1.563 (06A1NbCuN) 10Ni14 STBL G346 A334-3.4 7 4 A333-8 1.566 SEW680 (20Mn23A1) X8Ni9 A334-8 2

美标与国标金属材质对照表

美国标准日本标准国标标准A283-C SS400Q235-A,B,C GB/T3274-1988A285-C SB41020R,16MnR GB6654-1996A516-70A516-60SGV480/SGV41016MnR GB6654-1996A36 SS400Q235-A GB/T3274-1988A240 TP304SUS3040Cr18Ni9GB/T4237-92A240 TP304L SUS304L 0Cr19Ni10GB/T4237-92A240 TP316SUS3160Cr17Ni12Mo2GB/T4237-92A240 TP316L SUS316L 0Cr17Ni14Mo2GB/T4237-92A240 TP317SUS3170Cr19Ni13Mo3GB/T4237-92A240 TP317L SUS317L 00Cr19Ni13Mo3 GB/T4237-92A53A,B STPG37010,20GB/T8163-1999GB9948-88A106B STPT37020GB/T8163-1999GB9948-88A312-TP304 SUS304TP 0Cr18Ni9GB/T14976-2002A312-TP304L SUS304LTP 00Cr19Ni10GB/T14976-2002A312-TP316SUS316TP 0Cr17Ni12Mo2GB/T14976-2002A312-TP316L SUS316LTP 00Cr17Ni12Mo2GB/T14976-2002A312-TP317L SUS317LTP 00Cr19Ni13Mo3 GB/T14976-2002A179STB34010,20GB9948-88A249 TP304SUS304TB 0Cr18Ni9GB/T13296-91A249 TP304L SUS304LB 00Cr19Ni10GB/T13296-91A249 TP316 SUS316TB 0Cr17Ni12Mo2GB/T13296-91A249 TP316L SUS316LTB 00Cr17Ni12Mo2GB/T13296-91A249 TP317L SUS317LTB 00Cr19Ni13Mo3 GB/T13296-91A213 TP304SUS304TB 0Cr18Ni9GB/T13296-91A213 TP304L SUS304LTB 00Cr19Ni10GB/T13296-91A213 TP316L SUS316LTB 00Cr17Ni14Mo2 GB/T13296-91 317J1SS 317J1SS N/A 管道 管 (包括附件及内部) 钢板 资料转换到中国的标准/替代材料

美标材料对照清单

- 17 - ? Comparison list for casting & forging. Casting Forging Nominal Designation ASTM JIS BS ASTM JIS BS A126-CLASS A G5501-FC20 1452-14 - - - A126-CLASS B G5501-FC25 1452-17 - - - Cast iron A126-CLASS C G5501-FC30 1452-20 - - - A197 G5702-FCMB28 6681-B28-10 - - - A47-32510 G5702-FCMB35 6681-B32-10 Malleable iron A47-35018 G5702-FCMB37 - - - - A395 G5502-FCD40 2789-420 - - - - G5502-FCD45 2789-450 - - - Ductile iron A536 G5502-FCD55 2789-550 - - - A216-WCA G5151-SCPH1 - A105 G3201-SF45 1503-161B - G5101-SC46 1504-161 - - - A216-WCB G5151-SCPH2 B A105 G3201-SF50 1503-161C WCC - - - - - Carbon steel - G5101-SC55 C - - - CARBON - 1/2Mo A217-WC1 G5111-SCA51 1504-240 A182-Fl - 1503-240B 1/2Cr - 1/2Mo - 1/2Ni A217-WC4 - - - - - 1Cr - 1/2Mo 1/2Ni A217-WC5 - - A182-FL2 - 1503-620 11/4Cr – 1/2Mo A217-WC6 - F11 - - - 21/4Cr – 1/2Mo A217-WC9 G5111-SCA51 F22 - 1503-622 - 3Cr – 1Mo - - - F21 - - 5Cr – 1/2Mo (C 0.15) - - - F5 - 1503-625 5Cr – 1/2Mo (C 0.25) A217-C5 - 1504-629 F5A - - 7Cr – 1/2Mo - G5111-SCA52 - F7 - - 9Cr – 1Mo A217-C12 - 1504-629 F9 - - CARBON STEEL FORLOW TEMP A352-LCB - 4242-GRA A350-LF1 - - CARBON - Si - - - A350-LF2 - - CARBON-1Mo FORLOW TEMP A352-LC1 - - - - - 21/2Ni A352-LC2 - - - - - 31/2Ni A352-LCB - - A350-LF3 - - Cr – Ni – Cu – Al - - - A350-LF4 - - 13Cr A217-CA15 G5121-SCS1 A182-F6 GA303-SUS51B 1503-713 18Cr – 8Ni (C 0.03) A351-CF3 - - A182-F304L GA303-SUS28B 1503-801 18Cr – 8Ni (C 0.08) A351-CF8 G5121-SCS13 - A182-F304 GA303-SUS27B - 18Cr – 8Ni (C 0.10) - - 1504-801 A182-F304H - - 18Cr – 8Ni – 2Mo (C 0.03) A351-CF3M G5121-SCS16 - A182-F316L GA303-SUS33B 1503-545B 18Cr – 8Ni – 2Mo (C 0.08) A351-CF8M G5121-SCS14 1632-GRC A182-F316 GA303-SUS32B - 18Cr – 8Ni – 2Mo (C 0.10) - - - A182-F316H - - 18Cr – 8Ni – Ti (C 0.08) - - - A182-F321 G4303-SUS29B 1503-821Ti 18Cr – 8Ni – Ti (C 0.10) - - 1504-821Ti - G4303-F321H 1503-821Nb 18Cr – 8Ni – Cb (C 0.08) A351-CF8C - - A182-F347 G4303-SUS43B - 18Cr – 8Ni – Cb (C 0.10) - - 1504-821Nb A182-F347H - - 18Cr – 8Ni – Ta – Cb (C 0.08) - - - A182-F348 - - 18Cr – 8Ni – Ta – Cb (C 0.10) - - - A182-F348H - - 25Cr – 20Ni (C 0.15) - - - A182-F310 - - 22Cr – 12Ni (C 0.08) A351-CH18 - - - - - 22Cr – 12Ni (C 0.10) A351-CH10 - - - - - 22Cr – 12Ni (C 0.20) A351-CH20 - - - - - 23Cr – 19Ni (C 0.20) A351-CH20 - - - - - 23Cr – 19Ni (C 0.35) A351-HK30 - - - - - 23Cr – 19Ni (C 0.45) A351-HK40 - - - - - 13Cr – 33Ni – Mo (C 0.35) A351-HT30 - - - - - 15Cr – 13Ni – 2Mo – Cb(C 0.10) CF10MC - - - - - 19Cr-27Ni-2Mo-3Cu (C0.07) CN7M - -- - - - 8Cr-20Ni (0.20) - - - A182-F10 - - HASTELLOY. B A494-N-2MV - - - - - ENGINEERING DATA ? 9. ?? ? ??? ???

美标材料对照表

COYARD SAS - FRANCE Tableau des alliages de fonderie ASTM NORM GRADE UNS N°Designation Equivalent barre Densité (g/cm3)Fonderie COYARD Al Bi C Cr Cu Fe Mn Mo N Ni Nb P Pb Si S Sn W V Tensile strength,ksi (MPa)Yield strength,min ksi (MPa)in.(50mm),min,%Reduction of area, min, %Aluminium Bismuth Carbone Chrome Cuivre Fer Manganèse Molybdène Azote Nickel Niobium Phosphore Plomb Silicium Soufre Etain Tungstène Vanadium Carbon Chromium Copper Iron Manganese Molybdenum Nitrogen Nickel Columbium Phosphorus Silicon Sulfur Vanadium CARBON STEEL A216WCA J02502On request 0,25max 0,50max 0,30max Bal.0,70max 0,20max 0,50max 0,04max 0,60max 0,045max 0,03max 60 to 85 (415 to 585)30 (205)2435A216WCB J03002A105 Standard 0,30max 0,50max 0,30max Bal.1,00max 0,20max 0,50max 0,04max 0,60max 0,045max 0,03max 70 to 95 (485 to 655)36 (250)2235A216 WCC J02503Standard 0,25max 0,50max 0,30max Bal.1,20max 0,20max 0,50max 0,04max 0,60max 0,045max 0,03max 70 to 95 (485 to 655)40 (275)2235A217WC1J12524 Standard 0,25/ Bal.0,5-0,80,45-0,65/ /0,040,60,04565 to 90 (450 to 620)35 (240)2435A217WC4On request 0,05-0,200,50-0,80Bal.0,5-0,80,45-0,650,70-1,10/0,040,60,04570 to 95 (485 to 655)40 (275)2035A217WC5Standard 0,05-0,200,50-0,90Bal.0,4-0,70,90-1,200,60-1,00 /0,040,60,04570 to 95 (485 to 655)40 (275)2035A217WC6J12072 A182 F11Standard 0,05-0,201,00-1,50Bal.0,5-0,80,45-0,65//0,040,60,04570 to 95 (485 to 655)40 (275)2035A217WC9A182 F22 On request 0,05-0,182,00-2,75Bal.0,4-0,70,90-1,20//0,040,60,04570 to 95 (485 to 655)40 (275)2035A217WC11On request 0,15-0,211,00-1,50Bal.0,5-0,80,45-0,65//0,0200,30-0,600,01580 to 105 (550 to 725)50 (345 )1845A217C5J42045Standard 0,204,00-6,50Bal.0,40-0,700,45-0,65//0,040,750,04590 to 115 (620 to 795)60 (415)1835A217C12J82090On request 0,208,00-10,00Bal.0,35-0,650,90-1,20// 0,041,000,04590 to 115 (620 to 795)60 (415)1835A217C12A A182 F91On request 0,128,0-9,5Bal.0,30-0,600,85-1,050,400,060-0,10 0,0200,20-0,500,01885 to 110 (585 to 760)60 (415)2045A217 CA15 J91150 410 Standard 0,15 11,5-14,0 Bal. 1,00 0,50 1,00 / 0,040 1,50 0,040 90 to 115 (620 to 795) 65 (450) 18 30 AUSTENITIC & AUSTENITIC-FERRITIC (DUPLEX) A351CF3, CF3A J92500304L Standard 0,0317,0-21,0/Bal.1,500,50/8,0-12,0/0,0402,000,040//70 (485), 77 (530)30 (205), 35 (240)35,0A351CF8, CF8A J92600304Standard 0,0818,0-21,0/Bal.1,500,50/8,0-11,0/0,0402,000,040//70 (485), 77 (530)30 (205), 35 (240)35,0A351CF3M, CF3MA J92800316L Standard 0,0317,0-21,0/Bal.1,502,0-3,0/9,0-13,0/0,0401,500,040//70 (485), 80 (550) 30 (205), 37 (255) 30,0A351CF8M J92900316Standard 0,0818,0-21,0/Bal.1,502,0-3,0/ 9,0-12,0/0,0401,500,040//70 (485)30 (205)30,0A351CF3MN J92804316LN On request 0,0317,0-21,0/Bal.1,502,0-3,00,10-0,20 9,0-13,0/0,0401,500,040//75 (515)37 (255)35,0A351CF8C J92710347On request 0,0818,0-21,0/Bal.1,500,50/9,0-12,0/0,0402,000,040//70 (485)30 (205)30,0A351CF10A182 F321 0,04-0,1018,0-21,0/Bal.1,500,50/8,0-11,0/0,0402,000,040//70 (485)30 (205)35,0A351CF10M J929010,04-0,1018,0-21,0/Bal.1,502,0-3,0/9,0-12,0/0,0401,500,040//70 (485)30 (205)30,0A351CH80,0822,0-26,0/Bal.1,500,50/12,0-15,0/0,0401,500,040//65 (450)28 (195)30,0A351CH100,04-0,1022,0-26,0/Bal.1,500,50/12,0-15,0/0,0402,000,040//70 (485)30 (205)30,0A351CH200,04-0,2022,0-26,0/Bal.1,500,50/12,0-15,0/0,0402,000,040//70 (485)30 (205)30,0A351CK20310 0,04-0,2023,0-27,0/Bal.1,500,50/19,0-22,0/0,0401,750,040//65 (450)28 (195)30,0A351HK300,25-0,3523,0-27,0/Bal.1,500,50/19,0-22,0/0,0401,750,040//65 (450)35 (240)10,0A351HK400,35-0,4523,0-27,0/Bal.1,500,50/19,0-22,0/0,0401,750,040//62 (425)35 (240)10,0A351HT300,25-0,3513,0-17,0/Bal.2,000,50/33,0-37,0/0,0402,500,040//65 (450)28 (195)15,0A351CF10MC 0,1015,0-18,0/Bal.1,501,75-2,25/13,0-16,0/0,0401,500,040//70 (485) 30 (205) 20,0A351CN7M N08007Alloy 20-UNS N08020-Carpenter 20CB-3 8,08 Standard 0,0719,0-22,03,0-4,0Bal.1,502,0-3,0/ 27,5-30,5/ 0,0401,500,040//62 (425)25 (170)35,0A351CN3MN N08367 AL6XN On request 0,03max 20,0-22,00,75max Bal.2,00max 6,0-7,00,18-0,26 23,5-25,5/0,040max 1,00max 0,010max //80 (550)38 (260)35A351CD4MCu 0,0424,5-26,52,75-3,25Bal.1,001,75-2,25/ 4,75-6,00/0,041,000,04//100 (690)70 (485)16,0A351CE8MN 0,0822,5-25,5/Bal.1,003,0-4,50,10-0,308,0-11,0/ 0,0401,500,040//95 (655)65 (450)25,0A351CG6MMN 0,0620,50-23,50/Bal.4,00-6,001,50-3,000,20-0,40 11,50-13,500,10-0,300,0401,000,030/0,10-0,30 85 (585)42,5 (295)30,0A351CG8M J93000317Standard 0,0818,0-21,0/Bal.1,503,0-4,0/ 9,0-13,0/0,041,500,04//75 (515)35 (240)25,0A351CF10SMnN 0,1016,0-18,0/Bal.7,00-9,00/0,08-0,18 8,0-9,0/0,0603,50-4,500,030//85 (585)42,5 (295)30,0A351CT15C 0,05-0,1519,0-21,0/ Bal.0,15-1,50// 31,0-34,00,50-1,500,030,50-1,500,03//63 (435)25 (170)20,0A351CK3MCuN S31254A182 F44 - 254-SMO On request 0,02519,5-20,50,50-1,00Bal.1,206,0-7,00,18-0,2417,5-19,5/0,0451,000,010//80 (550)38 (260)35A351CE20N 0,2023,0-26,0/Bal.1,500,500,06-0,20 8,0-11,0/0,0401,500,040//80 (550)40 (275)30A351CG-3M J92999317L Standard 0,0318,0-21,0/Bal.1,503,0-4,0/ 9,0-13,0/0,041,500,04//75 (515)35 (240)25A351CD3MWCuN 0,0324,0-26,00,5-1,0Bal.1,003,0-4,00,20-0,30 6,5-8,5/0,0301,000,0250,5-1,0 / 100 (700)65 (450)25,0A351 CN2MCuN N08904 904L / Uranus B6 7,95 Standard 0,02 19,0-23,01,0-2,0Bal. 2,0max 4,0-5,0 23,0-28,00,045max 1,00max 0,035max 65,00 28,00 35,00 CARBON STEEL A352LCA Carbon Steel On request 0,250500,300,700,200,500,040,600,0450,0360,0-85,0 (415-585)30,0 (205)24A352 LCB J03003Carbon Steel ASTM A352 LF2 On request 0,300,500,30Bal.1,000,200,500,040,600,0450,0365,0-90,0 (415-585)35,0 (240)2435A352LCC J02505 Carbon-Manganese Steel Standard 0,250,50 0,30 Bal. 1,200,200,500,040,600,0450,03 70,0-95,0 (485-655)40,0 (275)2235A352LC1Carbon-Molybdenum Steel On request 0,250,50-0,0800,45-0,650,040,600,04565,0-90,0 (450-620)35,0 (240)2435A352LC221/2 % Nickel Steel On request 0,250,50-0,802,00-3,000,040,600,04570,0-95,0 (485-655)40,0 (275)2435A352LC2-1Nickel-Chromium-Molybdenum Steel On request 0,221,35-1,85 0,55-0,750,30-0,60 2,50-3,500,040,500,045105,0-130,0 (725-895)80,0 (550)1830A352LC331/2% Nickel Steel On request 0,150,50-0,803,00-4,000,040,600,04570,0-95,0 (485-655)40,0 (275)2435A352LC441/2% Nickel Steel On request 0,150,50-0,804,00-5,000,040,600,04570,0-95,0 (485-655) 40,0 (275)2435A352LC99% Nickel Steel On request 0,130,500,300,900,208,50-10,00,040,450,0450,03 85,0 (585)75,0 (515)2030A352 CA6NM 121/2 %Chromium, Nickel-Molybdenum Steel On request 0,06 11,5-14,0 1,00 0,4-1,0 3,5-4,5 0,04 1,00 0,03 110,0-135,0 (760-930) 80,0 (550) 15 35 NICKEL ALLOYS A494CZ-100N02100Cast Nickel 1,001,25max 3,00max 1,5095,00min 0,032,000,0350,00 (345)18,00 (125)10,00A494M-35-1N24135Monel 4008,8Standard 0,3526,0-33,03,50max 1,50Bal.0,50max 0,031,250,0365,00 (450)25,00 (170)25,00A494 M-35-2N04020Monel On request 0,3526,0-33,03,50max 1,50Bal.0,50max 0,032,000,0365,00 (450)30,00 (205)25,00N05500Monel K500 8,47 A494M-30H 0,3027,0--33,03,50max 1,50Bal.0,032,7-3,70,03100,00 (690)60,00 (415)10,0A494M-25S On request 0,2527,0-33,03,50max 1,50Bal.0,033,5-4,50,03A494M-30C N24130Weldable Monel 0,3026,0-33,03,50max 1,50Bal.1,0-3,0 0,031,0-2,00,0365,00 (450)32,50 (225)25,00A494 N-12MV N30012 Hastelloy B On request 0,12 1,004,0-6,0 1,00 26,0-30,0Bal. 0,040 1,00 0,030 0,20-0,60 76,00 (525) 40,00 (275) 6,00 A494N-7M N30007Hastelloy B29,22On request 0,071,03,00max 1,00 30,0-33,0Bal.0,0401,000,03076,00 (525)40,00 (275)20,00A494CY-40N06040Inconel 6008,47On request 0,4014,0-17,011,00max 1,50Bal.0,033,000,03070,00 (485)28,00 (195)30,00A494CW-12MW N30002Hastelloy C On request 0,1215,5-17,54,5-7,51,0016,0-18,0Bal.0,0401,000,030 3,75-5,250,20-0,4072,00 (495)40,00 (275)4,00A494N10276Hastelloy C-2768,89 Standard 0,0215,5-17,54,5-7,516,0-18,0Bal.3,75-5,250,20-0,40 72,00 (495)40,00 (275)4,00A494CW-6M N30107Hastelloy C Modified On request 0,0717,0-20,03,0max 1,0017,0-20,0Bal.0,0401,000,03072,00 (495)40,00 (275)25,00A494CW-2M N26455Hastelloy C4C 0,0215,0-17,52,0max 1,0015,0-17,5Bal.0,030,800,031,0max 72,00 (495)40,00 (275)20,00A494CW-6MC N26625Inconel 6258,44On request 0,06 20,0-23,05,0max 1,008,0-10,0Bal.3,15-4,50 0,0151,000,01570,00 (495)40,00 (275)25,00A494CY5SnBiM 3,0-5,00,05 11,0-14,02,0max 1,52,0-3,5Bal.0,030,50,033,5-5,0A494CX2MW N26022Hastelloy C-228,690,0220,0-22,52,0-6,0 1,0012,5-14,5Bal.0,0250,800,0252,5-3,50,35max 80,00 (550)45,00 (280)30,0A494 Cu5MCuC N08825Incoloy 8258,140,050max 19,5-23,51,50-3,50Bal. 1,0max 2,5-3,538,0-44,0 0,60-1,20 0,030max 1,0max 0,030max 75,00 (520) 35,00 (240) 20,0 N08800 Incoloy 800 7,94 IRON-CHROMIUM-NICKEL-MOLYBDENUM & DUPLEX (AUSTENITIC/FERRITIC) ALLOYS A8901A (CD4MCu)J93370Duplex Grade 1A On request 0,04max 24,5-26,52,75-3,25 Bal.1,00max 1,75-2,254,75-6,00 0,040max 1,00max 0,04max /100 (690)70 (485)16A8902A (CE8MN)J93345Duplex Grade 2A On request 0,08max 22,5-25,5/Bal.1,00max 3,00-4,500,10-0,308,00-11,000,04max 1,50max 0,04max /95 (655)65 (450)25A8903A (CD6MN)J93371Duplex Grade 3A On request 0,06max 24,0-27,0/Bal.1,00max 1,75-2,500,15-0,254,00-6,000,040max 1,00max 0,04max /95 (655)65 (450)25 A8904A (CD3MN)J92205Duplex Grade 4A A182 F51 - AISI 22-05 - UNS S31803 7,8 Standard 0,03max 21,0-23,51,00max Bal.1,50max 2,5-3,50,10-0,304,5-6,50,04max 1,00max 0,020max /90 (620)60 (415)25A8905A (CE3MN)J93404Duplex Grade 5A A182F53 - AISI 25-07 - UNS S32750 On request 0,03max 24,0-26,0/Bal.1,50max 4,0-5,00,10-0,306,0-8,00,04max 1,00max 0,04max /100 (690)75 (515)18A8906A (CD3MWCuN)J93380Grade 6A Zeron100A182F55 - UNS S32760 On request 0,03max 24,0-26,00,5-1,0Bal.1,00max 3,0-4,00,20-0,306,5-8,50,030max 1,00max 0,025max 0,5-1,0 100 (700)65 (450)25A8901B (CD4MCuN) J93372 0,04max 24,5-26,52,7-3,3Bal.1,00max 1,7-2,30,10-0,254,7-6,00,04max 1,00max 0,04max /100 (700)70 (485)16 A8907A Ferralium 255 UNS S32550 COPPER-NICKEL ALLOYS B369 C9640070/30 Copper-Nickel On request 0,15Bal.0,25-1,51,5max 28,0-32,060,0032,0020 ALUMINIUM-BRONZE B148Grade A (9A)C95200Aluminium Bronze On request 8,5-9,5Bal.2,5-4,065 (450)25 (170)20B148Grade B (9B)C95300Aluminium Bronze On request 9,00-11,0Bal.0,75-1,565 (450)25 (170)20B148Grade C (9C)C95400Aluminium Bronze On request 10,0-11,583,0min 3,0-5,00,50max 1,5max 75 (515)30 (205)12B148C95410Aluminium Bronze On request 10,0-11,5Bal.3,0-5,00,50max 1,5-2,575 (515)30 (205)12B148Grade D (9D)C95500Nickel Aluminium Bronze Standard 10,0-11,578,0min 3,0-5,03,5max 3,0-5,590 (620)40 (275)6B148Grade E (9E)C95600Silicon Aluminium Bronze On request 6,0-8,0Bal.0,25max 1,75-3,25 60 (415)28 (195)10B148Grade F (9F) C95700Manganese Nickel Aluminium Bronze On request 7,0-8,5Bal.2,0-4,011,0-14,01,5-3,00,03max 0,10max 90 (620 )40 (275)20B148C95800Nickel Aluminium Bronze 7,64 Standard 8,5-9,578,0min 3,5-4,50,8-1,54,0-5,00,03max 0,10max 85 (585)35 (240)15 B148 C95900Aluminium Bronze On request 12,0-13,5Bal. 3,0-5,0 1,5max 0,5max Caractéristiques mécaniques Composition , % 07/02/2006