fluent欧拉离散模型算例

Chapter 23: Using the Eulerian Multiphase Model for Granular Flow This tutorial is divided into the following sections:

23.1. Introduction

23.2. Prerequisites

23.3. Problem Description

23.4. Setup and Solution

23.5. Summary

23.6. Further Improvements

23.1. Introduction

Mixing tanks are used to maintain solid particles or droplets of heavy fluids in suspension. Mixing may

be required to enhance reaction during chemical processing or to prevent sedimentation. In this tutorial, you will use the Eulerian multiphase model to solve the particle suspension problem.The Eulerian multiphase model solves momentum equations for each of the phases, which are allowed to mix in any proportion.

This tutorial demonstrates how to do the following:

?Use the granular Eulerian multiphase model.

?Specify fixed velocities with a user-defined function (UDF) to simulate an impeller.

?Set boundary conditions for internal flow.

?Calculate a solution using the pressure-based solver.

?Solve a time-accurate transient problem.

23.2. Prerequisites

This tutorial is written with the assumption that you have completed one or more of the introductory tutorials found in this manual:

?Introduction to Using ANSYS FLUENT in ANSYS Workbench: Fluid Flow and Heat Transfer in a Mixing Elbow (p.1)

?Parametric Analysis in ANSYS Workbench Using ANSYS FLUENT (p.77)

?Introduction to Using ANSYS FLUENT: Fluid Flow and Heat Transfer in a Mixing Elbow (p.131)

and that you are familiar with the ANSYS FLUENT navigation pane and menu structure. Some steps in

the setup and solution procedure will not be shown explicitly.

23.3. Problem Description

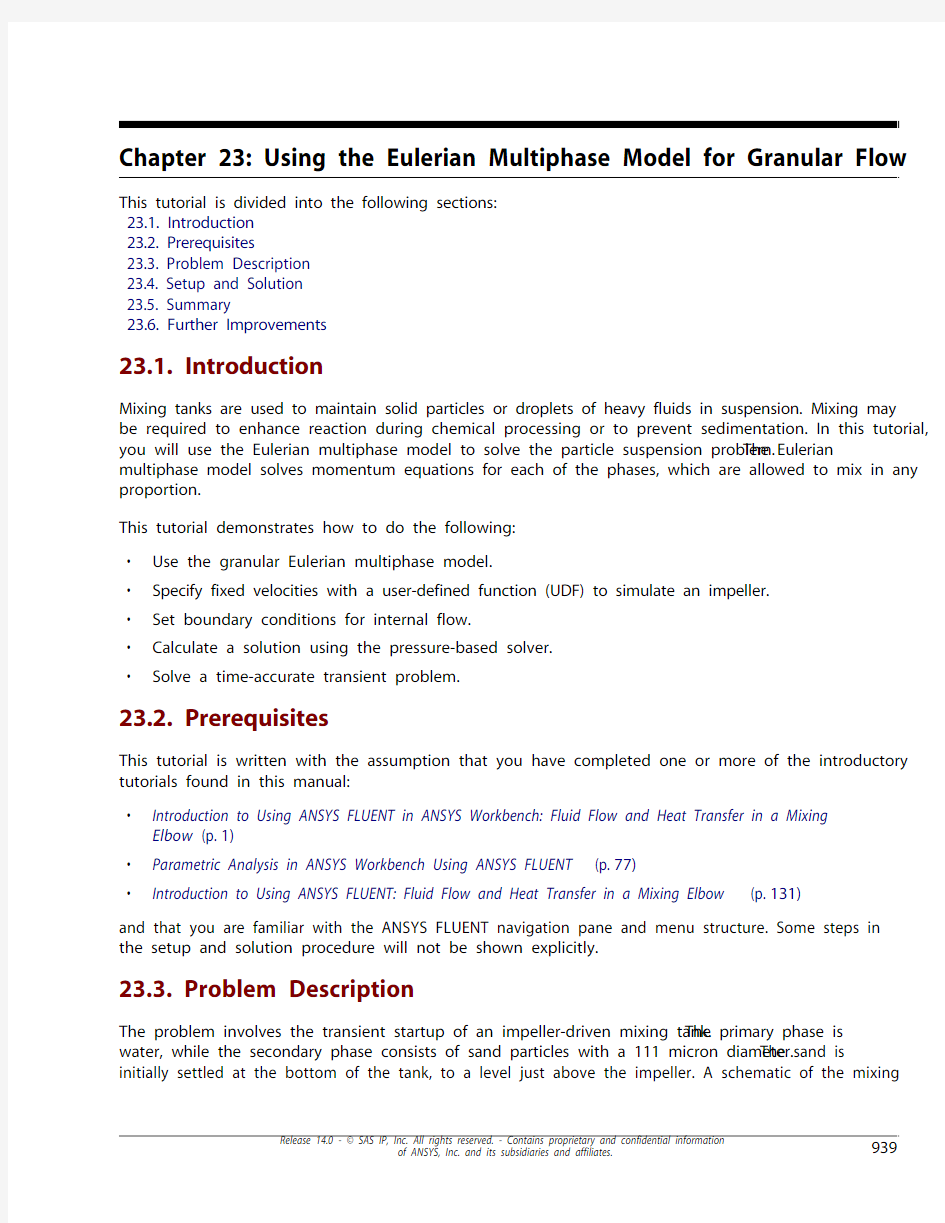

The problem involves the transient startup of an impeller-driven mixing tank.The primary phase is water, while the secondary phase consists of sand particles with a 111 micron diameter.The sand is initially settled at the bottom of the tank, to a level just above the impeller. A schematic of the mixing

Chapter 23: Using the Eulerian Multiphase Model for Granular Flow

tank and the initial sand position is shown in Figure 23.1 (p.940).The domain is modeled as 2D axisym-metric.

Figure 23.1 Problem Specification

The fixed-values option will be used to simulate the impeller. Experimental data are used to represent

the time-averaged velocity and turbulence values at the impeller location.This approach avoids the

need to model the impeller itself.These experimental data are provided in a user-defined function. 23.4. Setup and Solution

The following sections describe the setup and solution steps for this tutorial:

23.4.1. Preparation

23.4.2. Step 1: Mesh

23.4.3. Step 2: General Settings

23.4.4. Step 3: Models

23.4.5. Step 4: Materials

23.4.6. Step 5: Phases

23.4.7. Step 6: User-Defined Function (UDF)

23.4.8. Step 7: Cell Zone Conditions

23.4.9. Step 8: Solution

23.4.10. Step 9: Postprocessing

23.4.1. Preparation

1.Extract the eulerian_multiphase_granular.zip from the ANSYS_Fluid_Dynamics_Tu-

torial_Inputs.zip archive which is available from the Customer Portal.

Setup and Solution Note

For detailed instructions on how to obtain the ANSYS_Fluid_Dynamics_Tutori-

al_Inputs.zip file, please refer to Preparation (p.3) in Introduction to Using ANSYS

FLUENT in ANSYS Workbench: Fluid Flow and Heat Transfer in a Mixing Elbow (p.1).

2.Unzip eulerian_multiphase_granular.zip.

The files,mixtank.msh and fix.c can be found in the eulerian_multiphase_granular

folder created after unzipping the file.

https://www.360docs.net/doc/e418550713.html,e FLUENT Launcher to start the 2D version of ANSYS FLUENT.

4.Enable Double-Precision.

For more information about FLUENT Launcher, see Starting ANSYS FLUENT Using FLUENT Launcher in the User’s Guide.

Note

The Display Options are enabled by default.Therefore, after you read in the mesh, it will

be displayed in the embedded graphics window.

Note

The double precision solver is recommended for modeling multiphase flow simulations.

23.4.2. Step 1: Mesh

1.Read the mesh file mixtank.msh.

File?Read?Mesh...

A warning message will be displayed twice in the console.You need not take any action at this point,

as the issue will be rectified when you define the solver settings in Step 2.

23.4.3. Step 2: General Settings

General

1.Check the mesh.

General?Check

ANSYS FLUENT will perform various checks on the mesh and report the progress in the console. Ensure that the reported minimum volume is a positive number.

2.Examine the mesh (Figure 2

3.2 (p.942)).

Figure 23.2 Mesh Display

Extra

You can use the right mouse button to check which zone number corresponds to each boundary. If you click the right mouse button on one of the boundaries in the graphics window, its zone number, name, and type will be printed in the console.This feature is especially useful when you have several zones of the same type and you want to distinguish between them quickly.

3.

Modify the mesh colors.General ? Display...a.

Click the Colors... button to open the Mesh Colors dialog box.

Chapter 23: Using the Eulerian Multiphase Model for Granular Flow

Setup and Solution You can control the colors used to draw meshes by using the options available in the Mesh Colors dialog box.

i.Select Color by ID in the Options list.

This will assign a different color to each zone in the domain, rather than to each type of

zone.

ii.Close the Mesh Colors dialog box.

b.Click Display and close the Mesh Display dialog box.

The graphics display will be updated to show the mesh.

Chapter 23: Using the Eulerian Multiphase Model for Granular Flow

Figure 23.3 Mesh Display Using the C

olor by ID Option Array 4.Modify the view of the mesh display to show the full tank upright.

Graphics and Animations?Views...

Setup and Solution

a.Select axis from the Mirror Planes selection list and click Apply.

The mesh display will be updated to show both sides of the tank.

b.Click Auto Scale.

This option is used to scale and center the current display without changing its orientation (Figure

23.4 (p.946)).

Figure 23.4 Mesh Display of the Tank, Mirrored and Scaled

c.Click the Camera... button to open the Camera Parameters

dialog box.

Chapter 23: Using the Eulerian Multiphase Model for Granular Flow

Setup and Solution

i.Drag the indicator of the dial with the left mouse button in the counter-clockwise direction

until the upright view is displayed (Figure 23.5 (p.947)).

ii.Click Apply and close the Camera Parameters dialog box.

d.Close the Views dialog box.

Note

While modifying the view, you may accidentally lose the view of the geometry in the

display.You can easily revert to the default (front) view by clicking the Default button

in the Views dialog box.

Figure 23.5 Mesh Display of the Upright Tank

5.Specify a transient, axisymmetric model.

General

Chapter 23: Using the Eulerian Multiphase Model for Granular Flow

a.Retain the default Pressure-Based solver.

The pressure-based solver must be used for multiphase calculations.

b.Select Transient in the Time list.

c.Select Axisymmetric in the 2D Space list.

6.Set the gravitational acceleration.

a.Enable Gravity.

b.Enter -9.81 m/ for the Gravitational Acceleration in the X direction.

23.4.4. Step 3: Models

Models

1.Enable the Eulerian multiphase model.

Models?Multiphase?Edit...

a.Select Eulerian in the Model list.

b.Retain the default setting of 2 for Number of Eulerian Phases.

c.Click OK to close the Multiphase Model dialog box.

2.Enable the - turbulence model with standard wall functions.

Models?

Viscous?Edit...

Setup and Solution

a.Select k-epsilon (2eqn) in the Model list.

b.

Select Standard Wall Functions in the Near-Wall Treatment list.

This problem does not require a particularly fine mesh hence, standard wall functions can be used.

c.Select Dispersed in the Turbulence Multiphase Model list.

The dispersed turbulence model is applicable in this case because there is clearly one primary continuous phase and the material density ratio of the phases is approximately 2.5. Furthermore,the Stokes number is much less than 1.Therefore, the kinetic energy of the particle will not differ significantly from that of the liquid. For more information, see Model Comparisons in the Theory Guide.

d.Click OK to close the Viscous Model dialog box.

23.4.5. Step 4: Materials

Materials

In this step, you will add liquid water to the list of fluid materials by copying it from the ANSYS FLUENT ma-terials database and create a new material called sand.1.

Copy liquid water from the FLUENT materials database so that it can be used for the primary phase.

Chapter 23: Using the Eulerian Multiphase Model for Granular Flow

Setup and Solution

Materials?Fluid?Create/Edit...

dialog box.

a.Click the FLUENT Database... button to open the FLUENT Database Materials Array

b.Select water-liquid (h2o l ) from the FLUENT Fluid Materials selection list.

Scroll down the FLUENT Fluid Materials list to locate water-liquid (h2o l ).

c.Click Copy to copy the information for liquid water to your model.

d.Close the FLUENT Database Materials dialog box.

2.Create a new material called sand.

Chapter 23: Using the Eulerian Multiphase Model for Granular Flow

a.Enter sand for Name and delete the entry in the Chemical Formula field.

b.Enter 2500 kg/ for Density in the Properties group box.

c.Click Change/Create.

A Question dialog box will open, asking if you want to overwrite water-liquid.

d.Click No in the Question dialog box to retain water-liquid and add the new material (sand) to

the list.

The Create/Edit Materials dialog box will be updated to show the new material,sand, in the

FLUENT Fluid Materials drop-down list.

3.Close the Create/Edit Materials dialog box.

23.4.6. Step 5: Phases

Phases

Setup and Solution

1.Specify water (water-liquid ) as the primary phase.

Edit...

Phases?phase-1?

a.Enter water for Name.

b.Select water-liquid from the Phase Material drop-down list.

c.Click OK to close the Primary Phase dialog box.

2.Specify sand (sand ) as the secondary phase.

Phases?phase-2?Edit...

Chapter 23: Using the Eulerian Multiphase Model for Granular Flow

a.Enter sand for Name.

b.Select sand from the Phase Material drop-down list.

c.Enable Granular.

d.Retain the selection of Phase Property in the Granular Temperature Model list.

e.Enter 0.000111 m for Diameter.

f.Select syamlal-obrien from the Granular Viscosity drop-down list.

g.Select lun-et-al from the Granular Bulk Viscosity drop-down list.

h.Enter 0.6 for Packing Limit.

Scroll down in the Properties group box to locate Packing Limit.

i.Click OK to close the Secondary Phase dialog box.

3.Specify the drag law to be used for computing the interphase momentum transfer.

Phases?Interaction...

Setup and Solution

a.Select gidaspow from the Drag Coefficient drop-down list.

b.Click OK to close the Phase Interaction dialog box.

23.4.7. Step 6: User-Defined Function (UDF)

A UDF is used to specify the fixed velocities that simulate the impeller.The values of the time-averaged impeller velocity components and turbulence quantities are based on experimental measurement.The variation of these values may be expressed as a function of radius, and imposed as polynomials according to: =++++…

The order of polynomial to be used depends on the behavior of the function being fitted. For this tutorial,

the polynomial coefficients shown in Table 23.1: Impeller Profile Specifications (p.955)

Table 23.1 Impeller Profile Specifications

A1

A2

Variable

A3

A5

A6

A4

u velocity

-7.1357e-2

54.304

–

4.5578e+4

-1.966e+5

-3.1345e+3

3.1131e-2

v velocity

-10.313

–

1.186e+5

9.5558e+2

-2.0051e+4

kinetic energy

2.2723e-2

6.7989

1.8410e+5

9.4615e+3

-7.725e+4

-424.18

-6.5819e-2

dissipation

88.845

-9.120e+5

-5.3731e+3

1.1643e+5

1.9567e+6 For more information about setting up a UDF using the DEFINE_PROFILE macro, refer to the separate UDF Manual.Though this macro is usually used to specify a profile condition on a boundary face zone,

it is used in fix.c to specify the condition in a fluid cell zone. Hence, the arguments of the macro

have been changed accordingly.

1.Interpret the UDF source file fix.c.

Chapter 23: Using the Eulerian Multiphase Model for Granular Flow

Define?User-Defined?Functions?

Interpreted...

a.Enter fix.c for Source File Name.

If the UDF source file is not in your working folder, you must enter the entire folder path for Source File Name instead of just entering the file name. Alternatively, click Browse... and select fix.c in

the eulerian_multiphase_granular folder that was created after you unzipped the ori-

ginal file.

b.Enable Display Assembly Listing.

The Display Assembly Listing option displays the assembly language code in the console as the

function compiles.

c.Click Interpret to interpret the UDF.

d.Close the Interpreted UDFs dialog box.

Note

The name and contents of the UDF are stored in the case file when you save the

case file.

23.4.8. Step 7: Cell Zone Conditions

Cell Zone Conditions

Setup and Solution

For this problem, you do not have to specify any conditions for outer boundaries.Within the domain, there

are three fluid zones, representing the impeller region, the region where the sand is initially located, and the rest of the tank.There are no conditions to be specified in the latter two zones, so you need to set conditions only in the zone representing the impeller.

1.Set the boundary conditions for the fluid zone representing the impeller (fix-zone) for the primary

phase.

Cell Zone Conditions?fix-zone

You will specify the conditions for water and sand separately using the UDF.The default conditions

for the mixture (i.e., conditions that apply to all phases) are acceptable.

a.Select fix-zone in the Zone list.

b.Select water from the Phase drop-down list.

c.Click the Edit... button to open the Fluid dialog box.

i.Enable Fixed Values .

The Fluid dialog box will expand to show the related inputs.

ii.Click the Fixed Values tab and set the following fixed values:

Value Parameter

udf fixed_u Axial Velocity udf fixed_v Radial Velocity udf

fixed_ke Turbulence Kinetic En-ergy

udf

fixed_diss

Turbulence Dissipation Rate

d.Click OK to close the Fluid dialog box.

2.

Set the boundary conditions for the fluid zone representing the impeller (fix-zone ) for the secondary phase.

Cell Zone Conditions ? fix-zone

a.Make sure that fix-zone is selected in the Type list.

b.Select sand from the Phase drop-down list.

c.

Click the Edit... button to open the Fluid dialog box.

Chapter 23: Using the Eulerian Multiphase Model for Granular Flow