(完整版)汽车制动系统-英文文献及翻译

Brake systems

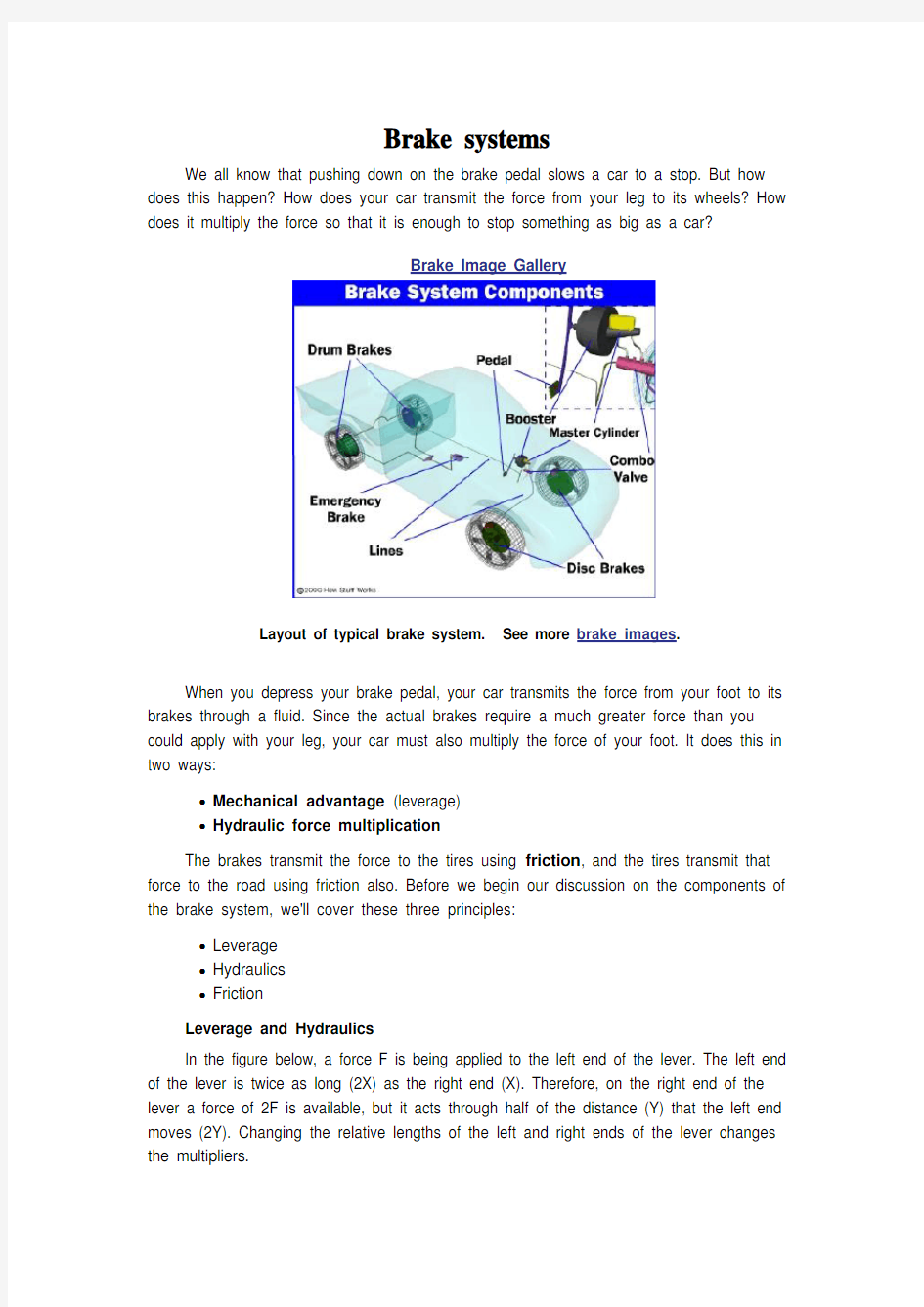

We all know that pushing down on the brake pedal slows a car to a stop. But how does this happen? How does your car transmit the force from your leg to its wheels? How does it multiply the force so that it is enough to stop something as big as a car?

Brake Image Gallery

Layout of typical brake system. See more brake images.

When you depress your brake pedal, your car transmits the force from your foot to its brakes through a fluid. Since the actual brakes require a much greater force than you could apply with your leg, your car must also multiply the force of your foot. It does this in two ways:

?Mechanical advantage (leverage)

?Hydraulic force multiplication

The brakes transmit the force to the tires using friction, and the tires transmit that force to the road using friction also. Before we begin our discussion on the components of the brake system, we'll cover these three principles:

?Leverage

?Hydraulics

?Friction

Leverage and Hydraulics

In the figure below, a force F is being applied to the left end of the lever. The left end of the lever is twice as long (2X) as the right end (X). Therefore, on the right end of the lever a force of 2F is available, but it acts through half of the distance (Y) that the left end moves (2Y). Changing the relative lengths of the left and right ends of the lever changes the multipliers.

The pedal is designed in such a way that it can multiply the force from your

leg several times before any force is even transmitted to the brake fluid.

The basic idea behind any hydraulic system is very simple: Force applied at one point is transmitted to another point using an incompressible fluid, almost always an oil of some sort. Most brake systems also multiply the force in the process. Here you can see the simplest possible hydraulic system:

Your browser does not support JavaScript or it is disabled.

Simple hydraulic system

In the figure above, two pistons (shown in red) are fit into two glass cylinders filled with oil (shown in light blue) and connected to one another with an oil-filled pipe. If you

apply a downward force to one piston (the left one, in this drawing), then the force is transmitted to the second piston through the oil in the pipe. Since oil is incompressible, the efficiency is very good -- almost all of the applied force appears at the second piston. The great thing about hydraulic systems is that the pipe connecting the two cylinders can be any length and shape, allowing it to snake through all sorts of things separating the two

pistons. The pipe can also fork, so that one master cylinder can drive more than one slave cylinder if desired, as shown in here:

Your browser does not support JavaScript or it is disabled.

Master cylinder with two slaves

The other neat thing about a hydraulic system is that it makes force multiplication (or division) fairly easy. If you have read How a Block and Tackle Works or How Gear Ratios Work, then you know that trading force for distance is very common in mechanical systems. In a hydraulic system, all you have to do is change the size of one piston and cylinder relative to the other, as shown here:

Your browser does not support JavaScript or it is disabled.

Hydraulic multiplication

To determine the multiplication factor in the figure above, start by looking at the size of the pistons. Assume that the piston on the left is 2 inches (5.08 cm) in diameter (1-inch / 2.54 cm radius), while the piston on the right is 6 inches (15.24 cm) in diameter (3-inch / 7.62 cm radius). The area of the two pistons is Pi * r2. The area of the left piston is therefore 3.14, while the area of the piston on the right is 28.26. The piston on the right is nine times larger than the piston on the left. This means that any force applied to the

left-hand piston will come out nine times greater on the right-hand piston. So, if you apply a 100-pound downward force to the left piston, a 900-pound upward force will appear on the right. The only catch is that you will have to depress the left piston 9 inches (22.86 cm) to raise the right piston 1 inch (2.54 cm).

A Simple Brake System

Before we get into all the parts of an actual car brake system, let's look at a simplified system:

Your browser does not support JavaScript or it is disabled.

A simple brake system

You can see that the distance from the pedal to the pivot is four times the distance from the cylinder to the pivot, so the force at the pedal will be increased by a factor of four before it is transmitted to the cylinder.

You can also see that the diameter of the brake cylinder is three times the diameter of the pedal cylinder. This further multiplies the force by nine. All together, this system increases the force of your foot by a factor of 36. If you put 10 pounds of force on the pedal, 360 pounds (162 kg) will be generated at the wheel squeezing the brake pads.

There are a couple of problems with this simple system. What if we have a leak? If it is a slow leak, eventually there will not be enough fluid left to fill the brake cylinder, and the brakes will not function. If it is a major leak, then the first time you apply the brakes all of the fluid will squirt out the leak and you will have complete brake failure.

Drum brakes work on the same principle as disc brakes: Shoes press against a spinning surface. In this system, that surface is called a drum.

Figure 1. Location of drum brakes. See more drum brake

pictures.

Many cars have drum brakes on the rear wheels and disc brakes on the front. Drum brakes have more parts than disc brakes and are harder to service, but they are less expensive to manufacture, and they easily incorporate an emergency brake mechanism.

In this edition of HowStuffWorks, we will learn exactly how a drum brake system works, examine the emergency brake setup and find out what kind of servicing drum brakes need.

Figure 2. Drum brake with drum in place

Figure 3. Drum brake without drum in place

Let's start with the basics.

The Drum Brake

The drum brake may look complicated, and it can be pretty intimidating when you open one up. Let's break it down and explain what each piece does.

Figure 4. Parts of a drum brake

Like the disc brake, the drum brake has two brake shoes and a piston. But the drum brake also has an adjuster mechanism, an emergency brake mechanism and lots of springs.

First, the basics: Figure 5 shows only the parts that provide stopping power.

Your browser does not support JavaScript or it is disabled.

Figure 5. Drum brake in operation

When you hit the brake pedal, the piston pushes the brake shoes against the drum. That's pretty straightforward, but why do we need all of those springs?

This is where it gets a little more complicated. Many drum brakes are self-actuating. Figure 5 shows that as the brake shoes contact the drum, there is a kind of wedging action, which has the effect of pressing the shoes into the drum with more force.

The extra braking force provided by the wedging action allows drum brakes to use a smaller piston than disc brakes. But, because of the wedging action, the shoes must be pulled away from the drum when the brakes are released. This is the reason for some of the springs. Other springs help hold the brake shoes in place and return the adjuster arm after it actuates.

Brake Adjuster

For the drum brakes to function correctly, the brake shoes must remain close to the drum without touching it. If they get too far away from the drum (as the shoes wear down, for instance), the piston will require more fluid to travel that distance, and your brake pedal will sink closer to the floor when you apply the brakes. This is why most drum brakes have an automatic adjuster.

Figure 6. Adjuster mechanism

Now let's add in the parts of the adjuster mechanism. The adjuster uses the

self-actuation principle we discussed above.

Your browser does not support JavaScript or it is disabled.

Figure 7. Drum brake adjuster in operation

In Figure 7, you can see that as the pad wears down, more space will form between the shoe and the drum. Each time the car stops while in reverse, the shoe is pulled tight against the drum. When the gap gets big enough, the adjusting lever rocks enough to advance the adjuster gear by one tooth. The adjuster has threads on it, like a bolt, so that it unscrews a little bit when it turns, lengthening to fill in the gap. When the brake shoes wear a little more, the adjuster can advance again, so it always keeps the shoes close to the drum.

Some cars have an adjuster that is actuated when the emergency brake is applied. This type of adjuster can come out of adjustment if the emergency brake is not used for

long periods of time. So if you have this type of adjuster, you should apply your emergency brake at least once a week.

Servicing

The most common service required for drum brakes is changing the brake shoes. Some drum brakes provide an inspection hole on the back side, where you can see how much material is left on the shoe. Brake shoes should be replaced when the friction material has worn down to within 1/32 inch (0.8 mm) of the rivets. If the friction material is bonded to the backing plate (no rivets), then the shoes should be replaced when they have only 1/16 inch (1.6 mm) of material left.

Photo courtesy of a local AutoZone store

Figure 9. Brake shoe

Just as in disc brakes, deep scores sometimes get worn into brake drums. If a

worn-out brake shoe is used for too long, the rivets that hold the friction material to the backing can wear grooves into the drum. A badly scored drum can sometimes be repaired by refinishing. Where disc brakes have a minimum allowable thickness, drum brakes have a maximum allowable diameter. Since the contact surface is the inside of the drum, as you remove material from the drum brake the diameter gets bigger.

Figure 10. Brake drum

制动系统

众所周知,踩下制动踏板可以使汽车减速至停止。但这是如何产生的呢?汽车是如何将力从你的腿传递到车轮的呢?汽车是如何将力放大到足够大以致可以将像汽车一样大的东西制动的呢?

制动系统组件

当你踩下制动踏板的时候,汽车通过液体把力从脚传递到制动器。因为制动器需要的真正力量比你的腿能提供的要大的多,所以汽车必须放大脚产生的力有两种方式:

机械杠杆作用

液力放大

制动器通过摩擦把力传递给轮胎,并且轮胎也是通过摩擦把力传递给路面的。在我们讨论制动系统的组成之前,先来介绍以下三条原则:

杠杆

液力

摩擦力

杠杆和液力

在下面的图中,一个力F加在杠杆的左端。左端的杠杆长度(2X)是右端(X)的两倍。因此杠杆右端可施加的力为2F ,但是右端移动的距离(Y)是左端距离(2Y)的一半。改变杠杆的左端和右端的长度可以改变放大系数。

任何液压系统背后的基本原理都是非常简单的:作用在某一点力通过通常是油一类的不可压缩的液体传递到另一点。大多数的制动系统也在这个过程中放大力。下面的是最简单的液压系统:

简单液压系统

在上图中,两个活塞放在两个充满油的玻璃液压缸中并且由充满油的管道相连。如果在一个活塞上施加一个向下的力,那么力将通过管道中的油传递到第二个活塞。因为油液是不可压缩的,所以传递效率很好,大部分的作用力都传递到了另一个活塞。

液压系统的好处连接两液压缸的管道可以是任何长度和形状,这样就可以使管道弯曲的通过两活塞之间的各种部件。管道也可以是分叉的,如果有需要的话,这样一个主缸可以驱动数个副缸。如下图所示:

带有两个副缸的主缸

液压系统的另一个好处是产生放大(或者缩小)力相当地容易。如果你一读过滑车设备工作原理或者齿轮齿数比原理,那么你就会知道在机械系统中把力转化为距离处理是很常见的。在液压系统中,我们所要做的就是相对地改变一组活塞和液压缸的尺寸。如下图所示:

液压增力原理

为了确定上图中的放大因子,先由观察活塞的尺寸开始。假设左边活塞的直径为2英尺(5.08cm而右边的直径为6英尺(15.24cm)。两个活塞的面积是Pi * r2 。因此左面活塞的面积是3.14,而右面的面积是28.26。右面活塞的面积是左边的九倍大。这就意味着无论在左面的活塞上施加多大的力,在右面的活塞上就会输出九倍于左面的力。所以,如果在左边活塞上施加100磅向下的力,那么在右面活塞上将产生900磅向上的力。唯一的补偿是左面的活塞要移动9英尺(22.86cm)来使右面提升1英尺(2.54cm)

一个简单的制动系统

在我们深入了解一个真实的制动系统的各部分之前,让我们先来看一个简化的系统:

我们可以看到踏板到枢轴的距离是液压缸到枢轴距离的4倍,所以施加在踏板上的力在传递到液压缸之前将被增加4倍。我们还可以看到制动缸的直径是踏板缸直径的3倍。这就将力进一步放大了九倍。最终这个系统将腿上的力增加了36倍。所以,如果在踏板上施加10磅的力,将在挤压制动带的轮上产生369磅(162kg)的力。

下面是这种简单系统所存在的问题。要是系统有泄漏该怎么办呢?如果是轻微泄漏,最终将会没有足够的油使制动缸充满,并且制动器将停止工作。如果是严重泄漏,那么在你制动的第一时间,所有的油液将从泄露处喷射而出,并且制动系统将彻底地不起作用。

鼓式制动器的工作原理和盘式制动器是一样的:制动面接触一个磨砂的表面。在这个系统中,那个表面称作制动鼓

图1.制动鼓的位置

许多汽车的后轮安装鼓式制动器,而盘式制动器安装在前面。鼓式制动器比盘式制动器有更多的零件并且更难检修。但是制造成本相对便宜,还有鼓式制动器容易组装一个紧急使用的制动装置。

在本版本的How StuffWorks中,我们将详尽了解鼓式制动系统是如何工作的。考察紧急制动系统的组成,并且找到鼓式制动器需要何种检修工作。

图2. 有鼓的鼓式制动器

图3.未安装鼓的鼓式制动器

让我们基础开始:

鼓式制动器

鼓式制动器可能看起来比较复杂,它可以是很复杂的,当你打开一个的时候。让我们拆开它,并解释每一块的作用。

图4. 鼓式制动器的组成

如盘式制动器,鼓式制动器有两个制动蹄和一个活塞。但是鼓式制动器也有一个调节机制,紧急刹车机制和大量的弹簧。

首先,基础知识:图5显示只有部分提供的制动力。

图5.工作状态下的鼓式制动器

当你踩下刹车踏板时,活塞推动紧靠着鼓的制动蹄。这是很简单的,但为什么我们需要所有这些弹簧呢?

这使它变的有点复杂许多鼓式制动器是自增力式的。图5表明,当制动蹄与鼓相接触的时候,两者间有一个楔入运动,这起到了产生更多的力量将制动蹄向鼓挤压。

由楔入运动提供的额外制动力使得鼓式制动器可以使用比盘式制动器更小的活塞。

但是由于这种楔入运动,在制动释放的时候制动蹄必须从鼓拉离开。这是使用其中部分弹簧的原因。其它弹簧的作用是将制动蹄固定并且驱动调节臂返回。

制动调节器

为了使鼓式制动器正确的工作,制动蹄必须紧贴着鼓但是不碰到它。如果离鼓太远的话,活塞将需要更多的油液以通过那段距离,并且当你制动时,制动踏板将下行而离地板更近。这就是为什么大多数的鼓式制动器有一个自动调节装置的原因。

图6.调节机构

现在让我们在把调节机构也加进来,这个调节器使用的是上面讨论过的自增力原理。

图7.工作状态下的鼓式制动调节器

在图7中,我们可以看到由于摩擦片的磨损,这使得制动蹄和鼓之间形成更大的空间。每次车停下的时候,相反的是制动蹄被拉的和鼓更紧。当间隙变的足够大时,调节杠杆足够摆动推进调节齿轮先前转动一个齿。调节装置有一个行程,就像一个螺栓,以便当它转动时旋开一点点,延长以填补间隙。当制动蹄进一步磨损,调节器又可以再向前。所以它总是保持制动蹄紧靠着鼓。

有些汽车紧急刹车时有一个被驱动的调节器。如果紧急制动很长一段时间没有使用,这种类型的调节器可以产生调节作用。所以如果你有这种类型的调节器,你应该每周至少使用一次紧急制动装置。

检修

鼓式制动器最常见的检修是更换制动蹄。一些鼓式制动器在背面设置了一个检查孔,通过这个孔,你可以看到制动蹄上还剩余多少摩擦材料。当摩擦材料

磨损到铆钉内1/32英寸(0.8mm)时,必须更换制动蹄。如果摩擦材料和垫板直接连接(无铆钉),那么当摩擦材料只剩下1/16英寸(1.6mm)时,就该换制动蹄了。

图9.制动蹄

正如在盘式制动器中,深的刻痕可能会磨穿到制动鼓。如果一个磨损的制动蹄使用过长的时间,把摩擦片固定到垫板上铆钉可以将制动鼓摸出一条凹槽。一个严重磨损的制动鼓有时可以被修补修复。盘式制动器有最小允许厚度,鼓式制动器有一个最大允许直径。因为接触表面是鼓的内侧。当你将材料从制动器中取出时,制动鼓的直径变大了。

图10.制动鼓

翻译资料英语

FINANCIAL INNOV ATION Like other industries, the financial industry is in business to earn profits by selling its products. If a soap company perceives that there is a need in the marketplace for a laundry detergent with fabric softener, it develops a product to fit the need .Similarly, in order to maximize their profits, financial institutions develop new products to satisfy their own needs as well as those of their customers; in other words, innovation-which can be extremely beneficial to the economy-is driven by the desire to get (or stay) rich. This view of the innovation process leads to the following simple analysis: A chance in the financial institutions for innovations that are likely to be profitable. Starting in the 1960s, individuals and financial institutions operating in financial markets were confronted with drastic changes in the economic environment: Inflation and interest rates climbed sharply and became hard to predict, a situation that changed demand conditions in financial markets. Computer technology advanced rapidly, which changed supply conditions. In addition, financial regulations became especially inconvenient. Banking institution discovers many old ways of doing business being able to not have earned money again; they provide the masses finance with service and financial products sale neither well. Many financial intermediary is discovered they have no way to raise having arrived at a fund, but these self that will not a suspense of business right away with original tradition finance implement. For existing under new economy environment, research and development puts up banking institution be obliged to being able to satisfy customer need moreover the new product being able to gain a profit of and serving, this process is called financial engineering. In their case, necessity was the mother of innovation. Our discussion of why financial innovation occurs suggests that there are three basic types of financial innovations: Escapism to responding to needing condition change, to the small advantages supplying with condition change and to controlling. We have had one now understandable that banking institution is innovative for instance the cause institutions, let’s look at examples of how financial institutions in their search for profits have produced financial innovations of the three basic types. 1

汽车制动系统-毕业设计外文资料翻译

Automobile Brake System The braking system is the most important system in cars. If the brakes fail, the result can be disastrous. Brakes are actually energy conversion devices, which convert the kinetic energy (momentum) of the vehicle into thermal energy (heat).When stepping on the brakes, the driver commands a stopping force ten times as powerful as the force that puts the car in motion. The braking system can exert thousands of pounds of pressure on each of the four brakes. Two complete independent braking systems are used on the car. They are the service brake and the parking brake. The service brake acts to slow, stop, or hold the vehicle during normal driving. They are foot-operated by the driver depressing and releasing the brake pedal. The primary purpose of the parking brake is to hold the vehicle stationary while it is unattended. The parking brake is mechanically operated by when a separate parking brake foot pedal or hand lever is set. The brake system is composed of the following basic c omponents: the “master cylinder” which is located under the hood, and is directly connected to the brake pedal, converts driver foot’s mechanical pressure into hydraulic pressure. Steel “brake lines” and flexible “brake hoses” connect the master cylinder to the cylinders” located at each wheel. Brake fluid, specially designed to work in extreme conditions, fills the system. “Shoes” and “pads” are pushed by cylinders to contact the “drums” and “rotors” thus causing drag, which (hopefully) slows the car. The typical brake system consists of disk brakes in front and either disk or drum brakes in the rear connected by a system of tubes and hoses that link the brake at each wheel to the master cylinder (Figure).

汽车全部零部件英文翻译

汽车全部零部件英文翻译 车轮系统 Wheeling System 轮毂 Wheel Hub 轮胎 Tire 轮胎汽门嘴 Tire Valve 轮圈 Wheel Disk 轮圈盖 Wheel Cover 车轮系统 Wheeling System 电装品 Electrical Parts 电瓶 Battery 中央门控 Central Door Lock 分电盘 Distributor 火星塞 Spark Plug 汽车用电子钟 Digital Clock 汽车音响 Car Audio 防盗器 Car Burglar Alarm 雨刷及雨刷连杆 Wiper / Linkage 保险丝座Fuse Seat 保险丝 Fuse 洗涤壶 Windshield Washer 配线 Wire Harness 马达类 Motor 高压线组 Ignition Cable 喇叭 Horn 发电机Alternator (Components) 开关类 Switch 蜂鸣器 Buzzer 预热塞 Glow Plug 仪表 Combination Meter 灯泡 Bulb 灯类 Lamp 点火线圈 Ignition Coil 继电器 Relay 倒车雷达 Reverse Sensor 电池充电器 Battery Charger

闪光器 Flasher 省电器 Energy Saving Unit 端子 Terminal 电动座椅装置 Power Seat Unit 马达零件 Motor Components 电装品 Electrical Parts 汽车用光盘 Car CD 汽车用液晶显示器 Car LCD 调整器 Regulator 整流器 Rectifier 电子点火器 Ignition Module 倒车显示器 Rear View Display 定速器 Cruise Controller HID车灯安定器组合 HID Ballast Complete Set for Headlights LED 灯 LED Lamp 车灯控制器 Lighting Controller 点火线圈模块 Ignition Coil Module 外装品 Exterior Parts 水箱饰罩 Radiator Grille 天线 Antenna 车身护条 Side Protector 防撞护垫 Bumper Pad 后视镜 Door Mirror 装饰贴纸、标志Ornament Mark 轮弧 Fender Trim 挡泥板 Mud Guard 扰流板 Spoiler 前防撞杆 Guard Assy (Front) 后防撞杆 Grard Assy (Rear) 内装品 Interior Parts 仪表板 Instrument Panel 中央置物箱 Console 孔塞 Grommet Plug 地毯 Floor Mat

汽车制动系统(机械、车辆工程毕业论文英文文献及翻译)

Automobile Brake System汽车制动系统 The braking system is the most important system in cars. If the brakes fail, the result can be disastrous. Brakes are actually energy conversion devices, which convert the kinetic energy (momentum) of the vehicle into thermal energy (heat).When stepping on the brakes, the driver commands a stopping force ten times as powerful as the force that puts the car in motion. The braking system can exert thousands of pounds of pressure on each of the four brakes. Two complete independent braking systems are used on the car. They are the service brake and the parking brake. The service brake acts to slow, stop, or hold the vehicle during normal driving. They are foot-operated by the driver depressing and releasing the brake pedal. The primary purpose of the brake is to hold the vehicle stationary while it is unattended. The parking brake is mechanically operated by when a separate parking brake foot pedal or hand lever is set. The brake system is composed of the following basic components: the “master cylinder” which is located under the hood, and is directly connected to the brake pedal, converts driver foot’s mechanical pressure into hydraulic pressure. Steel “brake lines” and flexible “brake hoses” connect the master cylinder to the “slave cylinders” located at each wheel. Brake fluid, specially designed to work in extreme conditions, fills the system. “Shoes” and “pads” are pushed by the slave cylinders to contact the “drums” and “rotors” thus causing drag, which (hopefully) slows the c ar. The typical brake system consists of disk brakes in front and either disk or drum brakes in the rear connected by a system of tubes and hoses that link the brake at each wheel to the master cylinder (Figure). Basically, all car brakes are friction brakes. When the driver applies the brake, the control device forces brake shoes, or pads, against the rotating brake drum or disks at wheel. Friction between the shoes or pads and the drums or disks then slows or stops the wheel so that the car is braked.

汽车英语单词常用缩写

汽车英语单词常用缩写 汽车英语单词常用缩写 CVVT是英文ContinueVariableValveTiming的缩写,翻译成中 文就是连续可变气门正时机构 TSI是Turbo-charging,涡轮增压;Super-charging,机械增压 和Injection,燃油直喷,三个关键特色的首字母缩写。 DSG(DirectShiftGearbox)中文表面意思为“直接换挡变速器”。 ABS即英文AntilockBrakingSystem的缩写,意为“防抱死制动 系统” 4WD即英文FourWheeldrive的缩写,意为“四轮驱动系统” 4WS即英文FourWheelSteer的'缩写,意为“四轮转向系统”。 SRS即英文SupplementalRestraintSystem的缩写,意为“汽车 安全气囊” MPV的全称是Multi-PurposeVehicle,即多用途汽车 GPS即英文GlobalPositionsystem的缩写,意为“全球导航系统” EGR即英文ExhaustGasRecycle的缩写,意为“废气再循环系统” ATF即英文AutomaticTransmissionFluid的缩写,意为“自动 变速器油”。 ECT即英文EmissionControlSystem的缩写,意为“电子控制自 动变速器” PPS英文ProgressivePowerSteering的缩写,意为“电子控制 液压动力转向系统”

VIN即英文VehicleIdentificationNumber的缩写,意为“机动 车身份条形码” OBD即英文OnB0ardDiagnostics的缩写,意为“车载诊断系统” ASR即英文AccelerationSlipRegulation的缩写,意为“汽车 驱动防滑控制系统” VSC即英文VehicleStabilityControl的缩写,意为“汽车稳定 控制系统” TWC即英文ThreeWayCatalyticConverter的缩写,意为“三元 催化转换器” ISC是“怠速控制系统”

汽车系统英文对照大全

汽车系统英文对照大全 A 涡轮增压是turbo,机械增压是supercharger,而燃油分层直喷Fuel Stratified Injection缩写是fsi AFS:自适应照明系统主动前轮转向系统 AYC:主动偏航控制系统主动横摆控制系统 ASC:主动式稳定控制系统自动稳定和牵引力控制车轮打滑控制 ABS:防抱死制动系统 ASR:防滑系统 ASL:音量自动调节系统排档自动锁定装置 AUX:音频输入端口 ADS:自适应减振系统 ACC:自适应巡航控制系统车距感应式定速巡航控制系统 AWD:全时四轮驱动系统 ACD:主动中央差速器 AMT:电子自动变速箱电控机械式自动变速器 All-Speed TCS:全速段牵引力控制系统 ACIS:电子控制进气流程系统丰田可变进气歧管系统 ABD:自动制动差速系统 AGF:亚洲吉利方程式国际公开赛 AUTO:自动切换四驱 ASC+T:自动稳定和牵引力控制系统 ABC:主动车身控制 AXCR:亚洲越野拉力赛 ARP:主动防侧翻保护 AFM:动态燃油管理系统 APEAL:新车满意度中国汽车性能、运行和设计调研 AT:自动变速器 Asian festival of speed:亚洲赛车节 AOD:电子控制按需传动装置 AACN:全自动撞车通报系统 ARTS:智能安全气囊系统 AWS:后撞头颈保护系统 AIAC:奥迪国际广告大赛 AVS:适应式可变悬架系统 Audi AAA:奥迪认证轿车 ATA:防盗警报系统 ALS:自动车身平衡系统 ARS:防滑系统 ASPS:防潜滑保护系统 ASS:自适应座椅系统

AQS:空气质量系统 AVCS:主动气门控制系统 ASF:奥迪全铝车身框架结构 A-TRC:主动牵引力控制系统 AHC:油压式自动车高调整 AMG:快速换档自动变速箱 AHS2:“双模”完全混合动力系统 AI:人工智能换档控制 APRC:亚太汽车拉力锦标赛 ARTS:自适应限制保护技术系统 ACU:安全气囊系统控制单元 AP:恒时全轮驱动 AZ:接通式全轮驱动 ASM:动态稳定系统 AS:转向臂 APC:预喷量控制 Active Light Function:主动灯光功能 ACE:高级兼容性设计 Audi Space Frame:奥迪全铝车身技术AWC:全轮控制系统 ASTC:主动式稳定性和牵引力控制系统 B BA:紧急制动辅助系统 BEST:欧盟生物乙醇推广项目 Brake Energy Regeneration:制动能量回收系统BLIS:盲区信息系统 BAS:制动助力辅助装置BRIDGESTONE:普利司通轮胎 Biometric immobilizer:生物防盗系统 BCI:蓄电池国际协会国际电池大会BAR:大气压 BDC:下止点 BBDC:北京奔驰-戴克汽车新工厂 B:水平对置式排列多缸发动机 BF:钢板弹簧悬架 BCM:车身控制模块 BCS:博世汽车专业维修网络 BMBS:爆胎监测与制动系统 BFCEC:北京福田康明斯发动机有限公司

汽车制动器论文中英文对照资料外文翻译文献

毕业设计(论文)外文翻译 AUTOMOTIWE FINAL DRIVE FINAL DRIVE A final drive is that part of a power transmission system between the drive shaft and the differential. Its function is to change the direction of the power transmitted by the drive shaft through 90 degrees to the driving axles. At the same time. it provides a fixed reduction between the speed of the drive shaft and the axle driving the wheels. The reduction or gear ratio of the final drive is determined by dividing the number of teeth on the ring gear by the number of teeth on the pinion gear. In passenger vehicles, this speed reduction varies from about 3:1 to 5:1. In trucks it varies from about 5:1 to 11:1. To calculate rear axle ratio, count the number of teeth on each gear. Then divide the number of pinion teeth into the number of ring gear teeth. For example, if the pinion gear has 10 teeth and the ring gear has 30 (30 divided by 10), the rear axle ratio would be 3:1. Manufacturers install a rear axle ratio that provides a compromise between performance and economy. The average passenger car ratio is 3.50:1. The higher axle ratio, 4.11:1 for instance, would increase acceleration and pulling power but would decrease fuel economy. The engine would have to run at a higher rpm to maintain an equal cruising speed. The lower axle ratio. 3:1, would reduce acceleration and

汽车内饰件常见英语翻译

汽车内饰件常见英语翻译

01-零件(Part) 一、零件总成(Parts Assembly) 1、发动机舱系统(Engine Compartment System) 1.引擎盖隔音垫Hood 2.前围前隔音垫Dashout 2、乘员舱饰件系统(Passenger Compartment System) 1.主地毯Carpet 2.顶棚Headliner 3.前围后隔音垫Dashinner 4.脚垫Mat 5.衣帽架Package Tray 6.中通道隔音垫Tunnel Insulator 7.座椅靠背地毯Seat Back Carpet 3、行李箱饰件系统(Trunk Trim System) 1.侧饰板Side trim 2.备胎盖Trunk

Carpet 3.内饰板Decklid Trim 4、外饰系统(Exterior Trim Systems) 1.密封条Sealing 2.轮罩Wheel House 3.防水膜Water Shield 二、外协件(Outsourcing Parts) 1.塑料固定扣(尼龙扣)Plastic Fixed Buckle (Nylon Buttons) 2.塑料尾部连接块卡扣Plastic Tail Connection Buckle 3.塑料尾部连接块顶端卡扣Plastic Tail Top Connection Buckle 4.金属连接扣Metal Connection Buckle 5.塑料保险带扣Plastic Seat Belts Buckle 6.组合卡子Combination Bands 7.尼龙拉手Nylon Shake Hander

英文简历必备-个人资料中英翻译

个人资料 name 姓名 alias 别名 pen name 笔名 date of birth 出生日期 birth date 出生日期 born 出生于 birth place 出生地点 age 年龄 native place 籍贯 province 省 city 市 autonomous region 自治区prefecture 专区 county 县 nationality 民族,国籍citizenship 国籍 duel citizenship 双重国籍address 地址 current address 目前地址present address 目前地址permanent address 永久地址postal code 邮政编码 home phone 住宅电话 office phone 办公电话business phone 办公电话Tel.电话 sex 性别 male 男

female 女 height 身高 weight 体重 marital status 婚姻状况family status 家庭状况married 已婚 single/unmarried 未婚divorced 离异 separated 分居 number of children 子女人数none 无 street 街 lane 胡同,巷 road 路 district 区 house number 门牌 health 健康状况 health condition 健康状况blood type 血型 short-sighted 近视 far-sighted 远视 color-blind 色盲 ID card No.身份证号码 date of availability 可到职时间available 可到职membership 会员,资格president 会长 vice-president 副会长director 理事 standing director 常务理事

中英文文献翻译—汽车制动系统的概述

附录 Automobile Brake System The braking system is the most important system in cars. If the brakes fail, the result can be disastrous. Brakes are actually energy conversion devices, which convert the kinetic energy (momentum) of the vehicle into thermal energy (heat).When stepping on the brakes, the driver commands a stopping force ten times as powerful as the force that puts the car in motion. The braking system can exert thousands of pounds of pressure on each of the four brakes. Two complete independent braking systems are used on the car. They are the service brake and the parking brake. The service brake acts to slow, stop, or hold the vehicle during normal driving. They are foot-operated by the driver depressing and releasing the brake pedal. The primary purpose of the brake is to hold the vehicle stationary while it is unattended. The parking brake is mechanically operated by when a separate parking brake foot pedal or hand lever is set. The brake system is composed of the following basic component s: the “master cylinder” which is located under the hood, and is directly connected to the brake pedal, converts driver foot’s mechanical pressure into hydraulic pressure. Steel “brake lines” and flexible “brake hoses” connect the master cylinder to the “slave cylinders” located at each wheel. Brake fluid, specially designed to work in extreme conditions, fills the system.

(完整版)汽车内饰件常见英语翻译

01-零件(Part) 一、零件总成(Parts Assembly) 1、发动机舱系统(Engine Compartment System) 1.引擎盖隔音垫Hood 2.前围前隔音垫Dashout 2、乘员舱饰件系统(Passenger Compartment System) 1.主地毯Carpet 2.顶棚Headliner 3.前围后隔音垫Dashinner 4.脚垫Mat 5.衣帽架Package Tray 6.中通道隔音垫Tunnel Insulator 7.座椅靠背地毯Seat Back Carpet 3、行李箱饰件系统(Trunk Trim System) 1.侧饰板Side trim 2.备胎盖Trunk Carpet 3.内饰板Decklid Trim 4、外饰系统(Exterior Trim Systems) 1.密封条Sealing 2.轮罩Wheel House 3.防水膜Water Shield 二、外协件(Outsourcing Parts) 1.塑料固定扣(尼龙扣)Plastic Fixed Buckle (Nylon Buttons) 2.塑料尾部连接块卡扣Plastic Tail Connection Buckle 3.塑料尾部连接块顶端卡扣Plastic Tail Top Connection Buckle 4.金属连接扣Metal Connection Buckle 5.塑料保险带扣Plastic Seat Belts Buckle 6.组合卡子Combination Bands 7.尼龙拉手Nylon Shake Hander 8.塑料拉手Plastic Handle 9.索环Lasso 10.拉索组件Lasso Components 11.阅读灯面板组件Reading Lamp Panel Components 12.遮阳板组件Sunshading Board Components

汽车系统英文大全

汽车系统英文大全 A AFS:自适应照明系统主动前轮转向系统 AYC:主动偏航控制系统主动横摆控制系统 ASC:主动式稳定控制系统自动稳定和牵引力控制车轮打滑控制ABS:防抱死制动系统 ASR:防滑系统 ASL:音量自动调节系统排档自动锁定装置 AUX:音频输入端口 ADS:自适应减振系统 ACC:自适应巡航控制系统车距感应式定速巡航控制系统 AWD:全时四轮驱动系统 ACD:主动中央差速器 AMT:电子自动变速箱电控机械式自动变速器 All-Speed TCS:全速段牵引力控制系统 ACIS:电子控制进气流程系统丰田可变进气歧管系统 ABD:自动制动差速系统 AGF:亚洲吉利方程式国际公开赛 AUTO:自动切换四驱 ASC+T:自动稳定和牵引力控制系统 ABC:主动车身控制 AXCR:亚洲越野拉力赛 ARP:主动防侧翻保护 AFM:动态燃油管理系统 APEAL:新车满意度中国汽车性能、运行和设计调研 AT:自动变速器 Asian festival of speed:亚洲赛车节 AOD:电子控制按需传动装置 AACN:全自动撞车通报系统 ARTS:智能安全气囊系统 AWS:后撞头颈保护系统 AIAC:奥迪国际广告大赛 AVS:适应式可变悬架系统 Audi AAA:奥迪认证轿车 ATA:防盗警报系统 ALS:自动车身平衡系统 ARS:防滑系统 ASPS:防潜滑保护系统 ASS:自适应座椅系统 AQS:空气质量系统 AVCS:主动气门控制系统 ASF:奥迪全铝车身框架结构 A-TRC:主动牵引力控制系统

AHC:油压式自动车高调整 AMG:快速换档自动变速箱 AHS2:“双模”完全混合动力系统 AI:人工智能换档控制 APRC:亚太汽车拉力锦标赛 ARTS:自适应限制保护技术系统 ACU:安全气囊系统控制单元 AP:恒时全轮驱动 AZ:接通式全轮驱动 ASM:动态稳定系统 AS:转向臂 APC:预喷量控制 Active Light Function:主动灯光功能 ACE:高级兼容性设计 Audi Space Frame:奥迪全铝车身技术 AWC:全轮控制系统 ASTC:主动式稳定性和牵引力控制系统 B BA:紧急制动辅助系统 BEST:欧盟生物乙醇推广项目 Brake Energy Regeneration:制动能量回收系统BLIS:盲区信息系统 BAS:制动助力辅助装置 BRIDGESTONE:普利司通轮胎 Biometric immobilizer:生物防盗系统 BCI:蓄电池国际协会国际电池大会 BAR:大气压 BDC:下止点 BBDC:北京奔驰-戴克汽车新工厂 B:水平对置式排列多缸发动机 BF:钢板弹簧悬架 BCM:车身控制模块 BCS:博世汽车专业维修网络 BMBS:爆胎监测与制动系统 BFCEC:北京福田康明斯发动机有限公司 C CCS:智能定速巡航控制系统 CSI:中国售后服务满意度调研 CVVT:连续可调气门正时 CVT:无级变速器 CZIP:清洁区域内部组件 CCC:全国汽车场地锦标赛 CVTC:连续可变气门正时机构连续可变配气正时

英文翻译资料:各种工具

各种工具toolbox 工具箱 bench 工作台 vice, clamp 虎钳(美作:vise) saw 锯 bow saw 弓锯 circular saw 圆锯(美作:buzzsaw) compass saw, scroll saw 钢丝锯fretsaw 细锯 handsaw 手锯 chisel 口凿 cold chisel, burin 冰凿 gouge, firmer gouge 半圆凿 plane 刨子 moulding plane 型刨 jack plane 粗刨 rabbet plane 槽刨 drawknife 刮刀 scraper 三角刮刀 rasp 粗锉 file 锉 square 尺

miter 斜槽规 scriber 近线尺 set square, triangle 三角板brace 手拉曲柄锉 hand drill 手钻 drill, bit 钻,有柄钻 gimlet, auger 钻,无柄钻countersink 锥口钻 gauge, marking gauge 量规hammer 锤 mallet 木槌 nail 钉 brad 平头钉 tack, stud 圆头钉 screw 螺丝钉 screwdriver 螺丝刀,改锥screw tap 螺丝攻 nail puller 拔钉器 ruler 尺 tape measure 卷尺 folding ruler 折尺sandpaper, emery paper 砂纸

toolbox 工具箱 bench 工作台 vice, clamp 虎钳(美作:vise) saw 锯 bow saw 弓锯 circular saw 圆锯(美作:buzzsaw) compass saw, scroll saw 钢丝锯fretsaw 细锯 handsaw 手锯 chisel 口凿 cold chisel, burin 冰凿 gouge, firmer gouge 半圆凿plane 刨子 moulding plane 型刨 jack plane 粗刨 rabbet plane 槽刨 drawknife 刮刀 scraper 三角刮刀 rasp 粗锉 file 锉 square 尺 miter 斜槽规

汽车制动系统-英文文献及翻译

Brake systems We all know that pushing down on the brake pedal slows a car to a stop. But how does this happen? How does your car transmit the force from your leg to its wheels? How does it multiply the force so that it is enough to stop something as big as a car? Brake Image Gallery Layout of typical brake system. See more brake images. When you depress your brake pedal, your car transmits the force from your foot to its brakes through a fluid. Since the actual brakes require a much greater force than you could apply with your leg, your car must also multiply the force of your foot. It does this in two ways: ?Mechanical advantage (leverage) ?Hydraulic force multiplication The brakes transmit the force to the tires using friction, and the tires transmit that force to the road using friction also. Before we begin our discussion on the components of the brake system, we'll cover these three principles: ?Leverage ?Hydraulics ?Friction Leverage and Hydraulics In the figure below, a force F is being applied to the left end of the lever. The left end of the lever is twice as long (2X) as the right end (X). Therefore, on the right end of the lever a force of 2F is available, but it acts through half of the distance (Y) that the left end moves (2Y). Changing the relative lengths of the left and right ends of the lever changes the multipliers.