Automatic Detection of Region-Mura defect in TFT-LCD

IEICE TRANS.INF.&SYST.,VOL.Exx–??,NO.xx XXXX200x

1 PAPER

Automatic Detection of Region-Mura Defect in TFT-LCD

Jae Y.LEE?a)and Suk I.YOO?b),Nonmembers

SUMMARY Visual defects,called mura in the?eld,some-times occur during the manufacturing of the?at panel liquid crys-tal displays.In this paper we propose an automatic inspection method that reliably detects and quanti?es TFT-LCD region-mura defects.The method consists of two phases.In the?rst phase we segment candidate region-muras from TFT-LCD panel images using the modi?ed regression diagnostics and Niblack’s thresholding.In the second phase,based on the human eye’s sensitivity to mura,we quantify mura level for each candidate, which is used to identify real muras by grading them as pass or fail.Performance of the proposed method is evaluated on real TFT-LCD panel samples.

key words:Machine vision,image segmentation,regression diagnostics,industrial inspection,visual perception.

1.Introduction

Recently,TFT-LCD(Thin Film Transistor Liquid Crystal Display)devices have become a major technol-ogy for FPD(Flat Panel Display).As the FPD market becomes more and more competitive,the quality of the display becomes a more critical issue for manufactur-ers.The most important process to control the quality of the display is to inspect visual defects that some-times occur during the manufacturing of the?at panel liquid crystal displays.Human visual inspection,which is still used by most manufacturers,has a number of drawbacks including limitations of human sensitivity, inconsistent detection due to human subjectivity,and high cost.Automatic inspection using machine vision techniques can overcome many of these disadvantages and o?er manufacturers an opportunity to signi?cantly improve quality and reduce costs.

One class of defects includes a variety of blem-ishes,called mura?in the?eld,which appear as low contrast and non-uniform brightness regions,typically larger than single pixels[12],[15].They are caused by a variety of physical factors such as non-uniformly dis-

Manuscript received January1,2004.

Manuscript revised January1,2004.

Final manuscript received January1,2004.

?The authors are with the School of Computer Science and Engineering,Seoul National University,Shilim-Dong, Gwanak-Gu,Seoul151-742,Korea.

a)E-mail:leejy@ailab.snu.ac.kr

b)E-mail:siyoo@ailab.snu.ac.kr

?Mura is a Japanese word meaning blemish that has been adopted in English to provide a name for imperfections of a display pixel matrix surface that are visible when the display screen is driven to a constant gray

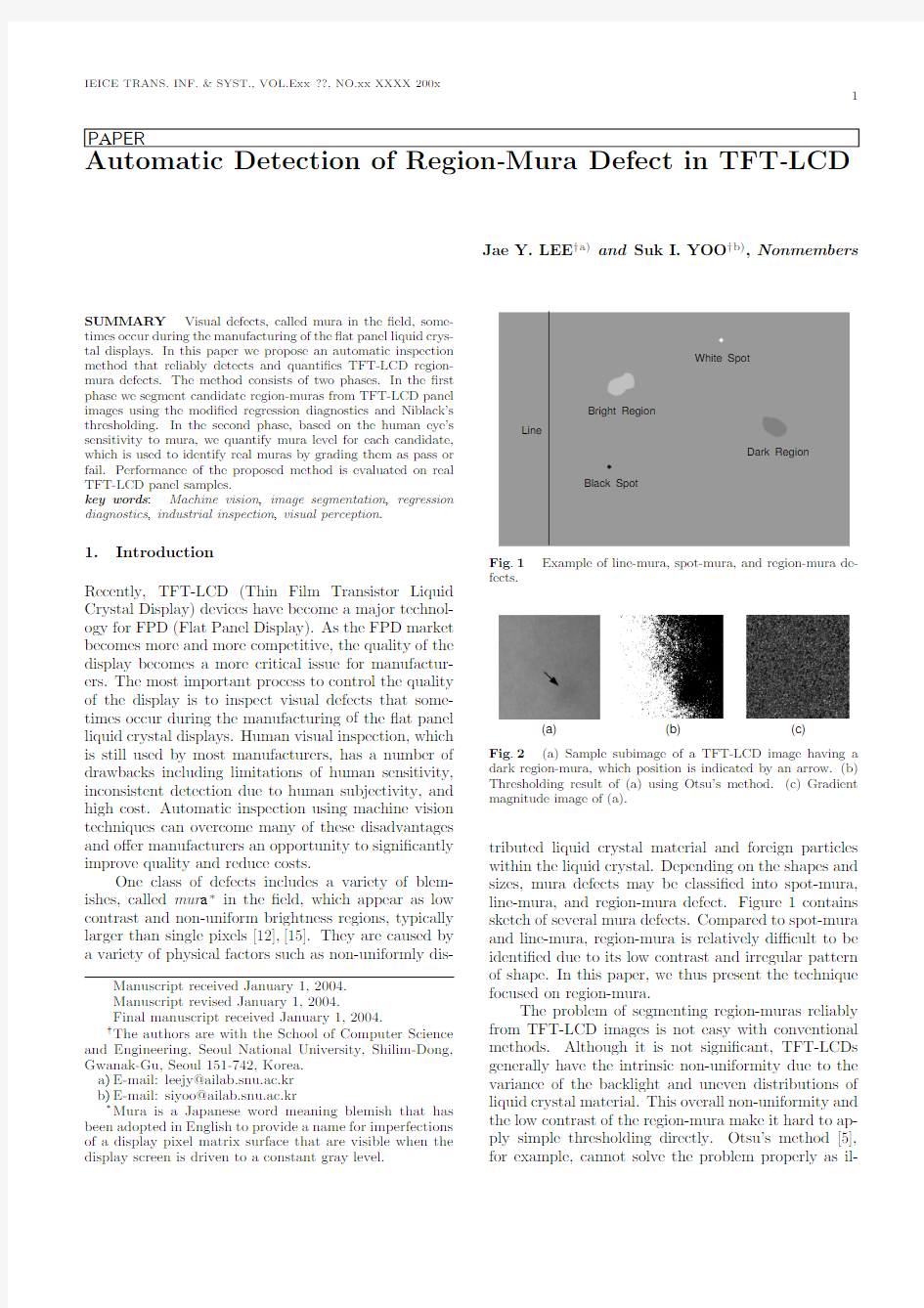

level.Fig.1Example of line-mura,spot-mura,and region-mura de-

fects.

(a)(b)(c)

Fig.2(a)Sample subimage of a TFT-LCD image having a dark region-mura,which position is indicated by an arrow.(b) Thresholding result of(a)using Otsu’s method.(c)Gradient magnitude image of(a).

tributed liquid crystal material and foreign particles within the liquid crystal.Depending on the shapes and sizes,mura defects may be classi?ed into spot-mura, line-mura,and region-mura defect.Figure1contains sketch of several mura https://www.360docs.net/doc/2319273751.html,pared to spot-mura and line-mura,region-mura is relatively di?cult to be identi?ed due to its low contrast and irregular pattern of shape.In this paper,we thus present the technique focused on region-mura.

The problem of segmenting region-muras reliably from TFT-LCD images is not easy with conventional methods.Although it is not signi?cant,TFT-LCDs generally have the intrinsic non-uniformity due to the variance of the backlight and uneven distributions of liquid crystal material.This overall non-uniformity and the low contrast of the region-mura make it hard to ap-ply simple thresholding directly.Otsu’s method[5], for example,cannot solve the problem properly as il-

2

IEICE TRANS.INF.&SYST.,VOL.Exx–??,NO.xx XXXX

200x

Pass/Fail Classification Mura Level Quantification

(a)

(b)(c)(d)

(e)

(f)

Fig.3Overview of our region-mura inspection procedure.(a)Input image.(b)Ex-tracted windows (W ×H pixels).(c)Local segmentation results.(d)Merged segmenta-tion result.(e)Post-processed image.(f)Extracted candidate region-mura which mura level is to be quanti?ed.

lustrated in Fig.2(b).Also,region-muras have smooth change of brightness from their surrounding regions,and therefore,they have no clear edge as shown in Fig.2(c).This characteristic invalidates the precondi-tions required for gradient magnitude based approaches [9],[13].Another problem in TFT-LCD image quality inspection is to quantify mura level for each region-mura.Quanti?cation is necessary to control a mura acceptance level according to the panel quality level re-quired by the industry.

In this paper we describe an automatic inspec-tion method that reliably detects and quanti?es TFT-LCD region-mura defects.The method consists of two phases.In the ?rst phase we segment candidate region-muras from TFT-LCD panel images using the modi?ed regression diagnostics [6]and Niblack’s thresholding [7].In the second phase,based on the human eye’s sensitiv-ity to mura,we quantify mura level for each candidate,which is used to identify real muras by grading them as pass or fail.2.

Approach Overview

The overall inspection procedure is shown in Fig.3.For each TFT-LCD panel under test,prede?ned full-screen constant test patterns are displayed to produce digital input images.Figure 3(a)shows a TFT-LCD panel im-

age captured when the display screen is driven to a con-stant gray pattern.Each input image is then divided into overlapping windows for local processing.The win-dow size,W ×H ,and the amount of overlapping,?W and ?H ,are estimated from a priori knowledge.Seg-mentation of region-mura is performed on each win-dow and the local segmentation results are merged into a single binary image with their original positions in the input image,as shown in Fig.3(d).This local pro-cessing is to reduce the overall non-uniformity in the input image.The merged binary image is then post-processed by median ?ltering,morphological closing,and morphological opening [16]to remove noise and re-?ne the segmentation result.Finally candidate region-muras are extracted from the post-processed image and their mura levels are quanti?ed in order to identify real muras.

The most critical part of our approach is to seg-ment region-muras from each window image,which can be outlined as follows:

1.We use the modi?ed regression diagnostics to roughly estimate the background region in the win-dow image.The estimated background region is then approximated by a low order polynomial to generate a background surface.

2.Subtraction of the background surface from the

Y.and SUK I.YOO:AUTOMATIC DETECTION OF REGION-MURA DEFECT IN TFT-LCD

3

original window image is used to?nd threshold to obtain the binary segmentation result.This sub-traction is to remove the in?uence of non-uniform background and transform the segmentation prob-lem into a simple thresholding one.

Section3describes our local segmentation proce-dure in detail.Section4presents human perception model and quanti?cation formula on mura level.In Sect.5,performance of our method is evaluated on real TFT-LCD panel samples,and?nally the conclusion is presented in Sect.6.

3.Local Segmentation

3.1Background Surface Estimation

To remove the in?uence of non-uniform background, we?rst have to estimate background surface robustly. The problem of background surface estimation can be viewed as a robust regression problem in data?tting [8].Let I be a window image of size W×H pixels. Each pixel located at(x,y)with the intensity value z xy,called a data pixel,will be denoted by(x,y;z xy) for x=1,...,W,y=1,...,H.The data set is then de?ned to be a set of data pixels as

Ψ={(x,y;z xy)|x=1,...,W,y=1,...,H}.(1) The data set is approximated by a bivariate polynomial model f(d)(x,y)of order d,

f(d)(x,y)=

m+n≤d

a mn x m y n,(2)

such that f(d)(x,y)gives the estimated intensity value at(x,y)for x=1,...,W,y=1,...,H.The residual of the xy th data pixel with respect to f(d),denoted by r xy,is the di?erence between the original and the estimated intensity of the xy th data pixel given by r xy=z xy?f(d)(x,y).(3) The simplest way to estimate the model parame-ters,a mn’s,may be the least-squares(LS)regression method,in which the model parameters are estimated by minimizing the sum of the squared residuals: min

x,y

r2xy.(4)

The LS method,however,performs poorly in terms of robustness because even a single aberrant data point,or an outlier,can completely perturb the regression result [8].

In our approach,we use a modi?ed version of re-gression diagnostics[6]to estimate the background sur-face robustly.Diagnostics are certain quantities com-puted from the data with the purpose of pinpointing aberrant data points,after which these outliers can

be

(a)(b)(c)(d)

(e)(f)(g)(h)

Fig.4The process of local segmentation(l=2,h=4).(a) Input window image.(b)Computed diagnostic measure J.(c) Constructed binary image withα=20.(d)Median-?ltered im-age of(c).(e)Estimated background surface f(h)

B

.(f)Absolute

residuals with respect to f(h)

B

.(g)Thresholding result of residu-als with T=2.(h)Post-processing result.

removed,followed by a LS analysis on the remaining ones.Our background surface estimation algorithm, when the size of region-mura is upper-bounded byα% of the window size,works as follows:

1.For each data pixel p inΨ,

a.Remove p from the data set.LetΨ?p be the

resulting data set:

Ψ?p=Ψ?{p}.(5)

b.Determine the polynomial of order l?tting

Ψ?p,denoted by f(l)?p,using the LS.

https://www.360docs.net/doc/2319273751.html,pute the diagnostic measure J(p)de?ned

to be the mean of the absolute residuals of the

data pixels inΨ?p with respect to f(l)?p:

J(p)=

1

W H?1

Ψ?p

|z xy?f(l)?p(x,y)|.(6)

2.Construct a binary image so thatα%data pixels

which have small value of J are classi?ed as white with value one and the others as black with value zero.

3.Apply median?ltering to the binary image.

4.Remove probable outliers fromΨby excluding

data pixels which correspond to the white pixels in the median-?ltered binary image,giving an es-timation of the background region denoted byΨB.

5.Determine the polynomial of order h?ttingΨB,

denoted by f(h)

B

,using the LS.

The order of polynomial for diagnostics measure,l, is determined to be the average order of the background variations of the LCD panel images and the order for ?nal background?tting,h,is determined to be the max-imal order of the background variations,where the or-der of background variation is de?ned to be the least order of polynomial that can?t the background with

4

IEICE TRANS.INF.&SYST.,VOL.Exx–??,NO.xx XXXX

200x

(a)

(b)

(c)

(d)

Fig.5Single polynomial model versus composite model:(a)biquadratic (d =2)for both diagnostics measure and background ?tting;(b)biquartic (d =4)for both diag-nostics measure and background ?tting;(c)–(d)biquadratic for diagnostics measure and biquartic for background ?tting.The input image of (c)is same as (a)and the input image of (d)is same as (b).From left to right,each column corresponds to input win-dow image,diagnostics measure,constructed binary image,median-?ltered binary image,background surface ?t,absolute residuals,thresholding result of residuals (T =2),and post-processing result.

acceptable ?tting error less than prede?ned threshold.

The process of background surface estimation is il-lustrated in Fig.4.When the size of a region-mura is much less than αW H/100pixels or the window image has no region-mura,however,some background pixels may be included in the α%data pixels.The median ?ltering solves this problem to some extent as shown in Fig.4(d).It should be pointed out that a ?xed thresh-olding on J is not probable since the range of J varies widely over images according to the contrast and size of the region-muras and the degree of non-uniformity of the background.The estimated background surface re-?ects the brightness variations of the background quite well as shown in Fig.4(e).

We use two polynomial models of di?erent orders for the background surface estimation:one of order l for diagnostics measure and the other of order h for ?nal background ?tting.The LCD panel images have varying order of background non-uniformity over im-ages.Therefore,with a ?xed single polynomial model,it is hard to ?t them e?ectively:If the order of poly-nomial model is less than the variations in the back-ground,some background pixels,which are not ?tted by the model,can be incorrectly classi?ed as outliers (Fig.5(a)).Moreover some weak region-muras can be missed due to incorrect ?tting.On the other hand,if the order of polynomial model is too high,it can over?t

the data set including outliers and give unreliable diag-nostic measures especially when the size of the region-mura is large (Fig.5(b)).In our two-model strategy,the over?t is minimized using the low order polynomial model and the possible misclassi?cations are corrected by the high order model (Fig.5(c)and (d)).3.2

Thresholding

Previously,we have robustly estimated the background

surface f (h )

B including the background region ΨB .Let r ?xy be the residual of the xy th data pixel with respect to f (h )

B given by

r ?

xy =z xy ?f (h )

B (x,y ).

(7)

The segmentation problem is then transformed into a simple thresholding one on the residuals.The threshold is determined based on the distribution of the residuals of the background pixels.Let μbe the residual mean and σbe the standard deviation of the residuals of the background pixels given by

μ=1|ΨB |

(x,y ;z xy )∈ΨB

r ?

xy (8)

σ2

=

1

|ΨB |

(x,y ;z xy )∈ΨB

(r ?xy ?μ)2

,

(9)

Y.and SUK I.YOO:AUTOMATIC DETECTION OF REGION-MURA DEFECT IN TFT-LCD

5

Fig.6Segmentation examples.

where |ΨB |is the cardinality of ΨB .For a given thresh-old T ,according to Niblack’s method [7],the image is then segmented into a binary image so that the defect region is to be white with value one and the background region to be black with value zero as follows:

Z (x,y )= 1,|r ?

xy ?μ|/σ>T

0,|r ?

xy ?μ|/σ≤T (10)Resulting binary images are merged into a single binary image as described in Sect.2and then post-processed,giving candidate region-muras.Figure 6shows three examples with their original window images,3D views,and ?nal images processed.In Fig.6,the top image has one dark circular mura,the middle image has two dark muras,and the bottom image has two adjacent bright muras,and all muras were successfully segmented.4.

Visual Perception Based Identi?cation

In order to identify the real region-muras from the can-didates found in the previous section,the properties of the human visual perception have to be considered.In this section,we ?rst present human perception model and,based on it,formulate a measurement index on mura level.The ?nal identi?cation procedure is then followed.

4.1Visual Perception Model

The fovea is always focused on the object of interest by the accommodation ability of the eye.The typical sim-ulation of the retina consists of object region,object-background region,and surround-background region

Fig.7

Observation ?eld for computation of mura level.

with di?erent luminance stimuli [14].The regions are arranged in the observation ?eld as concentric ones,with the object in the middle followed by the object-background and the surround-background as shown in Fig.7.The object-background is the close neighbor-hood of the object that has a strong in?uence on the perception of the object.The width of the object-background is set to be a half of radiate distance from the object center such that d 2=0.5d 1.Its size is biolog-ically motivated [10].The surround-background region consists of the area of the complete retina and has a relatively weak in?uence on the perception of the ob-ject.The luminance stimulus of each region can be simpli?ed to the mean of the gray intensity of the cor-responding region in the image and will be denoted by I o for the object,I b for the object-background,and I s for the surround-background,respectively.If the surround-background is uniform and I s =I b ,we can ignore its in?uence on the perception of the object [2].4.2Measurement Index on Mura Level

The ability of the eye to discriminate between changes in luminance is explained by Weber’s law [1]:if L and L +?L are just noticeably di?erent luminances,?L/L is nearly a constant C w (C w is Weber’s constant).Ac-cording to Weber’s law,in the luminance term,the level of visibility of an object can be expressed as

Q L =

|L o ?L b |/L b

C w

,

(11)

where L o denotes luminance stimuli of the object and L b denotes luminance stimuli of the object-background.The luminance stimuli of the surround-background L s is ignored in Eq.(11),assuming uniform surround such that L s =L b .In the image intensity term,we can discard the in?uence of L b on ?L from Eq.(11)since the luminance is unevenly mapped to gray level in FPD devices so that ?I ’s,the just-noticeable intensity dif-ference,are nearly equal over all gray levels (e.g.,256gray levels for 8-bit display)when the object size is ?xed.Under this consideration Eq.(11)can be trans-formed into

6

IEICE TRANS.INF.&SYST.,VOL.Exx–??,NO.xx XXXX

200x

(a)(b)(c)(d)

Fig.8(a)A window image with a candidate region-mura in the middle.The minimal bounding rectangle is displayed with white color.(b)The region of the candidate region-mura.(c) The intensity-scaled residual image to have maximum255and minimum0.(d)The region of the object-background.

Q I=|I o?I b|

?I

.(12)

The just-noticeable intensity di?erence(JND),?I,in-creases quickly as the object area decreases[3].In a recent SEMI standard on FPD[17],using ergonomics approach,the relation between mura area and JND has been formulated as

JND=1.97/A0.33+0.72,(13) where A is the area of a mura.Finally,from Eq.(12) and Eq.(13),we thus have the following measurement index on mura level:

Q I=

|I o?I b|

1.97/A0.33+0.72

.(14)

4.3Identi?cation

For each candidate region-mura,we?rst locate a W×H window such that the minimal bounding rectangle of the candidate is centered within the window.Let I be the located window image.Next,by approximating the image surface of I except the pixels belonging to some candidate region-muras detected,we generate a polynomial surface,f(h)

B

,of order h.The image I is

then subtracted from f(h)

B ,giving a residual image R.

This subtraction,making I s=I b,removes the in?uence of non-uniform surround-background on the perception of the candidate region-mura.The object-background region is obtained by dilating the candidate mura region with w /2×h /2structuring element[16]and then by excluding the candidate mura region from the dilation result,where w is the width of the minimal bounding rectangle and h is the height of the rectangle.Finally, we compute the level of the candidate region-mura from Eq.(14)using I o,I b,and A given by

I o=

1

|Ψo|

p∈Ψo

R(p),(15)

I b=

1

|Ψb|

p∈Ψb

R(p),and(16)

A=|Ψo|,

(17)

(a)(b)(c)(d)

Fig.9Experimental results for three sample TFT-LCD panel

images.(a)Input images.(b)Results from Otsu’s method.(c)

Results from Chow and Kaneko’s method.(d)Results from our

method.

where R(p)is the residual of the data pixel p with re-

spect to f(h)

B

,Ψo is the set of data pixels of the can-didate mura region,andΨb is the set of data pixels

of the object-background region.If the level of a can-

didate region-mura exceeds the mura acceptance level

required by the industry,the candidate region-mura is

identi?ed to be the real.Figure8shows an example

illustrating this identi?cation procedure.

5.Experiments

5.1Experiment I

In the?rst experiment,we compare the segmentation

performance of our method with Chow and Kaneko’s

adaptive thresholding method[4].Chow and Kaneko

employed256×256pixel images and divided them into

7×7blocks of64×64pixel subimages with a50%

overlap.For each subimage having bimodal histogram,

a threshold was assigned to the center of it.Then

the threshold surface was interpolated from these lo-

cal thresholds,giving every pixel in the image its own

threshold.This method historically forms the foun-

dation of local thresholding method,and is frequently

cited in the literature.

Figure9shows the experimental result for three sample TFT-LCD panel images.The size of each input

image in Fig.9(a)is256×256pixels.The global thresh-

olding results from Otsu’s method[5]are included to

show the underlying non-uniformity in the image back-

grounds(Fig.9(b)).Figure9(c)shows the segmenta-

tion results from Chow and Kaneko’s method.The

parameters for bimodality test[11]were optimized for

each input image.Figure9(d)is the results from our

method withα=20and T=2.

Y.and SUK I.YOO:AUTOMATIC DETECTION OF REGION-MURA DEFECT IN TFT-LCD

7

Mura Level (Q)

A r e a (A )

Fig.10Plot of mura level and area of all candidate region-muras detected.Candidates claimed

by human inspection are

denoted by blue asterisk (?)and the

other candidates by red dot (?).

As shown in

Fig.9(c),with Chow and Kaneko’s method,the mura

regions are localized quite well as like with our method,but

some background regions are in-correctly segmented as candidate regions.

It is because the bimodality rarely occurs in the background

regions and thus interpolation from neighboring thresholds can be

ine?ective.5.2Experiment II

The next experiment has been performed on 200TFT-LCD panel samples consisting of 30bad panels and 170good panels.Each bad panel has at least one region-mura,totally 40region-mura defects,which was de-tected by human visual inspection in the ?eld.Good panels are those claimed to have no defect.The test patterns were black,blue,gray,green,red,and white,and thus 1,200input images were captured.The resolu-tion of each image is 1280×1024.Each of 1,200panel images was processed using our inspection algorithm with 256×256window size and with l =2,h =4,α=20,and T =2,and total 257candidate have been detected in the ?rst phase when all the identi-cal detections on the same region of a TFT-LCD panel were counted as one.There can be maximum of six detections on the same region of a panel as six di?er-ent pattern images are captured for each panel.In the second phase,the mura level values of all candidate region-muras were computed.For multiple detection case,the largest mura level value was selected.The mura level value of each real region-mura claimed by human inspection was then greater than 5.5,which is shown with blue asterisk (?)in Fig.10,while the aver-age of the mura level values of all the other candidates was less than 5.5,shown with the red dot (?)in Fig.10.Based on this result,the mura level threshold was set to

)1(#17.75=I Q )

5(#52.43=I Q )10(#54.26=I Q )

20(#83.16=I Q )

30(#94.10=I Q )

40(#02.9=I Q )50(#78.7=I Q )

60(#72.5=I Q Fig.11Inspection results and quanti?cation examples.Real region-muras claimed by human inspection are numbered with italic font.

be 5.5.Figure 11shows the inspection result for each candidate region-mura and selected candidate images ordered by computed mura level value to demonstrate the correspondence to human visibility.It took 0.49second,in average,to process each panel image.

From this experiment,all 40region-muras claimed by human inspection have been successfully detected but 23additional candidates,which are shown in Fig.12,have been also identi?ed to be real when the mura level threshold was set to be 5.5.These 23addi-tional defects identi?ed to be real but not claimed by human inspection re?ects the limitations of human vi-sual inspection including inconsistency and weak sensi-tivity.Finally,the mura level threshold can be adjusted according to the panel quality level required by the in-dustry:the threshold can be lowered until all weak defects required by industry can be detected or made larger to detect only serious ones.6.

Conclusion

For machine vision inspection for region-muras in TFT-LCD,a technique using mura levels was suggested.From the experiment performed on 200real TFT-LCD

8

IEICE TRANS.INF.&SYST.,VOL.Exx–??,NO.xx XXXX

200x

Fig.12Additional 23detections not claimed by human in-spection but identi?ed to be real.

panel samples,the computed mura level was shown to corresponds to human visibility quite well.In the 200test samples,our method was able to detect all of region-muras claimed by human inspection as well as some other region-muras not caught by human inspec-tion.We thus expect that the identi?cation scheme based on mura level quanti?cation can o?er manufac-turers a means to control the panel quality level more consistently.Acknowledgments

This work was supported by the Mechatronics Cen-ter of Samsung Electronics Co.,Ltd.with the project of ICT 04212003-0005,and partially by the project of ICT 04212000-0008and the BK21.The ICT at Seoul National University provided research facilities for this work.

References

[1]S.Hecht,“The visual discrimination of intensity and the

Weber-Fechner law,”J.Gen.Physiol.,vol.7,pp.241,1924.[2]P.Moon and D.E Spencer,“The visual e?ect of nonuniform

surrounds,”J.Opt.Soc.Amer.,vol.35,pp.233–248,1945.[3]H.R.Blackwell,“Contrast thresholds of the human eye,”

J.Opt.Soc.Amer.,vol.36,pp.624–643,1946.

[4] C.K.Chow and T.Kaneko,“Automatic boundary detec-tion of the left-ventricle from cineangiograms,”Comput.Biomed.Res.,vol.5,pp.388–410,1972.

[5]N.Otsu,“A threshold selection method from gray-level his-tograms,”IEEE Trans.Syst.,Man,Cybern.,vol.SMC-9,

pp.62–66,1979.

[6] D.A.Belsley,E.Kuh,and R.E.Welsch,Regression Diag-nostics,John Wiley &Sons,USA,1980.

[7]W.Niblack,An Introduction to Image Processing,Prentice-Hall,1986,pp:115–116.

[8]P.J.Rousseeuw and A.M.Leroy,Robust Regression and Outlier Detection.New York:John Wiley &Sons,1987.[9]

S.D.Yanowitz and A.M.Bruckstein,“A new method for image segmentation,”Comput.Vision,Graph.,Image Pro-cess.,vol.46,pp.82–95,1989.

[10]

K.Belkacem-Boussaid, A.Beghdadi,and H.Depoisot,“Edge detection using Holladay’s principle,”Proc.IEEE Int.Conf.Image Processing,vol.1,pp.833–836,1996.

[11]J.R.Parker,Algorithms for Image Processing and Com-puter Vision,John Wiley &Sons,1997.

[12]

W.K.Pratt,S.S.Sawkar and K.O’Reilly,“Automatic blemish detection in liquid crystal ?at panel displays,”IS&T/SPIE Symposium on Electronic Imaging:Science and Technology,1998.

[13]

Francis H.Y.Chan,https://www.360docs.net/doc/2319273751.html,m,and H.Zhu,“Adaptive thresholding by variational method,”IEEE Trans.Image Processing,vol.7,no.3,pp.468–473,1998.

[14]

Lars Heucke,Mirko Knaak,and Reinhold Orglmester,“A new image segmentation method based on human bright-ness perception and foveal adaptation,”IEEE Signal Pro-cessing Letters,vol.7,no.6,pp.129–131.June 2000.

[15]

VESA Flat Panel Display Measurements Standard Ver.2.0,June 1,2001.

[16]R.C.Gonzalez,R.E.Woodes,Digital Image Processing.2nd ed.,Prentice Hall,2002.

[17]

De?nition of measurement index (semu)for luminance mura in FPD image quality inspection,SEMI standard:SEMI D31-1102,

https://www.360docs.net/doc/2319273751.html,

Jae Y.LEE is currently a Ph.D can-didate in the School of Computer Science and Engineering at Seoul National Uni-versity,Seoul,Korea.He received the BS degree (1996)in mathematics and the MS degree (1998)in computer science from the Seoul National University,Seoul,Ko-rea.His research interests include pattern recognition and machine vision applica-

tions.

Suk I.YOO has been a professor of the School of Computer Science &En-gineering at the Seoul National Univer-sity,Seoul,Korea since 1985.His research interests include content-based image re-trieval,machine learning,pattern recogni-tion,and bioinformatics.He is a member of IEEE,ACM,AAAI,and SPIE.He re-ceived the BS (1977)from the Seoul Na-tional University,Seoul,Korea,the MS (1980)from the Lehigh University,Beth-lehem,PA,and the Ph.D (1985)in computer engineering from the University of Michigan,Ann Arbor,MI,U.S.A..

全自动面条机改变了面条供不应求的现状

全自动面条机改变了面条供不应求的现状今天,小编与大家一起探讨一下中国关于吃的一些发展方面,所谓舌尖上的中国。在悠久的历史先河当中,吃一直是一个人们经常会谈及的话题,在我国每个家庭绝大多数都是一日三餐,而三餐的主食主要是米饭或面食,说到面食,小编首先想到的就是面条啦。 面条在主食行列中一直占据着重要的位置,而且面条具有很多的优势和特点,比如说,面条有汤有面,含有丰富的碳水化合物,具有暖胃、好消化、能提供足够的能量、营养高的作用,所以面条在中国的历史悠久,食用范围广,喜欢面条的人群面广,在现在的21世纪,虽然人们的生活水平提高了,但是面条作为 我国最传统的美食依然受到广大国人的欢迎。正因为如此,面条的需求量一直很大,据数据统计,每年超市或者市场面条的消费水准是最高的,面条的消费量高于其他产品类,由于人们对其主要的需求,也是为了适应机械化的生产活动,全自动面条机应运而生。 接下来,咱们就讲一讲这个帮助面条业跟上时代步伐的大咖——全自动面条机。 全自动面条机是现在新一代面条机的代表,它最重要的特点就是全自动化,自动化程度高于其他种类面条机。有很多用户在购买时都会担心会不会用,会不会操作起来特别繁琐啊这些个问

题,全自动面条机也正是考虑到这个大众问题,所以设计出的成品操作简便,灵活应用,在业内人士都称其为傻瓜式操作,足见其使用起来简单易懂。然鹅,操作简单归简单,主要参数可不能落下,甚至于全自动面条机的主要参数相对于其他面条机来说更加科学规范化。 如果你以为全自动面条机就只有这几个优势那就错了,全自动面条机还有很多优势的,下面由我来一一阐述。 就材质方面,全自动面条机全身采用的是不锈钢材料,使得全自动面条机拥有耐腐蚀耐磨经久耐用的优势,不仅如此,全自动面条机还可以为我们节约成本,提高生产水平,用最小的投资赢得最大的收益。全自动面条机还有一个最大的特点就是可以利用全自动化省去人力操作,多功能一体化具有全自动的特点一次成型,节省劳动力,并且可以大批量的生产面条,在面条最后一 道制作工艺中采取自动挑面技术。 当然了,在使用全自动面条机的时候一定要按照操作规范走,切记安全第一。下面也为大家整理了一些全自动面条机在使用中的安全操作须知: 第一,全自动面条机在开机操作之前一定要先阅读机械说明书,并牢记操作步骤;第二,在开机前仔细检查机械有无异常情况发生,一旦发现有异常情况,一定要禁止使用;第三,一定记得定期给面条机涂抹润滑油,防止机器生锈影响生产;最后,在使用过程中一定要注意安全用电。

果蔬切丁机技术参数

果蔬切丁机技术参数 【诸城市德川工贸】不知道大家吃没吃过牛肉炖萝卜丁、猪肉炖土豆丁,热乎乎,香喷喷的菜端到餐桌上,怕是各位都忍不住想多吃几口吧。那么在罐头加工工厂,这种萝卜丁、土豆丁以及各类果蔬切成丁不可能都用人工来切,这也就用到了小编这次要说的果蔬切丁机。那么今天我们一起了解一下关于果蔬切丁机技术参数 #详情查看#【德川工贸:果蔬切丁机】 【诸城市德川工贸:果蔬切丁机特点】 我公司根据市场需要,综合各类技术所研发此类果蔬切丁机,适合各种果蔬切丁需要。本机采用304不锈钢制做,符合食品安全卫生标准,客户可以放心使用。所切蔬菜丁小规格为1.8mm,大规格为

120mm,调整范围广,可满足各类切丁厂家的需要。设备制做外型美观,操作简单,果蔬切出来的丁形状规则,大小均等,是果蔬切丁厂家的不二之选。 【诸城市德川工贸:果蔬切丁机简介】 切丁机结构紧凑,采用优化卫生设计, 机壳,切割刀栅均采用不锈钢材料制 成,切刀采用切削,工作效率高,可 以切制5、8、10、15mm的立方体 或长方体,调整厚度切割旋纽,可对 推杆进行无级调速,以满足不同切割 厚度的要求。采用了预压力设计,保 证在切割过程中切出的物料均匀光 滑并保证切割尺寸正确。本机可适应土豆、萝卜、芋头、苹果以及各种根、茎类蔬菜的切丁,是果蔬加工中的的设备。 切丁机采用复合刀具,一次成形,形状规则,切面光滑,成形率高。本机设计先进,操作方便,耗能低,效率高,采用铝镁合金及不锈钢材料,防腐,美观,符合卫生标准。拨盘带动被切物体高速旋转,利用物体离心力,借助立刀将被切物体切成片状,然后经过圆盘切刀切成条状,并将被切物料送入横切断刀口,由横切断刀切成所需要的立方体或长方体。 【诸城市德川工贸:果蔬切丁机参数】 1.生产能力:在切制15mm立方体时产量为1000kg/h。 2.切菜规格:可切制5、8、10、15mm的立方体或长方体,也可以根据要求定做其他尺寸的刀具。 3.总功率:0.75kw/380v 4.外形尺寸:710*660*1010mm 5.机器重量:100kg

家用面条机的设计与分析

家用面条机的设计与分析 -----机械系统设计课程论文 姓名:肖虎 学号: 2009092553 学院:机电学院 班级: 09机制 3班 指导老师:李盛林 2012年12月20日

目录 一、目的及背景 (3) 1.1 目的: (3) 1.2 背景: (3) 二、方案设计 (4) 2.1 背景: (4) 2.2 黑箱法分析: (5) 三、各工步设计 (6) 3.1 放面团 (6) 3.2一级输送 (6) 3.3压面 (6) 3.4二级输送 (6) 3.5 切面机构 (6) 四、各子系统设计 (6) 4.1 动力系统选取 (6) 4.2 传动系统设计 (6) 4.3 压面机构 (6) 4.4 切面机构 (7) 4.5 机械生产效率计算 (7) 五、产品前景 (8) 产品优势 (8) 产品前景 (8) 六、参考文献 (8)

摘要:该机械采用小功率驱动,经济节能;通过2次压面工艺,提高面条的品质;一次出面,效率高,省事,省时,省心,方便,快捷。 关键词:清洁,2次压面,封闭,品质 一、目的及背景 1.1 目的: 针对传统手工制作面食存在的劳动强度大、工序复杂、效率低、不卫生等缺陷,运用机械原理,设计了家用面条机,以适应市场对面条机节能、体积小、造型新颖、操作简单、维修方便、光洁卫生等需求。 1.2 背景: 随着生活水平的不断提高,生活节奏日益加快,饮食制作快捷化就自然想到用饮食机械来代替传统手工制作。市场上已经出现许多如和面机、洗面机、面条机、饺子机等形状各异、种类繁多的面食品加工机械,但是大多为大型面食品加工机械,面条家用加工机械并不多,且功能单一,纵观世界面条机, 一方面向高生产率、全自动的方向发展, 另一方面由敞开型向封闭型、重量轻、体积小、造型美. 一次成条方向发展。随着人们对食品各方面要求的提高,家用面条机开始受到家庭厨子的喜爱,面对全国广大市场,家用面条机发展空间广阔,经济前景好。纵观世界面条机, 一方面向高生产率、全自动的方向发展, 另一方面由敞开型向封闭型、重量轻、体积小、造型美. 一次成条方向发展 面条的规格: 品质规格:根据麦类作物学报中中国面条的标准化实验室制作与评价方法研究,西北农林科技大学学报中面条品质评价方法研究进展,把面条的色泽、外观、软硬度、粘弹性、光滑性、食味;作为评价面条的标准,其中外观,软硬度,粘弹性,光滑性很大程度受到机械加工的影响。 尺寸规格:南方以2X2mm方截面型面条为主,北方以5mm圆形面条为主,长度从150-250mm不等。

全自动果蔬切丁机设计

摘要: 二十一世纪以来,我国的食品行业的发展大大改革在加工食品的早期开放的日益提高,人们的生活和高要求的食品包装食品机械的食品工业的发展,提高人民的物质生活不断为了满足食品行业促进各类食品机械和食品机械的发展,机器的自动化和加工食品中的社会发展必然的一种先进的发展需求促进社会主义经济建设的不断发展,人们的物质生活旁边的新要求,食品的质量,为水果量的变化来满足人们的日常需求,和小食品包装市场供应系统方便法就提到了议事日程,,其优势是用来节省时间,提高效率,为大规模生产劳动释放保证效处理的实现是否手工制作,产品质量,降低了原材料的浪费通过蜗轮蜗杆传动电机在表盘的切碎机的基本工作原理,拨号环周运动剑架圈,它是负责由和3线切丁机目前市场上的主要大尺度,主要的大型酒店和食品加工厂,餐厅设计这些切丁在一个大酒店,至少一个切丁切丁和广泛的应用,然而,国内的多功能机切丁种类很多,现在出现了一片碎机,效率高,使用方便操作,能耗低,大产量高,适合工厂,只有在学校的食堂,食品加工厂,用作一种蔬菜,不能满足家庭生活的改善的多功能机,切丁的需求,更好的满足用户的需求,和实用价值,这些小机器,和功能,可以满足普通家庭的需求巨大 关键词:食品,机,发展

Abstract: Since the 21st century, the development of food industry of our country greatly the reform open early in the processed food is improved day by day, people's lives with the high demand from the food packaging Food machinery of the development of the food industry The improvement of people's material life continually in order to meet the demand of the food industry to promote the development of various types of food machinery and development An advanced development in food machinery and automation of the machine and the social development inevitable in processed foodsPromoting the development of socialist economic construction constantly, people's material living next to the new requirements The quality of food, fruit quantity change in order to meet the demands of the people's daily, and convenient method of the supply system of small food packaging market supply immediately mentioned the agenda, extensibility and, Behold, no hard crusts cut of each fruit fruit julienne slices of fruit Application of food machinery's [1] this machine Application of food machine, reduces the labor intensity of the workers, the advantage is used to save time, improve efficiency, large labor production release In order to guarantee the special effect processing to realize whether the handmade, product quality, reduces the waste of raw materialsThe basic work principle of shredded machine via the worm gear worm drive motor on the dial, dial ring week exercise sword rack

全自动一次成型挂面机操作方法技巧

全自动一次成型挂面机操作方法技巧 我们一共将制面的整个过程分为3大步骤进行操作分析 1.和面:将面粉倒入拌面机内,然后按规定25%左右的比例进行加水,启动运力,把面和水拌均匀达颗粒状(10分钟后使用最佳),即可倒入面条机使用。 2.调整:用手轮进行调整轧辊间隙,各组轧辊间隙的参考数据是:(330以上机组例外)在调整过程中,调紧或放松手轮的多少,有时不易一次调准,关键是要弄清道理,耐心把握,不熟练时可停机调整,正常后锁紧手轮。 3.操作:把拌好的面粉放入面斗内,按刀并固定挡刀板,就可开机运转,第三组下来面板要用手引到下一组(多组照此类推)经过面条机压辊压制,出面条操作完毕。

重庆友乐乐机械专业生产各种款式的面条机,热门搜索词:重庆全自动面条机、重庆面条机、重庆压面机、贵州面条机、四川面条机、云南面条机、重庆面条机厂、面条机多少钱一台、多功能家用面条机价格、重庆面条机厂家。欢迎大家登录我公司网址详细咨询,友乐乐竭诚为您服务!! 产品关键词:全自动面条机、重庆老牌面条机、重庆老式面条机、重庆传统面条机

2. 3. 面通过拉丝处理 结构紧凑,造型新颖,辊具有揉面功能,生产面条时不需另外熟化,广受客户的青睐。 4. 转动部位采用高精轴承,经久耐用,运转灵活,性能稳定。 5. 护板采用不锈钢,面斗木质部分用不锈钢板装

重庆友乐乐机械有限公司位于重庆市巴南区金竹工业园内,前身为“重庆永利食品机械厂”,因自身发展需要,2015年底由重庆的合川区搬迁到了巴南区金竹工业园区内,不但交通地理环境更加便利,而且大大提升了我公司在研发、制造领域同周边“重庆大江工业集团”和“长安铃木公司”配套厂的综合协作能力。“友乐乐”是一家专业从事食品机械设计、制造、销售、服务为一体的企业,公司不断开拓创新,迅速发展。公司主打产品为面条机、米粉机和粉条机、凉皮机等,企业以创新、科技、服务和经济效益为设计理念,以优越的性能和人性化的智能设计赢得了广大新老客户的信赖,以过硬的质理和精湛的技术,在行业内享有较高的声誉! 我们的目标:创业路上友(有)乐乐! 我们的宗旨:销售的不仅仅是产品,更重要的是服务;最终目的是帮助选择我们的朋友获取适宜的利润!! 产品关键词:全自动面条机、重庆老牌面条机、重庆老式面条机、重庆传统面条机

果蔬物流系统方案设计

元谋县果蔬物流中心 方案设计书 班级:物流0912 组长:姚富有 组员:王瑜刘芫杏

孙丽娟施丽蓉 目录 前言 1、我国冷藏业当前存在的问题-----------------------------------------------------------3 2、我国冷藏库建设未来发展方向的探索- ------------------------------------------------------3 1、基本设计 1.1果蔬冷链仓库平面图----------------------------------------------------------------------- -------6 1.2果蔬冷链必要设施及设备------------------------------------------------------------------------7 1.21国际形势-------------------------------------------------------------------------------------------7 1.22果蔬冷链物流仓储设施设----------------------------------------------------------------------7 2.库存优化选择 2.1出入库流程-------------------------------------------------------------------------------------------- 9 2.11仓库作业过程---------------------------------------------------------------------------------------9 2.12入库作业流程---------------------------------------------------------------------------------------9 2.13 出库作业流程- -------------------------------------------------------------------------------------9 2.2货物优化方案-----------------------------------------------------------------------------------------10 2.21物动量分析表- -------------------------------------------------------------------------------------10 2.22 堆码示意- ------------------------------------------------------------------------------------------11 2.23 货物存储及货位分配----------------------------------------------------------------------------11 2.24 货物盘点-------------------------------------------------------------------------------------------12 2.25 库

切丁机说明书

系列切丁机使用说明书必须仔细观看使用说明书才能开机,否则机器损坏为人为的责任。 苏州中名机械制造有限公司 地址:江苏省苏州市相城区黄桥镇生田路6号 邮编:215031 公司主页:

前言 首先衷心地感谢您惠购本公司的产品,希望本公司的产品能为贵公司带来更多的经济效益。 本使用说明书是为了安全使用本机器而制作的参考简介。 本机的操作人员或保养人员在进行操作或检修保养之前,必须仔细阅读使用说明书并正确理解其操作方法及各项注意事项,然后再进行操作或检修保养。 如果不是使用说明书进行操作,可能会造成重大事故的发生。 请讲本使用说明书放置于机器附近的容易查看处,并妥善保管,以便随时查看。 当把本机出售或转让给他人时,请务必将本使用说明书一同交给用户,以便用户操作和检修等。 本使用说明书如丢失或破损等,请尽快与本公司或销售代理店联系购取。 温馨提示 一、必须由专人使用本机。 二、开机之前必须先确认电源电压为380V,无缺相现象。 三、为了保护刀具和人身安全,开机前先检查设备上是否有异 物,如果有异物,请先断电、清理、再开机操作。 四、为了操作人员的安全,在切割时禁止谁意开关门并把手伸 进去,必须把设备电源切断并等刀具停稳方可开门,否则 造成的人身安全由购方自行负责。

五、操作完毕后必须及时关机并切断本设备电源。 六、切割工作完成后必须对设备进行清洗及保养。 七、清洗刀具或更换刀具前必须先关机再切断本设备电源。 八、不得切带硬骨的或冷冻的肉类进行切割,本机只适合切割 麻冻状态-4℃以上的纯肉。

目录

一、概述 ZJTS系列切丁机参照国际先进设计制造,结构合理,该机械能做到精确切“丁”、“丝”、“片”且工作效率高。 ZJTS切丁机是肉类制品生产制作工艺中的一个重要设备。将肉块,脂肪等主要原料,切割成用户所需要的肉丁,调整刀栅的尺寸可切除肉丝、肉片。肉丁尺寸的大小由刀栅中刀片数量来决定。本厂生产的350型和550型切丁机适用于大,中,小型肉类食品加工厂,也可按用户提出的要求,制定生产特殊工艺要求的产品。 本厂生产的切丁机结构紧凑,安全实用,维修清洗方便,组装灵活,具有下列优点: 1.安全防护性能良好,前门打开后转动的切刀立即停转。 2.刀栅及大切刀装拆方便,不用工具即可全部卸下,便于清洗更换刀栅。 3.测压机构可使一次切割的肉料的量增加,并有助于预压力加快达到设定 值,提高生产效率。 4.拨叉结构的设计提高了产品切割质量,减小噪声、降低机械故障率。 5.调整预压力旋钮,可保证产品在切割过程中始终如一。 6.肉料可步进进料,可最大限度地减少在切割过程中对产品的挤压。 7.改变刀栅中刀片的数量,可切割出不同尺寸的肉丁,组合方便。

全自动挂面机生产线技术流程

郑州大型面食设备制作厂家哪家比较专业,下面小编介绍下这类设备的基本信息: 一.冷风定条区:通常采用不加温,而加强空气流动的办法,以大量干燥空气来促进面条去湿,使挂面形状初步固定,除去表面水份。表面硬化,由塑体向弹性转变,雨天(或梅雨)要提前开扇和排潮,冬季送温略提前,因湿面表面蒸发缓慢不易定条,避免温度过度,会使面条湿性差,面表面水份蒸发过多,影响内蒸发阶段的湿度降低,保潮湿度过度,造成面条拉伸,断条上薄下厚,相互粘连等现象。

二、内蒸发区(保潮发汗): 此区以水份内扩散为主,强化通风,使空气循环畅通,此时跨区温度上升,不要过“急”,要使温度形成“梯度”,保持一定湿度,一方面是向面条中心转移热能,缩小表面与内部的温差,另一方面加快内部水份的扩散,使表面水份汽化速度与内部水份转移速度一致,水份慢慢蒸发,如果此时温度、湿度差过大,会造成表层干得快,表面“结膜”、“关门”、“龟裂”等现象,内外水份不平衡,最后挂面外干内湿,导致面条酸面、酥面等质量问题,存放期短。 郑州大杰食品机械有限公司位于郑州市马寨经济开发区,临近郑州西四环环城高架及郑州西区CCD四个中心、郑州绕城公路陇海西路站下口。 本厂遵循以创新经营高科技为导向,以客户需求为焦点,不断开发新产品。以质量求生存的经营理念和诚信销售热情服务为广大客户提供优质产品。 我公司以生产食品机械为主,专业生产挂面机、方便面机、中低温挂面成套设备、热干面自动生产线、全自动成套熟面机、生鲜面机设备、手盘面机生产线、波纹面机成套设备、面叶生产线、饺子皮机、混沌皮机、凉皮机、米皮机等食品机械的研发与制造,产品远销三十多个省、市、自治区,和非洲等国家和地区。 长期以来,本公司坚持以创新经营、精致为本的经营理念,让顾客满以为宗旨,不断开发新产品,以优质的产品和良好的信誉,赢得了用户的信赖和好评。

自动揉面机的揉面特点及工作原理

自动揉面机的揉面特点及工作原理 一、自动揉面机(也称自动压面机)是一种安全、高效、实用的面食加工机具。经它揉和后的面片可以提高面的筋度,增加面的白度和韧性。经过揉压的面团制作面馒头及各类食品、面包、糕点,香甜、劲道、光泽度好,口感好。该机效率高,安全系数高,可以代替传统的人工揉面和繁重的体力劳动,使用方便,具有别的机型不可代替的待征和优越性。广泛适用于机关、学校、厂矿食堂、个体食品经营者、面食加工单位,也是配置馒头生产线的理想设备。 二、揉面机结构特征:自动揉面机主要有机架、传动部分、压面部分、输送折叠部分、外罩五大部分组成。传动部分主要采用链条、轧辊齿轮、主动齿轮组成,具有传动平稳,噪音小的特点。压面部分主要有可调轧辊、上轧辊、下轧辊组成,实现自动翻面的功能。输送折叠部分主要有左右支架、输送带组成,运用不同线速原理,实现自动传送自动折叠,代替了繁重的手工操作,既卫生又安全。同时为保证轧辊两端间一致,采用蜗轮、蜗杆、偏心轮调整机构,可实现无极调整,使压面厚度两侧一致。

三、揉面机的工作原理: 将定量的面团放在下输送带上,开动机器,自动输送到轧辊间,面团在输送带和轧辊的作用下自动完成喂入和压面过程。压完后经上输送带自动传送到下输送带上,由于采用不同线速度,使面皮自动完成折叠和输送、喂入,转入下一轮揉压。经过反复折叠、揉压,反复数遍达到理想压面效果,使面的结构更为紧密,更具光滑度,使压制后的面团获得较好的层次和口感。

重庆友乐乐机械专业生产各种款式的面条机,热门搜索词:重庆全自动面条机、重庆面条机、重庆压面机、贵州面条机、四川面条机、云南面条机、重庆面条机厂、面条机多少钱一台、多功能家用面条机价格、重庆面条机厂家。欢迎大家登录我公司网址详细咨询,友乐乐竭诚为您服务!! 产品关键词:全自动面条机、重庆老牌面条机、重庆老式面条机、重庆传统面条机

蔬菜切丝机的设计

摘要 随着近年来我国蔬菜出口的迅速崛起,蔬菜加工出口已成为我国的重要创汇渠道。但疏菜加工机械却远远滞后于蔬菜出口的发展,并且价格昂贵。由此我们研制了多功能蔬菜加工机,一机多用,取代了部分功能单一、效率低下、价格昂贵的进口机械。本文首先研究了蔬菜切割、输送、定位、成型的基本理论,然后设计了多功能蔬菜加工机的切削装置、送料装置和传动机构等,使之能够达到对块根状及叶菜状蔬菜进行切片、丝、段等规格形状的加工。同时应用新科技,采用先进的数字调速电机,省去复杂的变速机构与调节机构。试验表明,该设备出成率、效率达到进口机械水平,价格较进口设备降低50%以上,可填补此类机械的国内空白,取得良好的经济效益和社会效益 关键词:多功能,蔬菜,加工机 第一章引言 1.1 课题的目的和意义 蔬菜是人生活中必不可少的营养丰富的食品之一,可为人体提供必需的维生素、矿物质、膳食纤维等有益于人体健康的功能成分。随着人们生活水平的不断提高,生活节奏加快,对食用方便、营养丰富、经过加工的精细蔬菜的需求越来越大,对产品的品质要求越来越高。蔬菜出口在我国起步虽晚,但由于中国蔬菜富含营养、品种齐全、质优价廉,深受各国消费者的青睐,因而近几年蔬菜出口发展十分迅速,己成为创汇农业的支柱产业。 调查结果显示,目前我国蔬菜加工机械却远远滞后于蔬菜出口的发展,现在主要靠合资外方从国外进口,价格昂贵,如牛芬、胡萝卜切丝机,从日本进口一台普通(长短、粗细不可调)切丝机,需人民币1.2万多元。为适应蔬菜加工的需要,我们设计多功能蔬菜加工机,一机多用,只需更换切刀和部分零件,即可加工各种异型块根状蔬菜,如铅笔屑状(牛芬)、各种异型状片(胡萝卜、土豆的梅花状、菊花、树叶状、球拍状等)、丝条(胡萝卜、牛芬等)、自由片(牛芬、胡萝卜、姜、蒜等)及酱菜等。该机的多功能化,取代了部分功能单一、价格昂贵的进口机械,蔬菜加工厂家只需购买一台设备就可加工多适合出口需要的不同规格的产品。投资少,效益高,适应于多品种、批量生产的需要,提高了设备利用率。 加快蔬菜机的发展,提高企业技术装备水平,无疑将成为山东蔬菜出口发展的战略突破口,增值增效潜力巨大。本课题旨在研制一种高效、可靠、实用、多功能蔬菜加工机械,重点解决我国蔬菜加工机械功能单一、进口机械价格昂贵的问题。 1.2 蔬菜加工机械的种类 (1)多功能旋转式切菜机,其原理是使需要的切的蔬菜高速旋转,利用离心力使蔬菜紧贴刀片进行加工,是一个蔬菜加工行业、食品行业、脱水蔬菜厂、速冻食品二次加工常用的机器。使用它可将有固定形状的如:芥菜、萝卜、土豆等块切制成所需要厚度的片和丝,一般采用防腐铝外壳及高级合金刀片,具有结构紧凑、合理、操作简便、调整维修方便、耐腐蚀的特点。其缺点是:切片或切丝的形状不规则。厚度不均。 (2)离心式切菜机采用先进工作原理,其特点为结构紧凑、坚固耐用、易于维修,可提高生产率,降低劳动强度,对萝卜、土豆、白薯、圆白菜等根茎类可加工成菜丝、菜条、菜片、广泛适合大、中型酱菜厂和速冻食品厂使用。 (3)切丁机性能优于其它机器,可一道工序完成块条的加工,省时省力,操做方便,适合芥菜、萝卜、黄瓜(包括咸制黄瓜)、土豆、洋葱、香瓜、胡萝卜、

(整理)大小五组面条机压辊的调整说明

大小五组面条机压辊的调整说明 大小五组面条机压辊的调整说明: 第一道辊:1-2毫米 第二道辊:1.5毫米 第三道辊:0.5毫米 第四道辊:0.5毫米 2调整时压辊两端间隙须一致。 3各压辊之间面片如发现拉断或折叠现象可调整压辊间隙,拉断时缩小下对压辊间隙或加大上对压辊间隙,折叠时加大对压辊间隙或缩小上对压辊间隙。 调整适合后锁紧压辊方可进行面条加工。

友乐乐面条机厂家、半自动面条机、全自动面条机价格

双面撒粉,自动挑条一次成型,流水线式生产,双面撒粉,自动化程度高,操作简单,效率高。 2. 3. 面通过拉丝处理 结构紧凑,造型新颖,辊具有揉面功能,生产面条时不需另外熟化,广受客户的青睐。 4. 转动部位采用高精轴承,经久耐用,运转灵活,

重庆友乐乐机械有限公司位于重庆市巴南区金竹工业园内,前身为“重庆永利食品机械厂”,因自身发展需要,2015年底由重庆的合川区搬迁到了巴南区金竹工业园区内,不但交通地理环境更加便利,而且大大提升了我公司在研发、制造领域同周边“重庆大江工业集团”和“长安铃木公司”配套厂的综合协作能力。“友乐乐”是一家专业从事食品机械设计、制造、销售、服务为一体的企业,公司不断开拓创新,迅速发展。公司主打产品为面条机、米粉机和粉条机、凉皮机等,企业以创新、科技、服务和经济效益为设计理念,以优越的性能和人性化的智能设计赢得了广大新老客户的信赖,以过硬的质理和精湛的技术,在行业内享有较高的声誉! 我们的目标:创业路上友(有)乐乐! 我们的宗旨:销售的不仅仅是产品,更重要的是服务;最终目的是帮助选择我们的朋友获取适宜的利润!!

(毕业设计)蘑菇切丁机的设计

毕业论文(设计) 题目:蘑菇切丁机的设计 姓名: 学院: 专业: 班级: 学号: 指导教师: 年月日

目录 摘要....................................................................... I Abstract ........................................................................................................................................... II 1绪论. (1) 1.1研究的目的及意义 (1) 1.2国内外研究现状 (3) 2切丁机总体方案的确定 (3) 2.1切丁机的总体构成 (6) 2.2整机结构设计 (6) 3主要零部件的设计与计算 (4) 3.1传动方案的确定 (4) 3.2滚筒的设计 (5) 3.3部分零件的规格设计 (5) 3.4 电动机的选择................................................................................ 错误!未定义书签。 3.5 V带的设计计算 (6) 3.6V带轮的设计 (8) 3.7直齿圆柱齿轮的设计计算............................................................. 错误!未定义书签。 3.8轴的结构设计计算......................................................................... 错误!未定义书签。 3.9轴承的选择及校核......................................................................... 错误!未定义书签。 3.10键的选择和校核 (17) 3.11切刀的设计 (18) 3.12机体结构设计 (22) 4结论............................................................................................................ 错误!未定义书签。 4.1 本设计的优点................................................................................ 错误!未定义书签。 4.2 存在的不足和建议........................................................................ 错误!未定义书签。5总结............................................................................................................ 错误!未定义书签。参考文献....................................................................................................... 错误!未定义书签。致谢............................................................................................................... 错误!未定义书签。

面条机主要结构与工作原理

面条机主要结构与工作原理 1、构造: MT5-200NT5-250型面条机是由电动机,主传动装置,二对进料压辊,一对后片压辊,一对压实薄压辊,一对实压光辊,共五对压辊。一付切机刀及断条机构组成。 2、原理: 本机采用五对压辊连续滚压法,将和好的面粉加入面斗内,第一道压辊压出两片面片,然后进入第二道压辊,将两片后成入片压实,然后通过托面槽引入第三道压辊,再次将面片压实,再经过第四道压辊将面片压光,最后通过面刀切成面条。 以上产品有两种方式控制面条长度 (1)普通型:是利用脚踏板自动断面条。 (2)配有挑条器系统,是自动断面,面条长度出厂已设定。

重庆友乐乐机械专业生产各种款式的面条机,热门搜索词:重庆全自动面条机、重庆面条机、重庆压面机、贵州面条机、四川面条机、云南面条机、重庆面条机厂、面条机多少钱一台、多功能家用面条机价格、重庆面条机厂家。欢迎大家登录我公司网址详细咨询,友乐乐竭诚为您服务!! 产品关键词:全自动面条机、重庆老牌面条机、重庆老式面条机、重庆传统面条机

2. 3. 面通过拉丝处理 结构紧凑,造型新颖,辊具有揉面功能,生产面条时不需另外熟化,广受客户的青睐。 4. 转动部位采用高精轴承,经久耐用,运转灵活,性能稳定。 5. 护板采用不锈钢,面斗木质部分用不锈钢板装

重庆友乐乐机械有限公司位于重庆市巴南区金竹工业园内,前身为“重庆永利食品机械厂”,因自身发展需要,2015年底由重庆的合川区搬迁到了巴南区金竹工业园区内,不但交通地理环境更加便利,而且大大提升了我公司在研发、制造领域同周边“重庆大江工业集团”和“长安铃木公司”配套厂的综合协作能力。“友乐乐”是一家专业从事食品机械设计、制造、销售、服务为一体的企业,公司不断开拓创新,迅速发展。公司主打产品为面条机、米粉机和粉条机、凉皮机等,企业以创新、科技、服务和经济效益为设计理念,以优越的性能和人性化的智能设计赢得了广大新老客户的信赖,以过硬的质理和精湛的技术,在行业内享有较高的声誉! 我们的目标:创业路上友(有)乐乐! 我们的宗旨:销售的不仅仅是产品,更重要的是服务;最终目的是帮助选择我们的朋友获取适宜的利润!! 产品关键词:全自动面条机、重庆老牌面条机、重庆老式面条机、重庆传统面条机

面条机辊压横压力的概念

面条机辊压横压力的概念 1、横压力的概念 物料通过压辊间隙时,物料将对压辊产生经向作用力和切向作用力。径向作用力叫横压力;切向作用力叫接触应力。 横压力始终垂直辊面,其作用结果是将两辊分离。横压力的大小是随物料厚度的变化而变化的。在辊隙稍前初横压力值最大。 接触应力把物料拉入辊隙中,但方向取决于物料相对压辊的速度,由于b-b界面处物料相对压辊的速度,所以该截面处的接触应力为零。 2横压力的计算 横压力时设计辊压机械的重要参数,其大小影响辊压机的结构参数和功能消耗,影响横压力的因素很多。 实验测得:物料硬度越大,温度越低,辊隙越小,横压力越大。 目前要从理论上准确的计算横压力很难,仅能借助于与食品物料相近的理论进行计算。 根据材料的蜕变理论计算横压力。假设物料为牛顿流体,根据流体力学原理进行推导。

重庆友乐乐机械专业生产各种款式的面条机,热门搜索词:重庆全自动面条机、重庆面条机、重庆压面机、贵州面条机、四川面条机、云南面条机、重庆面条机厂、面条机多少钱一台、多功能家用面条机价格、重庆面条机厂家。欢迎大家登录我公司网址详细咨询,友乐乐竭诚为您服务!! 产品关键词:全自动面条机、重庆老牌面条机、重庆老式面条机、重庆传统面条机

2. 3. 面通过拉丝处理 结构紧凑,造型新颖,辊具有揉面功能,生产面条时不需另外熟化,广受客户的青睐。 4. 转动部位采用高精轴承,经久耐用,运转灵活,性能稳定。 5. 护板采用不锈钢,面斗木质部分用不锈钢板装

重庆友乐乐机械有限公司位于重庆市巴南区金竹工业园内,前身为“重庆永利食品机械厂”,因自身发展需要,2015年底由重庆的合川区搬迁到了巴南区金竹工业园区内,不但交通地理环境更加便利,而且大大提升了我公司在研发、制造领域同周边“重庆大江工业集团”和“长安铃木公司”配套厂的综合协作能力。“友乐乐”是一家专业从事食品机械设计、制造、销售、服务为一体的企业,公司不断开拓创新,迅速发展。公司主打产品为面条机、米粉机和粉条机、凉皮机等,企业以创新、科技、服务和经济效益为设计理念,以优越的性能和人性化的智能设计赢得了广大新老客户的信赖,以过硬的质理和精湛的技术,在行业内享有较高的声誉! 我们的目标:创业路上友(有)乐乐! 我们的宗旨:销售的不仅仅是产品,更重要的是服务;最终目的是帮助选择我们的朋友获取适宜的利润!! 产品关键词:全自动面条机、重庆老牌面条机、重庆老式面条机、重庆传统面条机

全自动面条机

全自动面条机 面条是我国人民所喜爱的主食品种,市场需求巨大,永远不愁销路,是充满商机的投资项目。全自动挂面机由多组压辊组成,有自动进料,自动压面,自动分条和自动上架等功能。全自动挂面机采用齿轮传动,使用可靠、传动平衡、结构紧凑、操作简便、使用安全、体积小、噪音低,穗华面条机可主要机条又可生产挂面并从进料到出面条连续作业,节省劳动力,适用大中型食堂、饭店乡镇企业及个体挂面、面条加工作坊。 二、工作原理 本机采用五对轧辊连续滚压法,将和好的面粉加入面斗内,第一道轧辊压出两片面片,然后进入第二道轧辊,再次将面片压实,再经过第四道轧辊将面片压光,最后通过面刀切成面条。 三、性能特点 1、采用齿轮传动,运转平稳、安全可靠。 2、采用自动挑条系统,效率高、质量好。 3、自动输送、自动断面、自动上杆,一次成型。 四、机器使用与维护 1、接电源试车时须将踏板踏下,以防止机器反转时损坏切刀上的离合器。 2.面斗内叶刺是代替人工和面的,不得随意拆除,面斗内加面,不得过量压实,操作时严禁用手直接进入面斗内和面。 3、情况,如无异常现象方可操作使用。

4、禁其它物件掉入轧辊及齿轮内,以防损坏机器,每班工作面必须把部位的残面清理干净。 5、须以常清理,如发现皱拆现象,可调整梳刀,使梳刀紧贴在面刀、刀槽根部。 6、时,应先将梳刀各齿前端修成锐角,且与底面平直装入面刀时,应将梳刀压紧无间隙。 7、把干面条放入机器重压,禁止把新压制的长面条不经搅碎重新放入机器重压。 8、检查各处螺母是否松动。 9、工作完毕后,应将残存在机器上的所有余面清理干净以免造成下次开车前将面机轧辊及面刀梳刀损坏。

全自动面条机操作技巧和工艺技术

全自动面条机操作技巧和工艺技术 1、全自动面条机介绍 新一代挂面机参数以及功能,新一代挂面机具有自动切断、挂干、烘干等功能,新一代挂面机可采用220v通用电压,操作更加便捷易懂,新一代挂面机完全可以达到无需专人看守,完全自动化工作整个流程。广东穗华全自动面条机(全自动挂面机),是一种新型面条设备,该面条机器从进料到出面连续作业,具有高产高效、省时省力、操作简便等优点,生产的面条韧性好、口感好。穗华面条机械畅销全国并出口到20多个国家和地区。 2、全自动挂面机操作技巧 1.和面:将面粉倒入拌面机内,然后按规定25%左右的比例进行加水,启动运力,把面和水拌均匀达颗粒状(10分钟后使用最佳),即可使用 2.调整:用手轮进行调整轧辊间隙,各组轧辊间隙的参考数据是:(330以上机组例外)在调整过程中,调紧或放松手轮的多少,有时不易一次调准,关键是要弄清道理,耐心把握,不熟练时可停机调整,正常后锁紧手轮 3.操作:把拌好的面粉放入面斗内,按刀并固定挡刀板,就可开机运转,第三组下来面板要用手引到下一组(多组照此类推)操作完毕。 3、全自动挂面机工艺技术 1、和面系统 该设备由面粉提升机,面粉输送机、盐水混合器、和面机、电器控制柜几部分组成,把送来的面粉和混合好的盐水定量控制,形成雾化状态,使料坯颗松散,干湿均匀。 2、压面、切条系统 熟化机、复合机、压延机、切条机、给杆机、挑条机六部分连为一体完成面条的成型阶段。和好的料坯经10分种熟化,搅拌使面粉充分吸水、嘭化形成湿面筋网络,送入复合机同时制成两张面片,压和成一张,然后经四级对辊压延,以不破坏面筋组织的压延比压制出厚0。8~2毫米的面片。压好的面片经过切面刀,按不

学习面条机安全操作规程

学习面条机安全操作规程 1、压面机在使用前,应对滚压轮及各种附件按需要在断电情况下进行安装调正,确认正确牢固时,方可进行运行。 2、压面操作时,严禁手指接近滚轮,不得在运转时用手送压面条及扣压轴轮。 3、压杆、滚轮等严禁放在托盘上,以防掉下砸伤脚面或其他。 4、使用完毕后切断电源,要对压面轮及其他可卸部件进行单独清洗,严禁用水冲洗带电设备。 面条机的工作原理是把面粉经过面条机压辊相对转动挤压形成面片,再经前机头切面刀对面片进行切条,从而形成面条。面条的形状取决于切面刀的规格,所有机型均可安装不同规格的切面刀,故一台机器经过更换不同规格的面刀可以做成各种规格的面条,使面条的形状随心所欲! 面条机器应安装在干燥、通风的水平地面上,确保机器工作平稳、可靠。 面条机使用前应检查电源电压是否与本机使用相符;有接地符号的线芯是否 可靠接地;转向是否符合要求(为便于包装运输,顺面簸箕未安装在机器上)

重庆友乐乐机械专业生产各种款式的面条机,热门搜索词:重庆全自动面条机、重庆面条机、重庆压面机、贵州面条机、四川面条机、云南面条机、重庆面条机厂、面条机多少钱一台、多功能家用面条机价格、重庆面条机厂家。欢迎大家登录我公司网址详细咨询,友乐乐竭诚为您服务!! 产品关键词:全自动面条机、重庆老牌面条机、重庆老式面条机、重庆传统面条机

2. 3. 面通过拉丝处理 结构紧凑,造型新颖,辊具有揉面功能,生产面条时不需另外熟化,广受客户的青睐。 4. 转动部位采用高精轴承,经久耐用,运转灵活,性能稳定。 5. 护板采用不锈钢,面斗木质部分用不锈钢板装

重庆友乐乐机械有限公司位于重庆市巴南区金竹工业园内,前身为“重庆永利食品机械厂”,因自身发展需要,2015年底由重庆的合川区搬迁到了巴南区金竹工业园区内,不但交通地理环境更加便利,而且大大提升了我公司在研发、制造领域同周边“重庆大江工业集团”和“长安铃木公司”配套厂的综合协作能力。“友乐乐”是一家专业从事食品机械设计、制造、销售、服务为一体的企业,公司不断开拓创新,迅速发展。公司主打产品为面条机、米粉机和粉条机、凉皮机等,企业以创新、科技、服务和经济效益为设计理念,以优越的性能和人性化的智能设计赢得了广大新老客户的信赖,以过硬的质理和精湛的技术,在行业内享有较高的声誉! 我们的目标:创业路上友(有)乐乐! 我们的宗旨:销售的不仅仅是产品,更重要的是服务;最终目的是帮助选择我们的朋友获取适宜的利润!! 产品关键词:全自动面条机、重庆老牌面条机、重庆老式面条机、重庆传统面条机