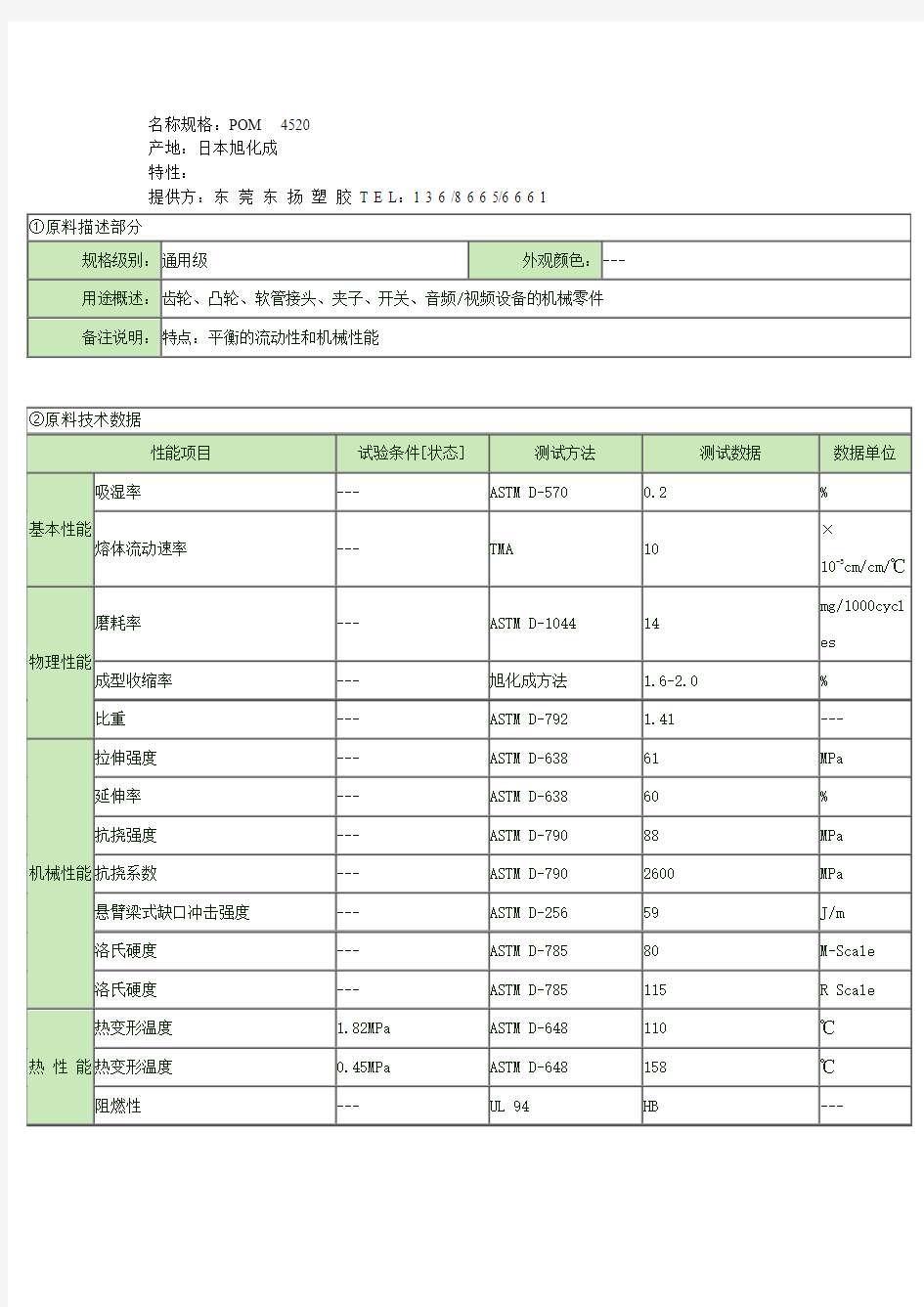

POM 4520物性表

名称规格:POM 4520

产地:日本旭化成

特性:

提供方:东莞东扬塑胶T E L:1 3 6 /8 6 6 5/6 6 6 1

①原料描述部分

规格级别:通用级外观颜色:---

用途概述:齿轮、凸轮、软管接头、夹子、开关、音频/视频设备的机械零件

备注说明:特点:平衡的流动性和机械性能

②原料技术数据

性能项目试验条件[状态] 测试方法测试数据数据单位基本性能

吸湿率--- ASTM D-570 0.2 %

熔体流动速率--- TMA 10

×

10-5cm/cm/℃

物理性能磨耗率--- ASTM D-1044 14

mg/1000cycl

es

成型收缩率--- 旭化成方法 1.6-2.0 %

比重--- ASTM D-792 1.41 ---

机械性能拉伸强度--- ASTM D-638 61 MPa

延伸率--- ASTM D-638 60 %

抗挠强度--- ASTM D-790 88 MPa

抗挠系数--- ASTM D-790 2600 MPa

悬臂梁式缺口冲击强度--- ASTM D-256 59 J/m

洛氏硬度--- ASTM D-785 80 M-Scale 洛氏硬度--- ASTM D-785 115 R Scale

热性能热变形温度 1.82MPa ASTM D-648 110 ℃热变形温度0.45MPa ASTM D-648 158 ℃阻燃性--- UL 94 HB ---

物性材料表

特性Feature 耐高温、耐冲击、高流动性、尺寸稳定。High temperature resistance, impact resistance, high liquidity, dimension stability. 用途Use 电子、电器零件、汽车部件等。Electronic, electrical parts, auto parts, etc. 注塑条件Injection conditions 预干燥温度Pre-drying temperature 预干燥时间Pre-drying time 进料区温度Feed zone temperature 压缩区温度Compression zone temperature 熔融区温度Melting zone temperature 喷嘴温度Nozzle Temperature 模具温度Mold 注射压力Injection pressure 物理机械性能Physical and mechanical properties 项目Project 单位unit 试验方法Test method 数值Value 密度Density 熔点Melting point 成型收缩率Mold Shrinkage 吸水率(24小时,23℃)Water Absorption (24 hours, 23 ℃) 熔融指数Melt Index 阻燃等级Flame Rating 拉伸断裂强度Tensile Strength 拉伸模量Tensile modulus 断裂伸长率Elongation at break 弯曲强度Bending 弯曲模量Bending modulus 悬臂梁(无缺口)冲击强度Izod (unnotched) impact strength 悬臂梁缺口冲击强度Izod notched impact strength 洛氏硬度Rockwell hardness 热变形温度(0.45MPa)Heat Deflection Temperature(0.45MPa) Dielectric Strength 绝缘破坏强度 Arc resistance 耐电弧性 Dielectric Constant 介电常数 Dielectric Losses 介电损耗 Characteristics 特性 平衡吸湿量Moisture Absorption at Equilibrium 线性成型收缩率,横向Linear Mould Shrinkage, Transverse 断裂伸长率Elongation at Break 屈服伸长率Elongation at Yield

PBT SK642FR 杜邦 物性表

PBT SK642FR NC010杜邦DuPont Crastin?物性数据表: 产品文字由久隆塑胶原料提供TeL134******** Crastin?SK642FR是一种阻燃UL94V-01.5mm;GF15%玻璃纤维增强的聚对苯二甲酸乙二醇酯PBT,注塑成型。Crastin?SK642FR is a flame retardant,15%glass reinforced polybutylene terephtalate for injection molding.It is recognized as UL94V-0at1.5mm. 熔体体积流动速度(MVR)14cm3/10min ISO1133 温度250°C ISO1133 载荷5kg ISO1133 模塑收缩率(平行)0.7%ISO294-4,2577 模塑收缩率(垂直) 1.3%ISO294-4,2577 拉伸模量6500MPa ISO527-1/-2 断裂应力95MPa ISO527-1/-2 断裂伸长率3%ISO527-1/-2 拉伸蠕变模量(1h)6000MPa ISO899-1 拉伸蠕变模量(1000h)4800MPa ISO899-1 无缺口简支梁冲击强度(+23°C)53kJ/m2ISO179/1eU 无缺口简支梁冲击强度(-30°C)40kJ/m2ISO179/1eU 简支梁缺口冲击强度(+23°C)8kJ/m2ISO179/1eA 简支梁缺口冲击强度(-30°C)7kJ/m2ISO179/1eA 熔融温度(10°C/min)225°C ISO11357-1/-3 热变形温度(1.80MPa)203°C ISO75-1/-2 热变形温度(8.00MPa)116°C ISO75-1/-2 维卡软化温度(50°C/h50N)207°C ISO306 线性热膨胀系数(平行)50E-6/K ISO11359-1/-2 线性热膨胀系数(垂直)110E-6/K ISO11359-1/-2 1.5mm名义厚度时的燃烧性V-0class IEC60695-11-10 测试用试样的厚度 1.5mm IEC60695-11-10 UL注册UL-- 厚度为h时的燃烧性V-0class IEC60695-11-10 测试用试样的厚度0.8mm IEC60695-11-10 燃烧性-氧指数31%ISO4589-1/-2 相对介电常数.(100Hz) 3.7-IEC60250 相对介电常数.(1MHz) 3.5-IEC60250 介质损耗因子(100Hz)30E-4IEC60250 介质损耗因子(1MHz)170E-4IEC60250 体积电阻率>1E13Ohm*m IEC60093 表面电阻率1E15Ohm IEC60093 介电强度28kV/mm IEC60243-1 相对漏电起痕指数250-IEC60112

PBT+GF 物性表

PBT,30%glass fibres,injection moulding,flame retardant ISO Shortname:ISO 7792-1-PBT,GFHMR,09-110,GF30;ISO 1043-PBT GF FR(17)Property Test Condition Unit Standard guide value Rheological properties C Melt volume-flow rate 260°C;5kg cm3/(10min) ISO 1133-137C Molding shrinkage,parallel 60x60x2;250°C /WZ 80°C;600bar %ISO 294-40.3C Molding shrinkage,transverse 60x60x2;250°C /WZ 80°C;600bar %ISO 294-40.9Post-shrinkage,parallel 60x60x2;120°C;4h %ISO 294-40.1Post-shrinkage,transverse 60x60x2;120°C;4h % ISO 294-4 0.1 Mechanical properties (23°C/50%r.h.)C Tensile modulus 1mm/min MPa ISO 527-1,-211500C Tensile Stress at break 5mm/min MPa ISO 527-1,-2125C Tensile Strain at break 5mm/min %ISO 527-1,-2 2.1C Charpy impact strength 23°C kJ/m2ISO 179-1eU 50C Charpy impact strength -30°C kJ/m2ISO 179-1eU 50C Charpy notched impact strength 23°C kJ/m2ISO 179-1eA <10C Charpy notched impact strength -30°C kJ/m2ISO 179-1eA <10Izod impact strength 23°C kJ/m2ISO 180-1U 45Izod impact strength -30°C kJ/m2ISO 180-1U 45Izod notched impact strength 23°C kJ/m2ISO 180-1A <10Izod notched impact strength -30°C kJ/m2ISO 180-1A <10Flexural modulus 2mm/min MPa ISO 178-A 10500Flexural strength 2mm/min MPa ISO 178-A 200Flexural strain at flexural strength 2mm/min %ISO 178-A 2.6Ball indentation hardness N/mm2ISO 2039-1186C Puncture energy 23°C J ISO 6603-2 2.3C Puncture energy -30°C J ISO 6603-2 2.1C Puncture maximum force 23°C N ISO 6603-2669C Puncture maximum force -30°C N ISO 6603-2 649 Thermal properties C Melting temperature 10°C/min °C ISO 11357-1,-3225C Temperature of deflection under load 1.80MPa °C ISO 75-1,-2200C Temperature of deflection under load 0.45MPa °C ISO 75-1,-2220Vicat softening temperature 50N;120°C/h °C ISO 306205C Coefficient of linear thermal expansion,parallel 23to 55°C 10-4/K ISO 11359-1,-20.2C Coefficient of linear thermal expansion,transverse 23to 55°C 10-4/K ISO 11359-1,-20.9C Burning behavior UL 940.38mm Class UL 94V-0C Burning behavior UL 940.8mm Class UL 94V-0C Oxygen index Method A % ISO 4589-2 32 Pocan B 4239 000000 Page 1of 3

PA10T材料物性表

P ROVISIONAL D ATA S HEET G RIVORY HT G RIVORY XE 4027 BLACK 9916 Product description Grivory XE 4027 black 9916 is a 30% glass-fibre reinforced flame retardant (UL 94 V-0) engineering thermoplastic material based on a semicrystalline, partially aromatic co-polyamide. Grivory XE 4027 black 9916 is free of halogens and red phosphorus. RoHS: Grivory XE 4027 black 9916 is in compliance with RoHS (2002/95/EC, Re-striction of Hazardous Substances). WEEE:Parts produced from Grivory XE 4027 black 9916 are not subject to "selec-tive treatment" according the Directive 2002/96/EC on Waste Electrical and Elec-tronic Equipment. ISO polymer designation: PA 10T/X ASTM designation: PPA, polyphthalamide The main distinguishing features of Grivory HT-PPA, when compared to other poly-amides, are its good performance at high temperatures providing parts which are stiffer, stronger, have better heat distortion and dimensional stability as well as excel-lent chemical resistance and low moisture absorption. Grivory XE 4027 black 9916 is especially suitable for injection moulded components in electrical and electronic applications which require a flame class acc. UL 94 V-0. The material is suitable for lead-free SMT reflow soldering acc. i.e. JEDEC J-STD-020C (peak temperature 260°C). Compo-nents conforming to JEDEC MSL1 are achievable.

PBT+PC 基础创新塑料 553 物性表

PBT/PC基础创新塑料VALOX553物性表: 产品提供久隆塑胶原料tEl134******** GF30%玻璃纤维增强,阻燃V0,PBT+PC共混物,具有良好的翘曲的特点。应用:泵壳、轴承座、电器元件,聚光灯,电动马达,泵配件。30%GR PBT+PC,UL94V-0.Reduced warpage characteristics.Applications; appliance handles,spotlights,electric motors,pump housings,etc. 密度(73°F)1590公斤/立方米ASTM D792 吸水率(24小时)0.07%ASTM D570 熔体流动7.0g/10分钟负荷2.16公斤,温度250℃ 断裂伸长率 2.5%5毫米/分钟;ASTM D638 断裂拉伸强度110兆帕ASTM D638 弯曲模量6887.85兆帕ASTM D790 弯曲强度179兆帕ASTM D790 洛克硬度R118-ASTM D785 悬臂梁缺口冲击强度(1/8)的0.0854千焦/米ASTM D256 UL94燃烧性V-0-UL94测试厚度0.864毫米 氧指数34%ISO4589 0.46兆帕的热变形温度(66磅)205°C ISO75/Be 热变形温度在1.8兆帕(264磅)135°C ISO75/Ae 热释放速率(平行)21.6E-6/K ASTM D696 电介质强度(短时)25.6千伏/毫米ASTM D149 耗散因素(1兆赫)0.02-ASTM D150 电介质常数(1兆赫) 3.7-ASTM D150 体积电阻率>1E15欧姆*厘米ASTM D257 耐电弧性90?ASTM D495

锂电材料物性对比

电池材料厂家技术标准积累 深圳市贝特瑞 MSG-S(518) 负极石墨粒径:D10=9.764;D50=17.136um;D90=28.189;水分:0.039;碳含量:99.952;TAP密度;1.036 比表面 积:2.784;首次容量/效率:363.51/94.18 深圳市贝特瑞 518 负极石墨粒径:D10=9.862;D50=16.888um; D90=28.374;水分:0.04%; 碳含量:99.962; TAP密度;1.042% 比表面积:2.625;首次容量/效率:352.3/92.5% 深圳市贝特瑞 AG 负极石墨粒径:D10=7.137;D50=18.058um; D90=37.495;水分:0.035;碳含量:99.676;TAP密度:1.001 首次容量/效率:320.83/90.42% 深圳市贝特瑞 AG 负极石墨粒径:D10=7.53;D50=17.779um; D90=39.648;水分:0.041;碳含量:99.743;TAP密度:1.002 ,首次容量/效率:326.51/90.67% 深圳市贝特瑞 SAG-23 负极石墨粒径:D10=8.318;D50=21.097um; D90=47.119;水分:0.04;碳含量:99.925;TAP密度:1.021 ,比表面积:4.605;首次容量/效率:332.11/92.08 深圳市贝特瑞 818 负极石墨粒径:D10=11.453;D50=18.226um; D90=28.762;水分:0.036;碳含量:99.964;TAP密度:1.121 比表面积:1.947;首次容量/效率:364.63/95.29% 深圳市贝特瑞 818 负极石墨粒径:D10=10.859;D50=18.033um;

PBT 4815物性表

PBT 4815物性表数据资料 特性:含有玻纤15%,强度大,成型容易,难燃等级达1/8inch,UL 94V-0 用途:连接器、冷却风扇、插座、线圈轴、汽机车零件、开关、电视机零件、整流器。 PBT 4815 台湾长春物性表 资料由长城塑胶提供 T e L 1 3 6 8 6 6 5 8 5 1 7 PBT 4815 台湾长春企业集团物性数据 ①原料描述部分 规格级别:难燃强 化级 外观颜色:黑色本色 用途概述:连接器、冷却风扇、插座、线圈轴、汽机车零件、开关、电视机零件、整流器。 备注说 明: 特性:含有玻纤15%,强度大,成型容易,难燃等级达1/8inch,UL 94V-0 ②原料技术数据 性能项目试验条件 [状态] 测试方法测试数据数据单位 基本性能吸水率--- ASTM D-570 0.03 % 物理性能成型收缩率--- ASTM D-955 0.4-2.0 % 比重--- ASTM D-792 1.43-1.52 --- 玻璃纤维含 量 --- Ash 15 % 机械性能引张强度--- ASTM D-638 900-1100 Kg/cm2 引张伸长率--- ASTM D-638 4-5.5 % 挠曲强度--- ASTM D-790 1400-1800 Kg/cm2 挠曲弹性率--- ASTM D-790 45000-65000 Kg/cm2 IZOD冲击强 度 --- ASTM D-256 5月7日Kg.cm/cm 洛氏硬度--- ASTM D-785 93 M-Scale 电气性能诱电率60Hz ASTM D-150 3.3 ---

诱电正接60Hz ASTM D-150 0.001 --- 体积电阻率--- ASTM D-257 >1016Ω.cm 表面电阻率--- ASTM D-257 >1014Ω 绝缘破坏强 度 --- ASTM D-149 22 KV/mm 耐电弧性--- ASTM D-495 90 sec 热性能耐燃性 3.0mm UL 94 V-0 --- 热变形温度 4.6Kg/cm2 ASTM D-648 220 ℃ 线膨胀系数--- ASTM D-696 5.5 10-5cm/cm℃熔点--- DSC 225 ℃ 热变形温度 18.6Kg/cm 2 ASTM D-648 205 ℃ PBT 1100 高粘度,超韧性,成型表面光滑。用于扣件组具,电脑键盘,文具外壳,旋钮开关等。 PBT 1200 高流动,表面光泽度良好。用于扣件组具,电脑键盘,文具外壳,旋钮开关等。PBT 2000 流动性佳,阻燃UL94V-0级。用于汽车零件,OA器材部件,瓦斯炉零件等。PBT 2100 流动性佳,阻燃UL94V-0级。用于汽车零件,OA器材部件,瓦斯炉零件等。PBT 3015 玻纤增强15%,低粘度,耐热性佳。用于汽车零件,马达端盖,碳刷座等。PBT 3020 玻纤增强20%,中粘度。用于汽车零件,马达端盖,碳刷座,工业产品零件等。PBT 3030 玻纤增强30%,高强度,耐热。用于汽车零件,马达端盖,碳刷座,工业产品零件等。 PBT 4115 含玻璃15%,高强度,阻燃。用于连接器,插座,线圈轴,电视机零件等。PBT 4120 含玻璃20%,强韧耐热性佳。用于连接器,插座,线圈轴,电视机零件等。PBT 4130 含玻璃30%,强韧耐热性佳。用于连接器,插座,线圈轴,电视机零件等。PBT 4140 含玻璃40%,高强度,低翘曲。用于连接器,插座,整流器,电视机零件等。PBT 4815 玻纤增强15%,强度大,阻燃。用于连接器,插座,整流器,电视机零件等。PBT 4830 玻纤增强30%,强度大,阻燃。用于连接器,插座,整流器,电视机零件等。PBT 5630 玻纤增强30%,无卤阻燃。用于连接器,线圈轴,开关,电视机零件,整流器等。 PBT 5115 玻纤增强15%,无卤阻燃,黑色规格。用于连接器,开关,电视机零件,整流器等。 PBT 5130 玻纤增强30%,无卤阻燃,黑色规格。用于连接器,开关,电视机零件,整流器等。 PBT 6730 玻纤增强30%,阻燃,低翘曲。用于小家电,连接器,冷却风扇。 PBT特性: 机械强度高,耐疲劳性和尺寸稳定性好,蠕变也小,这些性能在高温条件下也极少有变化。

杜邦 PBT HR5330HF 物性表

杜邦PBT HR5330HF本色NC010黑色BK503物性表: 产品提供久隆塑胶原料tEL134******** CRASTIN?HR5330HF是30%的玻璃纤维增强,高流量(HF),抗水解(HR)树脂。耐冲击性及强度出色的平衡性能。添加剂:润滑剂,、脱模助剂。特征:可焊、耐化学试剂、水解稳定。应用:汽车,电子电气。 熔体体积流动速度(MVR)8cm3/10min ISO1133 温度250℃ISO1133 载荷2.16kg ISO1133 模塑收缩率(平行)0.3%ISO294-4,2577 模塑收缩率(垂直) 1.0%ISO294-4,2577 拉伸模量8500MPa ISO527-1/-2 断裂应力110MPa ISO527-1/-2 断裂伸长率 2.9%ISO527-1/-2 无缺口简支梁冲击强度(+23°C)75kJ/m2ISO179/1eU 简支梁缺口冲击强度(+23°C)15kJ/m2ISO179/1eA 简支梁缺口冲击强度(-30°C)12kJ/m2ISO179/1eA 熔融温度(10°C/min)225°C ISO11357-1/-3 热变形温度(1.80MPa)205°C ISO75-1/-2 热变形温度(0.45MPa)220°C ISO75-1/-2 维卡软化温度(50°C/h50N)215°C ISO306 线性热膨胀系数(平行)21E-6/K ISO11359-1/-2 线性热膨胀系数(垂直)85E-6/K ISO11359-1/-2 1.5mm名义厚度时的燃烧性HB class IEC60695-11-10 测试用试样的厚度 1.5mm IEC60695-11-10 吸水性0.35%类似ISO62 吸湿性0.15%类似ISO62

材料物性表

EXTRUSION APPLICATION

Introduction Responsible for a long line of accomplishments in outstanding engineering plastics, UBE NYLON products have won the trust and respect of users the world over. UBE NYLON – NYLON 6, NYLON COPOLYMERS – is in wide use throughout industry with their unique properties utilized to their fullest potential. UBE NYLON 6 has a number of excellent properties as follows: Excellent in impact strength and rigidity Having a smaller friction coefficient, thus excellent in abrasion resistance Excellent in resistance to oils, solvents and chemicals Superior in heat resistance Appropriate to mass production, contributing to cost reduction Summary 1. Introduction 2. Nomenclature 3. Monofilament Applications 4. Film Applications 5. TERPALEX Polyamide 6/66/12 Copolymer Nomenclature The first 2 digits in the code indicate the type of Polyamide. The third and fourth digits indicate the molecular weight level for 1000 series. In case of copolymer, the third digit shows the viscosity level. The co-polymerization ratio can be roughly calculated from the fourth digit multiplying by 5. “T” means the basic grade for monofilament application and the grade contain some additives for maintain good process stability and high trans-parency. In case of “MT”, means monomer con-taining grade offering good flexibility and softness. 10: Polyamide 6 homopolymer 50: Polyamide 6/66 copolymer 70: Polyamide 6/12 copolymer Ex. 1022FDX04: : c.a. 22 x 1,000 = 22,000 Ex. 5034MTX1: : level = 3 (high viscosity) : c.a. 80/20(4 x 5 = 20et%) : monomer-contain type 2 Introduction

物性表

Safety Data Sheet complies with:directive 91/155/EEC revision:2.0 ISO 11014-1:Safety data sheet for chemical products. revision date:02/02/1998date of issue: 26/02/1998 p 1. Product and company identification Product name:Stanyl ?Product code:TE250F3 Manufacturer: DSM Engineering Plastics P.O. Box 43,6130 AA Sittard The Netherlands Emergency number: The Netherlands +31 (0)46 4 76 55 55 2. Composition/Information on ingredients This chemical product is a preparation Chemical nature:(poly)amide PA 46CAS number:50327-22-5Components contributing to the hazard: The material contains Sb 2O 3 as a synergist with an average content of max. 7%. Sb 2O 3 is classified as a harmful (Xn) substance with a risk phrase R40 carcinogen class 3. However, the Sb 2O 3 is embedded in an impervious matrix of polymer and is therefore less biological available than the free Sb 2O 3 (see also Section 15). 3. Hazards identification Most important hazards:Hazard warning not required Specific hazards: Vapour and fumes released at elevated processing temperatures may be irritant for the eyes, the nose, the throat and the respiratory tract and in case of overexposure may cause nausea and headache. The material is not classified as being a dangerous preparation according to the EEC-Directive 88/379 and the subsequent amendments. See also Section 15.4. First-Aid measures Inhalation: When fumes of molten material have been inhaled;- Move person to fresh air as quickly as possible - rest in half upright position - loosen clothing - keep warm In case of respiratory problems move person to first aid station for medical treatment.Skin contact: Any molten material on the skin/burns should be cooled (off) as quickly as possible by means of cold water.Cover the wound with sterile cloth and move person to first aid station or hospital for medical treatment.Attention: never pull off the molten material from the wound.Eye contact: Any material entering the eye should be flushed out with copious volumes of water.Ingestion: No danger of toxicity, this material is biologically inactive (see also Section 11). 5. Fire-fighting measures Extinguishing media: Water, water/foam, CO 2, ABC fire extinguisher powder.Specific Hazards: Treat the material as a solid that can burn. Moulded parts or solid granules generally burn slowly with flaming drips.

杜邦物性表 PBT CRASTIN LW9330 BK851

DuPont ? Crastin ? PBT thermoplastic polyester resin Crastin ? LW9330 BK851 Identification Resin Identification ISO 1043PBT+SAN-GF30 Part Marking Code ISO 11469 >PBT+SAN-GF30< Mechanical Stress at Break ISO 527MPa (kpsi) 133 (19.3) Strain at Break ISO 527% 2.2 Tensile Modulus ISO 527MPa (kpsi)9600 (1390) Notched Charpy Impact Strength ISO 179/1eA kJ/m 28 Unnotched Charpy Impact Strength ISO 179/1eU kJ/m 2 50 Thermal Melting Temperature ISO 11357-1/-3 °C (°F) 10°C/min 225 (437) Flammability Flammability Classification IEC 60695-11-10 0.75mm HB Flammability Classification UL94 0.75mm HB Contact DuPont for Material Safety Data Sheet, general guides and/or additional information about ventilation, handling, purging, drying, etc.ISO Mechanical properties measured at 4.0mm, ISO Electrical properties measured at 2.0mm, and all ASTM properties measured at 3.2mm. Test temperatures are 23°C unless otherwise stated. The DuPont Oval Logo, DuPont?, The miracles of science? and Crastin? are trademarks or registered trademarks of DuPont Company. Copyright? 2005. 050420/050420 The information provided in this data sheet corresponds to our knowledge on the subject at the date of its publication. This information may be subject to revision as new knowledge and experience becomes available. The data provided fall within the normal range of product properties and relate only to the specific material designated; these data may not be valid for such material used in combination with any other materials, additives or pigments or in any process, unless expressly indicated otherwise. The data provided should not be used to establish specification limits or used alone as the basis of design; they are not intended to substitute for any testing you may need to conduct to determine for yourself the suitability of a specific material for your particular purposes. Since DuPont cannot anticipate all variations in actual end-use conditions DuPont makes no warranties and assumes no liability in connection with any use of this information. Nothing in this publication is to be considered as a license to operate under or a recommendation to infringe any patent rights. DuPont advises you to seek independent counsel for a freedom to practice opinion on the intended application or end-use of our products. Caution: Do not use this product in medical applications involving permanent implantation in the human body. For other medical applications see "DuPont Medical Caution Statement", H-50102. https://www.360docs.net/doc/7f5469712.html, Crastin ? LW9330 BK851 is a 30% glass fiber reinforced, black polybutylene terephthalate alloy for injection molding. It has improved surface aesthetics, excellent dimensional stability and low warpage characteristics. Property Test Method Units Value

常用材料的热物性参数

表1 各种金属的热物性值 温度 C 比热 cal/(g·C) 导热系数 cal/(cm·s· C) 密度(g/cm3)液相 线、固相线温度 (C) =7.88(20C) =7.3(1500C) =7.0(1600C) =7.86(15C) =7.86(15C) =7.85(15C) =7.85(15C) =7.83(15C)

续表1 各种金属的热物性值 温度 C 比热 cal/(g·C) 导热系数 cal/(cm·s· C) 密度(g/cm3)液相 线、固相线温度 (C) =7.73(15C) Ts=1488 T L=1497 =7.84(15C) T S=1420 T L=1520 =7.7(15C) 13.1Cr,0.5Ni T S=1399 T L=1454 =7.0(15C) 比热相对于 普通铸铁

=7.1(15C) 温度 C 比热 cal/(g·C) 导热系数 cal/(cm·s· C) 密度(g/cm3)液相 线、固相线温度 (C) =7.5~7.8(15C) =8.92 T S=T L=1083

s=2.70(15C) T S=T M=660.2 温度 C 比热 cal/(g·C) 导热系数 cal/(cm·s· C) 密度(g/cm3)液相 线、固相线温度 (C) s=1.74 T L=T S=651 s=6.09 T S=1395 T L=1427

表2 铸型的热物性计算公式

硅砂,干型,呋喃铸型600C以下 0.385<<0.494 0.0058 塑料PBT物性参数 PBT是最坚韧的工程热塑材料之一,它是半结晶材料,有非常好的化学稳定性、机械强度、电绝缘特性和热稳定性。这些材料在很广的环境条件下都有很好的稳定性。 PBT吸湿特性很弱。非增强型PBT的张力强度为50MPa,玻璃添加剂型的PBT 张力强度为170MPa.玻璃添加剂过多将导致材料变脆。PBT的;结晶很迅速,这将导致因冷却不均匀而造成弯曲变形。对于有玻璃添加剂类型的材料,流程方向的收缩率可以减小,但与流程垂直方向的收缩率基本上和普通材料没有区别。一般材料收缩率在1.5%~2.8%之间。含30%玻璃添加剂的材料收缩0.3%~1.6%之间。熔点(225%C)和高温变形温度都比PET材料要低。维卡软化温度大约为170C.玻璃化转换温度(glass trasitio temperature)在22C到43C之间。由于PBT的结晶速度很高,因此它的粘性很低,塑件加工的周期时间一般也较低。 PBT树脂注塑模工艺条件 干燥处理:这种材料在高温下很容易水解,因此加工前的干燥处理是很重要的。建议在空气中的干燥条件为120C,6~8小时,或者150C,2~4小时。湿度必须小于0.03%.如果用吸湿干燥器干燥,建议条件为150C,2.5小时。 熔化温度:225~275C,建议温度:250C。模具温度:对于未增强型的材料为 40~60C。要很好地设计模具的冷却腔道以减小塑件的弯曲。热量的散失一定要快而均匀。建议模具冷却腔道的直径为12mm。 注射压力:中等(最大到1500bar)。 注射速度:应使用尽可能快的注射速度(因为PBT的凝固很快)。流道和浇口:建议使用圆形流道以增加压力的传递(经验公式:流道直径=塑件厚度+1.5mm)。可以使用各种型式的浇口。也可以使用热流道,但要注意防止材料的渗漏和降解。浇口直径应该在0.8~1.0*t之间,这里 t是塑件厚度。如果是潜入式浇口,建议最小直径为 0.75mm.典型用途家用器具(食品加工刀片、真空吸尘器元件、电风扇、头发干燥机壳体、咖啡器皿等),电器元件(开关、电机壳、保险丝盒、计算机键盘按键等),汽车工业(散热器格窗、车身嵌板、车轮盖、门窗部件等)。 a、机械性能:强度高、耐疲劳性、尺寸稳定、蠕变也小(高温条件下也极少有变化); b、耐热老化性:增强后的UL温度指数达120~140℃(户外长期老化性也很好); c、耐溶剂性:无应力开裂; d、对水稳定性:PBT遇水易分解(高温、高湿环境下使用需谨慎);塑料PBT物性参数