Clextral-Masterbatch

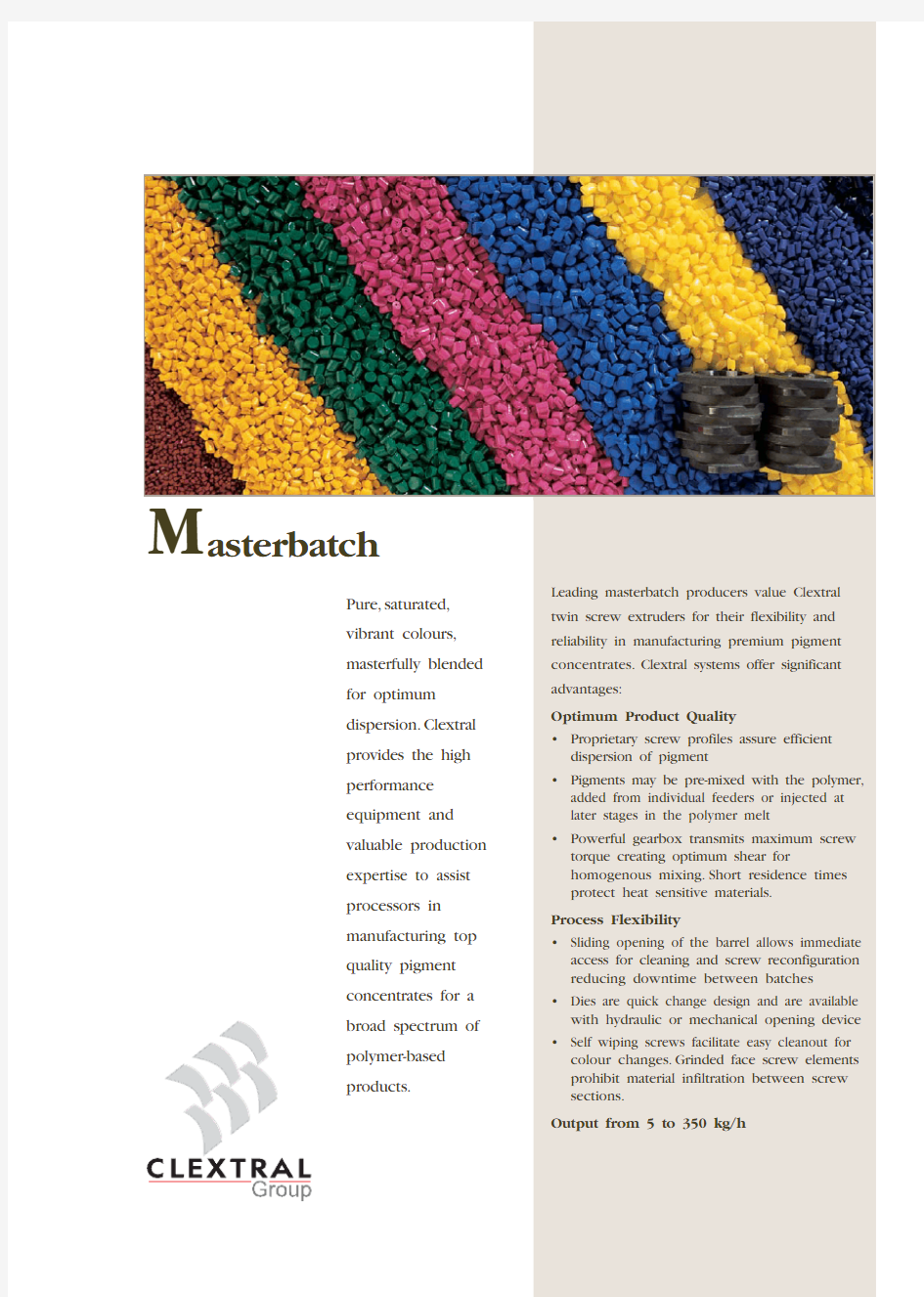

Pure,saturated,vibrant colours,masterfully blended for optimum dispersion.Clextral provides the high performance equipment and valuable production expertise to assist processors in manufacturing top quality pigment concentrates for a broad spectrum of polymer-based products.

M asterbatch

Leading masterbatch producers value Clextral twin screw extruders for their flexibility and reliability in manufacturing premium pigment concentrates.Clextral systems offer significant advantages:

Optimum Product Quality

?Proprietary screw profiles assure efficient dispersion of pigment

?Pigments may be pre-mixed with the polymer,added from individual feeders or injected at later stages in the polymer melt

?Powerful gearbox transmits maximum screw torque creating optimum shear for

homogenous mixing.Short residence times protect heat sensitive materials.Process Flexibility

?Sliding opening of the barrel allows immediate access for cleaning and screw reconfiguration reducing downtime between batches

?Dies are quick change design and are available with hydraulic or mechanical opening device ?Self wiping screws facilitate easy cleanout for colour changes.Grinded face screw elements prohibit material infiltration between screw sections.Output from 5 to 350 kg/h

CLEXTRAL

EUROPE:CLEXTRAL SAS, Z.I.de Chazeau, BP 10, 42702 FIRMINY Cedex FRANCE ? TEL:+33 4 77 40 31 31 ? FAX:+33 4 77 40 31 23 ? E-MAIL:clxsales@https://www.360docs.net/doc/7c13674334.html, NORTH AMERICA:CLEXTRAL INC, 14450 Carlson Circle, Tampa, FL 33626 USA ? TEL:+1 813 854 4434 ? FAX:+1 813 855 2269 ? E-MAIL:clextralusa@https://www.360docs.net/doc/7c13674334.html, SOUTH AMERICA:CLEXTRAL LATIN AMERICA, Calle Mardoqueo Fern ández N°128, OF.802, Providencia, Santiago, CHILE ? TEL:+56 2 335 59 76 ? FAX:+56 2 335 59 77E-MAIL:jcoelho@https://www.360docs.net/doc/7c13674334.html, - llacau@https://www.360docs.net/doc/7c13674334.html,

NORTH AFRICA:CLEXTRAL AFREM SERVICES, Lot.Mohamed Saddoune N°163C, KOUBA, Algiers, ALGERIA ? TEL:+213 21 21 01 17 ? FAX:+213 21 21 00 79 E-MAIL:mtonkin@https://www.360docs.net/doc/7c13674334.html,

ASIA PACIFIC:CLEXTRAL ASIA PACIFIC, Room 9001, Novel Building, 887 Huai Hai Road (M), 200020 Shanghai, CHINA ? TEL:+86 21 64 74 78 06 ? FAX:+86 21 64 74 68 08E-MAIL:jchen@https://www.360docs.net/doc/7c13674334.html, - eperroton@https://www.360docs.net/doc/7c13674334.html, - pbreillot@https://www.360docs.net/doc/7c13674334.html,

https://www.360docs.net/doc/7c13674334.html,

M asterbatch processing lines

C r e a t e d b y :A d v e r t i s i n g & M a r k e t i n g A s s o c i a t e s / P h o t o s :S t u d i o P o s i t i f F r a n c e / P r i n t e d i n F r a n c e / T h e i n f o r m a t i o n ,p h o t o g r a p h s ,c h a r t s ,s k e t c h e s ,e t c .:n o t c o n t r a c t u a l / C L E X T R A L ,A F R E M ,L Y M A C A N

D

E V O L U M a r e a l l r e g i s t e r e d m a r k s a n d C L E X T R A L G r o u p p r o p r i e t a r y / A l l r i g h t s r e s e r v e d - C o p y r i g h t s C L E X T R A L 2007.

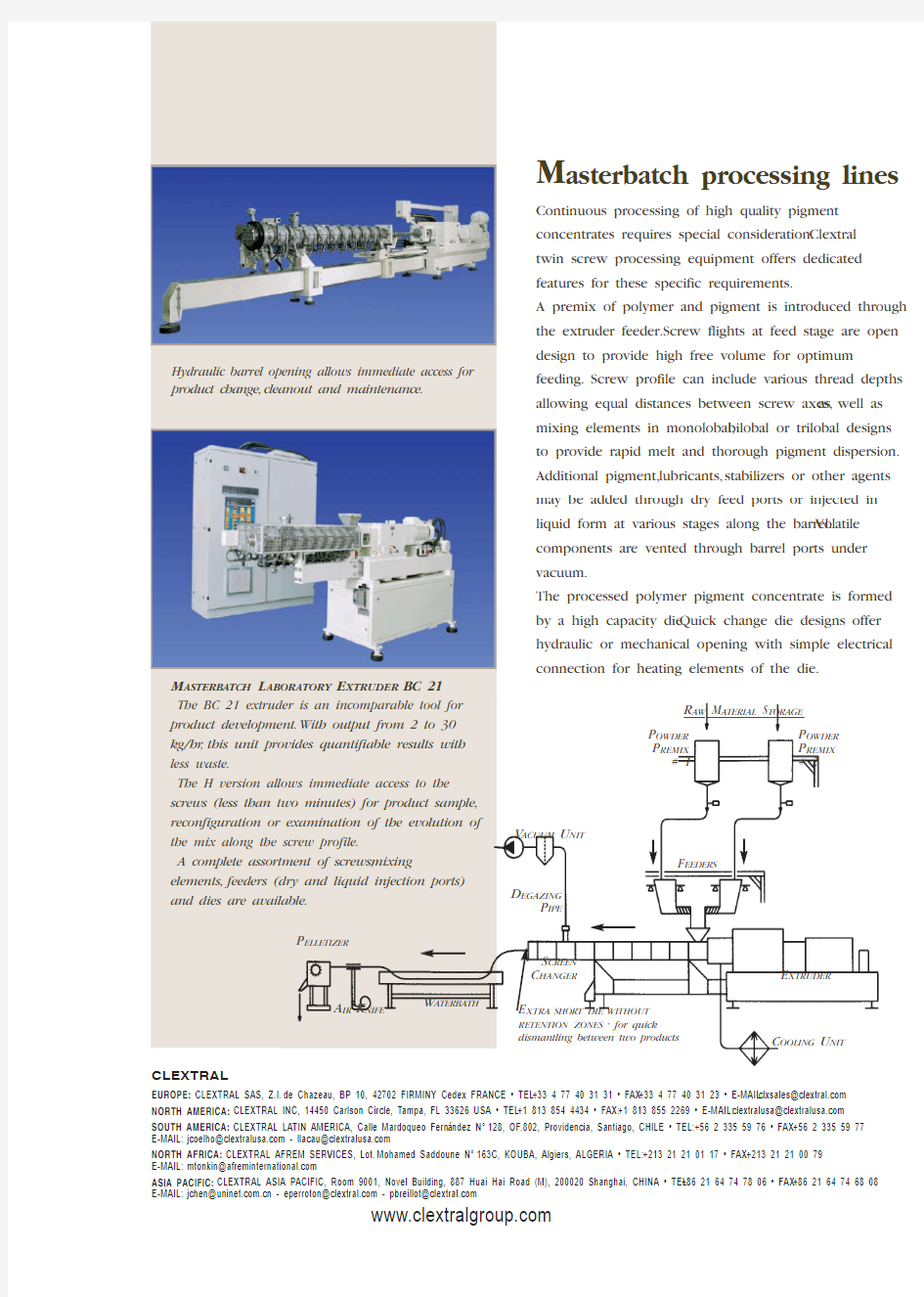

M ASTERBATCH L ABORATORY E XTRUDER BC 21

The BC 21 extruder is an incomparable tool for product development.With output from 2 to 30kg/hr ,this unit provides quantifiable results with less waste.

The H version allows immediate access to the screws (less than two minutes) for product sample,reconfiguration or examination of the evolution of the mix along the screw profile.

A complete assortment of screws,mixing

elements,feeders (dry and liquid injection ports)and dies are available.

Hydraulic barrel opening allows immediate access for product change,cleanout and maintenance.

Continuous processing of high quality pigment

concentrates requires special consideration.Clextral twin screw processing equipment offers dedicated features for these specific requirements.

A premix of polymer and pigment is introduced through the extruder feeder.Screw flights at feed stage are open design to provide high free volume for optimum

feeding.Screw profile can include various thread depths allowing equal distances between screw axes,as well as mixing elements in monolobal,bilobal or trilobal designs to provide rapid melt and thorough pigment dispersion.Additional pigment,lubricants,stabilizers or other agents may be added through dry feed ports or injected in liquid form at various stages along the barrel.Volatile components are vented through barrel ports under vacuum.

The processed polymer pigment concentrate is formed by a high capacity die.Quick change die designs offer hydraulic or mechanical opening with simple electrical connection for heating elements of the die.

R AW M ATERIAL S TORAGE

P OWDER P REMIX # 2

P OWDER P REMIX

# 1

F EEDERS

V ACUUM U NIT

D EGAZING

P IPE

S CREEN C HANGER

W ATERBATH

A IR K NIFE

P ELLETIZER

C OOLING U NIT

E XTRA SHORT DIE WITHOUT RETENTION ZONES - for quick

dismantling between two products

E XTRUDER