Introduction to Aircraft Lighting Specturm

Commercial Aircraft Products Group

January, 2003 1

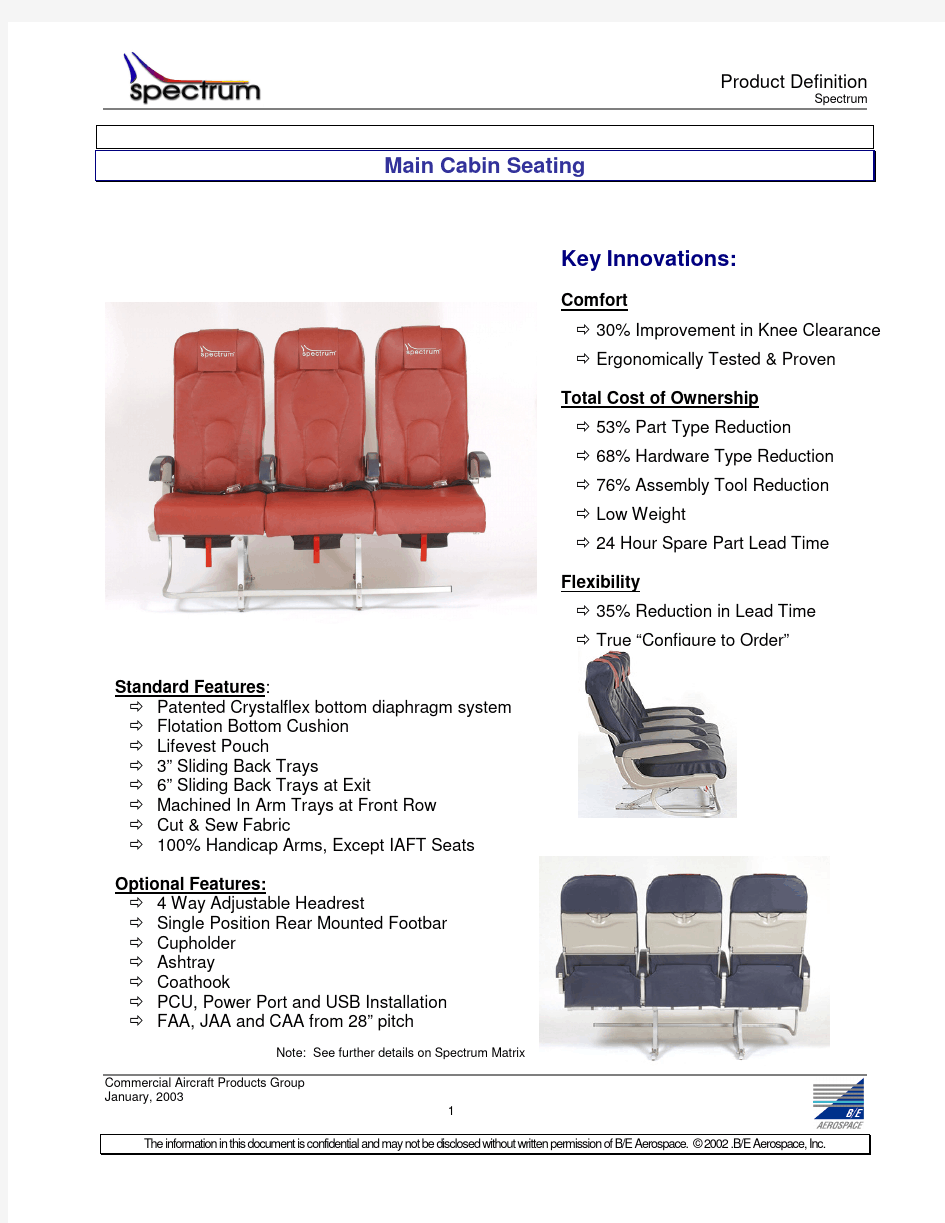

Main Cabin Seating

Key Innovations:

Comfort

30% Improvement in Knee Clearance Ergonomically Tested & Proven

Total Cost of Ownership

53% Part Type Reduction 68% Hardware Type Reduction 76% Assembly Tool Reduction Low Weight 24 Hour Spare Part Lead Time

Flexibility

35% Reduction in Lead Time True “Configure to Order”

Standard Features :

Patented Crystalflex bottom diaphragm system Flotation Bottom Cushion Lifevest Pouch

3” Sliding Back Trays

6” Sliding Back Trays at Exit

Machined In Arm Trays at Front Row Cut & Sew Fabric

100% Handicap Arms, Except IAFT Seats

Optional Features:

4 Way Adjustable Headrest

Single Position Rear Mounted Footbar Cupholder Ashtray Coathook

PCU, Power Port and USB Installation FAA, JAA and CAA from 28” pitch

Note: See further details on Spectrum Matrix

Commercial Aircraft Products Group January, 2003 2

FEATURES AND BENEFITS

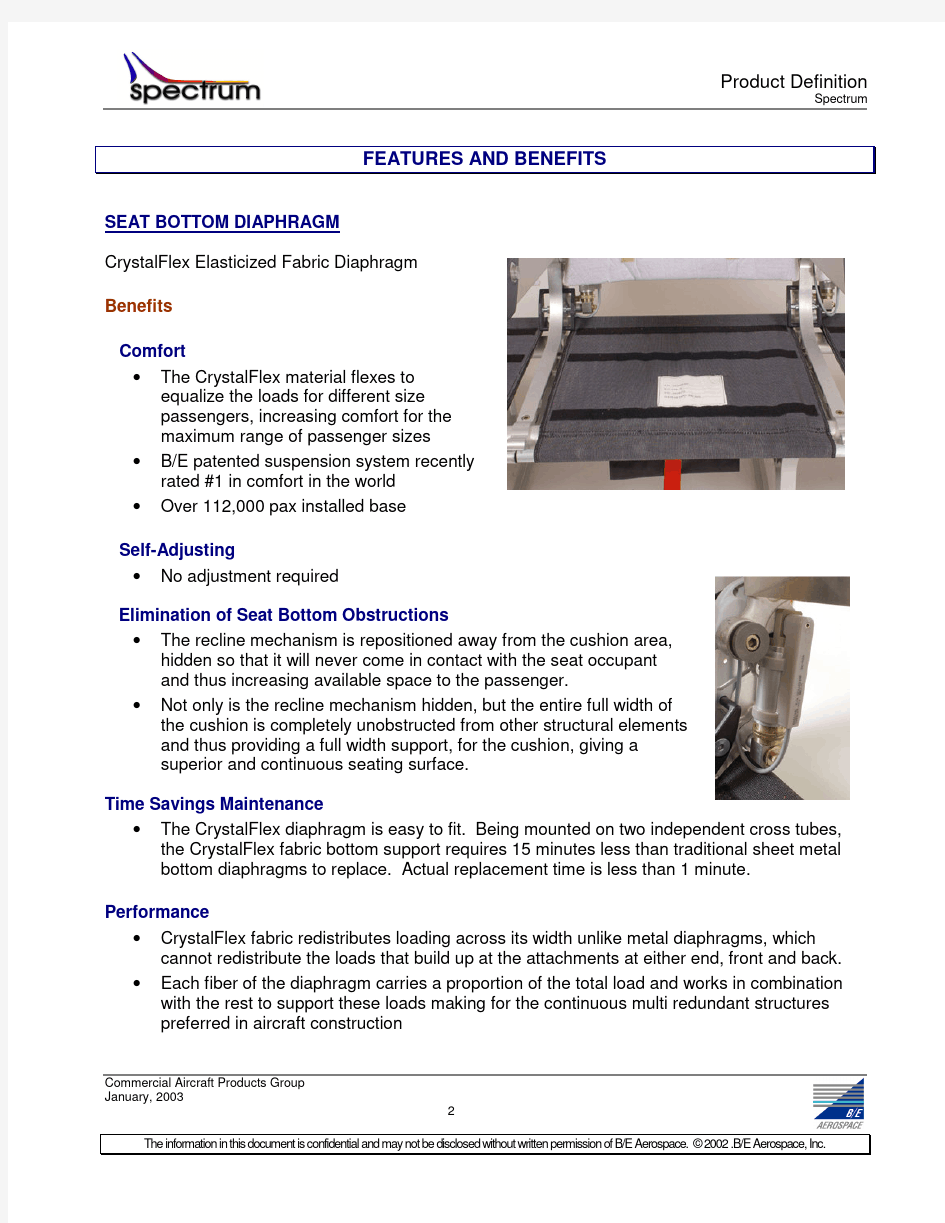

SEAT BOTTOM DIAPHRAGM

CrystalFlex Elasticized Fabric Diaphragm

Benefits

Comfort

? The CrystalFlex material flexes to

equalize the loads for different size passengers, increasing comfort for the maximum range of passenger sizes

? B/E patented suspension system recently

rated #1 in comfort in the world ? Over 112,000 pax installed base

Self-Adjusting

? No adjustment required

Elimination of Seat Bottom Obstructions

? The recline mechanism is repositioned away from the cushion area,

hidden so that it will never come in contact with the seat occupant and thus increasing available space to the passenger.

? Not only is the recline mechanism hidden, but the entire full width of

the cushion is completely unobstructed from other structural elements and thus providing a full width support, for the cushion, giving a superior and continuous seating surface.

Time Savings Maintenance

?

The CrystalFlex diaphragm is easy to fit. Being mounted on two independent cross tubes,

the CrystalFlex fabric bottom support requires 15 minutes less than traditional sheet metal bottom diaphragms to replace. Actual replacement time is less than 1 minute.

Performance

? CrystalFlex fabric redistributes loading across its width unlike metal diaphragms, which

cannot redistribute the loads that build up at the attachments at either end, front and back. ? Each fiber of the diaphragm carries a proportion of the total load and works in combination

with the rest to support these loads making for the continuous multi redundant structures preferred in aircraft construction

Commercial Aircraft Products Group

January, 2003

3

SEAT BACK FRAME

?Improved techniques in the production of volume produced sheet and tubular aluminum assemblies

have allowed B/E to offer a weight and shape

competitive ‘aluminum’ seat back that matches

the comfort needs of this market segment ?Contoured aluminum back with integral lumbar

Benefits

?

Excellent contouring provides comfortable

anthropometrical correct back surfaces.

?Hard seat back pan provides increased comfort by protecting the occupant from intrusion from the knees of the passenger sitting behind and the placement of bulky items into the magazine pocket.

?Cycle tested to 120,000 cycles @ 100 lbs.

Commercial Aircraft Products Group

January, 2003

4

BOTTOM CUSHIONS

?Bottom cushions are urethane foam with a fire-blocking layer

?The bottom cushion of all seats will be certified to TSO-C72c for use as a flotation device ?Bottom cushions are cycle tested to 300,000 cycles

?Cushion height & length designed to maximize comfort for smaller seat occupant

o Cushion height at nose = 17”

o Cushion Length = 18”

o6o rake on seat cushion

Typical seat on market today is 18” – 19” high

Cushion Benefits

?Bottom cushion comfort is greatly enhanced for the smaller seat occupant by incorporating a lower seat cushion.

?The bottom cushion height location will allow smaller passengers to position feet firmly on floor, thereby ensuring proper thigh support.

?Ergonomic data shows the shorter bottom cushion height & length does NOT negatively impact the larger seat occupant, therefore, maximizes comfort for the broadest range of

passengers. The seat cushion height and length is, in fact, enhanced through the new back pivot point position, which allows MORE shin space and room to stretch legs.

BACK CUSHION

?Back cushions are

firehard foam

The standard Spectrum back

cushion is a one-piece cushion

design with integral wings for

head support.

Back Cushion Benefits

?Back cushion assembly is easily removed from back by removal of two simple straps.

? ALL self-adhesive Velcro and bonding of the back foam has been eliminated.

Time Savings: Saves 6 minutes over conventional bonded designs. The new design approach allows quicker upgrade of cushions.

Standard Fixed Wing Design

Commercial Aircraft Products Group

January, 2003

5

UNDER SEAT CLEARANCE

?10.84” of under seat vertical clearance.

?Fully accommodates underseat luggage

RECLINE UNIT MECHANISM

?Spectrum design is a mid-height backrest pivot

?Pivot point is approximately 2 ?” higher than conventional main cabin seating

Benefits of Mid-Height Pivot Point

?Positioned at the height of the knees of a large occupant it reduces recline intrusion

into aft occupant living space.

Benefits of Recline Unit Design

?Spectrum recline mechanism can be quickly detached and replaced in less than 1minute

using only an Allen key.

?Spectrum recline unit is more robust than

traditional designs capable of 150% the load

of regular recline units

?Spectrum recline unit is hidden vertically in the back clearing the passenger space of obstructions. Thinner bottom cushions are used reducing seat weight and optimizing living space

?Infinite recline adjustment up to 4.5 inches

?Cycle tested to 250,000 cycles

Commercial Aircraft Products Group January, 2003 6

BACK MOUNT TRAY TABLE

?

Current generation tray table heights are commonly

positioned at 25” above the floor

? Spectrum

design uses a 26” high tray table that will

alleviate the passenger issue of thigh / leg clearance

? Independent third party focus group studies have validated

passengers’ need for more thigh room

Tray Table Design ? 3” (standard) and 6” (escape hatches) tray slides

? No lip on front to limit intrusion on eating and working space ? Lip on back of tray table ONLY

?

Tray table designed with 2.5 degree up angle to ensure level surface at flying altitude

Tray Benefits

? The 26” tray table allows more space to comfortably utilize laptops due to higher back pivot

point. Offers a higher eating / working surface ? Real and perceived increase in

personal living space ? Quick detach trays

Time Savings : Saves 5 minutes of service time over bolted designs

? Does not require in service

adjustment. Factory set

eliminates the need to adjust tray height and angle ? Cycle tested

In-back Tables

o 150 lbs static for 50,000

cycles (down)

o 25 lbs. for 50,000 cycles (stow and deploy)

Seats set at 31” pitch

Commercial Aircraft Products Group

January, 2003 7

IN-ARM TRAY TABLES

? Self-supporting, bi-fold machined in-arm food tray

? In-arm food tray is the same height as the back-mounted food tray ? 3” slide mechanism ? Cycle tested

In-arm Tables 150 lbs.

static download

50,000 cycles @ 25 lbs (stow and deploy)

END BAY COVER

Injection molded from durable plastic with

attachment points already molded in. Front-row bumper style to match standard seats.

Benefits

? Rugged design to protect from food service or

luggage damage

? Easily removable aisle bumpers designed to

protect from food service carts or luggage damage

? More rugged and durable than vacuum formed

endbay covers

? 100% handicap endbay with exception of in-arm table seats

? In-arm table seat endbay is styled to

complement standard seats in aircraft

? Integral attendant step, able to support 400

lbs.

? Provision for EPL and PC Power indicator

lights

In Arm Table Endbay

Commercial Aircraft Products Group

January, 2003

8

ARMS

Powder-coated aluminum with injection molded arm caps and escutcheons

Arm Design Benefits

?Modular design arm

?Arm can be removed without removing

backrest

?Same arm for all locations

?Tapered to provide maximum lateral

living space between and under arms

?Center arm can be rotated between back

cushions

?Large internal opening for ease of cable

routing and eliminates chaffing of cable

?Elimination of arm adjustment features

?Armrests cycle tested

Side 25,000

Down 50,000

Handicap Arm 100 lbs abuse load

Download Static 400 lbs

Sideload 250 lbs

Upload 100 lbs

Sideload 100 lbs/50,000 Cycles

?Color lasts under the most extreme conditions for injection molded armcaps

?Top or side mounted PCU

installations available (see matrix for

part number listing)

LITERATURE POCKETS

Quick detach literature pocket spring facilitates quick replacement with no tools

Commercial Aircraft Products Group January, 2003 9

FRAME CONSTRUCTION

Anodized beam sections and legs

Benefits

? Eliminates the need for powder coating,

which will need to be maintained as the seat gets older

? Anodizing is the most durable finish

available for aluminum and adds the

maximum protection for components from corrosion

Frame Construction Approach

? Frame construction uses section and leg

clamp joints to attach to lateral beams such that variations in leg position do not require the production of new variant beams to complete the new geometries, eliminates the need for rivets and bolts

Benefits

?

Strength of frame enhanced through the elimination of

drilling and cross hole attachments

? Reduces the proliferation of part numbers commonly

found in designs requiring bolted on or riveted parts ? Designed to easily accommodate optional modular

features within the same seat structure

Tracking for IFE Cables

Commercial Aircraft Products Group January, 2003 10

SEAT LEGS

Offset Assembly Benefits

? One-Piece machined

aluminum leg

? Offset where required

Benefits

? Design accommodates ALL single aisle

aircraft floor tracks

? Durable anodized material provides

decorative anti-corrosive finish

? Pre-configured for SEB boxes and PC

Power boxes

? Three stud, two shear plunger foot block on “every” seat vs. old standard of two stud, one

shear plunger

? This design accommodates worse-case loading conditions for 16g

Commercial Aircraft Products Group

January, 2003 11

DRESS COVERS

Single-piece dresscover installed over the seat

5 Cover Style Options (A – E fabric) (B – E Leather)

Benefits

? Traditional dress cover designs incorporate

tremendous amounts of Velcro connections causing bunching and making the dressing time consuming and frustrating ? No tools required

? Covers can be removed without removing

table latch

? Single piece non handed covers

Style A Style B

Style C

Style D

Style E

Commercial Aircraft Products Group

January, 2003

12

TRIM & FINISH

?Developed by our in-house Industrial Design group to complement Airbus and Boeing color schemes

?Two standardized color options facilitates stocking of trim and finish components reducing lead times

COLOR SCHEMES

Option

Seat

Component

Boeing

Color

Airbus

Color

Pantone

Color

A Endbay/Arms/Foodtray BAC7801 2.17 4C Warm Gray/Pepperdust

B Endbay/Arms/Foodtray BAC7734 7

C Light Gray

C Armcap/Escutchen BAC7800 7800 425C Dark Gray

D Armcap/Escutchen BAC7923 AIC5.23 Blue Black

SEAT BELTS

To simplify dynamic testing required, B/E offers the following seat belts:

?Amsafe nylon 3,000 lb. belt with standard length on buckle side

?Amsafe 90-degree buckle, P/N 2010-1-511-XXXX, for standard seating

?Optional P/N 2011-1-511-XXXX

?Choice of color within Am-Safe standard range of part numbers noted above.

SEAT CERTIFICATION

?Meets and/or exceeds FAA Amendment 25-64 and JAA Change 25-13 structural. TSO C39b plus FAR 25.562 certification standard, with TSO 127a an option ?The seat will meet AWN 64 at 29-inch pitch as standard, and will meet AWN 64 at 28-inch pitch with changes to the upright angle, where this is a certification requirement ?Seats at escape hatches can meet CAA AWN 79 and any applicable airframe manufacturer requirements

?Bottom cushion: flotation devices with certification to TSO-C72c

Commercial Aircraft Products Group January, 2003 13

ADDITIONAL OPTIONAL FEATURES

4 WAY ADJUSTABLE HEADREST

The 4-way adjustable headrest moves vertically, and ears move forward

Headrest Benefits

? Can remove dress covers

without removing headrest ? Quick-release headrest with

pre-set non-adjustable friction

SINGLE POSITION REAR MOUNTED FOOTBAR

?

Single position footbar fitted with a unique clamp on mechanism, the footbar is mounted

without drilling the beams and fold flat against the seat when not in use

? Aluminum extrusion with ridges ? Color options A or B

Commercial Aircraft Products Group January, 2003 14

CUPHOLDER

? The cupholder is an optional passenger convenience item, mounted to the seat back, just

above the rear meal tray. It provides a convenient storage for drinks without deploying the meal tray or when the meal tray is in use as a work surface

? It is neatly presented with a flush fitting lid in the closed position

? The cupholder is deployed by pulling down the lid. The lid forms the base to support drinks

and exposes a flip-up ring that prevents the cup from moving during turbulence ? The assembly is color coordinated with seat T&F

COATHOOK

? Side mounted spring loaded

ASHTRAY

? Drawer style mounted under arm ?

Allows for easy addition or removal

? 2/triple, 1/double

? Top mounted jewel box style for in arm tray seats

Commercial Aircraft Products Group January, 2003 15

PCU INSTALLATION

? Pre-certified for top or side mounted PCU’s ? Non handed installation improves

maintainability

? Pre-certified systems:

MAS top mounted with remote jack

RD-AX6733-XX

RJU: RD-AX6421-XX

MAS side mounted with integral jack

RD-AX6739-XX (LH) RD-AX6740-XX (RH)

Rockwell top mounted with remote jack

700-2327-00

RJU: 700-2205-002

Rockwell side mounted with integral jack

700-2326-003 (LH) 700-2326-004 (RH)

PC POWER/USB

? Allows for convenient passenger access to

power laptops computers and similar devices as well as simple connections to communications

? Located under seat bottom cushion

? 2 units per triple and 1 unit per double seat

assembly

? Pre-certified Systems:

KID 110V

General Dynamics 110V