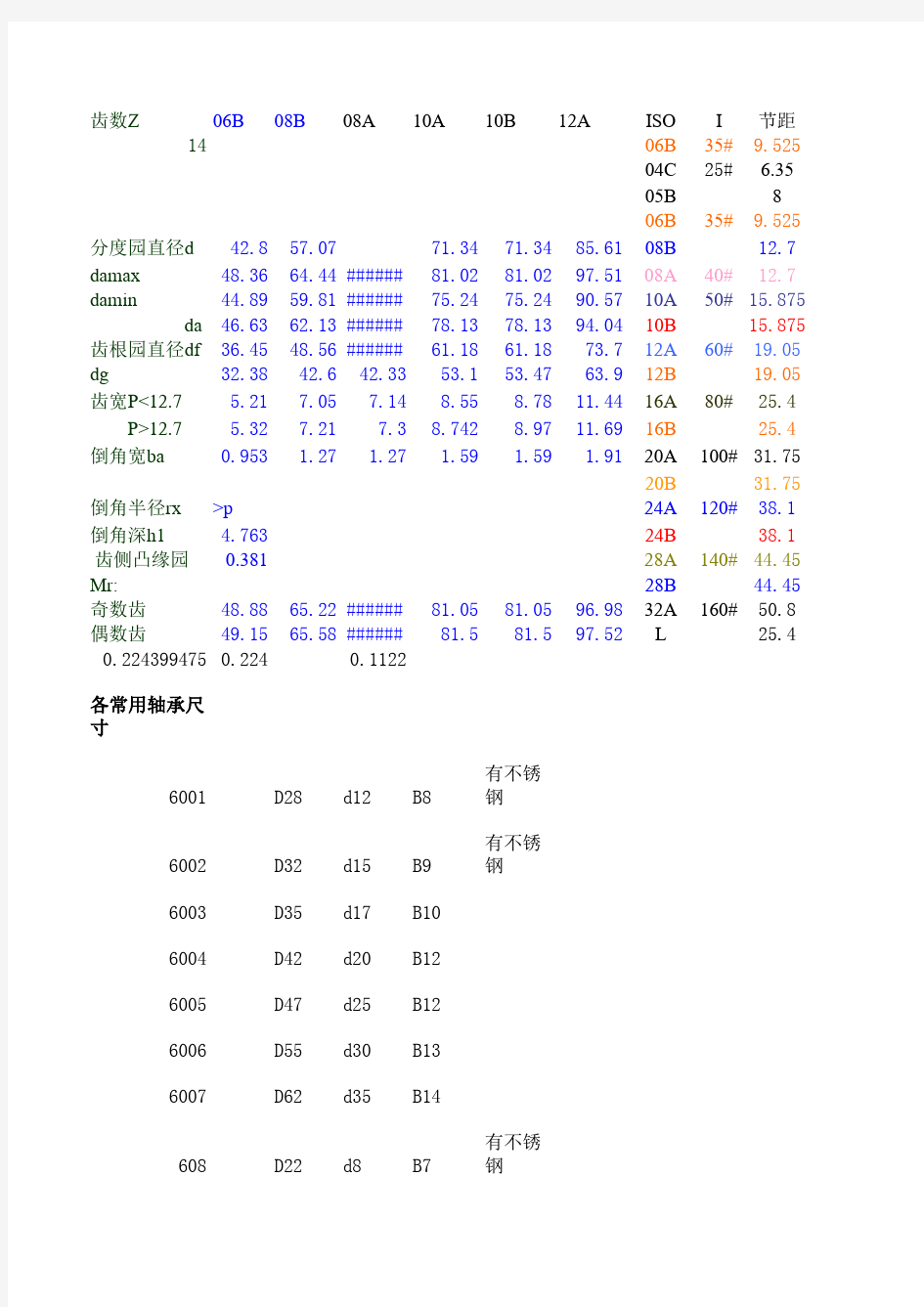

链轮计算公式

齿数Z06B08B08A10A10B12A ISO ANSI节距1406B35#9.525

04C25# 6.35

05B8

06B35#9.525分度园直径d42.857.0771.3471.3485.6108B12.7齿顶园直径damax48.3664.44######81.0281.0297.5108A40#12.7 damin44.8959.81######75.2475.2490.5710A50#15.875 da46.6362.13######78.1378.1394.0410B15.875齿根园直径df36.4548.56######61.1861.1873.712A60#19.05齿侧凸缘直径dg32.3842.642.3353.153.4763.912B19.05齿宽P<12.7 5.217.057.148.558.7811.4416A80#25.4 P>12.7 5.327.217.38.7428.9711.6916B25.4倒角宽ba0.953 1.27 1.27 1.59 1.59 1.9120A100#31.75

20B31.75倒角半径rx>p24A120#38.1倒角深h1 4.76324B38.1齿侧凸缘园角半径

0.38128A140#44.45量柱测量距Mr:28B44.45奇数齿48.8865.22######81.0581.0596.9832A160#50.8偶数齿49.1565.58######81.581.597.52C208BL25.4 0.2243994750.2240.1122

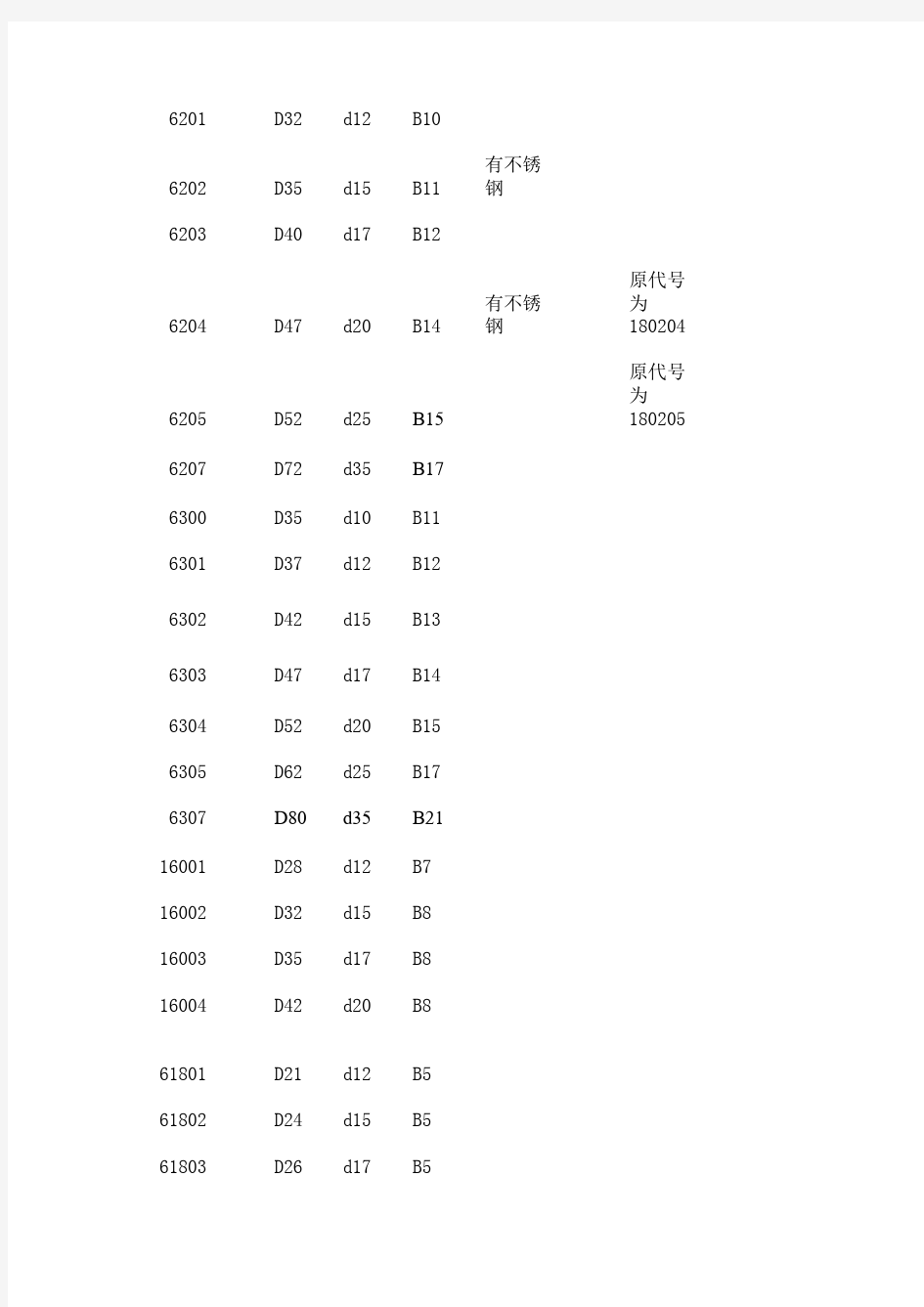

各常用轴承尺寸

6001D28d12B8有不锈钢

6002D32d15B9有不锈钢

6003D35d17B10

6004D42d20B12

6005D47d25B12

6006D55d30B13

6007D62d35B14

608D22d8B7有不锈钢

6201D32d12B10

6202D35d15B11有不锈钢

6204D47d20B14有不锈钢原代号为180204 6205D52d25B15原代号为180205 6207D72d35B17

6300D35d10B11

6301D37d12B12

6302D42d15B13

6303D47d17B14

6304D52d20B15

6305D62d25B17

6307D80d35B21

16001D28d12B7

16002D32d15B8

16003D35d17B8

16004D42d20B8

61801D21d12B5

61802D24d15B5

61803D26d17B5

61804D32d20B7

61900D22d10B6

61901D24d12B6

61902D28d15B7

61904D37d20B9

61907D55d35B10

200D30d10B9

205D52d25B15

6207LU(日本NTN公司)D72d35B17国产代号为6207-RS

180204D47d20B14新代号为6204-2RS

180205D52d25B15新代号为6205-2RS

NJ308E D90d40B23旧代号为42308E

NJ210E D90d50B20

轴用弹性挡圈槽沟尺寸

轴径φ6槽深φ5.7(公差0~-0.048)槽宽0.7(公差0.14~0)最小配用孔直径φ12.2轴径φ8槽深φ7.6(公差0~-0.06)槽宽0.9(公差0.14~0)最小配用孔直径φ15.2轴径φ10槽深φ9.6(公差0~-0.058)槽宽1.1(公差0.14~0)最小配用孔直径φ17.6轴径φ12槽深φ11.5(公差0~-0.11)槽宽1.1(公差0.14~0)最小配用孔直径φ19.6轴径φ15槽深φ14.3(公差0~-0.11)槽宽1.1(公差0.14~0)最小配用孔直径φ23.2轴径φ17槽深φ16.2(公差0~-0.11)槽宽1.1(公差0.14~0)最小配用孔直径φ25.6轴径φ20槽深φ19(公差0~-0.13)槽宽1.1(公差0.14~0)最小配用孔直径φ29轴径φ25槽深φ23.9(公差0~-0.21)槽宽1.3(公差0.14~0)最小配用孔直径φ35轴径φ30槽深φ28.6(公差0~-0.21)槽宽1.3(公差0.14~0)最小配用孔直径φ42轴径φ35槽深φ33(公差0~-0.25)槽宽1.7(公差0.14~0)

轴径φ40槽深φ37.5(公差0~-0.25)槽宽1.7(公差0.14~0)最小配用孔直径φ53

轴径φ70槽深φ67(公差0~-0.30)槽宽2.7(公差0.14~0)最小配用孔直径φ81孔用弹性挡圈槽沟尺寸

孔径φ12槽深φ12.5(公差0.11~0)槽宽0.9(公差0.14~0)最大配用轴直径φ4孔径φ15槽深φ15.7(公差0.11~0)槽宽1.1(公差0.14~0)最大配用轴直径φ6孔径φ20槽深φ21(公差0.13~0)槽宽1.1(公差0.14~0)最大配用轴直径φ10孔径φ21槽深φ22(公差0.13~0)槽宽1.1(公差0.14~0)最大配用轴直径φ11孔径φ24槽深φ25.2(公差0.13~0)槽宽1.3(公差0.14~0)最大配用轴直径φ13孔径φ25槽深φ26.2(公差0.21~0)槽宽1.3(公差0.14~0)最大配用轴直径φ14孔径φ28槽深φ29.4(公差0.21~0)槽宽1.3(公差0.14~0)最大配用轴直径φ17孔径φ30槽深φ31.4(公差0.25~0)槽宽1.3(公差0.14~0)最大配用轴直径φ18孔径φ32槽深φ33.7(公差0.25~0)槽宽1.3(公差0.14~0)最大配用轴直径φ20孔径φ35槽深φ37(公差0.25~0)槽宽1.7(公差0.14~0)最大配用轴直径φ23孔径φ36槽深φ38(公差0.25~0)槽宽1.7(公差0.14~0)最大配用轴直径φ24孔径φ37槽深φ39(公差0.25~0)槽宽1.7(公差0.14~0)最大配用轴直径φ25孔径φ40槽深φ42.5(公差0.25~0)槽宽1.7(公差0.14~0)最大配用轴直径φ27孔径φ42槽深φ44.5(公差0.25~0)槽宽1.7(公差0.14~0)最大配用轴直径φ29孔径φ47槽深φ49.5(公差0.30~0)槽宽1.7(公差0.14~0)最大配用轴直径φ32孔径φ52槽深φ55(公差0.30~0)槽宽2.2(公差0.14~0)最大配用轴直径φ38孔径φ55槽深φ58(公差0.30~0)槽宽2.2(公差0.14~0)最大配用轴直径φ40孔径φ62槽深φ65(公差0.30~0)槽宽2.2(公差0.14~0)最大配用轴直径φ45孔径φ68槽深φ71(公差0.30~0)槽宽2.7(公差0.14~0)最大配用轴直径φ50孔径φ72槽深φ75(公差0.30~0)槽宽2.7(公差0.14~0)最大配用轴直径φ55孔径φ80槽深φ83.5(公差0.35~0)槽宽2.7(公差0.14~0)最大配用轴直径φ63

滚子外径内链板高度内链节内宽销轴长度排距止锁端加长量单排每米质量(kg/m)

6.358.26 5.7213.513.92 3.91

3.3 6.02 3.18

57.1138.6 5.64 3.10.18

6.358.26 5.7213.510.24 3.30.4

8.5111.817.751713.92 3.90.7

7.9512.077.8517.814.38 3.90.6 10.1615.099.421.818.11 4.11

10.1614.739.6519.616.59 4.1

11.9118.0812.5726.922.78 4.6 1.5

12.0716.1311.6822.719.46 4.6

15.8824.1315.7533.529.29 5.4 2.6 15.8821.0817.0236.131.88 5.4

19.0530.1818.941.135.76 6.1 3.8 19.0526.4219.5643.236.45 6.1 5.6 22.2336.225.2250.845.44 6.67.5

25.433.425.453.448.36 6.610.1

25.442.2425.2254.948.877.4

27.9437.0830.9965.159.567.4

28.5848.2631.5565.558.557.9

15.8811.87.7516.7 1.5

直径φ12.2

直径φ15.2

直径φ17.6

直径φ19.6

直径φ23.2

直径φ25.6

直径φ29小配用孔直径φ35小配用孔直径φ42

直径φ53

直径φ81

直径φ4大配用轴直径φ6大配用轴直径φ10

直径φ11

直径φ13

直径φ14大配用轴直径φ17大配用轴直径φ18大配用轴直径φ20大配用轴直径φ23大配用轴直径φ24大配用轴直径φ25

直径φ27

直径φ29大配用轴直径φ32

直径φ38

直径φ40

直径φ45大配用轴直径φ50大配用轴直径φ55

直径φ63

16A

114.15 130.02 120.77 125.4 98.27 85.43 14.33 14.6475

2.54

129.31 130.03