仓库管理系统外文文献

International Journal of Computer Applications (0975 – 8887)

Volume 54– No.1, September 2012 Impact of Warehouse Management System

in a Supply Chain

Ramaa.A

R V C E

Dept. of Industrial Engg and Management, RVCE, B’lore.

K.N.Subramanya

R V C E

Dept. of Industrial Engg and

Management, RVCE, B’lore

T.M.Rangaswamy

R V C E

Dept. of Industrial Engg and

Management, RVCE, B’lore.

ABSTRACT

In a supply chain, warehousing function is very critical as it acts as a node in linking the material flows between the supplier and customer. In today’s competitive market environment companies are continuously forced to improve their warehousing operations. Many companies have also customized their value proposition to increase their customer service levels, which has led to changes in the role of warehouses. This paper highlights the findings of the study carried out to evaluate performance levels and enhance productivity of the manual warehouses by developing a WMS framework and cost benefit analysis.

General Terms

Supply chain, Warehouse Management system. Keywords

Warehouse management system, supply chain, cost benefit analysis, value stream mapping.

1.INTRODUCTION

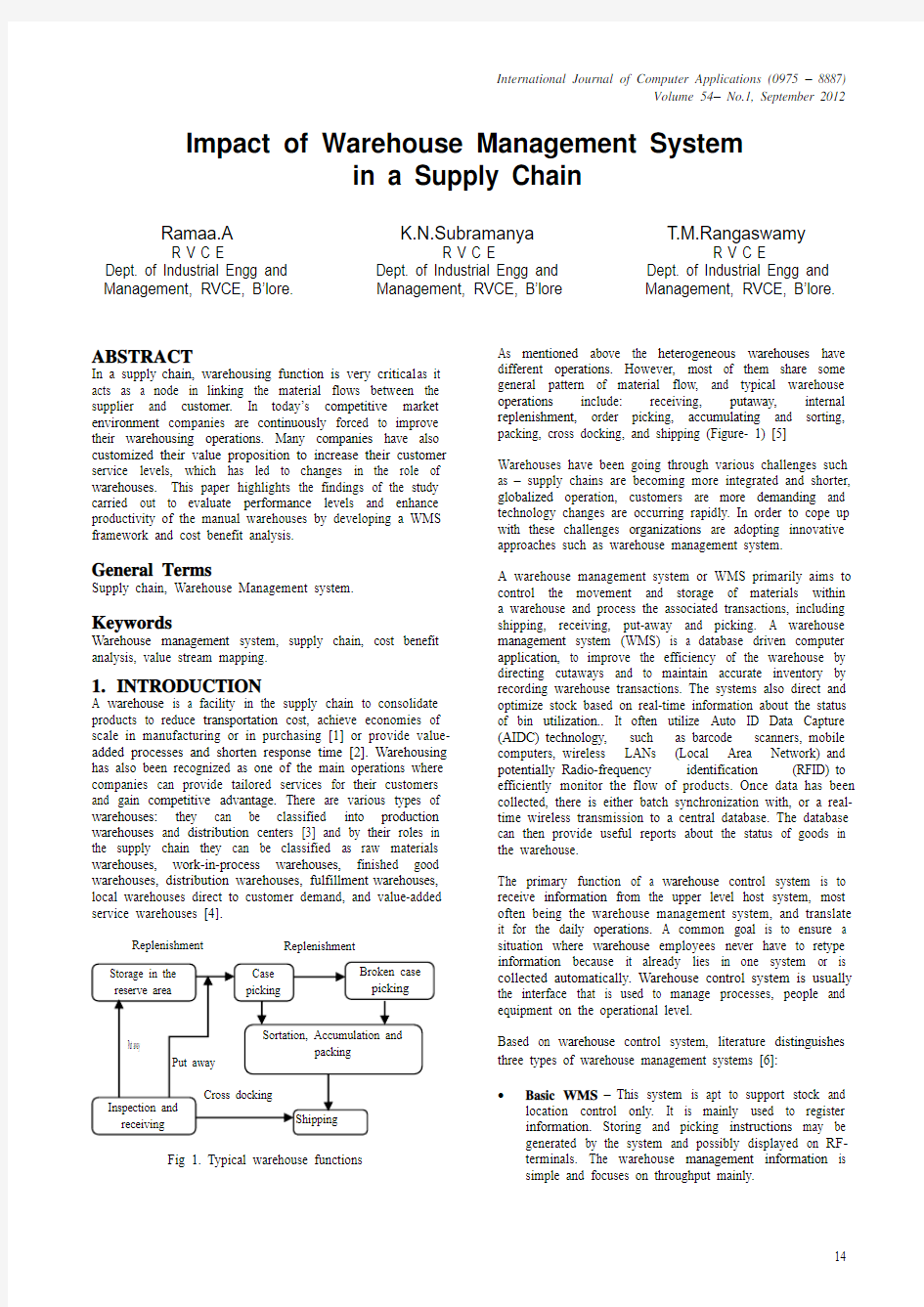

A warehouse is a facility in the supply chain to consolidate products to reduce transportation cost, achieve economies of scale in manufacturing or in purchasing [1] or provide value-added processes and shorten response time [2]. Warehousing has also been recognized as one of the main operations where companies can provide tailored services for their customers and gain competitive advantage. There are various types of warehouses: they can be classified into production warehouses and distribution centers [3] and by their roles in the supply chain they can be classified as raw materials warehouses, work-in-process warehouses, finished good warehouses, distribution warehouses, fulfillment warehouses, local warehouses direct to customer demand, and value-added service warehouses [4].

Fig 1. Typical warehouse functions As mentioned above the heterogeneous warehouses have different operations. However, most of them share some general pattern of material flow, and typical warehouse operations include: receiving, putaway, internal replenishment, order picking, accumulating and sorting, packing, cross docking, and shipping (Figure- 1) [5] Warehouses have been going through various challenges such as – supply chains are becoming more integrated and shorter, globalized operation, customers are more demanding and technology changes are occurring rapidly. In order to cope up with these challenges organizations are adopting innovative approaches such as warehouse management system.

A warehouse management system or WMS primarily aims to control the movement and storage of materials within a warehouse and process the associated transactions, including shipping, receiving, put-away and picking. A warehouse management system (WMS) is a database driven computer application, to improve the efficiency of the warehouse by directing cutaways and to maintain accurate inventory by recording warehouse transactions. The systems also direct and optimize stock based on real-time information about the status of bin utilization.. It often utilize Auto ID Data Capture (AIDC) technology, such as barcode scanners, mobile computers, wireless LANs (Local Area Network) and potentially Radio-frequency identification (RFID) to efficiently monitor the flow of products. Once data has been collected, there is either batch synchronization with, or a real-time wireless transmission to a central database. The database can then provide useful reports about the status of goods in the warehouse.

The primary function of a warehouse control system is to receive information from the upper level host system, most often being the warehouse management system, and translate it for the daily operations. A common goal is to ensure a situation where warehouse employees never have to retype information because it already lies in one system or is collected automatically. Warehouse control system is usually the interface that is used to manage processes, people and equipment on the operational level.

Based on warehouse control system, literature distinguishes three types of warehouse management systems [6]:

Basic WMS–This system is apt to support stock and location control only. It is mainly used to register information. Storing and picking instructions may be generated by the system and possibly displayed on RF-terminals. The warehouse management information is simple and focuses on throughput mainly.

International Journal of Computer Applications (0975 – 8887)

Volume 54– No.1, September 2012

?Advanced WMS– Above the functionality offered by a basic WMS, an advanced WMS is able to plan resources and activities to synchronize the flow of goods in the warehouse. The WMS focuses on throughput, stock and capacity analysis.

?Complex WMS– With a complex WMS the warehouse or group of warehouses can be optimized. Information is available about each product in terms of where it is located (tracking and tracing), what is its destination and why (planning, execution and control). Further, a complex system offers additional functionality like transportation, dock door, and value added logistics planning which help to optimize the warehouse operations as a whole.

Warehouse management systems can be stand alone systems or modules of an ERP (Enterprise Resource Planning) system or supply chain execution suite. The primary purpose of a WMS is to control the movement and storage of materials within a warehouse. The WMS can be deployed as a paper-based, RF/wireless based or combination of both.

2.LITERATURE REVIEW

Warehousing takes up to between 2% and 5% of the cost of sales of a corporation [7] and with today’s highly competitive global business environment organizations are emphasizing on Return on Assets, and hence minimizing warehousing costs has become an important business issue. Many firms are automating their basic warehousing functions to achieve the increase in throughput rates or inventory turns required for their warehousing operations to be cost effective.

It is necessary to allocate warehouse resources efficiently and effectively to enhance the productivity and reduce the operation costs of the warehouse [8]. One vital area determining the efficiency of warehouse is the determination of the proper storage locations for potentially thousands of products in a warehouse. Various factors affecting the storage assignment like order picking method, size and layout of the storage system, material handling system, product characteristics, demand trends, turnover rates and space requirements are been extensively studied. It has been suggested that selecting appropriate storage assignment policies (i.e. random, dedicated or class-based) and routing methods (i.e. transversal, return or combined) with regards to above factors is a possible solution to improve the efficiency [9]. Various decision support models and solution algorithms have also been established to solve warehouse operation planning problems [10].

The use of information systems for warehouse management is studied extensively in literature. Complexity of warehouse management is indicated among others by amount and heterogeneity of handled products, the extent of overlap between them, amount and type of technology as well as characteristics of associated processes. As the complexity increases it becomes necessary to use Warehouse management systems for handling warehouse resources and to monitor warehouse operations. The warehouses with a high amount of processed order lines and amount of stock keeping units will be best supported by customized software. It is difficult to update daily operations of inventory level, locations of forklifts and stock keeping units (SKUs) in real-time by using the bar-code-based or manual-based warehouse management systems [6]. RFID technology is adopted to facilitate the collection and sharing of data in a warehouse. Tests are performed for evaluating the reading performance of both the active and passive RFID apparatus. Implementing RFID technologies requires a thorough cost and benefit analysis of implementation. The costs of RFID implementation include tag reader costs, communication costs and other infrastructure costs. RFID can improve the automatic checkout process at a retail store, so it can reduce inventory costs as a result of more efficient shelf replenishment. RFID technologies can support the redesign of business processes; improve data quality; real-time data collection; synchronization and information sharing between the players of supply chain [10]. RFID implementation can also bring about additional benefits such as reduction losses due to shop lifting and increased use of point of sale applications [11].

Implementation of Warehouse Management System (WMS) will necessarily provide an increase in accuracy, reduction in labor costs if the labor employed to maintain the system is less than the labor saved on the warehouse floor and a greater ability to service the customer by reducing cycle times. WMS will not only lead in inventory reduction but also in greater storage capacity. An increase in accuracy and efficiency of the receiving process might lead to reduction in level of safety stock required. But the consequence of this reduction will hardly be visible to the overall inventory levels. WMS might just not affect the factors (lot sizing, lead times and demand variability) controlling the inventory levels. However WMS is instrumental in more efficient and organized that leads to increased storage capacity [8].

The implementation of WMS for a company demands significant investment and time period (several months) which has to be justified with the benefits obtained after implementation. The justification involves the excellent analysis of the current situation of the warehouse and warehouse operation for a specific period of time tuning the WMS. The firm should be prepared to change the entire process and system storage. Only WMS implementations without changing processes show that does not lead to cost savings or efficiency improvements, it will only reduce errors due to human factors.

3.WAREHOUSE PERFORMANCE MEASUREMENT

Measuring warehouse metrics is critical for providing managers with a clear vision of potential issues and opportunities for improvements. Metrics are tied directly to the business strategy and operation’s success drives the financial results of the organization. If warehouses are going to contribute to be a source for adding value to the supply chain then they need to measure their performance with perfect metrics.

The metrics for measuring performance in a warehouse fall into three main categories which includes order fulfillment, inventory management and warehouse productivity.

The establishment of metrics for auditing warehouse performance and assessment of WMS potential as a basis for investment justification should be the first steps in any WMS project [13]. The identification of proper metrics and opportunities for improvement can be a preliminary justification to determine potential payback [14]. The following metrics supplements the above process.

International Journal of Computer Applications (0975 – 8887)

Volume 54– No.1, September 2012

Table 1 – Performance Metrics of a warehouse

4. CASE STUDY

The study was conducted at India’s biggest retail company, which has developed expertise in Supply Chain Management of consumer product categories such as Fashion, Food and General Merchandise. The company operates from 60 strategically located hubs, servicing more than 2600 retail outlets spread across the length and breadth of India. Its network of facilities and specialized expertise enable it to manage more than 3 million SKUs per year. This requires 30 distinct supply chains to be managed simultaneously, each with their own specific requirements that require customized solutions.

Out of the three warehouses where the study was taken up, one had automated WMS and the other two warehouses were manually run and had a high cycle time of 773 minutes. The retail chain company possessed three more warehouses which were catering to a total of 14 stores across south India. With the company planning to add more stores and establish a centralized warehouse this chain would become inefficient. In order to improve the efficiency a study was taken to analyse the impact of implementation of WMS in these warehouses. The study began with the understanding the current state of operations of the warehouses. Value stream maps were used for the same. Value Stream Mapping is the simple process of directly observing the flow of information and material as they occur and summarizing them visually. A Value Stream involves all of the steps,

both value added and non-value added, required to bring a product or service through the process steps. It is a visual tool used to help see the hidden waste and sources of waste. A Current State Map is drawn to document how things actually operat e (this is the “as-is” process). Then, a Future System Map (how it should be) is developed to design a lean process flow through the elimination of the root causes of waste and through process improvements all leading to an implementation The current value stream map used in the study is as shown in figure 2.

In these warehouses, the goods were received in bulk and put-away in racks. On the receipt of order, articles were picked, packed and dispatched. The process was tedious to carry out as no WMS was available. Though scanners were used for Goods Receipt Note in these warehouses, it was still considered a manual warehouse. Many vendors providing goods for the warehouse were still sending the goods directly to the stores then to the warehouse owing to the infrastructure and capacity constraints. This greatly increases the logistics cost involved.

The current process had a cycle time of 773 minutes of which 537 minutes was non-value added time. A lot of time was wasted as the supplier had to wait about an hour before the unloading can take place. There was no system to schedule time for the arrival of vehicles. Since a flow through process was followed the goods were to be stored on the floor till they were dispatched. Amount of goods that can be stored directly corresponds to the total floor space available. The cubical space was not effectively utilized. Minimal racking was available to store “return to vendor goods”. With limited available infrastructure it was difficult to track and retrieve these items.

The future state value stream map is drawn incorporating WMS, Put –to –light system and racking stacking infrastructure and is shown in figure 3. As shown in the map the cycle time of the process reduces to 236 minutes. The non value added time reduces to 95 minutes. The manpower required is reduced by 40 percent. The process wise improvements are shown in the table 2

Table 2. Performance Improvements at Warehouse after

WMS Implementation

International Journal of Computer Applications (0975 – 8887)

Volume 54– No.1, September 2012

. Fig 2: Current state of the warehouse

Fig 3: Future state of the warehouse

International Journal of Computer Applications (0975 – 8887)

Volume 54– No.1, September 2012

4.1 Performance Improvements

Apart from the tangible benefits listed above there are many intangible benefits of implementing the WMS. Some the performance improving benefits are listed below: ? With WMS, time scheduling of vehicle is possible. This reduces the waiting of the supplier.

? With Advanced Shipment Note enabling the warehouse has prior information about the goods it is about to receive.

? WMS assisted put-away of goods is now possible.

? 100 percent goods traceability. With RF infrastructure in place the goods can be pin pointed to exact their location. ? Algorithm based picking simplifies picking operation. ? Auto updating of information prevents manual data entry and also reduces error rates.

? With many reports that can be generated decision making is assisted.

?

Processing one order requires 19 sheets in a manual system while with WMS the paper consumption per order reduces to 4 sheets.

The table 3 shows a comparison of WMS to Non WMS warehouse in terms of performance metrics adoption.

Table 3 Comparison of WMS / Non-WMS

4.2 Cost Benefit Analysis

The cost- benefit analysis for implementation of WMS in one of the warehouse is done. This was done by estimating the Net Present Value of the savings. The initial investment breakup for implementing WMS is as shown in table 4 Assumptions: ? Implementation period is assumed to be 6 months

?

Capital is borrowed at an interest rate of 10% for

a period of 2 years

? Transportation prices is assumed to increase by 10% once in the time horizon

? Cost figures may have a deviation of 10-15 percent than that of actual figures

?

Losses incurred during implementation are Rs. 10,00,000

Table 4: Initial Investment Breakup

Expenses

The Initial Investment bears equal distribution during the 6 month phase. The cash flow diagram below shows the expenses.

Fig 4. Cash flow diagram of the expenses

Key Savings

The tangible savings due to implementation of WMS are:

? consolidation of warehouses ?

manpower layoff

The initial savings are due to shut down of warehouses. Currently there are four Factory warehouses one each in Hyderabad, Vijayawada, Vishakhapatnam and Bangalore. A central warehouse in Bangalore can be used to cater to all stores in South India when WMS is implemented. With a central warehouse in place there is no requirement for the other three warehouses which can be closed down. Once the consolidation of all the warehouses is complete the manpower is gradually reduced.

International Journal of Computer Applications (0975 – 8887)

Volume 54– No.1, September 2012 The manpower reduction is assumed to be about 40 percent.

The layoff is done over a period of four months. Once this

process is complete the savings reach its peak. Now there is

slight increase in transportation cost as goods have to be sent

from Bangalore to other states as well. Thus there is a small

dip in savings from the 18th month. This conservative

estimate shows that the payback period is about 36 months

and net savings of Rs. 19,60,000.

The analysis shows benefits exceed the investments. WMS

implementation is a capital investment. It takes some time to

break even. But strategically it offers premium advantage to

the company.

Fig 5. Cumulative Flow Diagram of Savings after WMS

implementation

The net cash flow diagram showing both expenses and

savings is given below.

Fig 6. Net Cash Flow Diagram of a WMS implementation

5.CONCLUSION

As an impact of large product varieties and shortened

customer response times there is a greater emphasis on the

ability of the organizations to establish smooth and efficient

logistics operations. In this regard, warehouses play a vital

role because they function as nodes that direct the flow of

materials within a distribution network. The effects of

organizing warehousing activities can directly be seen in

customer service levels, lead times, and the cost structure of a

company. Hence we can conclude that warehousing

influences the performance of an entire supply chain.

With the boom in organized retailing it becomes necessary for

the players to continuously improve their process. The

retailers have to strive continuously to reduce their costs.

Technology being an enabler improved technology has to be

incorporated into the current processes. Also the processes

have to be designed in such a way that they provide for

incorporating changes.

The value stream mappings of the current systems showed

many bottlenecks that prevail in the system. These bottlenecks

restricted the capacity the warehouses could handle.

Performance and productivity of the warehouse suffered as

the operations were manually carried when it could be more

easily and more effectively done using machines. With WMS

implementation the cycle time of the process also decreases.

The cycle time reduces from 773 minutes to 236 minutes The

cost benefit analysis for WMS implementation in warehouse

shows a savings of Rs. 19,60,000 per month. The study

proves WMS to be an enabling factor for performance and

productivity improvement. The productivity of a WMS

warehouse is way higher than when the operations are

manually performed.

6.ACKNOWLEDGMENTS

We would like to thank our students Rishabh Shah, Sandeep,

Niranjan and Bopanna who have contributed to this research.

Also thank the company for providing us the opportunity to

conduct the study.

7.REFERENCES

[1]Bartholdi III JJ, Hackman ST (2006), Warehouse and

distribution science. https://www.360docs.net/doc/144591353.html,

[2]Gong Y, De Koster MBM (2008), A polling-based

dynamic order picking system for online retailers. IIE

Transactions 40 pages:1070–1082

[3]Ghiani G, Laporte G, Musmanno R (2004), Introduction

to Logistics Systems Planning and Control. John Wiley

& Sons, England

[4]Frazelle E (2001), World-class warehouseing and

material handling. McGraw-Hill, New York

[5]Tompkins JA, White JA, Bozer YA, Frazelle EH,

Tanchoco JMA (2003), Facilities planning. John Wiley

& Sons, NJ

[6]Faber, Nynke; De Koster, Rene B. M. (2002), Linking

warehouse complexity to warehouse planning and

control structure: An exploratory study of the use of

warehouse management information systems.

International Journal of Physical Distribution & Logistics

Management [online]. vol. 32,(5), pages. 381 – 395

[7]Heung Suk Hwang, Gyu Sung Cho (2006), A

performance evaluation model for order picking

warehouse design, Computers & Industrial Engineering

Vol. 51(2), pages: 335-342.

[8]T.C. Poon, K.L. Choy, Harry K.H. Chow , Henry C.W.

Lau, Felix T.S. Chan, K.C. Ho (2009), A RFID case-

based logistics resource management system for

managing order-picking operations in warehouses,

Expert Systems with Applications, Vol. 36(4), pages

8277-8301

International Journal of Computer Applications (0975 – 8887)

Volume 54– No.1, September 2012

[9]Felix T.S. Chan, H.K. Chan (2011), Improving the

productivity of order picking of a manual-pick and multi-level rack distribution warehouse through the implementation of class-based storage, Expert Systems with Applications, Vol. 38(3), pages 2686–2700. [10]Jinxiang Gu, Marc Goetschalckx, Leon F. McGinnis

(2007), Research on warehouse operation: A comprehensive review, European Journal of Operational Research, Vol. 177(1), pages 1–21.

[11]S.F. Wamba, T.R. Coltman, and K. Michael (2008).

RFID-Enabled warehouse optimisation: Lessons from early adopters in the 3PL industry. ICIS Ancillary meeting, Paris, France, pages 1-12. [12]J. Sounderpandian, R. V. Boppana, S. Chalasani, and A.

M. Madni. (2007) Models for cost-benefit analysis of RFID implementations in retail stores. IEEE Systems Journal, Vol(1), pp105-114,.

[13]Chris Caplice and Yossi Sheffi (1995), A review and

evaluation of logistics performance measurement systems, The International journal of Logistics Management, Vol. 6(1), pages 61-74.

[14]John M Hill (2002), Justifying warehouse management

systems, white paper, ESYNC.

企业物流外包外文翻译文献

企业物流外包外文翻译文献 (文档含英文原文和中文翻译) 物流外包——确保一个组织竞争优势的一种手段 摘要 物流方式表明将交付供应链中的独立单位整合成一个统一的系统的目标,完成结果所需的时间和资源的损失降到最小的材料和信息流动的直接管理。 一个最新方法的实施为公司的物流管理提供更多的成效,这个方法就是外包。物流外包带来诸多好处,如:减少库存、减少订单的交货时间、提高运输质

量、扩大生产的灵活性、降低生产成本和加速资金周转等。这保证了较低的生产成本和更好的质量交付,这是一个决定性的竞争优势。物流外包的应用有利于资源的合理配置,这是公司拥有的独特的竞争优势。 因此,物流外包将作为一种手段应用于公司的物流运输中,以确保一个组织的竞争优势。 关键词:外包,物流,供应商 1.简介 竞争优势,与不断增长的全球化和创新,开始逐渐失去其创意和新的竞争优势,在前端的灵活性,订单到交货时间减少,可靠的高质量的交付,和选择的机会。在竞争领域,厂家的能力加入其生产过程和系统的规划与个人消费者的喜好,将是一个的决定性的因素。只有通过建立灵活的生产管理系统,与个别客户订单问题的解决方案才是可能的。企业为什么要搞物流外包?它的紧迫性在哪里?物流外包与传统意义上的外委、外协有何本质区别?我们的企业离物流外包还远吗?这不仅是理论界要回答的问题,更是企业界应认真思考的问题。谈到物流外包必定涉及供应链和第三方的发展,涉及到现代物流的发展方向,更涉及企业的核心竞争力。理论界对这一点的认识显得有些浮躁,而企业对此的认识比较滞后。目前大多数企业守候在自营物流那片天地,真正搞物流外包的不到20%,并且不规范、不系统。尽管现在物流炒得很热,但企业对物流外包重要性的认识依然很浅。调查表明,湖南有82%的企业对现代物流的认识模糊,大多把货物运输或货代等同于现代物流;有54%的企业至今未有发展物流的计划或设想,更没有把重构内部供应链和发展物流外包提上议事日程,看来还需要更多的示范、引导,更多的宣传、培训和更多的市场培育。 首先,它需要的新的或最新的概念,如CFM(以客户为中心的制造),SCM(供应链管理),基于相同的概念作为企业资源规划(ERP),客户关系管理技术,生产管理的实施(客户关系管理)等,也将要求供应处理,物流中介机构的互动为基础的生产和有效的分配同步。 其次,它在微观和宏观层面上是一个必要的优化运输系统。复杂的运输基础设施的发展是基于标准化的商品,货物,运输方式,装卸货物,交货速度,拓宽道路和铁路网络,完善的售后服务维修。 第三,信息交流起着越来越重要的作用。工业企业在信息领域的互动,使信息可以以正确的形式被查阅,在合适的时间,通过正确的当局和真实类型,防止

9个常用的国外英文文献数据库

9个常用的国外英文论文文献数据库 9个论文文献数据库,科研搬砖,阅读涨姿势,论文写作小帮手!先说说什么是数据库:学术科研中说的「数据库」和「文献数据库」,往往是一种的形式,这个的贮存了大量文献数据(比如论文)可以简单的理解为一个网络图书馆。 数据库中的论文往往都是耗费了大量的时间和精力整理出来的,还有很多是需要购买才可以放在互联网上的,再加上维护这个本身就耗费颇多,因此这些数据库通常不是完全免费的,你可以在上面免费查找文献,浏览摘要等简介容,但是如果你要下载文献,就要付钱。 大学因为科研和教学需要,常年要下载大量的论文材料,所以就会和数据库的经营者签订很多协议,例如包年,就是给一定量的钱,然后就可以无限制下载论文。也有按照下载的数量进行计费。那英语作为世界第一学术语言,有哪些数据库是值得大家分享的呢?1、Wiley InterScience(英文文献期刊)Wiley InterScience是John Wiely & Sons公司创建的动态在线容服务,1997年开始在网上开通。通过InterScience,Wiley公司以许可协议形式向用户提供在线访问全文容的服务。Wiley InterScience收录了360多种科学、工程技术、医疗领域及相关专业期刊、30多种大型专业

参考书、13种实验室手册的全文和500多个题目的Wiley 学术图书的全文。网址:onlinelibrary.wiley./其中被SCI 收录的核心期刊近200种。期刊具体学科划分为:Business,Finance & Management (商业、金融和管理)、Chemistry (化学)、Computer Science(计算机科学)、Earth Science (地球科学)、Education (教育学)、Engineering (工程学)、Law(法律)、Life and Medical Sciences (生命科学与医学)、Mathematics and Statistics(数学统计学)、Physics (物理)、Psychology (心理学)。 2. ICPSRICPSR全称为Inter-university Consortium for Political and Social Research,即美国校际社会科学数据共享联盟。成立于1962年,位于美国密西根大学安娜堡分校(University of Michigan- Ann Arbor, 1817-),储存超过17000种调查研究资料,如军队官兵总名册,遗嘱、遗嘱查验与税收纪录,是现在世界上最大的社会科学数据中心,拥有600多个成员机构,包括大学和各种研究中心。网址:https://www.360docs.net/doc/144591353.html,/icpsrweb/landing.jsp其中400多个成员机构在美国,我国的国家人口发展研究战略课题组,大学,大学,科技大学,浸会大学也是成员之一。 3. IEEE 电气电子工程师学会IEEE(Institute of Electrical & Electronics Engineers)是电子信息领域最著名的跨国性学

工程管理中英文对照外文翻译文献

中英文对照外文翻译文献 中英文对照外文翻译 The Internet is Applicated in Real Estate The Real Estate Industry and the World Wide Web: Changing Technology, Changing Location.The Internet, in its Web based graphics version, has captured the imagination of both consumers and businesses. Its convenience, speed, low cost and versatility are being exploited on a daily basis in ever-changing ways. Together with its capacity to transform existing businesses, promote new businesses and facilitate exchange of information and data, its other striking attribute has been the speed with which this new technology has spread throughout the global economy. Keywords:The internet;Real Estate;Applicated The number of computer hosts grew by more than ten-fold between 1995 and early 1999. The number of Web sites increased almost 100-fold, to over two million, between 1995 and 1998.By the year 2000, there will be approximately 400-500 million Internet users in the world, and the total number of Web sites will exceed five million. This new technology has the potential for affecting the real estate industry directly and indirectly. Directly, it may become a tool that allows a real estate business to expand its information and sales network. Indirectly, it may change the location equation where and how firms do business which in turn will affect the role of firms involved in real estate development, investment and transactions. Measuring the Spread of the Web

物流外文文献及翻译

文献出处: Mahpula A、The Research of Regional Logistics Competitiveness [J]、Journal of Transport Geography, 2015, 15(2): 30-34、 原文 The Research of Regional Logistics Competitiveness Mahpula A Abstract At present, the development of logistics is the logistics demand rapid increase, the expanding market capacity, accelerates the construction of logistics infrastructure, third-party logistics fast growth the tendency, the whole logistics industry is developing in the direction of the information, globalization and specialization、At the same time, with the rapid increase of logistics demand, the development of the regional logistics more rapidly、Regional logistics is an important part of regional economy, the existence and development of regional logistics is the premise of existence and development of regional economy, no regional economy there would be no regional logistics、Regional logistics and regional economic development level, is closely related to the scale and the level of the different regional economic shape, size and industry, determines the level of regional logistics, the scale and structure form、Regional economic integration can make the area and regional logistics incline to reasonable, adapt to reasonable layout of industrial structure, to reduce logistics cost, promote the development of regional logistics、On the other hand, the regional economic development is inseparable from the development of regional logistics and regional logistics to provide support and guarantee for the development of regional economy, the development of the regional logistics will drive and promote the further development of regional economy、Therefore, the development of the regional logistics has become to improve the regional investment environment and industry development environment, expanding the scope of the regional influence, the key to enhancing regional competitiveness、 Keywords: Regional logistics; Regional logistics competitiveness; Evaluation index 1 Introduction The rapid development of world economy and the progress of modern science and technology, the logistics industry as an emerging service industry, is developing rapidly in the global scope、Internationally, logistics industry is considered to be the economic development of the artery and basic industry, its development degree

物流规划中英文对照外文翻译文献

物流规划中英文对照外文翻译文献(文档含英文原文和中文翻译)

设施规划 引言 设施规划在过去的十年间已经被赋予了全新的意义。在过去,设施规划一般被认为是一门科学。而在当今竞争激烈的全球市场,设施规划成为了一种策略。政府、教育机构和企业已经不再单独相互竞争,现在这些实体或企业将彼此联合为合作企业、组织协会,并最终合成为供应链,将客户纳入到整个供应链过程以保持竞争力。 这些年来设施规划问题一直是一个热门话题。尽管它已拥有很悠久的历史,但在目前的出版物、会议以及研究中,设施规划仍是最受欢迎的科目之一。设施规划的处理已经从清单式或者菜单式的方法发展到了高度复杂的数学建模。在本文中,我们使用了一个实用的设施规划方法,其利用了实证以及同时包含传统和现代概念的分析方法。值得提及的是,在本文中拥有很广泛的设施规划应用示例。例如,这本书的内容可以适用于一个新医院,一个装配部门,一个已有的仓库,或者一个机场的行李部的规划。无论问题是发生在医院、生产工厂、配送中心、机场、零售商店、学校、银行、还是办公室或者这些设施的任何部分;无论是在一个发达国家的现代化设施还是在一个发展中国家的过时设施中,本文给出的材料在进行规划时都非常有用。重要的是要认识到现代设施规划中将设施当作是一个动态的实体,一个成功的设施规划方案的关键因素是其适应性以及适合全新应用的能力。 设施规划的定义 当今的设施规划必须能够帮助组织实现供应链的优越性。实现供应链的优越性是一个有六个步骤、或者说六个等级的过程。一如既往,这些步骤与优越性、可见性、协同性、综合性、敏捷性等联系在一起。 当一家公司最大化供应链的各个功能(采购-制造-运输-储存-销售),个体部门(如金融、市场营销、销售、采购、信息技术、研发、生产、分配和人力资源等部门)的目标就是要成为公司最好的部门。组织的有效性不是重点,每个组

9个常用的国外英文论文文献数据库

9个常用的国外英文论文文献数据库9个论文文献数据库,科研搬砖,阅读涨姿势,论文写作小帮手!先说说什么是数据库:学术科研中说的「数据库」和「文献数据库」,往往是一种网站的形式,这个网站的贮存了大量文献数据(比如论文)可以简单的理解为一个网络图书馆。 数据库中的论文往往都是耗费了大量的时间和精力整理出 来的,还有很多是需要购买版权才可以放在互联网上的,再加上维护这个网站本身就耗费颇多,因此这些数据库通常不是完全免费的,你可以在上面免费查找文献,浏览摘要等简介内容,但是如果你要下载文献,就要付钱。 大学因为科研和教学需要,常年要下载大量的论文材料,所以就会和数据库的经营者签订很多协议,例如包年,就是给一定量的钱,然后就可以无限制下载论文。也有按照下载的数量进行计费。那英语作为世界第一学术语言,有哪些数据库是值得大家分享的呢?1、Wiley InterScience(英文文献期刊)Wiley InterScience是John Wiely & Sons公司创建的动态在线内容服务,1997年开始在网上开通。通过InterScience,Wiley 学术期刊集成全文数据库(Academic Search Premier,简称ASP):包括有关生物科学、工商经济、资讯科技、通讯传播、工程、教育、艺术、文学、医药学等领域的七千多种期刊,

其中近四千种全文刊。 学术研究图书馆(Academic Research Library,简称ARL)综合参考及人文社会科学期刊论文数据库,涉及社会科学、人文科学、商业与经济、教育、历史、传播学、法律、军事、文化、科学、医学、艺术、心理学、宗教与神学、社会学等学科,收录2,300多种期刊和报纸,其中全文刊占三分之二,有图像。可检索1971年来的文摘和1986年来的全文。商业信息数据库(ABI/INFORM)ABI即为Abstracts of Business Information的缩写,世界着名商业及经济管理期刊论文数据库,收录有关财会、银行、商业、计算机、经济、能源、工程、环境、金融、国际贸易、保险、法律、管理、市场、税收、电信等主题的1,500多种商业期刊,涉及这些行业的市场、企业文化、企业案例分析、公司新闻和分析、国际贸易与投资、经济状况和预测等方面,其中全文刊超过50%,其余为文摘,有图像。 医学电子期刊全文数据库(ProQuest Medical Library)该数据库收录有220种全文期刊,文献全文以PDF格式或文本加图像格式存储;收录范围包括所有保健专业的期刊,有护理学、儿科学、神经学、药理学、心脏病学、物理治疗及其它方面。 6. BlackwellBlackwell出版公司是世界上最大的期刊出版商之一(总部设在英国伦敦的牛津),以出版国际性期刊为主,

第三方物流外文文献(原文与翻译)

我国第三方物流中存在的问题、原因及战略选择 熊卫 【摘要】我国物流业发展刚刚起步,第三方物流的理论和实践等方面都比较薄弱。本文指出我国第三方物流存在的问题在于国内外第三方物流企业差距、物流效率不高、缺乏系统性管理、物流平台构筑滞后、物流管理观念落后等。分析了产生上述问题的原因,并提出了精益物流、中小型第三方物流企业价值链联盟、大型第三方物流企业虚拟化战略等三种可供选择的第三方物流企业发展战略。 【关键词】第三方物流;精益物流战略;价值链联盟;虚拟化战略 1引言 长期以来,我国国内企业对采购、运输、仓储、代理、包装、加工、配送等环节控制能力不强,在“采购黑洞”、“物流陷井”中造成的损失浪费难以计算。因此,对第三方物流的研究,对于促进我国经济整体效益的提高有着非常重要的理论和实践意义。本文试图对我国策三方物流存在的问题及原因进行分析探讨,并提出第三方物流几种可行的战略选择。 2我国第三方物流业存在的主要问题 (一)我国策三方物流企业与国外第三方物流企业的差距较大,具体表现在以下几个方面: 1、规模经济及资本差距明显。由于国外的大型第三方物流企业从全球经营的战略出发,其规模和资本优势是毫无疑问的,尤其初创时期的我国策三方物流业,本身的规模就很小,国外巨头雄厚的资本令国内企业相形见绌。 2、我国策三方物流业企业提供的物流服务水准及质量控制远不如国外同行。当国内一些企业还在把物流理解成“卡车加仓库“的时候,国外的物流企业早已完成了一系列标准化的改造。同时,国外的物流组织能力非常强大,例如德国一家第三方物流公司,公司各方面的物流专家遍布欧洲各地。如果有客户的货物需要经达不同的国家,那么欧洲各地的这些专家就在网上设计出一个最佳的物流解决方案。这种提供解决方案的能力就是这第三方物流公司的核心能力,而不像国内公司号称拥有多少条船,多少辆车。 3、我国加入WTO后物流产业的门槛降低。在物流服务业方面:我国承诺所有的服务行业,在经过合理过渡期后,取消大部分外国股权限制,不限制外国服务供应商进入

第三方物流问题战略外文翻译文献

第三方物流问题战略外文翻译文献 (文档含英文原文和中文翻译) 我国第三方物流中存在的问题、原因及战略选择 【摘要】我国物流业发展刚刚起步,第三方物流的理论和实践等方面都比较薄弱。本文指出我国第三方物流存在的问题在于国内外第三方物流企业差距、物流效率不高、缺乏系统性管理、物流平台构筑滞后、物流管理观念落后等。分析了产生上述问题的原因,并提出了精益物流、中小型第三方物流企业价值链联盟、大型第三方物流企业虚拟化战等三种可供选择的第三方物流企业发展战略。【关键词】第三方物流;精益物流战略;价值链联盟;虚拟化战略 1引言 长期以来,我国国内企业对采购、运输、仓储、代理、包装、加工、配送等

环节控制能力不强,在“采购黑洞”、“物流陷井”中造成的损失浪费难以计算。因此,对第三方物流的研究,对于促进我国经济整体效益的提高有着非常重要的理论和实践意义。本文试图对我国策三方物流存在的问题及原因进行分析探讨,并提出第三方物流几种可行的战略选择。 2 我国第三方物流业存在的主要问题 (一)我国策三方物流企业与国外第三方物流企业的差距较大,具体表现在以下几个方面: 1、规模经济及资本差距明显。由于国外的大型第三方物流企业从全球经营的战略出发,其规模和资本优势是毫无疑问的,尤其初创时期的我国策三方物流业,本身的规模就很小,国外巨头雄厚的资本令国内企业相形见绌。 2、我国策三方物流业企业提供的物流服务水准及质量控制远不如国外同行。当国内一些企业还在把物流理解成“卡车加仓库“的时候,国外的物流企业早已完成了一系列标准化的改造。同时,国外的物流组织能力非常强大,例如德国一家第三方物流公司,公司各方面的物流专家遍布欧洲各地。如果有客户的货物需要经达不同的国家,那么欧洲各地的这些专家就在网上设计出一个最佳的物流解决方案。这种提供解决方案的能力就是这第三方物流公司的核心能力,而不像国内公司号称拥有多少条船,多少辆车。 3、我国加入 WTO 后物流产业的门槛降低。在物流服务业方面:我国承诺所有的服务行业,在经过合理过渡期后,取消大部分外国股权限制,不限制外国服务供应商进入目前的市场,不限制所有服务行业的现有市场准入和活动。同时在辅助分销的服务方面也作出了类似的承诺。这些方面的限制将在以后 3—4 年内逐步取消,在此期间,国外的服务供应商可以建立百分之百的全资拥有的分支机构或经营机构,国内物流服务业将直面国际竞争。 (二)资源浪费严重,第三方物流效率不高。 从微观上看,由于受计划经济体制的影响,长期以来许多企业,尤其是国有企业走的是“大而全”、“小而全”的路子,它们拥有自己的仓库、车队、甚至远洋船队,造成物流过程的大量浪费,具体表现为仓库的闲置,物流业经营分散,组织化程度低,横向联合薄弱。而能够提供一体化、现代化、专业化、准时化、高效服务的第三方物流企业则很少。从宏观上看第三方物流未能跟上经

SQL数据库英文文献及翻译

SQL数据库英文文献及翻译 The fact that you are reading a book on SQL indicates that you, somehow, need to interact with databases. SQL is a language used to do just this, so before looking at SQL itself, it is important that you understand some basic concepts about databases and database technologies. Whether you are aware of it or not, you use databases all the time. Each time you select a name from your email address book, you are using a database. If you conduct a search on an Internet search site, you are using a database. When you log into your network at work, you are validating your name and password against a database. Even when you use your ATM card at a cash machine, you are using databases for PIN number verification and balance checking. But even though we all use databases all the time, there remains much confusion over what exactly a database is. This is especially true because different people use the same database terms to mean different things. Therefore, a good place to start our study is with a list and explanation of the most important database terms.Reviewing Basic Concepts What follows is a very brief overview of some basic database concepts. It is intended to either jolt your memory if you already have some database experience, or to provide you with the absolute basics, if you are new to databases. Understanding databases is an important part of mastering SQL, and you might want to find a good book on database fundamentals to brush up on the subject if needed. What Is a Database? The term database is used in many organized fashion. The simplest way to think of it is to imagine a database as a filing cabinet. The filing cabinet is simply a physical location to store data, regardless of what that data is or how it is organized Database A container (usually a file or set of files) to store organized data. Misuse Causes Confusion People often use the term database to refer to the database software they are running. This is incorrect, and it is a source of much confusion. Database software is actually called the Database Management System (or DBMS). The database is the container created and manipulated via the DBMS. A database might be a file stored on a hard drive, but it might not. And for the most part this is not even significant as you never access a database directly anyway; you always use the DBMS and it accesses the database for you. Tables When you store information in your filing cabinet you don't just toss it in a drawer. Rather, you create files within the filing cabinet, and then you file related data in specific files. In the database world, that file is called a table. A table is a structured file that can store data of a specific type. A table might contain a list of customers, a product catalog, or any other list of information. Table A structured list of data of a specific type. The key here is that the data stored in the table is one type of data or one list. You would never store a list of customers and a list of orders in the same database table. Doing so would make subsequent retrieval and access difficult. Rather, you'd create two tables, one for each list. Every table in a database has a name that identifies it. That name is always unique—meaning no other table in that database can have the same name. Table Names What makes a table name unique is actually a combination of several things including the database name and table name. Some databases also use the name of the database owner as part of the unique name. This means that while you cannot use the same table name

物流管理第三方物流毕业论文中英文资料外文翻译文献

中英文资料外文翻译文献 我国第三方物流中存在的问题、原因及战略选择 熊卫 【摘要】我国物流业发展刚刚起步,第三方物流的理论和实践等方面都比较薄弱。本文指出我国第三方物流存在的问题在于国内外第三方物流企业差距、物流效率不高、缺乏系统性管理、物流平台构筑滞后、物流管理观念落后等。分析了产生上述问题的原因,并提出了精益物流、中小型第三方物流企业价值链联盟、大型第三方物流企业虚拟化战略等三种可供选择的第三方物流企业发展战略。 【关键词】第三方物流;精益物流战略;价值链联盟;虚拟化战略 1引言 长期以来,我国国内企业对采购、运输、仓储、代理、包装、加工、配送等环节控制能力不强,在“采购黑洞”、“物流陷井”中造成的损失浪费难以计算。因此,对第三方物流的研究,对于促进我国经济整体效益的提高有着非常重要的理论和实践意义。本文试图对我国策三方物流存在的问题及原因进行分析探讨,并提出第三方物流几种可行的战略选择。 2我国第三方物流业存在的主要问题 (一)我国策三方物流企业与国外第三方物流企业的差距较大,具体表现在以下几个方面: 1、规模经济及资本差距明显。由于国外的大型第三方物流企业从全球经营的战略出发,其规模和资本优势是毫无疑问的,尤其初创时期的我国策三方物流业,本身的规模就很小,国外巨头雄厚的资本令国内企业相形见绌。 2、我国策三方物流业企业提供的物流服务水准及质量控制远不如国外同行。当国内一些企业还在把物流理解成“卡车加仓库“的时候,国外的物流企业早已完成了一系列标准化的改造。同时,国外的物流组织能力非常强大,例如德国一家第三方物流公司,公司各方面的物流专家遍布欧洲各地。如果有客户的货物需要经达不同的国家,那么欧洲各地的这些专家就在网上设计出一个最佳的物流解决方案。这种提供解决方案的能力

工程管理专业研究建设项目的工程造价大学毕业论文外文文献翻译及原文

毕业设计(论文) 外文文献翻译 文献、资料中文题目:研究建设项目的工程造价 文献、资料英文题目: 文献、资料来源: 文献、资料发表(出版)日期: 院(部): 专业:工程管理 班级: 姓名: 学号: 指导教师: 翻译日期: 2017.02.14

科技文献翻译 题目:研究建设项目的工程造价 研究建设项目的工程造价 摘要 在工程建设中,中国是拥有世界最大投资金额和具有最多建设项目的国家。它是一 项在建设项目管理上可以为广泛的工程管理人员进行有效的工程造价管理,并合理 确定和保证施工质量和工期的条件控制施工成本的重要课题。 在失去了中国建筑的投资和技术经济工程,分离的控制现状的基础上,通过建设成 本控制的基本理论为指导,探讨控制方法和施工成本的应用,阐述了存在的问题在 施工成本控制和对决心和施工成本的控制这些问题的影响,提出了建设成本控制应 体现在施工前期,整个施工过程中的成本控制,然后介绍了一些程序和应用价值工 程造价的方法在控制建设项目的所有阶段。 关键词:建设成本,成本控制,项目 1.研究的意义 在中国,现有的工程造价管理体系是20世纪50年代制定的,并在1980s.Traditional 施工成本管理方法改进是根据国家统一的配额,从原苏联引进的一种方法。它的特 点是建设成本的计划经济的管理方法,这决定了它无法适应当前市场经济的要求。 在中国传统建筑成本管理方法主要包括两个方面,即建设成本和施工成本控制方法 的测定方法。工程造价的确定传统的主要做法生搬硬套国家或地方统一的配额数量 来确定一个建设项目的成本。虽然这种方法已经历了20多年的改革,到现在为止,计划经济管理模式的影响仍然有已经存在在许多地区。我们传统的工程造价控制的

物流英文文献翻译英语论文

物流英文文献翻译英语论文 物流英文文献翻译及物流论文参考文献[1] 崔介何.物流学概论[M].北京〆北京大学出版社,2004年〆1-2. [2] 叶怀珍.现代物流学[M].北京〆高等教育出版社,2003〆49-56. [3] 许建帄.对培育广州物流市场的再思考[EB/OL]. [4] 深圳新闻网.“入仓即予退税”新政策助推物流发展[EB/OL]. [5] 吴德群.“入仓退税”适应国际采购商全球配送[N].深圳特区报,2006-01-23. [6] 广东禾田物流有限公司网.广东禾田物流有限公司简介[EB/OL]. [7] 快递公司网.广州物流市场[8] 来源.十一月回顾〆物流篇(三)[EB/OL]. [9] 徐晓阳,饶欠林. 深圳盐田港出口监管仓的现状与发[DB/OL].,2002. [10] 中华人民共和国国务院公报,中华人民共和国海关总署令——中华人民共和国海关对出口监管仓库及所存货物的管理办法[DB/OL]. [11] 公共商务信息导报,海关对出口监管仓库及所存货物的管理办法[DB/OL]. 2005-12-06. [12] Wei Liu,Wenshun Li,Wendy Huang.Analysis of the dynamic relation between logistics development and GDP growth in China[DB/OL]. http:// 毕业论文[13] Deng Mingran,Wang Hua. A government guarantee system of logistics development in China[DB/OL].,2006. [14] Goh,M,Ling,C. Logistics development in China[DB/OL]. ,2003. [15] Chen Siyun, The developing trend and countermeasures of Yantian port logistics[DB/OL]. 研究物流业及中国物流技术摘要为了进一步推进同中国发展物流业,作者基于中国物流业的现状,肯定其在中国工业发展过程中所取得的成就。通过学习物流产业的各方面,包括了解物流产业,标准术语,物流技术和管理知识,剖析主要的问题存在于中国当前的物流业,并提出合理化建议。关键词〆物流,发展,问题,方法1 前言现代物流工业是现代最受欢迎的行业。自从20世纪80年代早期物流概念从海外引入,物流业得到了迅猛的发展。目前,我国已有相当多的物流园区及中心, 发展了一系列现代物流技术和取得了一大批自主知识产权的创新成果。研制开发了具有自主知识产权的集成化物流管理系统(LOG++/SMCS),成功实现了与著名ERP系统(SAP R/3)的实时连接。改变了我国传统物流系统性能单一、集成度低的现状,标志着我国物流软件系统与国际现代物流管理系统的接轨。研究开发了新型结构快速堆垛机。其运行速度0~150m/min,起升速度0~40m/min,货叉速度0~20/40m/min々水帄方向采用激光测距技术,测距误差±1mm(500m以内),定位精度达到±3mm々垂直方向采用旋转编码器加齿形带技术,定位精度达到±3mm。进行了结构研究和动态性能分析,增加了设备的稳定性和可靠性々成功地将激光认址和旋转编码器、齿形带测距等新型检测技术整合到一起,运用于认址,从根本上改变了传统的认址方式,并采用冗余控制技术和故障自诊断技术等大大提高系统的效率与可靠性々新型货叉结构、带尺寸检测与条形码检测的新型载货台等10多项新技术,促进了物流关键设备的技术进步,大大缩短我国物流关键设备与国际先进水帄的差距。在2003年,国内外首创开发了具有国际先进水帄的推挽式激光导引AGV小车(专利产品)々攻克了路径规划、反射板布置、精确定位等难题,使小车能在卷接包机组内安全、灵活地行走和定位,实现完全自动化运送。2003年设计应用具有国际先进水帄的视觉识别移动式机器人自动辅料搭配系统。红河卷烟厂自动化物流系统和联想电脑公司集成化物流系统的成功开发与应用,填补了多项国内空白,创新出一批具有国际先进水帄的系统和设备,大大缩小我国物流系统关键设备及主要技术指标与先进国家的差距,在行业中产生了广泛影响。经过多年研究和探索,太原钢运储存公司通过与科研机构的合作,成功地发展出由电脑计划设计的自动化的仓储打包系统,同样也是处于世界领先水帄。由于受到政府的大力指出与重视,中国的现代物流业正以前所未有的速度发展。但是,还是值得指出的是,中国的物流业整体还是处在初级阶段。中国在2000 年的国内生产总值是8.94×1000亿元,其中流通领域总占比重仅仅百分之8.1 这比发达国家如英美日要低许多。2000年,沃尔玛,世界零售巨头的销售总额达193.3亿美元,占中国年零售业总额的46%。从上面可以看出,沃尔玛的销售额以每年20—30亿美元的速度增长。在国内的零售业领先的上海联合利华仅仅XX 人民

工程管理专业外文翻译--项目成本控制剖析(可编辑修改word版)

项目成本控制 1施工企业成本控制原则 施工企业的成本控制是以施工项目成本控制为中心,施工项目成本控制原则是企业成本管理的基础和核心,施工企业项目经理部在对项目施工过程进行成本控制时,必须遵循以下基本原则。 1.1成本最低化原则。施工项目成本控制的根本目的,在于通过成本管理的各种手段,促进不断降低施工项目成本,以达到可能实现最低的目标成本的要求。在实行成本最低化原则时,应注意降低成本的可能性和合理的成本最低化。一方面挖掘各种降低成本的能力,使可能性变为现实;另一方面要从实际出发,制定通过主观努力可能达到合理的最低成本水平。 1.2全面成本控制原则。全面成本管理是全企业、全员和全过程的管理,亦称“三全”管理。项目成本的全员控制有一个系统的实质性内容,包括各部门、各单位的责任网络和班组经济核算等等,应防止成本控制人人有责,人人不管。项目成本的全过程控制要求成本控制工作要随着项目施工进展的各个阶段连续进行,既不能疏漏,又不能时紧时松,应使施工项目成本自始至终置于有效的控制之下。 1.3动态控制原则。施工项目是一次性的,成本控制应强调项目的中间控制,即动 态控制。因为施工准备阶段的成本控制只是根据施工组织设计的具体内容确定成本目标、编制成本计划、制订成本控制的方案,为今后的成本控制作好准备。而竣工阶段的成本控制,由于成本盈亏已基本定局,即使发生了偏差,也已来不及纠正。 1.4目标管理原则。目标管理的内容包括:目标的设定和分解,目标的责任到位和执行,检查目标的执行结果,评价目标和修正目标,形成目标管理的计划、实施、检查、处理循环,即 PDCA 循环。 1.5责、权、利相结的原则。在项目施工过程中,项目经理部各部门、各班组在肩负成本控制责任的同时,享有成本控制的权力,同时项目经理要对各部门、各班组在成本控制中的业绩进行定期的检查和考评,实行有奖有罚。只有真正做好责、权、利相结合的成本控制,才能收到预期的效果。