模具检查表(Toolmaker Checklist for shipment)

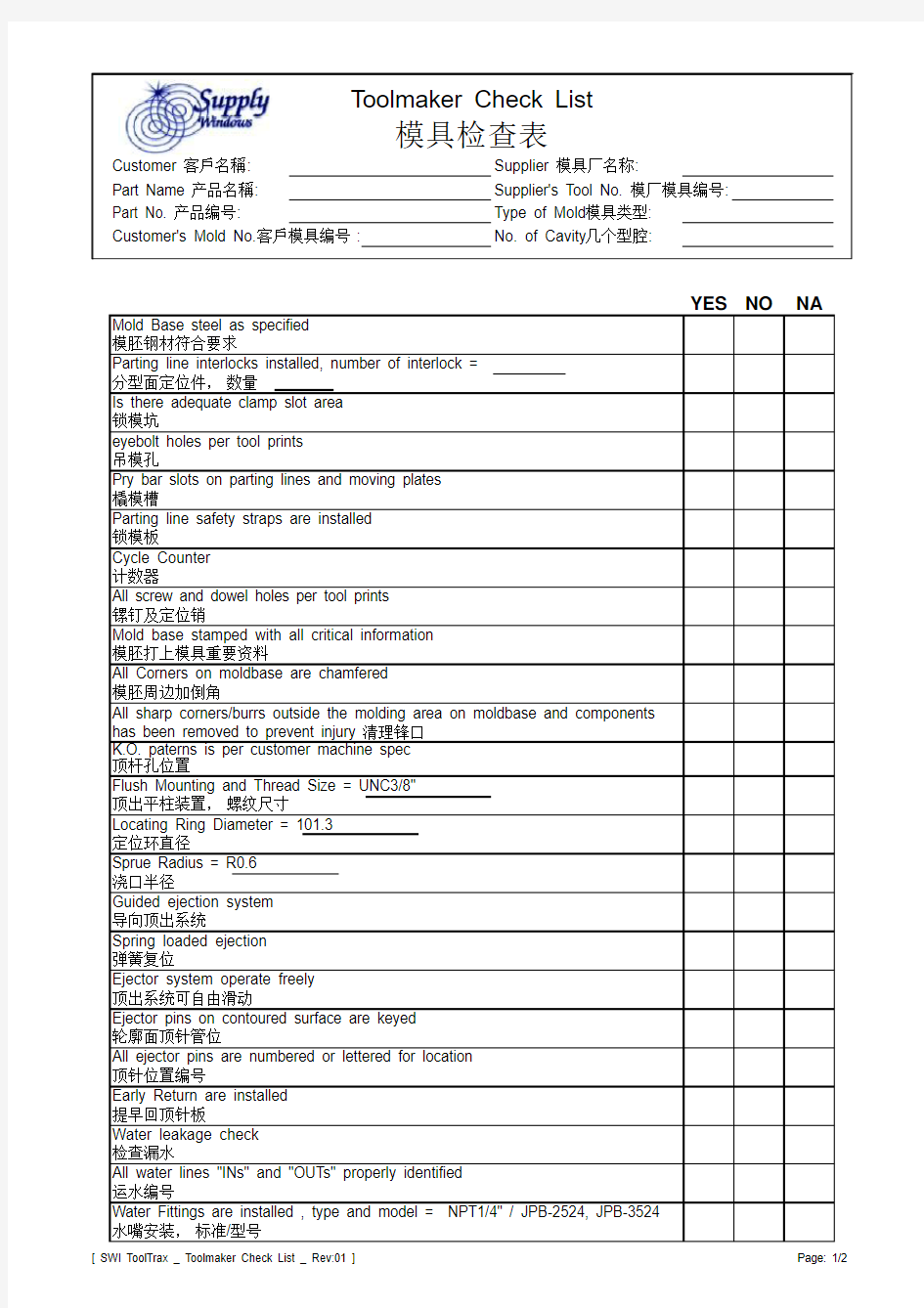

Toolmaker Check List

模具检查表

Customer 客戶名稱:Supplier 模具厂名称:

Part Name 产品名稱:Supplier's Tool No. 模厂模具编号:

Part No. 产品编号:Type of Mold模具类型:

Customer's Mold No.客戶模具编号 :No. of Cavity几个型腔:

YES NO NA Mold Base steel as specified

模胚钢材符合要求

Parting line interlocks installed, number of interlock =

分型面定位件,数量

Is there adequate clamp slot area

锁模坑

eyebolt holes per tool prints

吊模孔

Pry bar slots on parting lines and moving plates

橇模槽

Parting line safety straps are installed

锁模板

Cycle Counter

计数器

All screw and dowel holes per tool prints

镙钉及定位销

Mold base stamped with all critical information

模胚打上模具重要资料

All Corners on moldbase are chamfered

模胚周边加倒角

All sharp corners/burrs outside the molding area on moldbase and components

has been removed to prevent injury 清理锋口

K.O. paterns is per customer machine spec

顶杆孔位置

Flush Mounting and Thread Size = UNC3/8"

顶出平柱装置,螺纹尺寸

Locating Ring Diameter = 101.3

定位环直径

Sprue Radius = R0.6

浇口半径

Guided ejection system

导向顶出系统

Spring loaded ejection

弹簧复位

Ejector system operate freely

顶出系统可自由滑动

Ejector pins on contoured surface are keyed

轮廓面顶针管位

All ejector pins are numbered or lettered for location

顶针位置编号

Early Return are installed

提早回顶针板

Water leakage check

检查漏水

All water lines "INs" and "OUTs" properly identified

运水编号

Water Fittings are installed , type and model = NPT1/4" / JPB-2524, JPB-3524

水嘴安装,标准/型号

Note 备注:

Signoff by Toolmaker 模具厂签认

Check by 检查者:Date: Supervisor 主管:Date: