大豆播种机设计

Design and Test of Variable-rate Fertilization Control Device of Precision Planter for Soybean

WANG Xinzhong

College of Engineering Heilongjiang Bayi Agricultural University

DaQing, China

ndwxz@https://www.360docs.net/doc/416366160.html,

WANG Xi

College of Engineering Heilongjiang Bayi Agricultural University

DaQing, China

ndwangxi@https://www.360docs.net/doc/416366160.html,

Abstract—Utilizing the favorable condition of Heilongjiang reclamation area carrying out the precision agriculture sample, we have developed an automatic control device with the variable rate fertilization. This device adopts industrial control computer

is upper machine and variable rate fertilization controller for single chip computer as the core is lower machine, it is to be used

to the accompaniment of 6-line soybean precision planter, and it uses an electric control CVT(Continuously Variable Transmission) which controls the transmission ratio of discharging fertilizer system of the planter to change the volume of applying fertilizer. We carried out planting tests of the variable-rate fertilization with this control device on the 852 farm

in Heilongjiang province in 2005 and achieved good results.

Keywords-component; precision agriculture; variable rate fertilization; planter; computer;

I.I NTRODUCTION

Precision agriculture develops on the basis of 3s technology, it uses the ability of GPS on precision orientation to measure the output of each unite in field which is often defined in square meter and the surrounding spatial and temporal differentia of plants, analyses the reason of the differentia, and then computes the real volume of materials such as seeds, fertilizer, chemicals and irrigating water according to the needs of each unite plant. All of these efforts helps to optimize outputs, decrease materials cost, gain the maximal economy and social benefit, protect environment and realize the goal of sustainable agriculture.

The agriculture production efficiency is relatively low at present, and there is a common phenomenon of low resource using efficiency and input versus output ratio. The existed agriculture production is mainly implemented by large amount of agriculture materials such as fertilizer plunged into the field. The volume of fertilizer in each unite of plantation area is three times much of world’s level each year. Because too much fertilizers were used blindly, it causes a relatively low fertilizer use efficiency in China. By the expert decision system, variable rate fertilizing machine as the most important part of precision equipment can make variable rate fertilizing digital maps, deliver variable rate data to auto control system fixed in the planter to realize auto control fertilization and promote fertilizer use efficiency according to soil test data, corn yield data, field level elevation maps, variety of crop, local weather situation etc.

II.MATERIALS AND METHODS

A.SYSTEM CONSTRUCTION

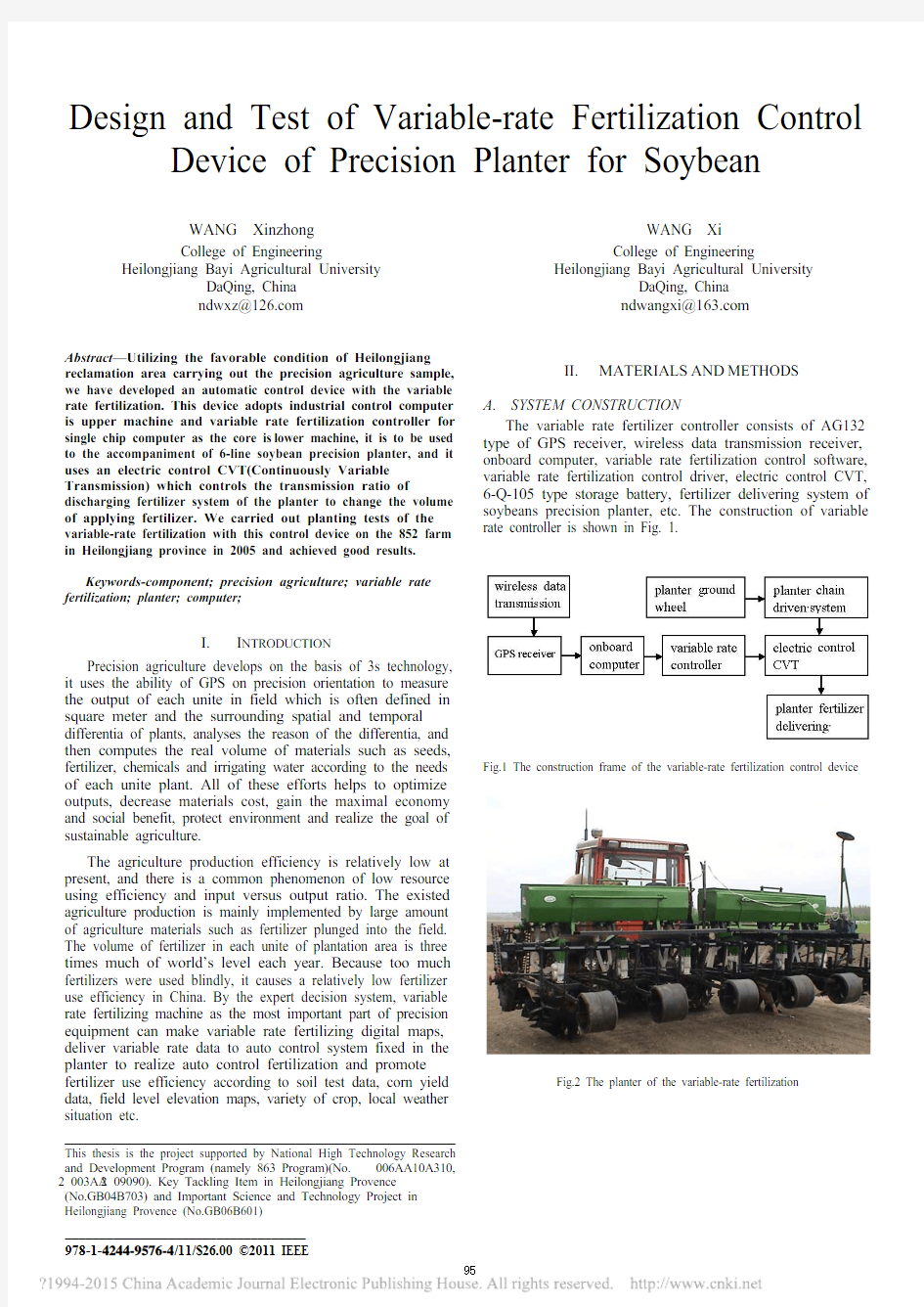

The variable rate fertilizer controller consists of AG132 type of GPS receiver, wireless data transmission receiver, onboard computer, variable rate fertilization control software, variable rate fertilization control driver, electric control CVT, 6-Q-105 type storage battery, fertilizer delivering system of soybeans precision planter, etc. The construction of variable rate controller is shown in Fig. 1.

Fig.1 The construction frame of the variable-rate fertilization control device Fig.2 The planter of the variable-rate fertilization

This thesis is the project supported by National High Technology Research and Development Program (namely 863 Program)(No.006AA10A310, 2003AA209090). Key Tackling Item in Heilongjiang Provence (No.GB04B703) and Important Science and Technology Project in Heilongjiang Provence (No.GB06B601)

___________________________________

B.PRICINPLE

This variable rate fertilizing controller is equipped on the domestic 6-line wind attracted soybean precision planter and is driven by the East Red 802 type tractor to execute planting, it’s position is fixed by a mobile DGPS and data is delivered through RS-232 into a computer fixed on the machine. The computer displays the planter position in the field on the LCD screen, reads variable rate fertilizing data corresponding to the location of the machine in the field from the variable rate fertilizing database, then transmits instruction into the variable rate controller. The variable rate controller controls the electric control CVT to change the transmission ratio and finally realizes the goal of changing fertilizer volume.

C.DGPS POSITIONING SYSTEM

The 852 farm experimental base in Heilongjiang province uses Differential GPS which consists of a ground fixed GPS deviation rectify station and a mobile DGPS receiver. The DGPS position error under submeter which means error distance within 1 meter can meet the needs of agriculture production in contrast that of GPS 15 meter with RTCM deviation rectify way. A mobile DGPS receiver is constructed by a mobile Ag132 type receiver which is used for receive GPS signal and PCC wireless data transmit receiver which is used for receiving the differential GPS signal. The PCC wireless data transmit receiver communicates with Ag132 type GPS receiver through RS-232 serial interface.

D.ONBOARD COMPUTER

The onboard computer is equipped with colorful LCD screen, CPU clock speed of 800MHz, windows 98 operating system, RS-232 interface which makes it convenient to communicate with Ag132 type of GPS receiver, equipped with PCMCIA data slot which makes user insert a CF data card to read and record variable rate fertilizing data.

Fig.3 variable rate fertilization controlling computer

E.VARIABLE RATE CONTROLLING SOFTWARE

Variable rate fertilizing controlling software is written in Visual Basic 6.0. It can control variable rate controller through LCD screen installed on the machine, fulfill the management of the border and corner of each field, number and area of field gridding and variable rate fertilizing data, and create maps of borderline, gridding, and variable rate fertilizing level of each unit. It uses the ability of Visual Basic in reading and writing function, data file is in the form of ACCESS, has the function of inputting planter parameters which is different according to different planter, and all of these enhance the universal and compatible of the software.

Fig.4 main interface of variable rate controlling software The software can display track of the machine by using a mouse to simulate GPS data change, receive DGPS positioning data and lookup corresponding data in the variable rate fertilizing database and then output this data in order to control variable rate fertilizing executing mechanism and feed back the result to the onboard computer.

Fig.5 variable rate controlling software

F.VARIABLE RATE CONTROLLER

Variable rate controller using MCS-51 single chip microcomputer as the core element ,the control circuit consists of AT89C51 single-chip microcomputer, serial interface, reset and anti-interference circuit, power constant voltage circuit, power polarity anti-protecting circuit, motor driving circuit,

voltage reference circuit, instrument amplifier circuit ,A/D change-over circuit and so on. The whole circuit was fixed in enclosure of casting aluminum alloy, and plugs and sockets of aluminum are used. for improving reliability The circuit

principle is shown in Fig. 6.

Fig.6 The circuit principle of variable rate controller

G. ELECTRIC CONTROL CONTINUOUSLY VARIABLE TRANSMISSION

onboard computer gives the orders of variable fertilizing, control the transmission ratio controlling equipment of the step less transmission, and different instruction corresponds to different ratio thus to fulfill the operation of variable rate fertilization. The fertilization instruction totals 100 with the range of 100 to 200. When instruction is 100, variable rate controller regulates the transmission ratio to 32.7, and 200 corresponds the transmission ratio of 17.4. The relationship between data instruction and transmission ratio is classified in table 1. The fitting curve of transmission ratio for an electric CVT is classified as Fig. 7.

Table 1 relationship between data instruction and electric CVT transmission

ratio data instruction 89 108 121134 179 191204Transmission ratio

39.7

30.7

27.3

24.2

18.7

18

17.7

CVT

Fig.8 The electric control CVT

III. CALIBRATION AND ADJUSTMENT TEST OF

FERTILIZER QUANTITY BEFORE SOWING The self-designed variable rate fertilizing equipment is fixed on a 6-line wind attracted soybean precision planter. Work of testing and demarcating fertilizer quantity is done before planting in the aim of finding out the relationship between fertilizer volume and data instruction. First outputs signal 200 which means the maximal volume of fertilizer, increases the height of planter, turns ground wheel of excluding fertilizer manually, receives the fertilizer falling from the single excluding mechanism, and then weighs the fertilizer. The maximal volume of fertilizer is calculated with formula (1).

ha Kg B N D q Q /22670

.01070.014.3348

.01000014.310000max u u u u u u u u

?1?

Where is Q max ümaximal fertilizer volume of planter (kg/ha );

q üfertilizer volume of single row excluder (Kg ), turn ground wheel 10 round, excluding fertilizer volume is 348g for geneva wheel excluder which is double rows.

D ü virtual diameter of ground wheel (m), should take into consideration of tyres subsidence and slippage. Diameter is 0.70m.

N ü number of excluder ground wheel turns with hand. in this experiment the ground wheel turns 10 round.

B ü planter row distance, in this experiment row distance is 0.70m. When the fertilization instruction output by onboard computer is 200, the maximal fertilizer volume is 226 Kg/ha, and when the instruction is 100, the minimal fertilizer volume is 120 Kg/ha. According to calculating from the fitting curve and formula in Fig. 9, the relationship between fertilizer volume and data instruction is classified as Table 2.

Table2. relationship between fertilizer volume and fertilizing data instruction data instruction 100115 128 140 153179200fertilizing volume

120

139 151 169 187

210

226

Fig.9 The fitting curve and formula of fertilizing volume. y1 indicates curve of real fertilizer volume change; y2 indicates fitting curve of fertilizer volume

IV. TEST OF VARIABLE RATE FERTILIZATION AND PLANTING IN THE

FIELD

The test is carried out in 852 farm of Heilongjiang province which is considered as the precision agriculture demonstration base. A sampled test of soil was carried out in the field in April, 2005 before nitrogen layer map, instant phosphorus layer map, instant kalium layer map, organic matter layer map, and PH layer map were created with the AFS software. A variable rate fertilizing description map was created by the AFS software according to the real state of the farm and data from description map was transferred to the self-designed variable rate

fertilizing software at the same time.

Fig.11 Test field of variable rate fertilizing for soybean

V. CONCLUSION

Taking advantage of 852 farm as precision agriculture demonstration base, we designed and developed a variable rate fertilizing controller and installed it on the domestic 6-line wind attracted soybean precision planter and achieved good results through learning and mastering the technology of variable rate fertilizing technology for precision agriculture in foreign countries.

VI. REFERENCES

[1] Wang Xinzhong, Wang Xi, Wang Chun, etal. Application test of

soybean sowing by veriable fertilization seeder in Heilongjiang reclamation areas [J]. Transactions of the CSAE. 2008,24(5):143-146(in Chinese)

Fig.10 Planting operation record figure of variable rate fertilizing for soybean

[2] Liang Chunying, Yi Shujuan, Wang Xi, etal. PID control stratgy of the

veriable rate fertilization control system [J]. Transactions of the Chinese Society for Agricultural Machinery. 2010.41(7):157-162(in Chinese) Heilongjiang Bayi Agricultural University cooperating with Baihua farming machines Factory of 852 farm fixed the self-designed variable rate fertilizing equipment on a 6-line wind attracted soybean precision planter which was refitted at the same time in 2005, and then developed the soybean precision planter with GPS. In the field of science research station on this farm, a variable rate fertilizing and planting experiment of soybean (Fig.11)was carried out by the planter which was driven by the East Red 802 type tractor. Soybean was Hongfeng 11, and fertilizer was compound fertilizer mixed by carbamide, potassium chloride, and diammonium phosphate. variable rate fertilizing and planting area was 60 mu. During variable rate fertilizing and planting operation of 60 mu area, GPS had precise orientation, and software control and record smoothly. The experiment of soybean planting showed: variable rate fertilizing has good results and can meet design requirements, the production of soybean is 3 ton/ ha.

[3] Wang Xi, Wang Xinzhong. Comparing and study on three kinds of

veriable fertilization executing institution [J]. Journal of agriculture mechanization research. 2006.(28)122-124(in Chinese)

[4] Zhuang Weidong, Wang Chun,Wang Xi. Development of the variable

fertilizing control software based on GPS ang soil nutrient map [J]. Journal of agriculture mechanization research. 2010.(32)189-192(in Chinese)

[5] Wang Xinzhong, Wang Xi, Wang Zhimin. Precision agriculture and

variable rate fertilization technology [J]. Journal of August First Land Reclamation University.2002.14(4):25-27(in Chinese)

[6] Wang Xi, Wang Zhimin, Zhuang Weidong. Application of DGPS in soil

sample work in Youyi farm [J]. Journal of August First Land Reclamation University. 2003.15(1):44-46(in Chinese)

[7] Shuhui Zhang, Chengli Ma, Caicong Wu,etal. The application of GIS in

variable rate fertilization for precision agriculture [J]. Journal of agriculture machinery,2003.34(3):92-95(in Chinese)

[8] Shuhui Zhang, Chengli Ma,Chunling Yu. Development and study of

GIS for variable rate fertilization for precision agriculture [J]. Journal of agriculture engineering, 2002.18(2):135-155(in Chinese)

[9] Shuhui Zhang, Chengli Ma, Caicong Wu,etal. The realization of a kind

of variable ratefertilization technology for precision agriculture [J]. Journal of agriculture engineering, 2003.19(1):129-131(in Chinese)

精密播种机设计_毕业设计

摘要 本设计是根据国内外播种机的发展趋势,通用性和适应性不断提高以及本着结构简单操作灵活的原则,而设计的一种能同时完成播种施肥工作的小型多功能精密播种机。该机结构上优点,使之能适应各种田地的播种。小到1-2分大的田块,大到上百亩的田块,不管是平坝、还是浅丘地区;无论是板结的土质,还是疏松的土质都能适应。还可以根据用户的不同需求,配置合适的播种器。通过调节犁铧和种子储存孔的行距,能够轻松地播种小麦、大麦、高粱、大豆、玉米等旱粮作物。本例着重对播种机排种器、排肥器、开沟器、覆土器以及镇压轮等结构进行设计选择。 关键词:精密播种播种机播种施肥

Abstract The design is based on the development trends and seeder, interoperability and adaptability in a constantly improving the structure and operation of flexible simple principles designed to simultaneously accomplish a small planting fertilization work multifunctional sophisticated seeder. This structural advantages so that they can adapt to a variety of fields planting. Applicable to all sizes of land; Whether plains or hills; Whether hard soil or loose soil. We can select the planting machine according to the different needs of users. By regulating platoon of vehicles and plow can easily sow wheat, barley, sorghum, soybean, corn and other crops. This example focuses on the design seeder platoon of vehicles, fertilization devices, trenching vehicles structure. Key words:precision planting seeder planting fertilization

精密播种机设计论文

本科毕业设计(论文)通过答辩 摘要 本设计是根据国内外播种机的发展趋势,通用性和适应性不断提高以及本着结构简单操作灵活的原则,而设计的一种能同时完成播种施肥工作的小型多功能精密播种机。该机结构上优点,使之能适应各种田地的播种。小到1-2分大的田块,大到上百亩的田块,不管是平坝、还是浅丘地区;无论是板结的土质,还是疏松的土质都能适应。还可以根据用户的不同需求,配置合适的播种器。通过调节犁铧和种子储存孔的行距,能够轻松地播种小麦、大麦、高粱、大豆、玉米等旱粮作物。本例着重对播种机排种器、排肥器、开沟器、覆土器以及镇压轮等结构进行设计选择。 关键词:精密播种播种机播种施肥

本科毕业设计(论文)通过答辩 Abstract The design is based on the development trends and seeder, interoperability and adaptability in a constantly improving the structure and operation of flexible simple principles designed to simultaneously accomplish a small planting fertilization work multifunctional sophisticated seeder. This structural advantages so that they can adapt to a variety of fields planting. Applicable to all sizes of land; Whether plains or hills; Whether hard soil or loose soil. We can select the planting machine according to the different needs of users. By regulating platoon of vehicles and plow can easily sow wheat, barley, sorghum, soybean, corn and other crops. This example focuses on the design seeder platoon of vehicles, fertilization devices, trenching vehicles structure. Key words:precision planting seeder planting fertilization

大豆玉米间作播种机设计与传动计算设计

大豆玉米间作播种机设计与传动计算设计

本科生毕业论文(设计)

撰写日期:2012年5月22日 摘要 间作套种能够充分利用空间和边行优势,提高土壤养分,增加作物的抗逆能力,提高土地利用率和单位面积产量。虽然市场上播种机的种类繁多,但缺乏针对大豆玉米间作套种的播种机。为了解决大豆玉米间作套种种植的问题,我们研究和设计了大豆玉米间作播种机。本文设计的大豆玉米间作播种选择了转仓式精密排种器,锄铲式开沟器和带有轮刺直径较大的地轮,播种机整机采用了地轮后置单体式,并进行了地轮轴和中间传动轴设计;在传动设计计算中主要论述了播种机1级、2级传动计算和链轮的设计。大豆玉米间作播种机与传统的播种机相比,新颖之处在于播种机可以同时播种玉米、大豆和为了防止地轮的滑移,采用了4个地轮共同带动中间传动轴,保证播种机精密播种质量。设计中在考虑实用的同时,兼顾经济节约,从而达到结构合理、生产成本低目的。该机一次作业可完成破茬开沟、播种和镇压等工序,作业时开沟均匀,播种作业质量高,可满足黄淮海地区农艺要求。 关键字:大豆;玉米;间作;播种机;传动设计

The Design and Transmission Calculation of Soybean-corn Interplanting Seeding Machine Abstract Intercropping can make full use of space and edge line advantage, improve soil nutrient, increase crop resilience and improve the land utilization rate and yield per unit of area.Although the market of the machine various, but it is lack of soybean-corm interplanting seeding machine.In order to solve the problem of soybean-corn interplant, we researched and designed soybean-corm interplanting seeding machine. In this paper,the machine chose warehouse type precision seed metering device, Shovel type ditcher and the larger diameter land wheel with having thorn,This seeding machine adopts the rear wheel.This paper have designed the axle and the middle transmission. In the chapter of transmission design and calculation, It mainly discussed the first and second line could drive calculation and the design of the https://www.360docs.net/doc/416366160.html,pared with the traditional machine, this machine can sow corn and soybean at the same time. In order to prevent land wheel slippage, we use the style of four land wheel driving transmission shaft. Considering practical at the same time, it take account of economic economy.This planter can perform the roots talk cutting ,opening,sending and packing operations once. Key Words:soybean;corn; interplanting; Seeder; Design of Transmission

最新小型荞麦播种机设计动力、传动、行走及功能转换机构

小型荞麦播种机设计动力、传动、行走及功能转换机构

编号毕业设计(论文) 题目山地用小型荞麦播种机动力、传动、行走及功能转换机构的设计 二级学院机械学院 专业机械设计制造及其自动化 班级 109040205 学生姓名张弛学号 10904020532 指导教师杨岩职称教授 时间2月25日——6月14日

目录 摘要 (Ⅰ) Abstract (Ⅱ) 第1章引言 (1) 第2章播种机概述 (2) 2.1播种机现状 (2) 2.2播种机分类 (4) 2.3播种机发展趋势 (5) 第3章小型荞麦播种机的设计计算 (6) 3.1总体传动设计方案的选择确定 (6) 3.2工作阻力的确定 (8) 3.3工作速度的确定 (8) 3.4驱动功率的确定 (8) 3.5地轮的转速 (9) 3.6传动比的确定 (9) 第4章链传动的设计 (10) 4.1地轮与排种器之间的链传动 (10) 4.2地轮与减速轴之间的链传动 (14) 第5章带传动的设计 (19) 第6章链轮的设计 (22) 6.1链轮的材料选择 (22) 6.2地轮与减速轴之间主动链轮的设计 (22)

6.2地轮与减速轴之间从动链轮的设计 (23) 6.3地轮与种箱之间主动链轮的设计 (24) 6.4地轮与种箱之间从动链轮的设计 (25) 第7章带轮的设计 (25)

7.1带轮的材料选择 (25) 7.2主动带轮的设计 (26) 7.3从动带轮的设计 (26) 第8章链轮的设计 (27) 8.1初步确定轴的最小直径 (27) 8.2减速轴的结构设计 (28) 8.3地轮轴的结构设计 (28) 第9章支架、扶手与轴承等选择设计及功能切换 (29) 9.1支架设计 (29) 9.2把手设计 (30) 9.3轴承选择 (31) 9.4功能切换 (31) 第10章三维建模及装配 (31) 结语 (34) 致谢 (35) 参考文献 (36)

2020年东北大豆种植技术 山东大豆种植

我国大豆品种选育传统上是以脂肪和蛋白质综合指标为育种目标,生产上一般是混合种植、混合收购。因此,尽管我国也育出了许多脂肪含量大于22%和蛋白质含量超过45%的优质大豆品种,但由于混合收购与加工,优质品种得不到较好的经济效益,一些大型油脂加工企业宁愿从国外进口优质专用大豆,也不愿意在国内采购,导致一方面国内市场大豆严重积压,价格下跌,另一方面进口大豆逐年猛增的尴尬局面。所以,为了增强我国大豆国际竞争力,“十二五”期间必须大力发展高脂肪、高蛋白质专用大豆品种生产,尤其在我国东北大豆主产区,实现专用品种单独生产、单独收购、单独加工,建立专用大豆生产基地,使东北地区成为我国优质专用大豆的生产与出口基地。在不同生态区域推广应用适宜的专用大豆优质高产配套栽培技术,严格进行保优栽培。针对不可专用品种的生育特性,充分利用已有的各项技术,对播期选择、播种方式与用量、施肥方法、抗旱防涝措施、病虫害综合防治等方面进行综合试验示范,摸索出适合的高产栽培模式加以推广应用,使专用大豆品种实现高产优质。同时,“十五”期间东北地区应将自己在大豆生产上的优势扩大到“绿色大豆”、“有机大豆”的发展上,扩大大豆出口。 一、品种选择 选用增产潜力大、内在及外观品质好的优质大豆品种,如合丰35、绥农14、黑农33、35,要求种子发芽率90%以上,纯度98%以上。进行种子播前精选,剔除病种及杂质等,同时根据不同土壤环境与病虫害情况,选用合适的种衣剂包衣,有的也可用微肥、菌肥、ABT生根粉等拌种,增强种子活力。

二、种子处理 (1)种子精选 种子质量好坏直接关系到大豆苗全、苗齐、苗壮。如果自留种子,播种前必须进行人工选用粒大、饱满、没有病虫口和杂质的种子。如在种子门店购买种子,买种时也选购粒大、饱满、没有病虫口和杂质的种子,且注意看包装是否标明有种子质量标准,一般大豆的种子质量标准必须达到以下标准纯度不低于98%,净度不低于98%,发芽率高于90%,含水量不高于13%。 (2)根瘤菌拌种 在新开垦或多年未种过大豆的地块,必须进行根瘤菌接种,方法是用2公斤菌籽加5公斤水,然后拌50公斤大豆种子。拌后放在阴凉地方,防止太阳直射杀伤根瘤菌。接种后,待种子晾干后可播种。如果用药剂拌种,尤其是酸性农药拌种,一般不宜接种根瘤菌。 三、精细施肥与播种 播前施土杂肥10~25t/hm2。一般播时施二铵150kg/hm2、钾肥100kg /hm2作基肥。种子精选时需剔除病斑粒、虫食粒和杂质,使种子达到大豆一级

播种机毕业设计

目录 1 播种机发展现状与趋势 (1) 1.1 我国播种机发展现状 (1) 1.2 播种机的发展前景 (2) 1.2.1 单粒精密播种机迅速发展 (2) 1.2.2 播种机的通用性和适应性不断提高 (2) 1.2.3 播种机向高速宽幅发展 (3) 1.2.4 广泛采用联合作业 (3) 1.2.5 新技术的应用不断普及 (3) 2 播种机概述 (5) 2.1 播种机类型 (5) 2.2 播种机主要结构 (5) 2.3 总体配置 (6) 2.3.1 主要技术参数 (7) 3 播种排种器 (8) 3.1 排种器的技术要求 (8) 3.2 立式圆盘排种器的特点 (9)

3.3 排种器参数设计 (9) 3.4 壳体造型 (10) 3.5 种子的充填 (10) 3.5.1 排种器种子充填力学分析 (10) 3.5.2 充种过成 (13) 4 排肥器 (15) 4.1 排肥器的要求 (15) 4.2 排肥器选择 (15) 5 开沟器及其起落机构 (18) 5.1 开沟器的要求 (18) 5.2 开沟器的结构类型 (18) 5.3 开沟器使用行距与前后列距离 (19) 5.4 芯铧式开沟器 (19) 6 输种管、覆土器、镇压轮 (21) 6.1 输种管 (21) 6.1.1 输种管的类型 (21) 6.1.2 输种管的主要参数 (21) 6.2 覆土器 (22)

6.3 镇压轮 (22) 6.3.1 镇压轮的结构类型和特点 (23) 6.3.2 镇压轮直径的确定 (24) 6.3.2 镇压弹簧参数设计 (25) 7 其他工作部件和机构 (27) 7.1 种子、肥箱 (27) 7.1.1 种子、肥料箱容量计算 (27) 7.1.2 种子、肥料箱结构特点 (28) 7.2 仿形机构 (28) 7.2.1 仿形机构类型 (28) 7.2.2 仿形机构主要参数 (29) 8 播种机组工作阻力与作业幅宽 (32) 8.1 工作阻力P与作业幅宽B (32) 8.2 播种机机组功率消耗N (32) 9 保养与保管 (33) 10 使用及注意事项 (34) 11 安全规则 (36) 12 常见故障与排除 (37)

马铃薯播种机设计说明书 精品

一种马铃薯播种机的设计 第一章绪论 1.1 设计的目的和意义 马铃薯蛋白质含量高,已得到广泛种植,是重要的经济和粮食作物,产量高,可用作蔬菜、粮食、畜牧饲料以及多种工业原料的生产,在我国是次仅次于大豆的第五大粮食作物。据统计20XX 年在我国的种植面积是6 995.1 万亩,总产量达1 415.6 万吨,几乎接近世界年产量的的1/4,位居世界第一(potatoweb )。 目前我国的人均产量与西方发达国家还相差太远,因此提高马铃薯的单位产量相当重要,其关键就是提高马铃薯种植的机械化作业水平。 但目前为止我国马铃薯种植的机械化普及率比较低,导致生产效率低,工作质量差,生产成本高,大部分的劳动由农民承担。我国目前马铃薯的种植主要还是传统种植的方法,依靠人力和畜力开沟,点种,覆土,其过程繁琐劳动强度大,效率低下,在进行大面积的种植时其缺点显得尤为突出,严重限制了我国马铃薯整体种植产业。 马铃薯种植的传统工艺在一定程度上也十分影响影响马铃薯的单位产量,主要体现在以下几个方面:(1)种薯一般是自己挑选预留的,不是农业单位专门培育的,在质量上大打折扣,种体没有经过特殊的技术处理,根本没有产量上的保证;(2)种薯的品种少且混杂,没有考虑到种子的区位因素,不同的地区环境往往采用不同的品种。(当然我国在这方面的研究也有相当大的差距,种子市场的种薯品种有限,今后我们应该加大对马铃薯种薯的培育)(3)传统的种植工艺使用人力和畜力,不仅工作效率低而且对种子周围土壤的破坏比较严重,影响种子日后的发芽和生长。 据调查,尽管已经拥有的了多种马铃薯种植机械,但大部分的播种机械结构比较复杂,成本比较大,不宜个体化推广。特别需要生产出可以满足马铃薯种植农艺要求的小型易推广的马铃薯播种机,这样才能够大幅度普遍的的提高我国马铃薯种植的整体劳动生产率,为农民农民的负担。由于国家实施了农机具购置补贴政策,这极大促进了广大农民及单位购买、使用马铃薯生产机械,马铃薯生产的机械化得到了前所未有的发展。本次设计是事先初步成型再通过总结已有马铃薯种植机械,分析发现问题,解决问题,改进设计。重点提高劳动生产效率,解放劳动力,简化播种机构,设计出一种新型的马铃薯播种机对于解决现有的问题,改善马铃薯播种机械的推广具有重要的意义。 马铃薯的用途很广,工业食品业等诸多方面应用广泛,可作为粮食蔬菜,市场需求逐年递增,可谓全能农作物。提高马铃薯的综合生产能力,对促进农产品加工业发展,优化农业结构,促进马铃薯机诸多产业的发展,保障我国粮食安全,改善人民生活水平,实现农业增效和农民增收等的意义重大。由于机械化播种的规范性更高,每亩可以节省种薯10公斤左右,机械化播种的规范化,精确化可每亩可增产250公斤左右。与人中种植相比,马铃薯机械化播种是工作效率至少提高3倍以上。推广马铃薯的机械化作业,可以大大提高马铃薯的综合生产能力,从而保障粮食安全,同时改善农民收入,对农业现代化建设和发展意义非凡。

大豆优势区域布局计划()doc

附件4: 大豆优势区域布局规划 <2008-2018年) 大豆是世界最主要的油料作物,是人类优质蛋白和油脂的主要来源,也是我国进口量最大的农产品。为促进国内大豆生产恢复发展,提高农民收益,稳定市场供给,在总结《高油大豆优势区域发展规划<2003-2007年)》实施情况的基础上,按照积极推进现代农业的总体要求,特制定本规划。 一、发展现状 近年来,我国大豆产业整体形势日趋严峻,消费不断增长,国内生产滑坡,国际依存度过高。但东北高油大豆优势区域发展规划的实施,为今后大豆产业的发展探索了路子。 <一)产业现状 近年来,我国大豆产业发展极不平衡,在需求快速增长的情况下,生产缓慢增长,加工业快速发展,进口急剧增加,已占供给总量的60%以上。 1. 生产波动下滑,自给率下降。近五年来,受市场价格及重大灾害的影响,我国大豆生产波动较大,总产四年

减一年增。2003年和2005年,在面积有所扩大的情况下,由于重大灾害的影响,导致总产下降。2006年和2007年,由于市场价格下跌,种豆比较效益下降,农民调减种植面积,加上自然灾害的影响,导致连续两年减产。2004年,由于价格高、气候好,大豆获得丰收,总产达到1740万吨,创历史最高记录。总产的波动下降难以满足需求的快速增长,尽管高蛋白和菜用大豆能满足自需,但油用大豆基本依赖进口,大豆自给率大幅下降,2001年我国大豆国内自给率为52.5%,2007年下降到29.2%,6年减少了23个百分点。 2. 市场价格波动剧烈,农民收益和市场供给不稳。受国际市场影响,近5年国内大豆及制品价格波动剧烈。2001年国内市场大豆价格约每公斤2元,2004年上涨到3- 3.2元,上涨幅度达到50%以上;2006年大豆价格又回落到每公斤 2.3元,下降近30%。2007年下半年,大豆价格再次迅速上涨,到2008年5月,达到 5.6元,上涨幅度高达240%。2008年东北大豆收获后,大豆价格又迅速回落至3 .2元。价格的剧烈波动,造成大豆种植收益忽高忽低,农民难以适应市场的变化,影响其种植积极性,同时也影响到相关产业的发展及市场的稳定。 3. 加工业快速发展,外资控制格局基本形成。近年,我国大豆加工业进入了调整、“洗牌”的巨变时期。布局

浅谈大豆栽培技术

浅谈大豆栽培技术 发表时间:2009-09-28T17:16:54.750Z 来源:《农民致富之友》2009年第5期供稿作者:刘雷麻君君[导读] 中国是大豆发源地,大豆一直是我国主要的粮食与油料作物之一一、概况 中国是大豆发源地,大豆一直是我国主要的粮食与油料作物之一,建国以后很长一段时期内我国的大豆面积、产量与出口量一直处于世界首位。但是近年来,我国在大豆高产优质品种选育及配套高产高效栽培技术研究、试验、组装与推广上发展缓慢,单产水平不高,导致种植大豆比较效益低。同时,美国、巴西、阿根廷等国家大豆发展迅猛,在国际大豆市场的份额越来越大,对我国大豆生产发展冲击很大。目前,我国大豆年产量约1300万吨左右,只占世界的10%,位居世界第四。1996年,我国更由大豆出口国变成净进口国。到2000年,大豆及豆饼进口量超过900多万吨,成为世界最大进口国。进入21世纪,随着人民生活质量的不断提高,对大豆的需求将越来越大,为此,在注重选育大豆新品种同时,必须做好技术推广工作。一方面要加强新的配套技术的研究、试验与示范;另一方面搞好现有高产栽培技术的组装与推广应用,努力提高大豆单产水平。“十五”期间,东北大豆主产区应继续推广“垄三”栽培、永常模式栽培、幸福模式栽培等比较成熟的技术,加强对窄行密植技术及由其衍生的大垄密、小垄密和平作窄行密植技术的研究与示范推广,以增产、提质、节本为目标,以精细播种、科学施肥、综合防治等为技术重点,实行大豆与玉米、小麦轮作,解决重茬、迎茬问题。同时在不同生态地区研究组装并推广适宜的高产配套技术与田间管理措施,大力推广大豆生产的标准化、集约化与机械化,到“十五”末期大豆平均单产达到180千克左右,使东北成为我国商品大豆与出口大豆的主要产区。 二、种植方法 1、品种选择与处理选用增产潜力大、内在及外观品质好的优质大豆品种,如合丰35、绥农14、黑农33、豫豆2 2、鲁豆11、中黄4号等,要求种子发芽率90%以上,纯度98%以上。进行种子播前精选,剔除病种及杂质等,同时根据不同土壤环境与病虫害情况,选用合适的种衣剂包衣,有的也可用微肥、菌肥、ABT生根粉等拌种,增强种子活力。2、合理耕作整地与轮作。大豆种植应坚持合理轮作,在东北可与玉米、小麦等轮作,减少重茬、迎茬面积,同时尽量秸秆还田,以培肥地力。整地以深松为原则,东北大豆主产区采用深松旋耕机进行深松耙茬,增强土壤通透性与抗旱耐涝能力,一般耕翻深度20厘米左右。垄作大豆整地要与起垄相结合,做到垄体垄沟深松。 3、机械化精量播种。东北大豆产区4月下旬到5月上旬开始播种,地膜大豆可适当提前播种。东北地区利用大豆播种机进行等距精量点播,使植株分布均匀,播种深度3~5厘米。垄作大豆采取窄行密植技术,一般60厘米小垄种2行,90~105厘米大垄种4行,小行距12厘米左右,亩密度加大到2.5万~3万株,增产15%~20%。 4、测土配方科学施肥。实行测土配方施肥与分层施肥相结合的科学施肥方法,根据不同土壤肥力情况和当地自然气候条件,经过化验与计算,确定化肥施用时间与用量。一般采取分层深施,即底肥施在垄下16~18厘米处,用量约占总施肥量的60%左右;种肥施在种下4厘米处,用量约占总施肥量的40%;另外,在始花期至终花期可根据长势进行叶面喷施。这样就满足了大豆在不同生育期对肥料的需求,提高了肥料利用率。 5、进行科学田间管理。重点是防治大豆病虫害,主要有孢囊线虫、根腐病、灰斑病、大豆食心虫、蚜虫等。蚜虫采取熏蒸防治方法,减少农药使用量。根腐病、孢囊线虫等可根据土壤条件因地制宜地采用种衣剂包衣、选用50%福美双或50%多福合剂按种子量的0.4%拌种等办法。大豆田间杂草很多,要筛选出低毒、高效、低残留的化学除草剂进行化学除草,尽量控制施用量。播种前或出苗前结合中耕进行一次土壤化学封闭除草,结荚期再喷一次除草剂,在开花末期至结荚期可根据大豆长势喷施化学调控剂,保证大豆高产。 三、注意事项 1、品种选择要适当。良种与良法结合才能获得高产,必须选择产量潜力大的优良大豆品种。窄行密植技术应采用矮秆、半矮秆的耐密品种,不宜选择生育期过长,植株过高的品种,保证在种植密度增加情况下获得高产。 2、保证播种质量播种不宜过深,也不应太浅,且做到深浅一致,否则都将影响种子发芽及植株的整齐度。 3、注意平衡施肥分层施肥时,应注意氮、磷、钾肥的施用比例以及不同生育阶段大豆对肥料的不同需求,同时注重硼肥、锌肥等微量元素的合理搭配。 (作者单位:150039 黑龙江省哈尔滨市香坊区向阳乡人民政府)

鸭嘴滚筒式播种机的设计研究

鸭嘴滚筒式播种机的设计研究 1精密播种机发展现状与趋势 播种机是农业生产中关键作业环节,必须在较短的播种农时内,根据农业技术要求,将种子播到田地里去,使作物获得良好的发育生长条件。作物的出苗、苗全和苗壮,因而由于精密播种可以保证种子在田间最合理分布,播种量精确,株距均匀,播深一致,为种子的生长发育创造最佳条件,可以大量节省种子,减少田间间苗用工,保证作物稳产高产。因此,现代农业对精密播种机械的要求越来越迫切[1]。 1.1我国精密播种机发展现状 我国从80年代末便开始研制精密播种机械。由于种子质量、整地条件、机械制造水平及机器价格等因素制约,我国80年代主要是推广半精量播种。90年代以来,我国逐步推广精密播种机,有10多个企业生产了20多种型号的精密播种机。精密播种机以作物种类分为玉米及大豆精密播种机、谷物(小麦)精密播种机、甜菜精密播种机;以配套动力分为小型(5.8~13.2kw)、中型(16.2~36.8kw)和大型播种机(40.4kw以上)精密播种机;以排种器形式分为机械式和气力式两大类精密播种机;机械式中又可分为垂直圆盘式、垂直窝眼式、锥盘式、纹盘式、水平圆盘式、带夹式等形式精密播种机。 1.2精密播种机的发展前景 1.2.1单粒精密播种机迅速发展 在国外,中耕作物如甜菜、玉米、棉花和某些蔬菜、豆类的播种都已大量采用精密播种,主要采用机械式和气力式两种精密播种机。由于气力式播种机对种子尺寸要求不严,不需精选分级,容易达到单粒精播,而且通用性较好,又能适合较高速播种,因此使用气力式播种机越来越多。 为了达到单粒精播,提高株距的均匀性,大多都采用可精调刮种器,将多余种

大豆播种机设计

Design and Test of Variable-rate Fertilization Control Device of Precision Planter for Soybean WANG Xinzhong College of Engineering Heilongjiang Bayi Agricultural University DaQing, China ndwxz@https://www.360docs.net/doc/416366160.html, WANG Xi College of Engineering Heilongjiang Bayi Agricultural University DaQing, China ndwangxi@https://www.360docs.net/doc/416366160.html, Abstract—Utilizing the favorable condition of Heilongjiang reclamation area carrying out the precision agriculture sample, we have developed an automatic control device with the variable rate fertilization. This device adopts industrial control computer is upper machine and variable rate fertilization controller for single chip computer as the core is lower machine, it is to be used to the accompaniment of 6-line soybean precision planter, and it uses an electric control CVT(Continuously Variable Transmission) which controls the transmission ratio of discharging fertilizer system of the planter to change the volume of applying fertilizer. We carried out planting tests of the variable-rate fertilization with this control device on the 852 farm in Heilongjiang province in 2005 and achieved good results. Keywords-component; precision agriculture; variable rate fertilization; planter; computer; I.I NTRODUCTION Precision agriculture develops on the basis of 3s technology, it uses the ability of GPS on precision orientation to measure the output of each unite in field which is often defined in square meter and the surrounding spatial and temporal differentia of plants, analyses the reason of the differentia, and then computes the real volume of materials such as seeds, fertilizer, chemicals and irrigating water according to the needs of each unite plant. All of these efforts helps to optimize outputs, decrease materials cost, gain the maximal economy and social benefit, protect environment and realize the goal of sustainable agriculture. The agriculture production efficiency is relatively low at present, and there is a common phenomenon of low resource using efficiency and input versus output ratio. The existed agriculture production is mainly implemented by large amount of agriculture materials such as fertilizer plunged into the field. The volume of fertilizer in each unite of plantation area is three times much of world’s level each year. Because too much fertilizers were used blindly, it causes a relatively low fertilizer use efficiency in China. By the expert decision system, variable rate fertilizing machine as the most important part of precision equipment can make variable rate fertilizing digital maps, deliver variable rate data to auto control system fixed in the planter to realize auto control fertilization and promote fertilizer use efficiency according to soil test data, corn yield data, field level elevation maps, variety of crop, local weather situation etc. II.MATERIALS AND METHODS A.SYSTEM CONSTRUCTION The variable rate fertilizer controller consists of AG132 type of GPS receiver, wireless data transmission receiver, onboard computer, variable rate fertilization control software, variable rate fertilization control driver, electric control CVT, 6-Q-105 type storage battery, fertilizer delivering system of soybeans precision planter, etc. The construction of variable rate controller is shown in Fig. 1. Fig.1 The construction frame of the variable-rate fertilization control device Fig.2 The planter of the variable-rate fertilization This thesis is the project supported by National High Technology Research and Development Program (namely 863 Program)(No.006AA10A310, 2003AA209090). Key Tackling Item in Heilongjiang Provence (No.GB04B703) and Important Science and Technology Project in Heilongjiang Provence (No.GB06B601) ___________________________________

智能装盘播种机精密播种监测系统的设计

图1 智能装盘播种机的结构 Fig.1Structure of intelligent plate planter 1.漂盘护栏 2.压辊 3.下料斗 4.点种斗 5.淋水斗 6.覆料斗 7.后加长架 8.电机链条护罩 9.控制面板10.电控盒11.保险座%12.装基电机13. 前加长架 DOI:中国农机化学报 Journal of Chinese Agricultural Mechanization 第35卷第6期2014年11月Vol .35No .6Nov.2014 智能装盘播种机精密播种监测系统的设计* 吉武俊,陈海燕 摘要:国内现行的烟草播种机多采用纯机械推板式播种器,其播种量无法控制,且漏种量高,控制性能差难以满足播种的要求。YZPB ― 200B 型智能装盘播种机采用步进电机驱动排种器,播种过程中采用霍尔转速传感器采集苗盘传送速度信号,并由单片机对采集数据进行分析和计算,动态调节步进电机转速,使排种器转速与苗盘传送速度保持一定的关系,从而达到自动控制排种器的目的;此外安装了监控系统对播种机的播种质量进行实时监控,提高了播种的质量。关键词:播种器;单片机;传感器;播种精度中图分类号:S223.2 文献标识码:A 文章编号:2095-5553(2014)06-0017-04 吉武俊,陈海燕.智能装盘播种机精密播种监测系统的设计[J].中国农机化学报,2014,35(6):17~20 Ji Wujun,Chen Haiyan.Design of the monitoring system for precision seeding in tobacco intelligent plate planter [J].Journal of Chinese Agricul -tural Mechanization,2014,35(6):17~20 (河南省职业技术学院,郑州市,450046) 收稿日期:2013年9月16日修回日期:2013年10月29日 *基金项目:河南省烟草公司科技公关项目(200831) 第一作者:吉武俊,男,1979年生,河北张家口人,硕士,讲师;研究方向为汽车应用技术教育。E-mail:mazhai920@https://www.360docs.net/doc/416366160.html, 0引言 播种器是播种机的核心部件,对播种质量起 决定性作用。目前我国烟草装盘播种多数地区仍采用手工或半机械化作业。传统播种机的播种器是依靠地轮驱动,当地轮阻力大时容易打滑,要想让播种器和地轮的前行速度保持一定的关系,达到精准播种,对其机械部分的设计要求很高,如果出现皮带松动等原因时,漏播率非常高。同时播种机工作时具有全封闭的特点,当播种机发生故障时由于没有及时发现,会造成断行性漏播,导致农业减产。YZPB ―200B 型智能装盘播种机将播种过程用三种传感器进行测点,单片机综合控制,让排种器转速与播种机作业速度一致,大大提高了播种 精度;为了防止断行性漏播,安装了监控系统对播种质量进行实时监控,提高了播种质量。 1智能装盘播种机的结构 烟草精量装盘播种机由机架、装基装置、压穴装 置、播种装置、淋水装置、覆基装置构成,如图1所示。其中机架是本产品的基础,主要完成传递动力及输送育苗盘的任务;装基装置主要作用是能够容纳一定的基质量,并向育苗盘的种穴内填充基质;压穴装置利用传动 V 带的摩擦力,使育苗盘在运行的状态下推动压穴装置, 使压穴装置被动上下运动,实现同步给育苗盘压窝;播种装置包括种子箱、排种器驱动步进电机、精量排种器,它的主要作用是通过两组传感器检测,给控制系统提供信号,单片机进行数字化控制,实现精确播种。 10.13733/j.jcam.issn.2095-5553.2014.06.005

精量播种机设计

毕业设计 学生姓名:马云鹏学号: 130501617 学院:机械工程学院 专业:机械设计制造及其自动化 题目:精量播种机设计 指导教师:张戌社(教授) 评阅教师:陈继荣(副教授) 2017 年 6 月

毕业设计中文摘要

毕业设计外文摘要

目录 第一章引言 (5) 1.1我国精量播种机发展背景 (5) 1.2 精量播种机研究意义 (5) 1.3精量播种机的发展前景 (6) 第二章精量播种机的概述 (8) 2.1播种机的类型 (8) 2.2播种机主要机构以及功能 (8) 第三章精量播种机的排种器 (11) 3.1精量排种器的发展前景 (11) 3.2排种器的技术要求 (11) 3.3排种器的选择 (12) 3.4勺轮式排种器的设计 (12) 3.5勺轮式排种器驱动的选择 (13) 3.6滚子链的计算 (14) 第四章开沟器的设计 (17) 4.1开沟器的技术要求 (18) 4.2开沟器不同的类型分析和分析 (18) 4.3开沟器的使用行距和前后距离 (20) 4.4芯铧式开沟器设计 (20) 4.5开沟器转轴的设计 (22) 4.6播种行距的调节和计算 (22) 4.6.1 行距的调整 (22) 4.6.2 播种量的调整和实验 (22) 第五章配套部件的设计 (24) 5.1输种管 (24) 5.2镇压轮的设计 (24) 5.2.1镇压轮直径的确定 (26) 5.2.2镇压弹簧的参数设计 (26) 5.3种箱以及肥箱 (27) 5.3.1肥箱 (27) 5.3.2种箱 (27) 5.4覆土器 (28) 5.5变速箱的选用 (29) 第六章排肥器 (30) 6.1排肥器的不同类型 (32) 6.2排肥器的选择 (32) 第七章剩余部件的设计 (33) 7.1洒水系统 (33) 7.2覆膜 (33)

机械毕业设计1630原茬小麦精少量播种机的设计说明书

摘要 播种机播种质量的优劣直接影响到农作物的产量以及农产品的成本,因此研制高质量的播种机械是现代农业的迫切要求。尽管我国大部分地区早已实现播种机械化,但目前的播种机质量还不能满足高产的要求。现在大面积麦田普遍存在着植株疏密不匀,出苗参差不齐,单株个体之间性状也表现较大差异等问题,限制了小麦产量的进一步提高。生产实践证明,解决这一问题的关键在于实行均匀播种。本课题的目的是针对现有小麦播种机播种中存在缺苗烧苗现象严重,存在疙瘩苗,设计制造了一种装配有种肥分施开沟器的小麦播种机,该小麦播种机能够显著提高小麦播种的均匀性,实现种肥分施,达到了节种、增产的目的。 关键词:小麦播种机;开沟器;排种器

Abstract The quality of sowing machine affects the outputs and the costs of the agricultural products directly , therefore it is urgent for modern agriculture to develop the high quality sowing machine. Although most areas in our country have already realized the sowing mechanization, the quality of the present sowing machine can not satisfy the demand of high yield . At present there are some problems restricting future improvement of wh eat yield in most areas ,such as ,different interspace among plants ,various sizes between seedlings and distinctive traits in individuals .Through production practices ,the key to solve this problem lies in implementing balance sowing .the main purpose of this subject is design a kind of wheat sowing machine assembling with equalizing device and furrow opener to replace the existing wheat sowing machine that result to severe absence and burning of the seedlings .this sort of wheat sowing machine in this book can improve significantly and remarkably the balance of wheat sowing and realize higher productivity. Key words: Wheat seeder;Furrow opener;Seed metering