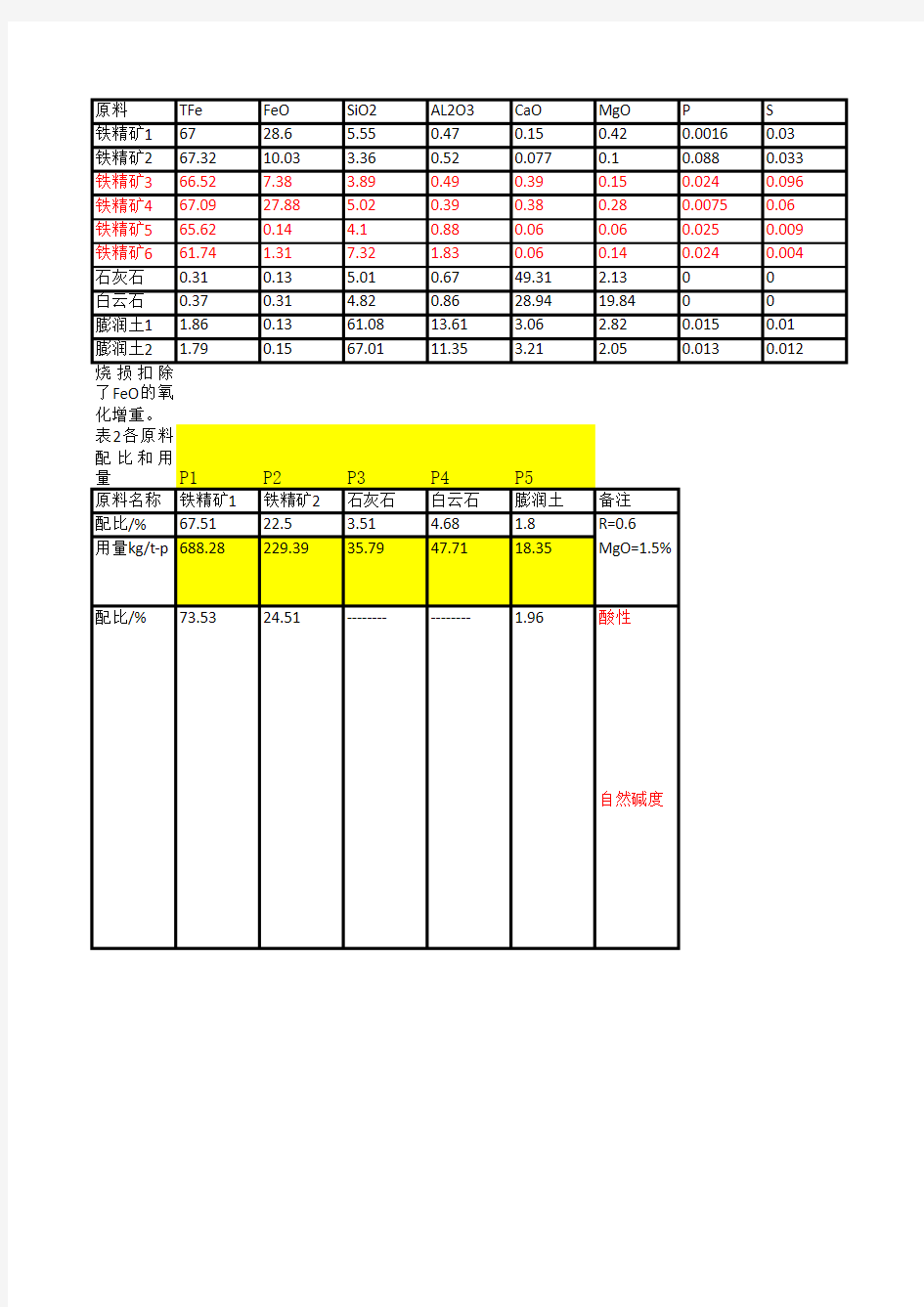

球团配料计算(新)

原料TFe FeO SiO2AL2O3CaO MgO P S

铁精矿16728.6 5.550.470.150.420.00160.03

铁精矿267.3210.03 3.360.520.0770.10.0880.033

铁精矿366.527.38 3.890.490.390.150.0240.096

铁精矿467.0927.88 5.020.390.380.280.00750.06

铁精矿565.620.14 4.10.880.060.060.0250.009

铁精矿661.74 1.317.32 1.830.060.140.0240.004

石灰石0.310.13 5.010.6749.31 2.1300

白云石0.370.31 4.820.8628.9419.8400

膨润土1 1.860.1361.0813.61 3.06 2.820.0150.01

膨润土2 1.790.1567.0111.35 3.21 2.050.0130.012

烧损扣除

了FeO的氧

化增重。

表2各原料

配比和用

量P1P2P3P4P5

原料名称铁精矿1铁精矿2石灰石白云石膨润土备注

配比/%67.5122.5 3.51 4.68 1.8R=0.6

用量kg/t-p688.28229.3935.7947.7118.35MgO=1.5%

酸性

配比/%73.5324.51---------------- 1.96

自然碱度

脱硫率0.95

F eO_球1

Fe0_Left0.01

碱度0.6

膨润土比例

碱度

焙烧后MgO

焙烧后总质

铁矿粉比例

LOI_i Bi=Pi[9*(100-LOIi-

0.58b1102.568 1.025682

0.47b2100.612 1.00612

0.39100.338 1.003377

0.37102.670 1.026697

1.0798.9360.989359

1.498.7410.987406

41.84b358.1730.581733

43.6b456.4330.564333

12.58b587.4240.874238

11.9888.0240.880242

0.02P1+0.02P2-P3=0

3.18P1+1.939P2+33.58P3-49.304P4-26.048P5=0

0.42P1+0.1P2+2.82P3+2.13P4+196.84P5=15

1.02455P1+1.0022P2+0.87315P3+0.581P4+0.56372P5=1000

P1-3P2=0

A1A2A3A4A5

膨润土比例11-49

碱度-3.18-1.93946.30426.048-33.588

焙烧后MgO%0.00420.0010.02130.19840.0282

焙烧后总质量 1.02568167 1.006120.58173330.56433330.874238333

铁矿粉比例1-3000

688.28229.3935.7947.7118.35

688.28229.3935.7947.7118.35

688.28229.3935.7947.7118.35

688.28229.3935.7947.7118.35

688.28229.3935.7947.7118.35

膨润土比例688.28229.3900-899.15

碱度-2188.73-444.81657.221242.75-616.3398

焙烧后MgO% 2.8907760.22940.7623279.4656640.51747

焙烧后总质量705.95618230.7920.8202426.9243416.04227342

铁矿粉比例688.28-688.2000

0.95Si)+FeOi]/(900+FeO球)

+0.56372P5=1000

B X

0P1688.28

0P2229.39

15P335.79

1000P447.71

0P518.35

19

-350

14

1001