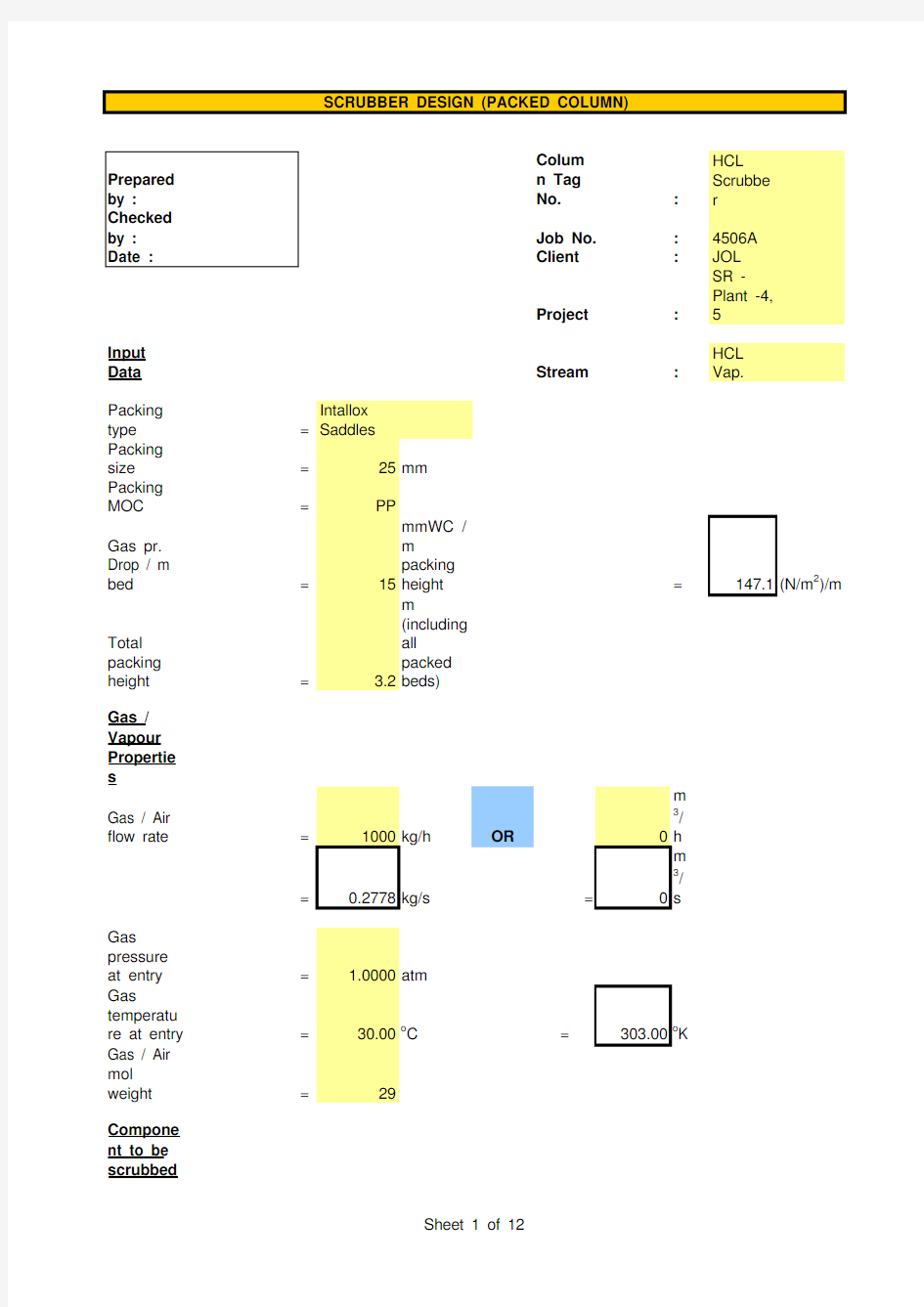

脱硫塔设计计算

Colum

n Tag

No.:HCL Scrubbe r

Job No.:4506A Client:JOL

Project:SR -Plant -4, 5

Input

Data Stream:HCL Vap.

Packing

type=Intallox Saddles

Packing

size=25mm Packing

MOC=PP

Gas pr.

Drop / m

bed=15mmWC /

m

packing

height=147.1(N/m2)/m

Total

packing

height= 3.2m (including all packed beds)

Gas / Vapour Propertie s

Gas / Air

flow rate=1000kg/h OR0m 3/ h

=0.2778kg/s=0m 3/ s

Gas

pressure

at entry= 1.0000atm

Gas

temperatu

re at entry=30.00o C=303.00o K Gas / Air

mol

weight=29

Compone

nt to be

scrubbed

SCRUBBER DESIGN (PACKED COLUMN)

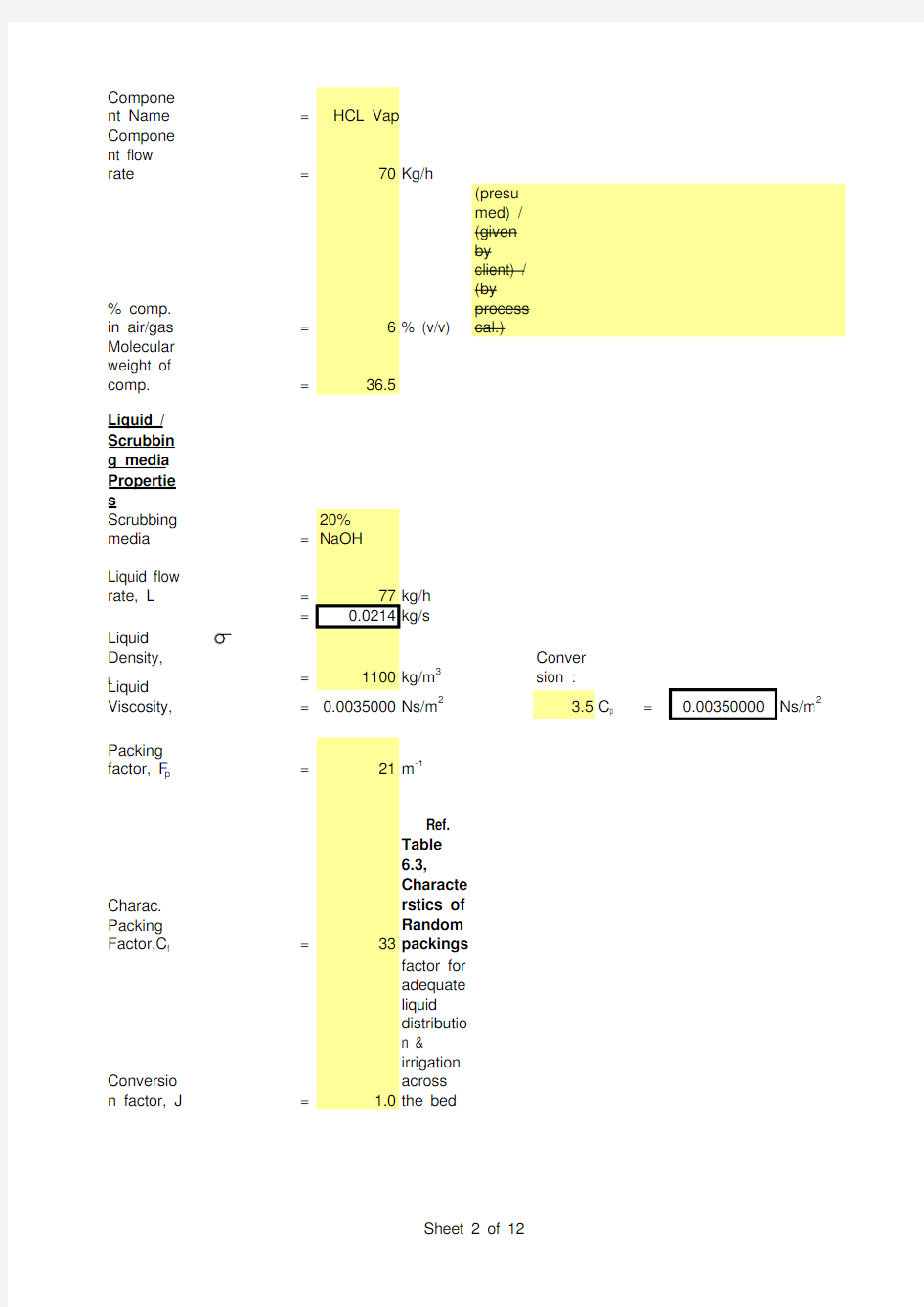

nt Name=HCL Vap Compone

nt flow

rate=70Kg/h % comp.

in air/gas=6% (v/v)

Molecular

weight of

comp.=36.5

Liquid /

Scrubbin

g media

Propertie

s

Scrubbing

media=20% NaOH

Liquid flow

rate, L

=77kg/h =0.0214kg/s

Liquid Density,

L =1100kg/m3

Conver

sion :

Liquid

Viscosity,=0.0035000Ns/m2 3.5C p =Ns/m2 Packing

factor, F p=21m-1

Charac.

Packing

Factor,C f=33 Ref. Table 6.3, Characte rstics of Random packings

Conversio

n factor, J= 1.0factor for

adequate

liquid

distributio

n &

irrigation

across

the bed

0.00350000

ons

TO CALCULATE COLUMN DIAMETER Since

larger flow

quantities

are at the

bottom for

an

absorber,

the

diameter

will be

chosen to

accommo

date the

bottom

conditions

.

To

calculate

Gas

density

Avg.

molecular

weight=29.45Kg / Kmol

Select vol.

flow rate

and mass

flow rate

from

above,

Selected

mass flow

rate=0.277778Kg/s Selected

vol. Flow

rate=0.234499m3/s Selected

molar flow

rate=0.009432Kmol/s

Therefore

, gas

density= 1.1846Kg/m3(mass flow rate / vol. Flow rate)

To find

L', G' and Tower c/s area Assuming essentially complete absorbtion ,

Compone nt

removed=0.0207

Kg/s

(molar

flow

rate x %

comp. x

mol.

Wt.)

Liquid

leaving=0.0420Kg/s (Inlet liquid flow rate + comp. Remov ed)

0.5=

Using0.00497

a

s

or

di

n

at

e,

Refer

fig.6.34

using a

gas

pressure

drop of147.1(N/m2)/m G' 2 C f

μL0.1 J=0.04

(from

graph)

- G) g c

Therefore,

G'=0.5

L

J

= 1.6665Kg / m2.s

Tower c/s

area=0.1667m2

( c/s

area =

mass

flow

rate / G'

)

Tower

diameter=0.4607m=460.7mm

=500mm

Correspon

ding c/s

area=0.1963m2

TO ESTIMATE POWER REQUIREMENT

Efficiency

of fan /

blower=60%

To

calculate

pressure

drop

Pressure

drop for

irrigated=470.72N/m2(pressu re drop per m packing

x total

ht. of

packing

)

packing

For dry

packing,

O/L Gas

flow rate,

G'=2.s

(Gas

inlet

flow

rate -

Compo

nent

remove

d) / c/s

area

O/L Gas

pressure=2

(subtra

cting

pressur

e drop

across

packing

)

Gas

density,

G

=

gas o/l

pr.

kelvin101330

= 1.1605Kg/m3

C D=96.7

Ref.

Table

6.3,

Characte

rstics of

Random

packings

Delta P =

Z

=

2

Pressure drop for packing

=

613.61N/m 2

(irrigate d

packing + dry packing )Pressure drop for internals

=25mmWC (packin g

support s and liquid distribut ors)

=245.17N/m 2

Gas velocity =

7.5m/s

Inlet

expansion & outlet = 1.5 x Velocity heads =

1.5 x (V 2 / 2g)

contractio n losses

=

42.19N m / Kg

=

49.97N/m 2

(divide by

density)

Total pressure drop

=

908.75N/m 2

(packin g +internal s +losses)

Fan power output

=pressure drop,N/m 2x (gas in -componen t removed)Kg/s

O/L gas density,3

=Power for fan motor

=0.34kW

(fan power output /motor efficien cy)

=0.45hp

Liq.-Vap.Flow

factor, F LV

=(L / V) x (V / L )=0.0025

Design for

an initial pressure drop of 15

mm H2O /m packing

From K 4v/s F LV ,K 4=

0.85

K 4 at flooding

= 6.50

Trial %flooding

=( (K 4 /K 4 at flooding)) x 100=36.1620

Gas mass flow rate,V m

= 13.1 F p (μL / L )0.1=

3.7763kg/m 2.s

Trial column c/s area =V / V m

(Trial A s )

=

0.0736m 2

Trial column dia., D

=0.3060m

D = (4/pi) x Trial A s

Round off 'D' to nearest standard size

Therefore,D

=0.500m

COLUMN DIAMETER / HYDRAULIC CHECK

(1/2)

Column C/S area,

A s=0.1963

m2A s =

(pi/4) x

D2

% flooding=% flooding = Trial % flooding x (Trial A s / A s)

Conclusi on Generally packed towers are designed for 50% --85% flooding. If flooding is to be reduced, (i) Select larger packing size and repeat the above steps.

OR

(ii) Increase the column diameter and repeat the above steps.

Norton's Correlati on :

ln HETP = n -0.187 ln + 0.213 ln μ

Applicable when,liquid phase surface tension >4 dyne/cm & < 36dyne/cm liquid viscosity > 0.08 cP & < 0.83cP

Conver sion :

Input Data 0.018 N/m =

dyne/cm

Liquid-phase Surface Tension,=

20dyne/cm Liquid Viscosity = 3.5

cP n

=

1.13080

Calculati on ln HETP =HETP

= 2.310437ft =

0.704221m

HETP PREDICTION

Norton's Correlation Applicable

Norton's Correlation NOT applicable

18

For

separation

s, less

than 15

theoritical

stages, a

20%

design

safety

factor can

be

applied.

Consideri

ng 20%

safety

factor,

HETP=

For

separation

s,

requiring

15 to 25

theoritical

stages, a

15%

design

safety

factor can

be

applied.

Consideri

ng 15%

safety

factor,

HETP=0.809854m