外文翻译--汽车悬架是如何工作的

附录:

英文原材料

How Car Suspensions Work

Without an intervening structure, all of wheel's vertical energy is transferred to the frame, which moves in the same direction. In such a situation, the wheels can lose contact with the road completely. Then, under the downward force of gravity, the wheels can slam back into the road surface. What you need is a system that will absorb the energy of the vertically accelerated wheel, allowing the frame and body to ride undisturbed while the wheels follow bumps in the road.

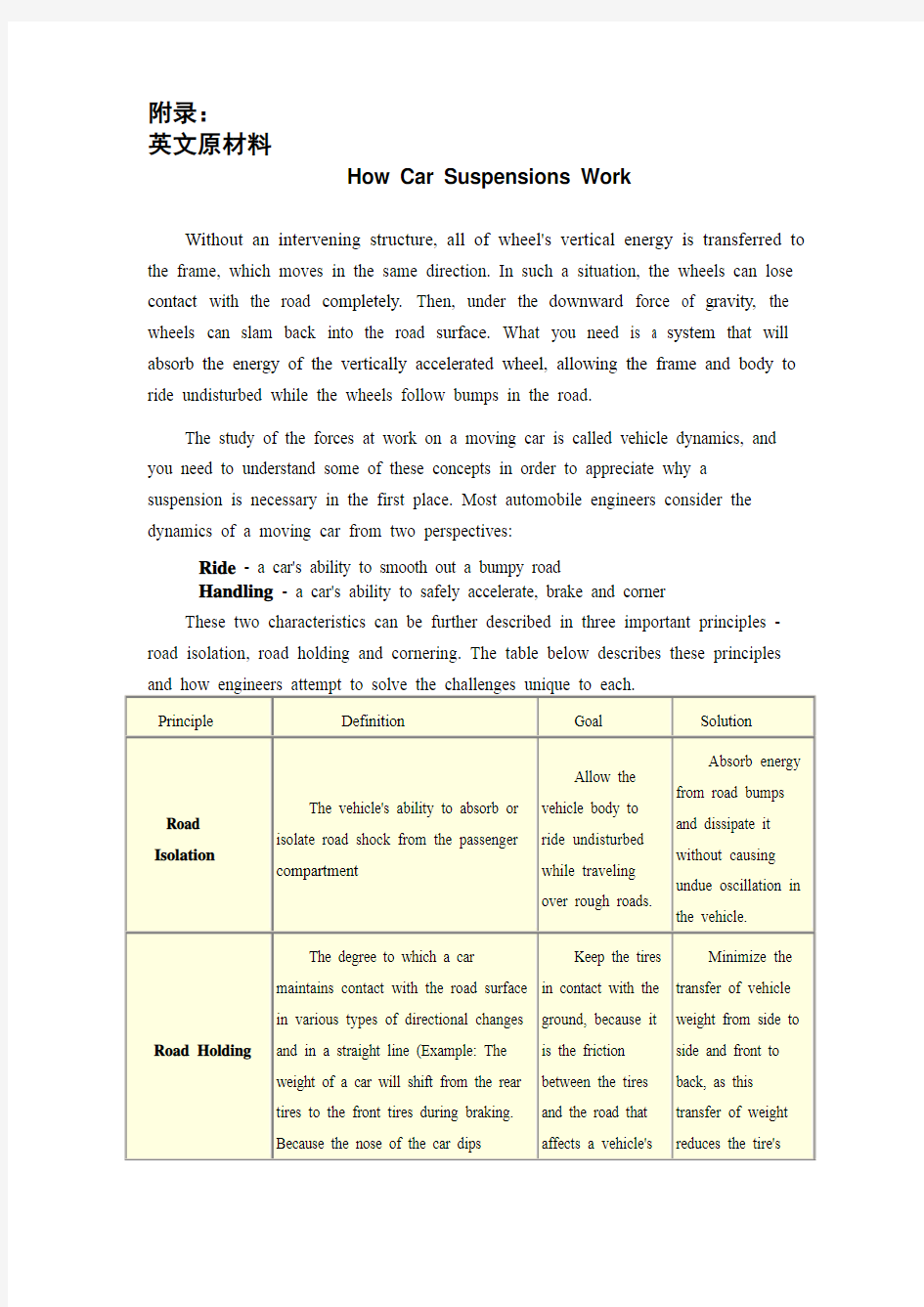

The study of the forces at work on a moving car is called vehicle dynamics, and you need to understand some of these concepts in order to appreciate why a suspension is necessary in the first place. Most automobile engineers consider the dynamics of a moving car from two perspectives:

spring to the axle. For many years, American car manufacturers preferred this design because of its simplicity.

The same basic design can be achieved with coil springs replacing the leaves. In this case, the spring and shock absorber can be mounted as a single unit or as separate components. When they're separate, the springs can be much smaller, which reduces the amount of space the suspension takes up.

Independent Rear Suspensions

If both the front and back suspensions are independent, then all of the wheels are mounted and sprung individually, resulting in what car advertisements tout as

"four-wheel independent suspension." Any suspension that can be used on the front of the car can be used on the rear, and versions of the front independent systems described in the previous section can be found on the rear axles. Of course, in the rear of the car, the steering rack -- the assembly that includes the pinion gear wheel and enables the wheels to turn from side to side -- is absent. This means that rear independent suspensions can be simplified versions of front ones, although the basic principles remain the same.

Next, we'll look at the suspensions of specialty cars.

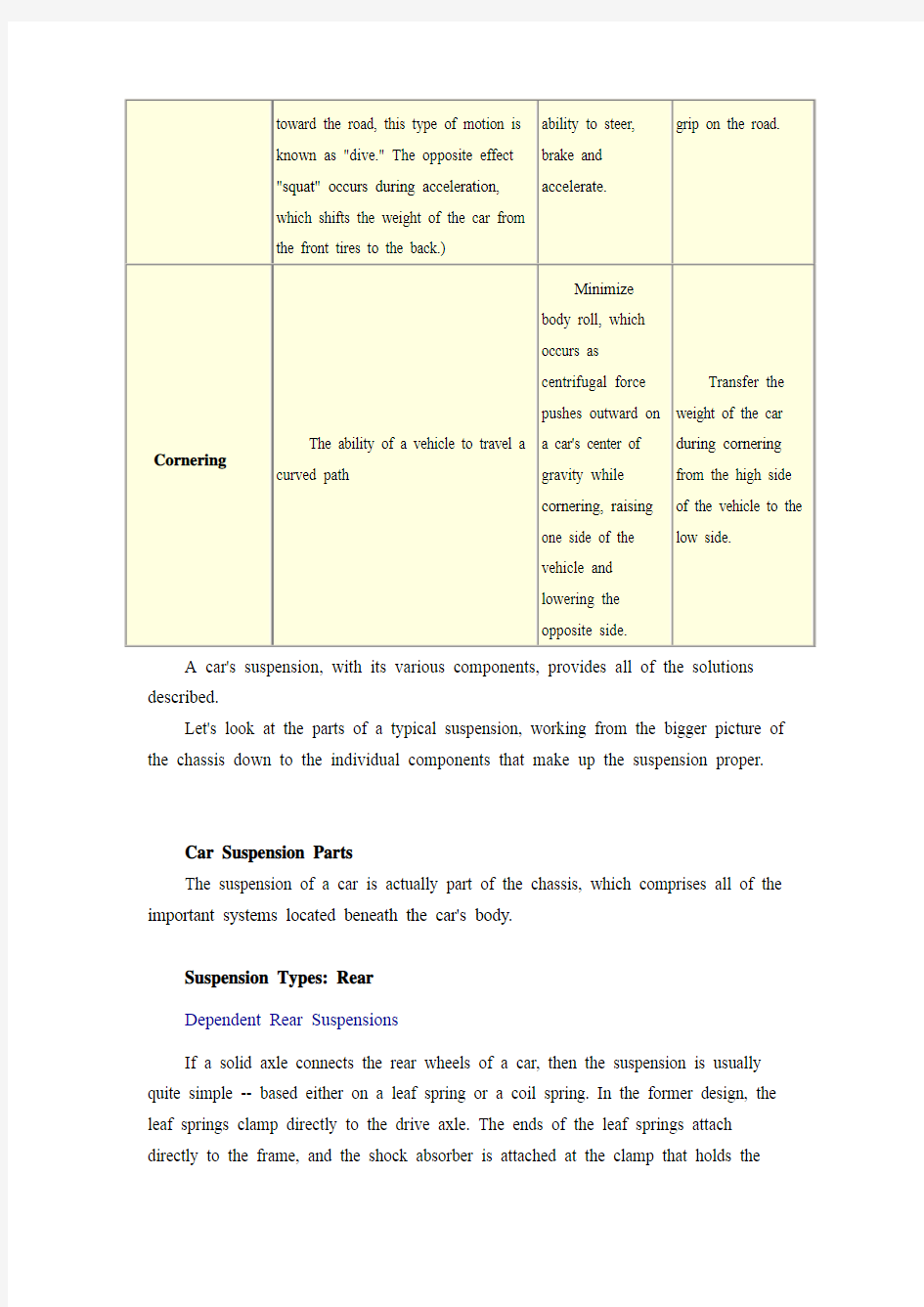

When the car wheel encounters a bump in the road and causes the spring to coil and uncoil, the energy of the spring is transferred to the shock absorber through the upper mount, down through the piston rod and into the piston. Orifices perforate the piston and allow fluid to leak through as the piston moves up and down in the pressure tube. Because the orifices are relatively tiny, only a small amount of fluid, under great pressure, passes through. This slows down the piston, which in turn slows down the spring.

Shock absorbers work in two cycles -- the compression cycle and the extension cycle. The compression cycle occurs as the piston moves downward, compressing the hydraulic fluid in the chamber below the piston. The extension cycle occurs as the piston moves toward the top of the pressure tube, compressing the fluid in the chamber above the piston. A typical car or light truck will have more resistance during its extension cycle than its compression cycle. With that in mind, the

compression cycle controls the motion of the vehicle's unsprung weight, while extension controls the heavier, sprung weight.

All modern shock absorbers are velocity-sensitive -- the faster the suspension moves, the more resistance the shock absorber provides. This enables shocks to adjust to road conditions and to control all of the unwanted motions that can occur in a moving vehicle, including bounce, sway, brake dive and acceleration squat.

翻译

汽车悬架是如何工作的

如果车身与车轮之间没有中间结构的话,汽车在行驶时所有车轮的垂直震动都将被传递到车身,并且都沿着相同的方向传递。在这种情况下,车轮可能会与道路完全分离。然后,在地心引力的作用下,车轮又回到路面。我们所需要的是一种系统,能吸收车轮垂直加速能量,使车架和车身在颠簸道路上行驶时,能不受干扰。

研究车在移动时受力情况的学科叫做车辆动力学,您需要了解一些概念,以明白为什么悬架摆在首位是必要的。大部分汽车工程师考虑动态行驶汽车从两个角度进行:

行驶—汽车在不平坦的道路上行驶的能力。

操控性—具有安全加速,刹车和转弯的能力。

这两个特点,可以进一步被体现在以下三种情况中—减震能力、抓地力、转弯性能。下面的表格描述了这些原则,以及工程师如何尝试解决每一个方面的问

题。

一辆车的悬架,其各组成部分,以及提供所有的解决方案的描述。

让我们看看,一个典型的悬架的工作状况,从大的底盘环境到组成悬架的每个零件。

汽车悬架,其实是底盘的一部分,位于汽车下方,其中包括了很多重要的系统。独立后悬架

悬架类型: 后悬架

如果是一个后桥与后轮直接相连的汽车,那么它的悬架系统一般来说都比较简单—基于钢板弹簧或者是螺旋弹簧之上。在赛车的悬架设计中,钢板弹簧直接与车轴相连。钢板弹簧的末端与车架相连,减震器与钢板弹簧相连。多年来,美国汽车制造商的首选这种设计就是因为它简单。

基本设计相同的情况下,才能实现螺旋弹簧取代钢板。在这种情况下,弹簧和减振器可以安装成一个单一的单位或作为单独的组件。当他们分开,弹簧体积可以制造的小得多,从而降低了悬架占用的空间。

非独立后悬架

HOW CAR SUSPENSIONS WORK——汽车悬架是如何工作的

Twin-tube Shock Absorber——双筒减振器

EXTENSIO

N CYCLE——伸

张周期

COMPRESS

ION CYCLE——

压缩周期

Upper Mo

u n t——上挂载

(吊环)

Piston Rod

——活塞杆

Oil——油

液

Reserve C

ylinder——储油

缸

Pressure T

ube——工作缸Base Valve——底阀

Lower Mount——下挂载(吊环)

当车轮在道路遇到颠簸导致弹簧压紧和收缩,弹簧上的能量通过上挂载转移到减振器,向下通过活塞杆和活塞进入。并当活塞向上和向下运动的时候允许液压油流过工作缸。因为油孔的开口相对较小,只有少量的液体在强大压力作用下通过。这使活塞减慢,这反过来又放缓的弹簧。

减振器的工作有两个周期-压缩周期和伸张周期。压缩周期出现,活塞向下的动作,压缩液压油进入活塞的油道。伸张周期出现,活塞顶部的压力管,压缩液体进入活塞以上的油道。一个典型的汽车或轻型卡车其伸张周期比其压缩周期将会有更多的阻力存在。要明白一点,压缩周期控制了汽车的非簧载重量的运动,而伸张周期控制了较重的簧载质量的运动。

所有现代的减震器对速度都是敏感的—即悬架运动的越快,减振器产生越大的阻力。这使减震器能适应道路的颠簸和控制汽车在行驶中所有的不利的振动,包括振动,摇摆,制动俯冲和加速后仰。

汽车专业毕业设计外文翻译

On the vehicle sideslip angle estimation through neural networks: Numerical and experimental results. S. Melzi,E. Sabbioni Mechanical Systems and Signal Processing 25 (2011):14~28 电脑估计车辆侧滑角的数值和实验结果 S.梅尔兹,E.赛博毕宁 机械系统和信号处理2011年第25期:14~28

摘要 将稳定控制系统应用于差动制动内/外轮胎是现在对客车车辆的标准(电子稳定系统ESP、直接偏航力矩控制DYC)。这些系统假设将两个偏航率(通常是衡量板)和侧滑角作为控制变量。不幸的是后者的具体数值只有通过非常昂贵却不适合用于普通车辆的设备才可以实现直接被测量,因此只能估计其数值。几个州的观察家最终将适应参数的参考车辆模型作为开发的目的。然而侧滑角的估计还是一个悬而未决的问题。为了避免有关参考模型参数识别/适应的问题,本文提出了分层神经网络方法估算侧滑角。横向加速度、偏航角速率、速度和引导角,都可以作为普通传感器的输入值。人脑中的神经网络的设计和定义的策略构成训练集通过数值模拟与七分布式光纤传感器的车辆模型都已经获得了。在各种路面上神经网络性能和稳定已经通过处理实验数据获得和相应的车辆和提到几个处理演习(一步引导、电源、双车道变化等)得以证实。结果通常显示估计和测量的侧滑角之间有良好的一致性。 1 介绍 稳定控制系统可以防止车辆的旋转和漂移。实际上,在轮胎和道路之间的物理极限的附着力下驾驶汽车是一个极其困难的任务。通常大部分司机不能处理这种情况和失去控制的车辆。最近,为了提高车辆安全,稳定控制系统(ESP[1,2]; DYC[3,4])介绍了通过将差动制动/驱动扭矩应用到内/外轮胎来试图控制偏航力矩的方法。 横摆力矩控制系统(DYC)是基于偏航角速率反馈进行控制的。在这种情况下,控制系统使车辆处于由司机转向输入和车辆速度控制的期望的偏航率[3,4]。然而为了确保稳定,防止特别是在低摩擦路面上的车辆侧滑角变得太大是必要的[1,2]。事实上由于非线性回旋力和轮胎滑移角之间的关系,转向角的变化几乎不改变偏航力矩。因此两个偏航率和侧滑角的实现需要一个有效的稳定控制系统[1,2]。不幸的是,能直接测量的侧滑角只能用特殊设备(光学传感器或GPS惯性传感器的组合),现在这种设备非常昂贵,不适合在普通汽车上实现。因此, 必须在实时测量的基础上进行侧滑角估计,具体是测量横向/纵向加速度、角速度、引导角度和车轮角速度来估计车辆速度。 在主要是基于状态观测器/卡尔曼滤波器(5、6)的文学资料里, 提出了几个侧滑角估计策略。因为国家观察员都基于一个参考车辆模型,他们只有准确已知模型参数的情况下,才可以提供一个令人满意的估计。根据这种观点,轮胎特性尤其关键取决于附着条件、温度、磨损等特点。 轮胎转弯刚度的提出就是为了克服这些困难,适应观察员能够提供一个同步估计的侧滑角和附着条件[7,8]。这种方法的弊端是一个更复杂的布局的估计量导致需要很高的计算工作量。 另一种方法可由代表神经网络由于其承受能力模型非线性系统,这样不需要一个参

底盘-10-麦弗逊式悬架的构造及拆装实训

底盘-10-麦弗逊式悬架的构造及拆装实训

汽修专业理实一体教案 课题项目七麦弗逊式悬架的结构、工作原理及拆装实训 教学目标一、知识目标 了解麦弗逊式悬架的工作原理原理二、技能目标 拆卸安装悬架 三、情感目标 培养团队合作能力 培养不怕脏不怕累的劳动精神 教学重点一、实训车间的行为规范 二、悬架及减震的工作原理 教学难点一、悬架的运动原理 二、规范的使用各种工具 教学准备一、转向系统实训台 二、拆装作业台 三、120件套工具箱 作业布置一、作业 二、实训报告 教学考核一、现场提问(30%) 二、现场实践操作(70%)

教学反思 教学内容或教学流程教法设计 一、课前三分钟 1.强调车间内不允许玩手机,督促班干部收缴手机 2.保持车间干净整洁,不准带入饮料零食等物 3.未经老师允许,不得擅自操作各个机械 4.检查教材、笔记本、笔 二、复习旧知与导入新课 1.复习旧知 底盘构成 2.导入新课 颠簸路面上,车辆如何减少震动,吸收能量? (1)弹簧延时,缓冲 (2)减震吸收能量 三、悬架的结构

『悬挂在汽车底盘安放位置的示意 图』 ●悬挂的概念和分类 首先让我们来了解一下什么 是悬挂:悬挂是汽车的车架与车桥或车轮之间的一切传力连接装置的总称,悬架的主要作用是传递作用在车轮和车身之间的一切力和力矩,比如支撑力、制动力和驱动力等,并且缓和由不平路面传给车身的冲击载荷、衰减由此引起的振动、保证乘员的舒适性、减小货物和车辆本身的动载荷。典型的汽车悬挂结构由弹性元件、减

震器以及导向机构等组成,这三部分分别起缓冲,减振和力的传递作用。绝大多数悬挂多具有螺旋弹簧和减振器结构,但不同类型的悬挂的导向机构差异却很大,这也是悬挂性能差异的核心构件。根据结构不同可分为非独立悬挂和独立悬挂两种。 『奥迪S4前后均采用了独立悬挂』 非独立悬挂由于是用一根杆件直接刚性地连接在两侧车轮上,一侧车轮受到的冲击、振动必然要影响另一侧车轮,这样自然不会得到较好的操纵稳定性及舒适性,同时由于左

外文文献翻译:汽车的发展

The development of automobile As the world energy crisis and the war and the energy consumption of oil -- and are full of energy in one day someday it will disappear without a trace. Oil is not inresources. So in oil consumption must be clean before finding a replacement. With the development of science and technology the progress of the society people invented the electric car. Electric cars will become the most ideal of transportation. In the development of world each aspect is fruitful especially with the automobile electronic technology and computer and rapid development of the information age. The electronic control technology in the car on a wide range of applications the application of the electronic device cars and electronic technology not only to improve and enhance the quality and the traditional automobile electrical performance but also improve the automobile fuel economy performance reliability and emission spurification. Widely used in automobile electronic products not only reduces the cost and reduce the complexity of the maintenance. From the fuel injection engine ignition devices air control and emission control and fault diagnosis to the body auxiliary devices are generally used in electronic control technology auto development mainly electromechanical integration. Widely used in automotive electronic control ignition system mainly electronic control fuel injection system electronic control ignition system electronic control automatic transmission electronic control ABS/ASR control system electronic control suspension system electronic control power steering system vehicle dynamic control system the airbag systems active belt system electronic control system and the automatic air-conditioning and GPS navigation system etc. With the system response the use function of quick car high reliability guarantees of engine power and reduce fuel consumption and emission regulations meet standards. The car is essential to modern traffic tools. And electric cars bring us infinite joy will give us the physical and mental relaxation. Take for example automatic transmission in road can not on the clutch can achieve automatic shift and engine flameout not so effective improve the driving convenience lighten the fatigue strength. Automatic transmission consists mainly of hydraulic torque converter gear transmission pump hydraulic control system electronic control system and oil cooling system etc. The electronic control of suspension is mainly used to cushion the impact of the body and the road to reduce vibration that car getting smooth-going and stability. When the vehicle in the car when the road uneven road can according to automatically adjust the height. When the car ratio of height low set to gas or oil cylinder filling or oil. If is opposite gas or diarrhea. To ensure and improve the level of driving cars driving stability. Variable force power steering system can significantly change the driver for the work efficiency and the state so widely used in electric cars. VDC to vehicle performance has important function it can according to the need of active braking to change the wheels of the car car motions of state and optimum control performance and increased automobile adhesion controlling and stability. Besides these appear beyond 4WS 4WD electric cars can greatly improve the performance of the value and ascending simultaneously. ABS braking distance is reduced and can keep turning skills effectively improve the stability of the directions simultaneously reduce tyre wear. The airbag appear in large programs protected the driver and passengers safety and greatly reduce automobile in collision of drivers and passengers in the buffer to protect the safety of life. Intelligent electronic technology in the bus to promote safe driving and that the other functions. The realization of automatic driving through various sensors. Except some smart cars equipped with multiple outside sensors can fully perception of information and traffic facilities

汽车悬架原理外文文献翻译

汽车悬架原理外文文献及翻译 (文档含中英文对照即英文原文和中文翻译) The rinciple Of Car Suspensions By William Harris University of Michigan When people think of automobile performance, they normally think of horsepower, torque and zero-to-60 acceleration. But all of the power generated by a piston engine is useless if the driver can't control the car. That's why automobile engineers turned their attention to the suspension system almost as soon as they had mastered the four-stroke internal combustion engine. The job of a car suspension is to maximize the friction between the tires and the road surface, to provide steering stability with good handling and to ensure the comfort of the passengers. In this article, we'll explore how car suspensions work, how they've evolved over the years and where the design of suspensions is headed in the future.

外文翻译---汽车车身总布置的方法

附录 Modern car’s design always stresses people-oriented, so safety, comfort, Environmental protection and energy saving have been the design theme And target in car design. Ergonomics layout design is not only relate to the effective use of internal space and improve car’s comfort and safety Performance, but it will also impact internal and external modeling results, and further affects the vehicle's overall performance and marketability.Soergonomics’application and research during car design and development process occupy an important position.After more than 50 years of construction and development, China’s Automobile industry has become the leading power of automobile production and consumption in the world. In particular, with the rise and rapid de velopment of independent brand’s vehicles, we pay more attention To the development processes and the technical requirements of hard Points’ layout. Through the three typical processes such as modern vehicle developing Process, body development process and using ergonomic to progress Inner auto-body layout, describe ergonomic layoationship between design, Aunt design in which stage of the process of vehicle development, the red The importance of working steps. The automobile body total arrangement is the automobile design most initial is also the most essential step, is other design stage premise and the foundation, to a great extent is deciding the body design success or failure. Picks generally in the actual design process With by forward and reverse two design method (1) to design (from inside to outside law) to design method namely "humanist", is coming based on the human body arrangement tool to define the pilot and the crew member gradually rides the space and the vehicle comes to pay tribute each article the arrangement, take satisfies the human body to ride with the driving comfortableness as the premise, said simply is determined first satisfies the human body to ride under the comfortable premise, carries on the indoor arrangement first, then carries on the complete bikes external styling design again. The concrete method and the step are as follows: ①Determine 5% and 95% manikin H position and the chair by the SAE recommendation's enjoyable line or the region law adjustment traveling schedule, seat

汽车保险中英文对照外文翻译文献

汽车保险中英文对照外文翻译文献(文档含英文原文和中文翻译)

汽车保险 汽车保险是在事故后保证自己的财产安全合同。尽管联邦法律没有强制要求,但是在大多数州(新罕布什和威斯康星州除外)都要求必须购买汽车保险;在各个州都有最低的保险要求。在鼻腔只购买汽车保险的两个州,如果没有足够的证据表明车主财力满足财务责任法的要求,那么他就必须买一份汽车保险。就算没有法律规定,买一份合适的汽车保险对司机避免惹上官和承担过多维修费用来说都是非常实用的。 依据美国保险咨询中心的资料显示,一份基本的保险单应由6个险种组成。这其中有些是有州法律规定,有些是可以选择的,具体如下: 1.身体伤害责任险 2.财产损失责任险 3.医疗险或个人伤害保护险 4.车辆碰撞险 5.综合损失险 6.无保险驾驶人或保额不足驾驶人险 责任保险 责任险的投保险额一般用三个数字表示。不如,你的保险经纪人说你的保险单责任限额是20/40/10,这就代表每个人的人身伤害责任险赔偿限额是2万美元,每起事故的热身上海责任险赔偿限额是4万美元,每起事故的财产损失责任险的赔偿限额是1万美元。 人身伤害和财产损失责任险是大多数汽车保险单的基础。要求汽车保险的每个州都强令必须投保财产损失责任险,佛罗里达是唯一要求汽车保险但不要求投保人身伤害责任险的州。如果由于你的过错造成了事故,你的责任险会承担人身伤害、财产损失和法律规定的其他费用。人身伤害责任险将赔偿医疗费和误工工资;财产损失责任险将支付车辆的维修及零件更换费用。财产损失责任险通常承担对其他车辆的维修费用,但是也可以对你的车撞坏的灯杆、护栏、建筑物等其他物品的损坏进行赔偿。另一方当事人也可以决定起诉你赔偿精神损失。

汽车外文翻译

As the world energy crisis, and the war and the energy consumption of oil -- and are full of energy, in one day, someday it will disappear without a trace. Oil is not in resources. So in oil consumption must be clean before finding a replacement. With the development of science and technology the progress of the society, people invented the electric car. Electric cars will become the most ideal of transportation. In the development of world each aspect is fruitful, especially with the automobile electronic technology and computer and rapid development of the information age. The electronic control technology in the car on a wide range of applications, the application of the electronic device, cars, and electronic technology not only to improve and enhance the quality and the traditional automobile electrical performance, but also improve the automobile fuel economy, performance, reliability and emissions purification. Widely used in automobile electronic products not only reduces the cost and reduce the complexity of the maintenance. From the fuel injection engine ignition devices, air control and emission control and fault diagnosis to the body auxiliary devices are generally used in electronic control technology, auto development mainly electromechanical integration. Widely used in automotive electronic control ignition system mainly electronic control fuel injection system, electronic control ignition system, electronic control automatic transmission, electronic control (ABS/ASR) control system, electronic control suspension system, electronic control power steering system, vehicle dynamic control system, the airbag systems, active belt system, electronic control system and the automatic air-conditioning and GPS navigation system etc. With the system response, the use function of quick car, high reliability, guarantees of engine power and reduce fuel consumption and emission regulations meet standards. The car is essential to modern traffic tools. And electric cars bring us infinite joy will give us the physical and mental relaxation. Take for example, automatic transmission in road, can not on the clutch, can achieve automatic shift and engine flameout, not so effective improve the driving convenience lighten the fatigue strength. Automatic transmission consists mainly of hydraulic torque converter, gear transmission, pump, hydraulic control system, electronic control system and oil cooling system, etc. The electronic control of suspension is mainly used to cushion the impact of the body and the road to reduce vibration that car getting smooth-going and

汽车变速器设计外文翻译

汽车变速器设计 ----------外文翻译 我们知道,汽车发动机在一定的转速下能够达到最好的状态,此时发出的功率比较大,燃油经济性也比较好。因此,我们希望发动机总是在最好的状态下工作。但是,汽车在使用的时候需要有不同的速度,这样就产生了矛盾。这个矛盾要通过变速器来解决。 汽车变速器的作用用一句话概括,就叫做变速变扭,即增速减扭或减速增扭。为什么减速可以增扭,而增速又要减扭呢?设发动机输出的功率不变,功率可以表示为 N = w T,其中w是转动的角速度,T是扭距。当N固定的时候,w与T是成反比的。所以增速必减扭,减速必增扭。汽车变速器齿轮传动就根据变速变扭的原理,分成各个档位对应不同的传动比,以适应不同的运行状况。 一般的手动变速器内设置输入轴、中间轴和输出轴,又称三轴式,另外还有倒档轴。三轴式是变速器的主体结构,输入轴的转速也就是发动机的转速,输出轴转速则是中间轴与输出轴之间不同齿轮啮合所产生的转速。不同的齿轮啮合就有不同的传动比,也就有了不同的转速。例如郑州日产ZN6481W2G型SUV车手动变速器,它的传动比分别是:1档3.704:1;2档2.202:1;3档1.414:1;4档1:1;5档(超速档)0.802:1。 当汽车启动司机选择1档时,拨叉将1/2档同步器向后接合1档齿轮并将它锁定输出轴上,动力经输入轴、中间轴和输出轴上的1档齿轮,1档齿轮带动输出轴,输出轴将动力传递到传动轴上(红色箭头)。典型1档变速齿轮传动比是3:1,也就是说输入轴转3圈,输出轴转1圈。 当汽车增速司机选择2档时,拨叉将1/2档同步器与1档分离后接合2档齿轮并锁定输出轴上,动力传递路线相似,所不同的是输出轴上的1档齿轮换成2档齿轮带动输出轴。典型2档变速齿轮传动比是2.2:1,输入轴转2.2圈,输出轴转1圈,比1档转速增加,扭矩降低。

麦弗逊式悬架的课程设计概要

前言: 悬架是汽车的车架与车桥或车轮之间的一切传力连接装置的总称,其作用是传递作用在车轮和车架之间的力和力扭,并且缓冲由不平路面传给车架或车身的冲击力,并衰减由此引起的震动,以保证汽车能平顺地行驶。典型的悬架结构由弹性元件、导向机构以及减震器等组成,个别结构则还有缓冲块、横向稳定杆等。弹性元件又有钢板弹簧、空气弹簧、螺旋弹簧以及扭杆弹簧等形式,而现代轿车悬架多采用螺旋弹簧和扭杆弹簧,个别高级轿车则使用空气弹簧。悬架是汽车中的一个重要总成,它把车架与车轮弹性地联系起来,因此悬架与车辆的行驶平顺性、操控稳定性具有极大的关系。悬架设计的好坏直接影响到整车的性能。因此开发出高品质的悬架是车辆工程师的一项重要任务。而悬架部分涉及的专业知识也比较高深,本文期望通过对悬架进行初级设计以达到对悬架有进一步了解的目 的。 关键词:悬架;减震器;弹簧计算 1

1悬架 1.1悬架的功用 汽车悬架是车架(或车身)与车轴(或车轮)之间的弹性联结装置的统称。它的作用是弹性地连接车桥和车架(或车身),缓和行驶中车辆受到的冲击力;保证货物完好和人员舒适;衰减由于弹性系统引进的振动,使汽车行驶中保持稳定的姿势,改善操纵稳定性;同时悬架系统承担着传递垂直反力,纵向反力(牵引力和制动力)和侧向反力以及这些力所造成的力矩作用到车架(或车身)上,以保证汽车行驶平顺;并且当车轮相对车架跳动时,特别在转向时,车轮运动轨迹要符合一定的要求,因此悬架还起使车轮按一定轨迹相对车身跳动的导向作用。 1.2 悬架的组成 一般悬架由弹性元件、导向机构、减振器和横向稳定杆组成。 1.弹性元件 弹性元件用来承受并传递垂直载荷,缓和由于路面不平引起的对车身的冲击。弹性元件种类包括钢板弹簧、螺旋弹簧、扭杆弹簧、油气弹簧、空气弹簧和橡胶弹簧等,这里我们选用螺旋弹簧。 2.减振器 减振器用来衰减由于弹性系统引起的振动,减振器的类型有筒式减振器,阻力可调式新式减振器,充气式减振器。 3.导向机构 导向机构用来传递车轮与车身间的力和力矩,同时保持车轮按一定运动轨迹相对车身跳动,通常导向机构由控制摆臂式杆件组成。种类有单杆式或多连杆式的。钢板弹簧作为弹性元件时,可不另设导向机构,它本身兼起导向作用。有些轿车和客车上,为防止车身在转向等情况下发生过大的横向倾斜,在悬架系统中加设横向稳定杆,目的是提高横向刚度,使汽车具有不足转向特性,改善汽车的操纵稳定性和行驶平顺性。

外文翻译---汽车悬架系统概述

附录Ⅰ:外文资料 Automotive Suspension System Overview The impact of the Vehicle in many aspects, Suspension plays a very important role . The components of the suspension system perform six basic functions: 1.Maintain correct vehicle ride height. 2.Reduce the effect of shock forces. 3.Maintain correct wheel alignment. 4.Support vehicle weight. 5.Keep the tires in contact with the road. 6.Control the vehicle’s direction of travel. Most suspension systems have the same basic parts and operate basically in the same way. They differ, however, in the way the parts are arranged. The vehicle wheel is attached to a steering knuckle. The steering knuckle is attached to the vehicle frame by two control arms, which are mounted so they can pivot up and down. A coil spring is mounted between the lower control arm and the frame. When the wheel rolls over a bump, the control arms move up and compress the spring. When the wheel rolls into a dip, the control arms move down and the springs expand. The spring force brings the control arms and the wheel back into the normal position as soon as the wheel is on flat pavement. The idea is to allow the wheel to move up and down while the frame, body, and passengers stay smooth and level. The unequal length control arm or short, long arm (SLA) suspension system has been common on American vehicles for many years. Because each wheel is independently connected to the frame by a steering knuckle, ball joint assemblies, and upper and lower control arms, the system is often described as an independent suspension. The short, long arm suspension system gets its name from the use of two control arms from the frame to the steering knuckle and wheel assembly. The two control arms are of unequal length with a long control arm on the bottom and a short control arm on the top. The control arms are sometimes called A arms because in the top view they are shaped like the letter A. In the short, long arm suspension system, the upper control arm is attached to a cross shaft through two combination rubber and metal bushings. The cross shaft, in turn, is bolted to the frame. A ball joint, called the upper ball joint, is attached to the outer end of the upper arm and connects to the steering knuckle through a tapered stud held in position with a nut. The inner ends of the lower control arm have pressed-in

汽车制动系统(机械、车辆工程毕业论文英文文献及翻译)

Automobile Brake System汽车制动系统 The braking system is the most important system in cars. If the brakes fail, the result can be disastrous. Brakes are actually energy conversion devices, which convert the kinetic energy (momentum) of the vehicle into thermal energy (heat).When stepping on the brakes, the driver commands a stopping force ten times as powerful as the force that puts the car in motion. The braking system can exert thousands of pounds of pressure on each of the four brakes. Two complete independent braking systems are used on the car. They are the service brake and the parking brake. The service brake acts to slow, stop, or hold the vehicle during normal driving. They are foot-operated by the driver depressing and releasing the brake pedal. The primary purpose of the brake is to hold the vehicle stationary while it is unattended. The parking brake is mechanically operated by when a separate parking brake foot pedal or hand lever is set. The brake system is composed of the following basic components: the “master cylinder” which is located under the hood, and is directly connected to the brake pedal, converts driver foot’s mechanical pressure into hydraulic pressure. Steel “brake lines” and flexible “brake hoses” connect the master cylinder to the “slave cylinders” located at each wheel. Brake fluid, specially designed to work in extreme conditions, fills the system. “Shoes” and “pads” are pushed by the slave cylinders to contact the “drums” and “rotors” thus causing drag, which (hopefully) slows the c ar. The typical brake system consists of disk brakes in front and either disk or drum brakes in the rear connected by a system of tubes and hoses that link the brake at each wheel to the master cylinder (Figure). Basically, all car brakes are friction brakes. When the driver applies the brake, the control device forces brake shoes, or pads, against the rotating brake drum or disks at wheel. Friction between the shoes or pads and the drums or disks then slows or stops the wheel so that the car is braked.