电气工程施工方案中英文

电气工程 Electric Works

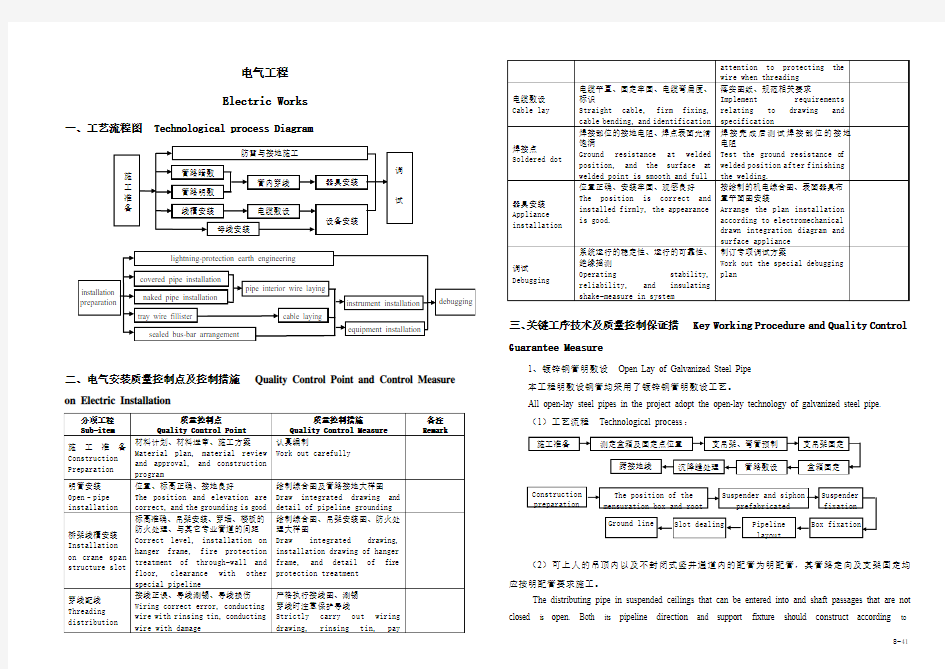

一、工艺流程图 Technological process Diagram

二、电气安装质量控制点及控制措施 Quality Control Point and Control Measure on Electric Installation

三、关键工序技术及质量控制保证措 Key Working Procedure and Quality Control Guarantee Measure

1、镀锌钢管明敷设

Open Lay of Galvanized Steel Pipe 本工程明敷设钢管均采用了镀锌钢管明敷设工艺。

All open-lay steel pipes in the project adopt the open-lay technology of galvanized steel pipe.

(1)工艺流程 Technological process :

(2)可上人的吊顶内以及不封闭式竖井通道内的配管为明配管,其管路走向及支架固定均应按明配管要求施工。

The distributing pipe in suspended ceilings that can be entered into and shaft passages that are not closed is open. Both its pipeline direction and support fixture should construct according to

requirements of open distributing pipes.

(3)按设计要求用冷煨法把管子煨出所需的弯度,20mm以下管径的管子用手板煨管器,25mm以上管径用液压煨管器(或专用煨管器),煨弯处凹扁度应符合规范规定。

Use the simmering method to simmer pipes with a necessary bend according to design requirements. Pipes that the pipe diameter is less than 20mm may adopt a palm simmer pipe machine. Pipes that the pipe diameter is more than 25mm may use a hydraulic simmer pipe machine (or special simmer pipe machine). The concavity at simmering bends should accord with specifications and regulations.

(4)断管采用钢锯或无齿锯,需断切的管子尺寸准确,将管子置于压力钳口中心卡紧,断口平齐。断口处用锉将管口内外锉光,无毛刺,管内铁屑清除干净。

Broken pipes adopt a hacksaw or a saw without teeth. The size of pipe needing to cut should be exact. Put pipes on the center of pressure jaw, and keep fractures even. At fracture, fill the inner or outer of pipe orifice smoothly without any burr. The scrap iron in pipe should be cleaned clearly.

(5)管子套丝采用套丝机,根据管子外径及扣距选用相应板牙,将管子用台虎钳或龙门压架钳紧牢固,再把绞板套在管端,均匀用力,不得过猛,随套随浇冷却液。丝扣不乱且干净清晰,管箍上好后,管口应对严,外露丝扣不应过长。(外露丝扣不得超过3扣)

The mantle fiber of pipe may adopt a mental fiber machine. Select corresponding dies according to the outer diameter and of pipe the pitch. Clamp the pipes firmly by using a vice or planer pressing pliers. Then cover the capstan on pipe ends. Exert evenly not too strongly, and pour the cooling fluid on it while covering. The clasp is not in disorder and cleaned clearly. After pipes are hoped well, pipe orifices should be aimed at accurately. And the exposed clasp should not be too long.

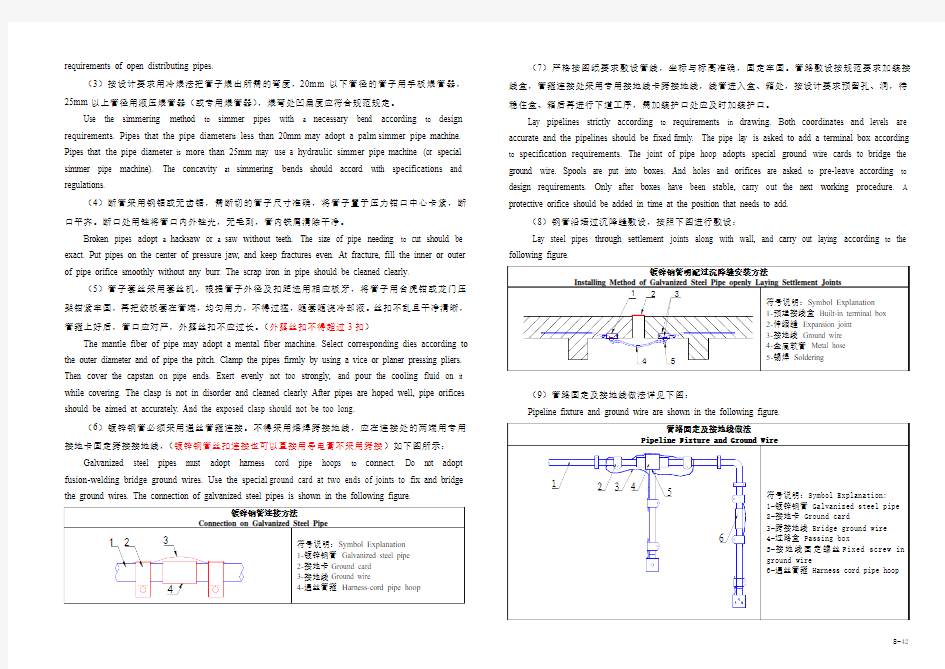

(6)镀锌钢管必须采用通丝管箍连接。不得采用熔焊跨接地线,应在连接处的两端用专用接地卡固定跨接接地线,(镀锌钢管丝扣连接也可以直接用导电膏不采用跨接)如下图所示:Galvanized steel pipes must adopt harness cord pipe hoops to connect. Do not adopt fusion-welding bridge ground wires. Use the special ground card at two ends of joints to fix and bridge the ground wires. The connection of galvanized steel pipes is shown in the following figure.

(7)严格按图纸要求敷设管线,坐标与标高准确,固定牢固。管路敷设按规范要求加装接线盒,管箍连接处采用专用接地线卡跨接地线,线管进入盒、箱处,按设计要求预留孔、洞,待稳住盒、箱后再进行下道工序,需加装护口处应及时加装护口。

Lay pipelines strictly according to requirements in drawing. Both coordinates and levels are accurate and the pipelines should be fixed firmly. The pipe lay is asked to add a terminal box according to specification requirements. The joint of pipe hoop adopts special ground wire cards to bridge the ground wire. Spools are put into boxes. And holes and orifices are asked to pre-leave according to design requirements. Only after boxes have been stable, carry out the next working procedure. A protective orifice should be added in time at the position that needs to add.

(8)钢管沿墙过沉降缝敷设,按照下图进行敷设:

Lay steel pipes through settlement joints along with wall, and carry out laying according to the following figure.

(9)管路固定及接地线做法详见下图:

Pipeline fixture and ground wire are shown in the following figure.

(10)管路过梁做法详见下图 The pipeline astillen is shown as in the following figure :

2、管内穿线 In-pipe Threading (1)工艺流程 Technological Process :

(2)选择导线 Select Conducting Wires : 1)根据设计要求选择导线规格及型号。

Select the specification and model of conducting wire according to design requirements. 2)绝缘层抽检:按制造标准,现场抽样检测绝缘层厚度和圆形线芯的直径,线芯直径误差不大于标称直径的1%;常用的BV 型绝缘电线的绝缘层厚度不小于下表规定。

Sampling check on insulating layer: sample to check the thickness of insulating layer and the diameter of round wire core at the spot according to manufacturing standards. The error of wire core should not be more than 1% of the equivalent diameter. The thickness of insulating layer in normal BV insulated wires should not be less than the regulations in the following table.

(3)穿带线:穿带线也是检查管路是否畅通,管路的走向及盒、箱的位置是否符合设计及施工图的要求。

Strip: the strip is also one of requirements to check whether the pipeline is dredged as while as the direction of pipeline and the position of box accord with designs and construction drawings.

(4)清扫管路 Pipeline Cleaning :

1)清扫管路的目的是清除管路中的灰尘、泥水等杂物。

The aim of pipeline cleaning is to eliminate messes such as dust and sediment.

2)清扫管路的方法:将布条的两端牢固地绑扎在带线上,两人来回拉动带线,将管内杂物清净。

The method of pipeline cleaning is as following: bind the two ends of cloth on a strip line, two personnel pull the strip line back and forth and clean the mess in pipe.

(5)放线与断线 Paying-off and Wire Breakage :

1)放线:放线时导线应置于放线架或放线车上。

Paying-off: When paying off, the conductive wire should be placed on paying-off supports or

vehicles.

2)断线:剪断导线时,导线的预留长度应按以下四种情况考虑:

Wire breakage: When cut off, the pre-left length of conductive wire should be considered according to four situations as following.

A 、接线盒、开关盒及灯头盒内导线的预留长度应为15cm 。

The pre-left length of conductive wire in terminal box, switch box, and lamp-holder box should be 15cm.

B 、配电箱内导线的预留长度应为配电箱体周长的1/2。

The pre-left length of conducting wire in distribution box should be 1/2 circumference of distribution box.

C 、出户导线的预留长度应为1.5m 。

The pre-left length of output conducting wire should be 1.5m. D 、共用导线在分支处,可不剪断导线而直接穿过。

At the branch of common conducting wires, the conducting wire may not be cut off to pass through directly.

(6)管内穿线 Threading in Pipe :

1)钢管(电线管)在穿线前,应首先检查各个管口的护口是否齐整,如有遗漏或破损,均应补

齐更换。

Before threading the steel pipe (wire pipe), firstly check whether shields at every pipe orifice are in

good order. If there is some leakage or damage, all of them should be supplemented and replaced.

2)当管路较长或转弯较多时,要在穿线的同时往管内吹入适量的滑石粉。

If the pipeline is longer or there are more swerves, inbreathe some suitable talc in the pipe while threading.

3)两人穿线时,应配合协调,一拉一送。

When threading, both personnel should coordinate harmoniously, one pulls and the other releases.

(7)导线连接Wire Connection:

1)单芯线并接头:导线并齐合拢。在距约12mm处用其中一根线芯在连接端缠绕5-7圈后剪断,把余头并齐折回压在缠绕线上进行涮锡处理。

Single core with parallel joint: conducting wires are combined and gathered up. At 12mm to it, use a wire core winding 5~7 circles at the joint and then cut off. Combine the rest and fold them at the wind wire to carry out the treatment of rinsing tin.

2)不同直径导线接头:如果是独根(导线截面小于2.5mm2)或多芯软线时,则应先进行涮锡处理。再将细线在粗线上距离绝缘层15mm处交叉,并将线端部向粗导线(独根)端缠绕5-7圈,将粗导线端折回压在细线上,最后再做涮锡处理。

Wire joints with different diameter: if a single cord (the cross section of wire is less than 2.5mm2) or a multiple cord, firstly carry out the treatment of rinsing tin. Then, cross the filament at the heavy gauge wire at 15mm away from the insulating layer, and wind the end of wire towards the end of heavy gauge wire (single) for 5~7 circles , fold the end of heavy gauge wire back to press on the filament, and finally do the treatment of rinsing tin.

(8)导线包扎Binding up Conducting Wire:

首先用橡胶(或粘塑料)绝缘带从导线接头处始端的完好绝缘层开始,在包扎过程中应尽可能的收紧绝缘带。采用橡胶绝缘带包扎时,应将其拉长2倍后再进行缠绕。然后再用黑胶布包扎,导线接头处两端应用黑胶布封严密。

Firstly, use a rubber (or viscous plastic) insulated tape to begin from the intact insulating layer at the beginning of wire joint. In the binding process, frap the insulated tape as soon as possible. When adopting a rubber insulated tape to bind, carry out binding after drawing it more than 2 times, and then bind with a black rubberized fabric. The two ends of wire joint should be sealed closely with the black rubberized fabric.

(9)线路检查及绝缘摇测

Line Check and Insulating Shake-measure:

1)线路检查:检查导线接、焊、包是否符合施工验收规范及质量验评标准的规定。不符合规定时应立即纠正,检查无误后再进行绝缘摇测。

Line check: Check whether the connection, weld, or wrap on conducting wire meet with the specification of construction acceptance and the regulation of quality check standard. If not meet with regulations, rectify them immediately. Carry out the insulating shake-measure again after checking without any error.

2)绝缘摇测:线路的绝缘摇测一般选用500V、量程为0-500MΩ的兆欧表。

Insulating shake-measure: The insulating shake-measure of line may select a 500V megohmmeter that the measurement range is 0~500MΩ.

3)一般线路绝缘摇测有以下两种情况:

There are two situations as followings for normal line insulating shake-measure.

A、电气器具未安装前进行线路绝缘摇测时,首先将灯头盒内导线分开,开关盒内导线连通。摇测应将干线和支线分开,一人摇测,一人应及时读数并记录。摇动速度应保持在120r/min左右,读数应采用lmin后的读数为宜。

When carrying out a line insulating shake-measure before not installing electric appliance, separate conducting wires in lamp holder box firstly, the conducting wires in switch box are connected. When a shake-measure, separate the main line with the branch line. One is to make a shake-measure, and the other should read and record readings in time. The shake speed should be kept about 120r/min, and the reading is suitable to adopt that of 1 minute later.

B、电气器具全部安装完在送电前进行摇测,应先将线路上的开关刀闸、仪表、设备等用电开关全部置于断开位置,摇测方法同上所述,确认绝缘摇测无误后再进行送电试运行。

Carry out shake-measure before transmitting power supply after all electric appliances have been installed completely, firstly put all electric switches such as knife switches, instruments, and equipments in circuit at the position of switch off. The method of shake-measure is same as the above. Carry out the test run of transmitting power supply again after confirming there is no error with insulating shake-measure.

3、桥架线槽安装Installing Bridge and Raceway:

本工程配电干线采用电缆桥架线槽明敷于吊顶、机房、配电竖井内,具体的施工流程和控制节点如下:

The main line for distribution in the project adopts the cable crane span structure slot laying openly on suspended ceilings, generator rooms, or distribution shafts. The specific construction flow and control node are as followings.

(1)工艺流程Technological Process:

(2)外观检查:部件齐全,表面光滑、无棱刺、不变形;厚度均匀、涂层完整,无锈蚀;

Appearance check: parts are all complete, smooth surface without any edge or deformation. The thickness is even, complete coating without any rust.

(3)桥架支吊架安装Installation of Crane-span-structure Support and Hanger Frame:

1)水平桥架吊装采用圆钢作吊杆,角钢作横担,砼结构上安装吊架采用膨胀螺栓在顶板上固定。

The hoisting of horizontal crane span structure adopt a round bar steel as a boom while an angle steel as a cross arm. The hanger frame installed on concrete structure may adopt an expansion bolt to fix on the roof.

2)竖向桥架支架采用型钢制作,固定件应与桥架配套。支架固定在墙体或楼板上,采用膨胀螺栓固定。

The vertical support of crane span structure adopts a structural steel to make, and the fixed fitting should be equipped with a crane span structure. The support is fixed on a wall or floor, and adopts an expansion bolt to fix.

3)电缆桥架吊装吊杆间距:水平距离为2m,垂直方向为1.5m。各支架同层横担应在同一水平面上,其高低偏差小于±5mm。桥架支撑点躲开接头处,距接头处0.5m为宜,在桥架拐弯和分支处,距分支点0.5m加支持点;支吊架距上层楼板不应小于150-200mm,距地面高度不应低于100-150mm;

The interval on hoisting boom of cable crane span structure is shown as following: the horizontal distance is 2m, the vertical is 1.5m. The cross arm at same layer in every support should be at a same level, and its high-low error is less than ±5mm. The support point of crane span structure is away from the joint and it is suitable for the distance being 0.5m to the joint. At the turning or branch of crane span structure, and there is an added support point at 0.5m to the branch point. The distance from support and hanger frame to upper floor should not be less than 150~200mm, the distance to the ground level should not be less than 100~150m.

(4)金属电缆桥架、线槽及其支架和引入或引出的金属电缆导管接地(PE)必须符合下列规定:

The ground (PE) of metal cable crane span structure, slot, and its leading-in or leading-out of metal cable guide tube must meet with following regulations.

1)金属电缆桥架线槽及其支架全长应不少于2处与接地(PE)干线相连接;

The metal cable crane span structure slot and its whole length of support should not be less than 2 sections to connect with the main line of ground (PE).

2)镀锌电缆桥架、线槽间连接板的两端不跨接接地线,但连接板两端必须有不少于2个有防松螺帽或防松垫圈的连接固定螺栓;

The two ends of junction plate between galvanized cable crane span structure and slot does not bridge with the ground wire, but there must be two jam nuts or fixed connecting bolts of lock washer at least.

3)非镀锌电缆桥架间连接板的两端跨接铜芯接地线,接地线最小允许截面积不小于4mm2;

The two ends of junction plate between non-galvanized cable crane span structures bridge the ground wires of copper cores. The minimum allowable cross section of ground wire should not be less than 4 mm2.

(5)桥架安装Bridge Installation:

1)直线段钢制电缆桥架长度超过30米应设伸缩节;跨越变形缝处设置补偿装置,线槽本身应断开,槽内用内连接板搭接,不许固定,保护地线和槽内导线均应留有补偿余量;过沉降缝安装如下图:

When the length of steel cable crane span structure in the straight line section is more than 30 meters, an expansion joint should be set up. At the crossing deformation seam, a compensation system should be set up, and the slot itself should be broken. In the slot, a junction plate may be used to join and not fixed. Both protective ground wire and conducting wire in slot should have some compensation allowances. The installation of over-settlement joint is shown as in the following figure.

2)电缆桥架转弯处的弯曲半径,不小于桥架内电缆最小允许弯曲半径,电缆最小允许弯曲半径见下表:

The bend radius at the turning of cable crane span structure should not be less than the minimum allowable bend radius of cable in crane span structure. The minimum allowable bend radius of cable is shown in the following table.

3)桥架通过连接板使用方颈螺栓进行连接,螺母位于桥架外侧;桥架线槽与盒、箱、柜等接茬处,进线和出线口均采用抱脚连接,用螺丝紧固,末端加封堵。

The crane span structure is connected with a square neck bolt through a junction plate. The nut is located at outside of crane span structure. The crane span structure slot adopts the band-type connection with joints, inlets, and outlets of box, case, and cabinet. It uses a screw to tight, and the ends should be blocked.

4)竖向线槽桥架与支架应牢固连接,每2m 固定一次。支架与楼板及墙体采用膨胀螺栓固定,

线槽桥架与支架之间采用方颈螺栓固定,螺栓的圆头在梯架的内侧,竖向桥架安装见下图:

The vertical slot crane span structure should be fixed to connect with the support fixing one time per 2 meters. The support adopts an expansion bolt to fix the connection with floor and wall. The connection between slot crane span structure and support may adopt a square neck bolt to fix. The round-nose of bolt is inside of ladder-support. The installation of vertical crane span structure is shown in the following figure.

5)敷设在竖井内和穿越不同防火分区的桥架,按设计要求位置,有防火隔堵措施;桥架在穿过防火墙及防火楼板时,采取防火隔离措施,防止火灾沿线路延燃,做法参看如下附图所示:

The crane span structure that is laid in shafts and through different fire protection subsections

should have some fire protection & insulating measures according to positions in design requirement. When through fire wall and fire floor, the crane span structure may adopt the fire insulating measure to prevent the fire continue to burn along the line. The method may refer to the attached figure as following.

(6)在同一线槽(包括绝缘在内)的导线截面积总和应该不超过内部截面积的40%。

The sum of wire section area in the same slot (including the insulating layer) should not be more than 40% of inner section area.

4、电缆敷设Cable Layout:

(1)工艺流程Technological Process:

(2)外观检查:电缆无压扁、扭曲,铠装不松卷。耐热、阻燃的电缆外护层有明显标识和制造厂标。

Appearance check: cables have no press flat or twist, and armours do not loose and crimp. The outside protective layer of heat resistant and fire resistant should have an obvious symbol and a manufacturer trademark.

(3)电缆敷设前进行绝缘摇测Carry out insulating shake measures before laying cables:(4)电缆穿楼板时应装套管,敷设完后应将套管用防火材料堵死,并做好封闭措施,防止水从套管内流入下层房间内;电缆穿楼板作法如下图所示:

Install a sleeve when crossing cables through floors. Block the sleeve with fire resistant materials after finish laying and arrange the close measure so as to avoid water flow from the sleeve into the sub-story room. The method that cables cross through floors is shown as in the following figure.

(5)电缆沿桥架或托盘敷设时,应单层敷设,排列整齐。不得有交叉,拐弯处应以最大截面电缆允许弯曲半径为准。在同一线槽(包括绝缘在内)的电缆截面积总和应该不超过内部截面积的40%。敷设时,应放一根立即卡固一根,常用卡固件有电缆卡带、电缆卡子,如下图所示:When laid along with a crane span structure or a tray, the cable should be laid with a single layer and put in order. There is no any cross, and the allowable bend radius of maximum section area cable at the corner of turning should be the standard. In the same slot (including insulations), the sum of cable section area should not be more than 40% of inner section area. When laying, put one and clasp one firmly. The normal clasps have a cable cassette and a cable clasp shown in the following figure.

(6)电缆穿过建筑沉降缝处,需要预留适当长度,预留长度须使伸缩缝移动时电缆不承受任何外力。

When passing through a settlement joint of building, the cable needs to be pre-left with proper length. The pre-left length must make the cable cannot endure any external force when moving the cable.

(7)电缆进出配电箱(柜)处以及管子管口处要做密封处理。

Both the distribution box (cabinet) that cables come in or goes out and the pipe orifice should be treated with seal.

(8)挂标志牌Hanging Labels:

1)标志牌规格应一致,并有防腐性能,挂装应牢固。

The specification of label should be consistent, and the label should have antisepsis performance and be hung firmly.

2)标志牌上应注明电缆编号、规格、型号及电压等级。

The label should note with serial number, specification, and model of cable as while as voltage level.

3)沿桥架敷设电缆,在其两端、拐弯处、交叉处应挂标志牌,直线段应适当增设标志牌。

Lay cables along the crane span structure. Hang the label at its two ends, turning, and cross. The label should be set up in addition properly at the section of straight line.

(9)电缆交接试验合格且对接线去向、相位和防火隔阻措施等检查确认才能通电。

Electrify only till the test of cable join is qualified and all such as connection direction, phase, and fire protection measure are checked and confirmed.

5、配电箱、柜安装Installation on Distribution Box and Cabinet:

本工程配电箱分为照明配电箱、动力配电箱、控制柜等几种类型。

The distribution box in the project may be divided into several types such as lighting distribution box, power distribution box, and control cabinet.

(1)配电箱安装工艺流程Technology Process on Installing Distribution Box:

(2)配电箱、柜安装Installing distribution box or cabinet:

1)配电箱挂墙明装Open Installation on Distribution Box Hanging on Wall:

配电箱挂墙明装时应保证安装位置正确,部件齐全,箱体开孔与导管管径适配。配电箱的所有进出电线导管及开孔处须有保护措施,以防止损坏电线电缆。配电箱采用膨胀螺栓在墙上固定。砼结构剪力墙明装配电箱见下图:

When installing openly the distribution box on wall, be sure to guarantee the installation position is correct. Parts are complete, and the open pore of box should be suit to the pipe diameter of guide tube. All guide tubes and open pores of wires in distribution box must have protective measures to prevent damaging the wire cable. The distribution box adopts expansion bolts to fix on a wall. The open distribution box on a shear wall of concrete structure is shown in the following figure.

2)落地柜安装Installation on Console:

动力控制箱出线回路较多,重量大,为了保证配电箱安装牢固,采用落地安装的配电柜。落地配电柜安装用槽钢做支架固定,落地柜在基础型钢上安装,基础型钢在安装找平过程中,需用

垫片的地方,最多不能超过三片;最终基础型钢顶部宜高出抹平地面10mm;基础型钢安装,其允许偏差必须符合下表:

The number of output loop in power control box is more, and the weight is large. To ensure installing the distribution box firmly, adopt a floor type of distribution cabinet. When installing the floor type of distribution cabinet, use a U-steel to fix the support. The console is installed in a piece of base steel. When the base steel needs some shims in the process of installation and make-level, the maximum number should not be more than 3. The top of base steel is suitable to be higher 10mm than the even ground. The allowable deviation of base steel must accord with the following table.

盘柜单独或成列安装时,其垂直度、水平度以及盘柜面平度和盘、柜间接缝的允许偏差必须符合下表要求。

When installed individually or in low, the verticality and levelness of disk cabinet and the allowable deviation between the levelness of disk cabinet and the seal between disk and cabinet must accord with following requirements.

(3)配电箱(柜)内接线Wiring in Distribution Box:

1)箱内配线整齐,绑扎成束,无绞接现象,在活动部位应用长钉固定,盘面引出及引进导线应留有适当余度,以利于检修;回路编号齐全,标识正确。导线连接紧密,不伤芯线,不断股。垫圈下螺丝两侧压的导线截面积相同,同一端子上导线连接不多于2根,防松垫圈等零件齐全。

The distribution in box is in order, and bound into bundle without any hinge joint. At flexible parts, use spikes to fix. The conducting wire led in/out of disks should leave proper clearances so as to be convenient to examine and repair. The serial number of loop is complete and the symbol is correct. The wire connects compactly not to damage cores without any break one. The wire section area at two sides of screws under washers is same. The number of wire connection at the same terminal should not be more than 2, and the parts such as lock washer are complete.

2)照明箱内,分别设置零线(N)和保护地线(PE)汇流排,零线和保护地线经汇流排配出。

In a lighting box, a null line (N) and a protective earth line (PE) should be set up separately into a bus bar. The null line and the protective earth line may be transmitted through the bus bar.

(4)绝缘摇测Insulating Shake Measure:

电箱全部安装完毕后,用1kV兆欧表对线路进行绝缘摇测。摇测项目包括相线与相线之间、相线与零线之间、相线与地线之间、零线与地线之间。

After finishing all distribution boxes, carry out an insulating shake measure on the circuit with a 1kV megohmmeter. The item of shake measure includes between phase line and phase line, phase line and null line, phase line and earth line, and null line and earth line.

6、电气器具安装

Installation on Electric Appliance:

本工程末端电气器具安装主要包括灯具、开关及插座的安装。

The installation of electric appliance at the end of the project mainly includes installing lamps, switches, and sockets.

(1)工艺流程Technological Process:

1)开关插座安装工艺流程:

Technological process for installing switch sockets

2)灯具安装工艺流程:

Technological process for installing lamps

(2)灯具安装基本要求Basic Requirement on Installing Lamps:

穿入灯具的导线在分支连接处不得承受额外应力和磨损,多股软线的端头需盘圈、涮锡;灯具内的导线不应过于靠近热光源,并应采取隔热措施当灯具距地面高度小于2.4m时,灯具的可接近裸露导体必须使用专用接地螺栓接地并有明显标识。

The conducting wire through lamps must not endure additional stresses and wears at the joint of branch. The terminals of multiple flexible cords need windings and rinsing tins. The conducting wire in lamp should not near light sources too much and adopt some heat-insulating measures. When the distance from lamps to the ground level is less than 2.4m, the exposed conductor that lamps may near must use the special grounding bolt to ground and have obvious marks.

(3)灯具安装

Installation on Lamps:

1)嵌入式灯具安装Installation on embedded lamp:

本工程办公区使用嵌入式荧光灯,嵌入式安装的荧光灯用Ф9的圆钢做灯具的吊杆,嵌入式荧光灯安装见下图:

The office area in the project uses embedded fluorescent lamps. The embedded fluorescent lamp that is installed uses Ф9round bar steel as a boom of lamp. The installation on embedded fluorescent lamp is shown as in the following figure.

本工程F01大堂区域使用嵌入式筒灯,嵌入式筒灯用筒灯的卡具在装饰龙骨上固定,如果筒灯的重量超过1.5kG,则需用Ф6圆钢吊杆固定筒灯,镇流器与灯具的本体分开的筒灯,镇流器需要单独固定,嵌入式筒灯安装见下图:

F01 hall in the project uses embedded trunk lamps. The embedded trunk lamps use the clamping apparatus of trunk lamp to fix on decorative keels. They need Ф6round bar steel boom to fix trunk

lamps if the weight of trunk lamp is more than 1.5KG . To trunk lamps that the ballast resistor is separated with the body of lamp, the ballast resistor needs to be fixed individually. The installation of embedded trunk lamps is shown as in the following figure.

2)壁灯安装 Installation on Wall Lamp:

墙内嵌入式安装的灯具,在结构施工阶段预留灯具孔洞,装饰施工阶段安装灯具,安全出口

指示灯安装见下图:

To the lamp installed and embedded in wall, pre-leave holes for lamps in the phase of structure construction. Install lamps at the phase of decoration and construction. The installation of indicator at safety outlet is shown in the following figure.

(4)开关、插座安装基本要求:

Basic Requirements on Installation of Switch and Socket

1)开关、插座的面板及接线盒盒体完整、无碎裂、零件齐全。

The panel of switch and socket and the body of terminal box are integrated without any break and all parts are complete.

2)暗装的开关、插座面板应紧贴墙面,四周无缝隙,安装牢固,表面光滑整洁、无碎裂、

划伤,装饰帽齐全。

The hidden switch and socket panel should be close to the wall compactly without any seam around. They are installed firmly and the surface is smooth and neat without any crack or scrape. The decorative nuts are complete.

3)开关位置应与灯位相对应,同一单元内开关方向应一致;开关边缘至门框边缘的距离为150-200mm ;不得置于单扇门后。

The position of switch should correspond to that of lamp. The direction of switch in the same unit should be consistent. The distance from the edge of switch to that of doorframe is about 150~200 mm. They should not be put at the back of single door.

4)在卫生间、大堂等墙面上贴石材瓷砖的地方,开关、插座的面板布置在瓷砖的几何中心,并紧贴墙面,安装端正,参见下图:

At the place stuck with stone ceramic tile on the wall in toilet and hall, the panel of switch and socket should be arranged at the geometrical center and stuck to the wall closely as while as installed correctly. It may refer to the following figure.

5)相同型号并列安装及同一室内开关安装高度一致,且控制有序不错位。暗装插座距地面要符合图纸要求;同一室内安装的插座安装高度一致。

The same model should be installed in parallel. The installing height of switch at the same room should be consistent and controlled in order without any dislocation. The distance of hidden socket to the surface should accord with requirements in drawings. The installing height of sockets at the same room should be consistent.

(5)开关、插座安装

Installation on Switch and Socket :

1)开关、插座接线:同一建筑物内的开关的通断位置一致,操作灵活、接触可靠,灯具的相线应经开关控制;单相两孔插座,面对插座的右孔或上孔与相线连接,左孔或下孔与零线连接;单相三孔插座,面对插座的右孔与相线连接,左孔与零线连接;单相三孔、三相四孔及三相五孔插座的接地或接零线接在上孔;插座的接地端子不与零线端子连接;同一场所的三相插座,接线的相序应一致。

Wiring on switch and socket: The on-off positions of switches in the same building should be consistent. They operate flexibly and touch reliably. The phase line of lamp should be controlled through switches. To socket with single-phase-two-hole, the right or upper hole facing to socket is connected with the phase line, and the right or lower hole is connected with the null line. To socket with single-phase-three-hole, the right hole facing to socket is connected with the phase line, and the left hole is connected with the null line. To socket with single-phase-three-hole, three-phase-four-hole, or three-phase-five-hole, the ground line or null line is connected with the upper hole. The grounding terminal of socket is not connected with that of null line. To three-phase socket at the same spot, the phase sequence of wiring should be consistent.

2)暗装开关、插座:先用錾子轻轻地将盒子内杂物清出盒外,将盒内清理干净,然后按接线要求,将盒内甩出的导线与开关、插座的面板连接好,将开关或插座推入盒内(如果盒子较深,大于 2.5cm时,应加装套盒),对正盒眼,用机螺丝固定牢固。固定时要使面板端正,并与墙面平齐。

Hidden switch and socket: firstly, use a cold chisel clean out the mess in box lightly. Clean the box, and connect the conducting wire out of box with the panel of switch and socket. Push the switch or socket into box (if the box is deeper more than 2.5cm, add a sleeve box). Aim at the hole of box, and use screws to fix firmly. When fixing, correct the panel and make it level with wall space.

3)明装开关、插座:先将从盒内甩出的导线由绝缘台的出线孔中穿出,再将绝缘台紧贴于墙面用螺丝固定在盒子或砖上,绝缘台固定后,将甩出的相线、地(零)线按各自的位置从开关、插座的线孔中穿出,按接线要求将导线压牢。然后将开关或插座贴于绝缘台上,对中找正,用螺丝固定牢。最后再把开关、插座的盖板上好。

Open switch and socket: firstly, pass the conducting wire out of box through the outlet hole of insulating plate. Then, stick the insulating plate to wall space closely, and use screws to fix on the box or brick. After fixing the insulating plate, pass the phase line and null line out of box through the outlet hole of switch and socket according to each position. Press the conducting wire firmly according to the connecting requirement. Then, stick the switch or socket on the insulating plate, center to aim at. Use screws to fix firmly. Finally, put the cover of switch and socket well again.

7、电机的检查及接线

Check and Connection on Electric Motor:

本工程设备较多,主要包括各类风机、水泵、制冷机组、配套泵、空调机组及末端设备组成。

In the project, there are various equipments mainly including fans, water pump, refrigerator set, auxiliary pump, air conditioning set, and terminal equipment.

(1)安装前检查Check before Installing:

电动机、电动执行机构本体、控制和启动设备完好,盘动转子轻快无卡阻及异常声响,电动机的引出线端子焊接或压接良好且编号齐全,附件备件齐全,润滑脂情况正常。无异常或不超过出厂保质期,无需进行抽芯检查。

Electromotor, electric executive body, control or startup equipment are all complete. Disk rotor rotates briskly without any abnormal noise. The weld or pressure welding of outlet terminal from electromotor is good and the serial number is all complete. The attached parts are all complete, and the situation of lubricating grease is normal. There is no abnormal for the above and all are not over the guaranteed period. They do not need to carry out core-loosing examination.

(2)安装及接线Installation and Wiring:

1)电机本体安装应由电工、钳工、起重工配合进行,按设计图就位。稳固稳装时电机垫片一般不超过三块,各种传动形式的轴向、径向、中心线平行误差都应在允许范围内。

The installation of electric motor body should be carried out coordinately by electricians, bench workers, and lifting workers according to design diagrams. The number of washers in electric motor should not be more than 3 normally to install steadily. All axial error, radial error, and parallel error of centre line in various transmission forms should be in the allowable scope.

2)严格按照相线颜色接线,固定牢固,金属软管必须接地,落地电机进线方法如下图所示:Wire strictly according to the color of phase line, and fix firmly. Metal hoses must be grounded. The inlet line of floor electromotor is shown as the following figure.

(3)电动机试运行前检查

Examination on Electromotor before Test Run:

1)条件Condition::

A、土建工程结束,现场清扫整理完毕,电机本体安装检查结束。

The civil engineering is finished. The spot has been finished cleaning and arranging. The examination on installing electric motor is finished.

B、冷却、调速、润滑等附属系统安装完毕,验收合格,分部试运行情况良好。

The installation of subsystems such as cooling, timing, and lubricating are finished. All are accepted and qualified. The situation of test run in subsection is good.

C、电机的保护、控制、测量、信号、励磁回路调试完毕,动作正常。

All of protection, control, measurement, signal, excitation loop, and debugging in electric motor are finished, and the action is normal.

D、多速电动机的接线、极性应正确。联锁切换装置应动作可靠,操作程序应符合产品技术条件规定。

The wiring and polarity of multi-speed electromotor should be correct. The interlock switching device should act reliably. The operating procedure should accord with technological condition of product regulations.

E、有固定转向要求的电机,试车通电前必须检查电机与电源的相序,并应一致。

To electric motors having fixed turning requirements, the electric motor and the phase sequence of power supply must be checked and should keep being consistent before trial run to electrify.

2)检查内容

Examining Contents:

A、电动机、电加热器及电动执行机构的可接近裸露导体必须接地(PE)。低压电动机使用1kV兆欧表进行测量,绝缘电阻值不低于1 MΩ。

All approachable and naked conductors of electromotor, electric heater, and electric executing body must be grounded (PE). Use 1kV megohmmeter to carry out measuring low-voltage electromotor. The insulation resistance should not be less than 1 MΩ.

B、测定电机定子线圈、转子线圈及励磁回路的绝缘、轴承座及台板的接触面清洁干燥,用500V摇表测量,绝缘电阻值不小于0.5MΩ。

Measure the insulation of stator coil, rotor coil, and excitation loop in electric motor, keep the contact surface of bearing block and bedplate clean and dry. Use 500V tramegger to measure. The insulation resistance should not be less than 0.5 MΩ.

C、100kW以上的电动机,应测量各相直流电阻值,相互差不应大于最小值的2%;无中性点引出的电动机,测量线间直流电阻值,相互差不应大于最小值的1%。

To electromotor of 100kW or more, measure DC resistance of every phase, and the inter-difference should not be more than 2% of the minimum value. To electromotor from non-neutral point, measure DC resistance between lines, and the inter-difference should not be more than 1% of the minimum value.

D、电气设备安装应牢固,螺栓及防松零件齐全,不松动。防水防潮电气设备的接线入口及接线盒盖等应做密封处理。

The installed electrical equipment should be firm. Both bolts and lock parts are all complete without any loose. Both wiring inlets and terminal-box covers in electrical equipment that is waterproof and damp-proof should be sealed.

E、在设备接线盒内裸露的不同相导线间和导线对地间最小距离应大于8mm,否则应采取绝缘防护措施。

In the terminal box of equipment, the minimum distance between naked and different phase wires and between conducting wire and ground should be more than 8mm. Otherwise, adopt an insulating protection measure.

F、电刷与换向器或滑环的接触良好。

The touch between electric brush and commutator or slip-ring is good.

G、盘动电机转子时,转动灵活无碰卡现象。

When rotating, the rotor of electric motor is flexible without any collision.

H、电机引出线相位正确、固定牢固、连接紧密,接线与铭牌一致。

The phase position of lead-out wire in electric motor should be correct. It is fixed firmly and connected closely. The wiring is consistent with the name plate.

I、电机外壳油漆完整,接地良好。

The paint at outer covering of electric motor is complete and the grounding is good.

J、照明、通风、消防装置齐全。

All devices of lighting, ventilation, and fire protection should be all complete.

8、防雷及接地工程

Lightning Protection and Ground Protection:

(1)工艺流程Technological Process:

(2)防雷接地系统焊接的要求:

Requirement on Welding Lightning Protection Ground System

所有的焊接处焊缝应饱满,并有足够的机械强度,不得有夹渣、咬肉、裂纹、虚焊、气孔缺陷,焊接处的药皮敲净。扁钢焊接时应注意:

All welding seams at weld joint should be full and have a well mechanical strength without any slag inclusion, nip, crack, faulty solder, or gas-hole default. The surface at welding joint should be cleaned clearly. Pay attention to the following when welding flat steels.

1)扁钢与扁钢焊接搭接长度不少于扁钢宽度的2倍,不少于三面施焊。

The length of welding join between flat steels should not be 2 times less than the width of flat steel, and they will weld at least with three faces.

2)钢板与扁钢焊接搭接长度不小于扁钢宽度的2倍,不少于三面施焊。

The length of welding joint between steel plate and flat steel should not be 2 times less than the width of flat steel, and they will weld at least with three faces.

3)圆钢与扁钢焊接搭接长度不小于圆钢直径的6倍,双面施焊。

The length of weld joint between round bar steel and flat steel should not be less than 6 times of the diameter of round bar steel. They are welded with two faces.

4)除埋设在混凝土中的焊接接头外,均要求作防腐处理。

Except that laid in concrete, all other weld joints are requested to take corrosion preventions.

(3)接地干线安装:接地干线穿墙时,必须加阻燃塑料套管保护,跨越伸缩缝时,应做煨弯补偿;接地干线距地面不小于300mm,距墙面不小于10mm,支持件系统采用绝缘子固定,支持件间的水平直线距离不大于1m,垂直部分为1.5m,转弯距离为0.3m;接地干线敷设应平直,水平度及垂直度允许偏差2‰,但全长不得超过10mm。

Installation on main ground line: when passing through a wall, the main ground line must be added a fire resistant plastic casing to protect. When crossing an expansion joint, it should make a compensation of simmering and bending. The distance of main ground line to the ground should not be less than 300mm, and that to wall space should not be less than 10mm. The support system adopts an insulator to fix. The distance of horizontal lines between supports should not be more than 1m. The vertical section is 1.5m. The distance of turning is 0.3m. The lay of main ground line should be level. The allowable deviation of levelness and verticality may be 2‰, but the whole length should not be more than 10mm.

(4)等电位安装Equipotential Installation:

所有进出该建筑物的金属管道及电缆金属外皮均应就近通过接地预埋钢板与防雷接地装置可靠连接成电气通路。

All metal pipelines in/out the building and the outside surface of cable metal should be connected reliably into an electrical channel through built-in ground steel plate and lightning protection ground device.

9、弱电系统安装主要控制节点:

Installing Main Control Node in LV System

本次弱电系统安装的内容包括:综合布线系统、广播系统、闭路电视及门禁系统的管线安装及工作区的末端器具安装。

The installation of weak current system includes the pipeline installation of comprehensive wiring system, broadcasting system, closed-circuit television, and entrance guard system and the appliance installation at the end of working areas.

弱电系统管路及线槽的安装控制节点参见本节电气管路和桥架线槽的安装控制要点。

The control node installing in pipeline and slot of weak current system may refer to the key of installation control on electric pipeline and crane span structure slot in the section.

(1)弱电系统线缆的敷设Laying Cables in LV System:

1)配线子系统电缆宜穿管或沿金属电缆桥架敷设,当电缆在地板下布放时,应根据环境条件选用地板下线槽布线、网络地板布线、高架(活动)地板布线、地板下管道布线等安装方式。

The cable in distribution subsystem is suitable to lay in crane span structure across pipe or along metal cable. When laying cables under the floor, select some installing modes such as slot wiring under floor, network floor wiring, elevated (mobile) floor wiring, and pipeline wiring under floor according to environmental conditions.

2)干线子系统垂直通道有电缆孔、管道、电缆竖井等三种方式可供选择,宜采用电缆竖井方式。水平通道可选择钢管敷设或电缆桥架方式。

There are three modes such as cable hole, pipeline, and cable shaft for the vertical channel in main line subsystem to select. It is suitable to select the mode of cable shaft. The horizontal channel may select the modes of steel pipe lay or cable crane span structure.

3)管内穿放大对数电缆时,直线管路的管径利用率为50%~60%,弯管路的管径利用率应为40%~50%。管内穿放4对对绞电缆时,截面利用率应为25%~30%。线槽的截面利用率不应超过50%。

When an amplification logarithm cable passes through the pipe, the availability of pipe diameter in

straight pipeline is 50%~60%, and that in bent pipe should be 40%~50%. When 4 pairs of paired cables pass through the pipe, the availability of cross section should be 25%~30%. The availability of cross section in slot should not be more than 50%.

4)对绞电缆敷设Laying Paired Cable:

A、对绞电缆的牵引和敷设

Pulling and Laying Paired Cable

用预置于管道中的拉绳将双绞电缆牵引穿入管道时,应使拉绳和线缆的连接点尽量平滑,连接固定可靠,并用胶带紧紧缠绕在连接点外面,牵引应缓慢平稳,切忌快速拉线。

When using a stay cord built in pipeline to pull the paired cable through pipeline, make the connecting point of stay cord and cable keep smooth as soon as possible. The connection should be fixed reliably and winded closely at the outside of connecting point by tape. The pull should be slow and stable, never pull the wire quickly.

对绞电缆可以利用缆线末端的铜芯线弯曲打结,制作牵引环等。

The paired cable may utilize the copper core at the end of cable to bend and knot so as to make out a tow lug.

同时牵引多根电缆时,最大不能超过40kg。对绞电缆在牵引和安装过程中,应作到避免弯曲超过90度。避免过紧的缠绕电缆和划破电缆外皮,避免损伤缆内导线,避免剥除电缆外皮,裸露双绞线部分过多。避免电缆终接时连接处解扭绞过长。操作中不要单独的抽拉和弯曲某一线对。

When pulling multiple cables at the same time, the maximum should not be more than 40kg. In the process of pull and installation, the paired cable should avoid being bent over than 90°. Prevent the cable winded too much and the cable surface scratched. Prevent damaging the conducting wire in cable. Prevent the outer surface of cable peeled and the paired wire naked too much. Prevent the twist of cable at joint too long. Do not pull or bend some certain paired wire individually in operation.

B、常用压线工具Normal Tool of Line Ball:

(2)工作区末端器具的安装

Terminal Kit Installation in Working Area

工作区主要包括用户信息插座到工作站终端设备间的连接缆线、适配器等,它将用户终端和网络连接起来。终端设备可以是电话机,计算机和数据终端,也可以是扬声器、摄象机等。

The working area mainly includes connecting cables and adapters between a user information socket to a terminal device of work station. It connects the user terminal with the network. The terminal devices may not only be telephone, computer, and data terminal, but also be loudspeaker and video camera.

从信息插座到终端设备的连接通常使用两端带连接插头(RJ45)的连接软线,但有些终端设备

需要选择适当的适配器或平衡/非平衡转换器才能连接到信息插座上。连接缆线长度一般为3m。

The connection from information socket to terminal device usually uses a connecting hose with plug (RJ45). But some terminal devices need to select proper adapter or balance/unbalance switcher so as to connect with the information socket. The length of connecting cable is 3m normally.

在进行接线时,线对扭绞节距不应破坏,接线端解扭长度不应大于13mm,UTP电缆的弯曲半径应不小于电缆外径的4~6倍,约25mm左右。当8条线依序插入接线槽顶部时,用压线钳将导线卡接到插座或插头模块中,并可听到清脆的响声。

When carrying out wiring, do not destroy the paired and twisted pitch. The un-twisted length of terminal should not be more than 13mm. The bend radius of UTP cable should not be less than 4~6 times of outside diameter in cable, and is about 25mm. When 8 wires are plugged into the top of wire slot in sequence, clasp the conducting wire to the socket or plug module by using a line-ball pincers, and hear a sound of clear click.

建筑物内扬声器的安装常见以下大样图:

The installation of loudspeaker in building is shown normally in the following enlarged drawing.

10、电气系统检验测试Check and Test on Electrical System:

(1)电气材料及设备进场检测

Checking electrical material and equipment in the spot

主要材料设备的检验方法(常规检验方法)

Check Method of Main Material and Equipment (Normal Check Method)

(2)电气系统检测Check and Measure on Electrical System:

1)配电柜检测Check and Measure on Distribution Cabinet

A、柜内检查Check in Cabinet:

依据施工设计图纸及变更文件,核对柜内的元件规格、型号。

Check the specification and model of component in cabinet according to construction design drawings and changed documents.

逐线检查柜内各设备间的连线及由柜内设备引至端子排的连线不能有错误,接线必须正确。为了防止因并联回路而造成错误,接线时根据实际情况,将被查部分的一端解开然后检查。检查控制开关时,应将开关转动至各个位置逐一检查。

Gradually examine the connecting wire among individual equipment in cabinet and the connecting wire from equipment in cabinet to terminal row without any wrong. The connection wiring must be correct. To prevent mistakes due to parallel loop, untie one end of examined section and then check when connecting according to actual situations. When checking control switches, turn switches to every position for checking gradually.

B、柜间联络电缆检查(通路实验):

Examination on Connecting Cable among Cabinets (Circuit Test)

柜与柜之间的联络电缆需逐一校对。在回路查线的同时,应检查导线、电缆、继电器、开关、按钮、接线端子的标记,与图纸要相符,对有极性关系的保护,还应检查其极性关系的正确性。

The connecting cable among cabinets need to proof gradually. While a loop check, do check whether the signs of conducting wire, cable, relay, switch, button, and wiring terminal accord with requirements in drawing. To the protection of polarity, check the correctness of its polarity relationship.

C、操作装置的检查:

Check on Operating Equipment

回路中所以操作装置应进行检查,检查接线是否正确,操作是否灵活,辅助触点动作是否准确。一般用导通法进行分段检查、整体检查。检查时应使用万用表,不宜用兆欧表(摇表)检查,因为摇表检查不易发现接触不良或电阻变值。

In loop, carry out checking the operating equipment. Check whether the wiring is correct, the operation is flexible, and the action of auxiliary contact is correct. Normally use the guide method to carry out sectional check and complete check. When checking, use a multimeter. Do not use a megohmmeter (or tramegger) to check because the tramegger check is not easy to find the imperfect contact or resistance value.

2)接地或接零检测Check and Measure on Grounding or Connecting to Neutral

逐一复查各接地处选点是否正确,接触是否牢固可靠,是够正确无误地连接到接地网上。禁止用一根导线做各处的串联接地。

Gradually check whether the selected points of every grounding location are right, the touch is firm or reliable or connected with the grounding net correctly. Do not use a conducting wire to ground in serial for every point.

设备的可接近裸露导体接地或接零连接完成。

The approachable and naked conductor of equipment is finished to ground or connect to neural.

接地点应与接地网连接,不可将设备的机身或电机外壳代地使用。

The ground point should connect with a ground network. Do not make the body of equipment or the outside covering of electric motor as grounding.

设备接地点应接触良好,牢固可靠且标识明显。要接在专为接地而设的螺钉上,不可用管卡等附属物为接地点。

The ground point of equipment should contact very well and be fixed reliably, and also the mark is very obvious. To connect with bolts that are set up for grounding, do not use an attachment such as pipe strap as the ground point.

不允许将一部分电气设备金属外壳采用保护接地,将另一部分电气设备金属外壳采用保护接零。

Do not permit one section of outside metal covering in electrical equipment is adopted as grounding protection and another section is adopted as neural protection.

装有电器的可开启门,门和框架的接地端子应用编织裸铜线连接,且有明显标识。

In a controllable door with electrical equipments, the ground terminal of door and frame may adopt a waved and naked copper wire to connect and have an obvious mark.

明敷接地干线,沿长度方向,每段为15-100mm,分别涂以黄色和绿色相间的条纹。

To a main line that grounds in open-lay, every section is 15~100mm along the direction of length, and is painted with stripes alternating with yellow and green.

测试接地装置的接地电阻值必须符合设计要求。

The value of ground resistance in ground-test device must meet with design requirements.

3)漏电测试检测Check and Measure on Leakage Test

以下两图所示为测试RCD参数如接触电压、环路(接地)阻抗、跳闸时间和跳闸电流时,仪表与被测项目的连接图。

The two following figures are the connecting diagrams between instruments and measured projects with RCD test parameters such as contact voltage, circuit (ground) resistance, trip time, and trip current.

Trip Time

为保证安全,当电气装置或相关的导线出现故障时,RCD必须在某一特定的时间内跳闸。允许跳闸时间范围参见下表。

To ensure the safety, RCD must trip in some certain time when there are some problems in electrical devices or relative wire. The allowable scope of trip time may refer to the following table.

跳闸电流

Trip Current

为了检测RCD的灵敏度,应测量跳闸电流。为此,测试电流应逐渐增大,直到RCD跳闸;如果RCD装置故障,应增大电流直到所选RCD的最大值

To check and measure the sensitivity of RCD, measure the trip current. Therefore the measured current should be increased gradually till RCD trips. If there is something wrong with RCD device,

increase the current till to the maximum value of selected RCD.

5)电动机检测Check and Measure on Electromotor

11、电气系统调试及组织Debugging and Organization in Electrical System

(1)电气线路绝缘摇测Insulating Shake-measure in Electric Circuit

1)第一次绝缘摇测:电气器具未安装前进行线路绝缘摇测时,首先将灯头盒内导线分开,开关盒内导线连通。摇测应将干线和支线分开,一人摇测,一人应及时读数并记录。摇动速度应保持在120r/min左右,读数应采用lmin后的读数为宜。

The first insulating shake-measure: when carry out the circuit insulating shake-measure before installing electric appliances, separate conducting wires in lamp holder box firstly, and connect with the conducting wire in switch box. When shake measure, separate the main line and the branch line. One take shake-measure, the other should do reading and record in time. The shaking sped should be kept at about 120r/min. The reading should be suitable to adopt that after 1 minute.

2)第二次绝缘摇测:电气器具、电箱全部安装完在送电前进行摇测,应先将线路上的开关刀闸、仪表、设备等用电开关全部置于断开位置,摇测方法同上所述,确认绝缘摇测无误后再进行送电试运行。

The second insulating shake-measure: carry out shake-measure before power transmission while all electric appliances and electric boxes have been finished. Switch off all electric switches such as knife switch, instrument, and equipment in circuit. The method of shake-measure is same as the above. Carry out electrification test run after confirming that there is no something wrong with shake measure.

3)电气线路绝缘遥测使用的仪器及要求:

Instruments and Requirements for Insulating Shake-measure in Electric Circuit

测试要求:Test Requirement

电线的绝缘摇测一般选用500V、量程为0-500MΩ的兆欧表。

The insulating shake measure of wiring may select the megohmmeter of 500V that the measurement range is 0~500MΩ normally.

1kV以下电缆用1kV摇表摇测线间及对地绝缘电阻应不低于10MΩ。

The insulation resistance of less than 1kV cable that is measured with a 1kV tramegger among wires and to the ground should not be less than 10MΩ.

封闭母线组装前应逐段进行绝缘测试,绝缘电阻值大于20MΩ。

Before assembling the closed bus set, carry out an insulation test. The insulation resistance is more than 20MΩ.

3-10kV电缆应事先做耐压和泄漏试验,试验标准应符合国家和当地供电部门规定,必要时敷设前仍需用2.5kV摇表测量绝缘电阻是否合格。

3~10kV cable should firstly make a test of withstand voltage and leakage. The test standard should accord with regulations by the state and local power supply department. If necessary, still need to use a

2.5kV tramegger to measure whether the insulation resistance is qualified before laying.

(2)配电柜检查调试

Checking and Debugging Distribution Cabinet

配电柜试运行前,检查配电柜内有无杂物,安装是否符合质量评定标准,相色、铭牌号是否齐全。

Before a test-run of distribution cabinet, check whether there is mess in distribution cabinet, the installation meets with the standard of quality evaluation, and phase color and name plate are all complete.

1)配电柜调试的具体流程

现场单独安装的低压电器交接试验

Exchanging test of low-voltage electrical equipment installed solely at the spot

动力成套配电(控制)柜、屏、台、箱、盘的交流工频耐压试验、保护装置的动作试验

AC power frequency withstand voltage test of power set distribution (control) cabinet, screen, stand, box, and plate as while as operating test of protective device

电气部分与机械部分的转动或者动作协调一致

Rotation or action coordination in electric and mechanical parts should coordinate consistently

整理编写调试记录报告

Arrange and compile a debugging and recording report

试运行

Test run

空载试运行

Test run under no-load

负荷试运行

Test run with load

2)在未关闭主开关时,直投柜要校相,将开关柜内各分开关处于断开位置。当主开关闭合后,逐个合上分开关。

Before not close the main switch, the direct-throwing cabinet will be carried out phase correcting. Put every sub-switch in cabinet at the position of off. When closing the main switch, switch on every sub-switch gradually.

3)配电(控制)柜、屏、台、箱、盘的交流工频耐压实验:

AC Frequency withstand voltage test of distribution (control) cabinet, screen, stand, box, and plate.

柜、屏、台、箱、盘等的交流工频耐压实验。交流工频耐压实验电压为1kV,但绝缘电阻值大于10MΩ时,可采用2500V兆欧表摇测替代,实验持续时间1min,无击穿闪络现象。

AC frequency withstand voltage test of cabinet, screen, stand, box, and plate. The voltage of AC frequency withstand voltage test is 1kV. But when the value of insulation resistance is more than 10MΩ, adopt 2500v shake-measure megohmmeter to replace. The last time of test is 1 minute without any breakdown flashover.

4)柜、屏、台、箱、盘的保护装置的动作试验:

Operating Test on Protective Device such as Cabinet, Screen, Stand, Box, and Plate

继电器检验和调整:检查继电器外壳与底座结合得是否牢固严密,外部接线端钮是否齐全,原铅封是否完好;检查继电器各元件的状态是否正常,元件的位置必须正确。

Testing and adjusting relays: Examine whether the combination between the outer-shell of relay and the foundation is fixed firmly, the end contact of external wiring is all complete, and the original lead sealing is in good condition. Examine whether the state of every component in relay is normal. The location of component must be correct.

5)校验和调整:

Check and Adjust

A、先用电阻表或万用表的欧姆档测量线圈是否通路。

Firstly, use the ohm gear of ohmmeter or multimeter to measure whether it is in channel.

B、绝缘电阻的测试。用500V摇表测量继电器所有导电部分和附近金属部分的绝缘电阻,一般按照下列内容逐项测试:

Test on insulation resistance. Use 500V tramegger to measure the insulation resistance of all conductive section in relay and the section near metal. Carry out testing gradually according to the following content normally.

C、接点对线圈的绝缘电阻。

Insulation resistance of contact in coil

D、校验电磁铁与线圈间的绝缘电阻。

Check the insulation resistance between electromagnet and coil.

E、线圈之间、接点之间的及其他部分的绝缘电阻。

Insulation resistance between coils, contacts, and other sections.

F、绝缘电阻一般不应低于10MΩ。如果绝缘电阻较低,应查明原因。

The insulation resistance should not be less than 10MΩnormally. If the insulation resistance is lower, find out the reasons.

6)在空载情况下,检查各保护装置的手动、自动是否灵活可靠。

Under no load, examine whether the manual and automatic of every protective device is flexible and reliable.

7)送电空载运行24h,无异常现象,经监理工程师及咨询公司、业主检查确认后,向监理公司及业主方各报一份存档。

Transmit the power supply to operate 24 hours with no load. If there is no abnormal situation, the inspection engineer, consultative company, and owner should submit a file to the inspection company and the owner separately after having confirmed.

(3)照明试运行Lighting Test Run

1)试运行前准备Preparation before Test Run:

电线绝缘电阻测试前电线的接续完成;照明箱、灯具、开关、插座的绝缘电阻测试在就位前或接线前完成;电气器具及线路绝缘电阻测试合格。

Finish the connection of wire before the wire insulation resistance test. Finish the insulation resistance test of lighting box, lamp, switch, and socket before taking their places or connecting. The tests of electric appliance and circuit insulation resistance are qualified.

2)照明器具试运行Test Run of Lighting Appliance:

A、电气照明器具应按系统进行通电试运行,系统内的全部照明灯具均得开启。

The electric lighting appliance should carry out electrifying test run according to the system. All lighting appliance in system should be opened.

B、建筑照明系统通电连续试运行时间应为24h。

The test run time to continuously electrify the lighting system in building should be 24 hours.

C、所有灯具均应开启,每2h记录运行状态一次,连续试运行时间内无故障;上述各项测量的数值要填入试运行记录表内。

All lamps should be opened and record with the operating situation one time per 2 hours. There should be no problem in continuous test-run time. The above value of every measurement should be filled in the test-run record.

(4)动力试运行Power Test Run

1)试运前应认真做好以下工作:

Do the followings well carefully before the test-run.

A、应对设备的安装情况,进行仔细的检查,根据技术资料,检查设备润滑、电器接线、电器绝缘、转动部分的防护措施,并对设备安装现场进行清理,做好试车前的准备工作。

Carry out examining the installing situation of equipment carefully. Check the protective measures of equipment lubrication, electric appliance wiring, electric appliance insulation, and turning sections according to technical data. And carry out cleaning the installing spot of equipment to make the preparation before test run.

B、恢复所有被临时拆开的线头和连接点,检查所有端子有无松动现象。

Restore all temporarily disassembled thread ends and connecting points to examine whether all terminals are loosed or not.

C、电动机在空载运行前应手动盘车,检查转动是否灵活,有无异常音响。对不可逆动装置的电动机应事先检查其转动方向。

Manually operate the barring before the electromotor operates under no load. Examine whether the turning is flexible and there is abnormal sound. To the electromotor with irreversible devices, firstly examine its turning direction.

D、检查所有熔断器是否导通良好。

Examine whether all fuse wires are good.

E、检查所有电气设备和线路的绝缘情况。

Examine the insulating situation of all electric equipments and circuits

F、检查备用电源、备用设备、应使其处于良好的状态。

Examine spare power supply and spare equipments, and make them in good condition.

G、送电试运前,应先制定操作程序;送电时,调试负责人应在场。

Work out the operating procedure firstly before the test run of power transmission. When transmitting, the debugging principal should be at the spot.

电气工程施工方案48500

电气施工方案报审表 工程名称:兴山县昭君镇廉租房一期及二期项目配套市政基础设施工程编号: 注:本表一式四份,项目监理机构、建设单位、施工单位、城建档案管理机构各一份。

兴山县昭君镇廉租房一期及二期项目配套 市政基础设施工程 电 气 工 程 施 工 方 案 施工单位:湖北江铭建设工程有限公司 编制人:杜德杰 审核人:姜波 审批人:刘永金 编制日期:年月日 电气工程施工方案

1.编制说明:本施工方案是根据本工程图纸要求以及国家颁发的技术方针,政策,规范.技术规程标准和各项管理制度. 且上级有关部门下达的各项规定的管理制度而编写.编写本方案是为了保证施工顺利进行,确保质量达到标准,严格按规范进行施工.本方案如有不妥之处,欢迎各位同行指出谢谢1.1编制目的 1.1.1为了更好的贯彻执行国家颁发的技术方针,政策,规范.技术规程标准和各项管理制度.且贯彻执行上级有关部门下达的各项规定的管理制度. 1.1.2保证施工顺利进行,确保质量达到标准,严格按规范进行施工无安全事故发生从到达优质工程. 1.1.3最终使本工程达到住户入住满意,放心. 1.2编制依据 《民用建筑电气设计规范》(LGJ/T16-92); 《建筑物防雷设计规范》(GB50057-94);2000版 《住宅设计规范》(GB50096-1999);2003版 《低压配电设计规范》(GB50052-95); 《火灾自动报警系统设计规范》(GB50116-98) 《高层建筑设计放火规范》; 《建筑电气质量验收规范》(GB50303-2002);2002版 《建筑工程施工质量验收统一标准》(GB50300-2001); 《智能建筑工程质量验收规范》(GB50339-2001); (98ZD701)常用电气控制原理图;(90SD180)电缆桥架安装 2.电气工程概括: 2. 1电气工程主要有高低压变配电系统,动力配电系统、电气照明系统、建筑物防雷接地系统、弱电系统、火灾自动报警及消防系统. 2.1.1本工程进分配电采用TN-C-S系统由地下室低压配电室配出的电缆干线均随电缆桥架明敷至电缆竖井和各供电点,本工程消防负荷为2级负荷,其于为3级负荷;2级负荷穿线管用钢管,. 3级负荷穿线管用PVC阻燃管。 2.1.2防雷接地系统,本建筑物按3级负荷防雷设防.本工程采用联合接地形式,即利用建筑物基础作接体.将防雷保护接地,电气保护接地,弱电设施接地及等电位连接接地共用接地体,共用接地装置综合接地电阻不大于1欧.

电气工程专项施工方案

目录 一、工程概况 (2) 二、编制依据 (5) 三、施工准备 (5) 四、电气工程主要施工方法及质量要求 (9) 五、电气安装各分项、检验批工程质量要求及电气通病的预防措施 (14)

一、工程概况 本工程项目占地面积约34000平方米,总建筑面积约136580万平方米,由4栋29层高层住宅、12栋5层多层住宅、整体地下车库组成。 1、工程名称:华润二十四城二期-1施工总承包第二标段 2、工程地点:沈阳市经济技术开发区沈海路8号 3、施工工期: 该工程项目总施工工期为2017 年04 月150日开工、2019 年06月20 日竣工,其中砌筑工程施工工期为2017年08 月15 日开始、至2018年6月1 日结束。 4、工程质量标准: 首先,满足施工合同要求,达到国家施工验收规范合格标准; 其次,确保至少一个单位工程获得“沈阳市玫瑰杯”; 第三,力争“辽宁省建设工程世纪杯(辽宁省优质工程)奖”,争创国家奖项。 5、安全、环境及文明施工标准: (1)执行国家、辽宁省、大连市现行安全生产文明施工、华润公司验评标准,达到“合格”标准。 (2)环境保护达到国家、辽宁省、沈阳市相关法规及规定要求。

6、工程所在地自然环境条件 ①、现场概貌 施工现场自然地坪基本平整。 ②、施工现场自然气候 沈阳属于北温带半湿润的季风性气候,同时受海洋、大陆性气候控制。特点明显,其特征是冬季漫长寒冷,春季干燥多风,夏季炎热多雨,秋季凉爽湿润,春秋季短,冬夏季长。 从搜集到的以往历年气象资料看:沈阳历年平均气温为7~8 摄氏度,七月平均气温24.6 摄氏度,1 月平均气温-11.4 摄氏度,极端最高气温38.7 摄氏度,极端最低气温-33.1 摄氏度。每年11 月中旬开始封冻,翌年3 月初解冻。由于受全球气候的影响,近几年封冻时间略有推迟,冻结深度略有减小。 降水量:沈阳历年平均降水天数为106 天,多集中在6~9 月份,年平均降水量为720 毫米。 蒸发量:年平均蒸发量为1420 毫米,每年4~9 月份蒸发量最大,占全年蒸发量的67.4% 。 湿度:历年月平均湿度为9.1 毫巴,6~9 月份湿度最大为21.37 毫巴,一、二、十二月份湿度小,月平均为1.92 毫巴。 风向:冬季多为西北风、北风,夏季多为西南风、南风,春秋季风力较大,最大风速为12~15米/秒。 日照:日照时间历年平均为2588.7 小时,日照率为58%,全年平均晴天136.7 天,云天145.3天,阴天为83 天。

电气工程施工方案范文

.电气工程施工方案 1.编制依据 1.1.1施工图纸:行政办公楼电施图 1.1.2《建筑电气工程施工质量验收规范》:(GB50303-2002); 1.1.3《火灾自动报警系统施工及验收规范》(GB50166-2002); 1.1.4《建筑电气通用图集》92DQ1-13 1.1.5《建筑电气工程施工工艺标准》(ZJQ00-SG-006-2003) 1.1.6《室内管线安装》D301-1~2 1.1.7《接地装置安装》03D501-4 1.1.8《等电位联结安装》02D501-2 1.1.9《封闭式母线及桥架安装》D701-1~2: 1.2编制范围: 照明系统、动力系统,公共及应急照明、防雷与接地系统。 2.工程概况: 本工程为框架结构,地上6层,地下1层,积3353.36m ,建筑高度23.90米(从室外地面消防车登高地面至主体顶层屋面), 属于多层办公楼,采用钢筋混凝土框剪结构,建筑耐火等级为一级。 3.供电系统方式、方法: 3.1电源 由市网引入两回路10KV高压电源,预留2(8*SC150)、3(8*125)钢管,于±0.000、—0.8m 处埋设进户,穿过建筑物外墙处设置防水挡板,做法参见《建筑通用图集》92DQ5.5-4。本工程中预留引入管。变电室电缆夹层设在地下一层。 3.2供电系统: 采用金属铠装封闭中置式柜,真空断路器,弹簧储能电动操作机构,直流操作电源110V。 高压电源两路,同时运行互为备用、母联断路器为手投加联锁,防止误操作。进线断路器装设三相过流、速断、零序、低电压保护;出线断路器(变压器柜)装设三相过流、速断、零序保护及两段(警告、跳闸)温度保护。进线隔离车与进线断路器有机械锁; 计量柜与进线断路器有电气锁;高压进线断路器与母联断路器有电气锁,确保两路电源不并列运行。配电系统的接地开形式为TN-C-S系统。 3.3照明系统 正常照明.包括住宅安装双管荧光灯;吸顶灯、壁灯:应急照明包括出口指示灯:疏散指示灯,应急壁灯,事故下继续工作照明。应急照明灯具选用镍镉电池作备用电源、应急电源。备用电源、应急电源为双电源末端互投疏散照明不小于20min,继续工作照明为连续。 3.4动力系统 本工程动力系统包括生活水泵、消防水泵、污水泵、消防喷淋泵、排风机、送风机、电梯等,其中与消防有关水泵、风机、电梯为一类负荷,采用双电源双回路末端互投,其余为二、三类负荷。 3.5电缆桥架、线槽 消防用线槽采用钢制涂防火涂料,电缆桥架的安装做法见《建筑电气通用图集》成电路92DQ5.50-59。 3.6弱电系统

室外电气工程施工方案

第一章工程概况 一、项目状况 工程位于海南省海口市三江镇,总用地面积362962吊,总建筑面积106148吊,建筑占地面积18733n i,本工程由6层防逃防暴中心,3层民警活动用房,6层备勤楼宿舍,4 层综合会见楼,1 号至7号4层普通监舍楼及8号艾滋病监舍楼,半地下室设备房,4 层文化教学楼,1 层伙房,2 层医院禁闭室组成的室外电气工程。 二、地形地貌与季节状况 本地段地势平坦开阔,属褐红色粘土性土地区。 但施工期正是多小雨季节,1 天下雨,3 天都无法正常工作,机械与材料无法进入施工现场,施工难度大,会因为多雨而延迟施工。 三、工程特点 1、工期紧:竣工期为2012年4月12日,市政工程必须于2011年12月12日开工,绝对工期为120天,这个工期是比较紧的。 2、任务重:工程包含雨水管、污水管、弱电、给水、消防、强电、道路及路灯等项目,任务相当重。 3、难度大:每年的1 至3 月份是海南的寒流期,连续不断的小雨,给施工造成很大的影响。这是工程的难点。 四、编制依据 按照建筑电气工程施工现场的质量管理要求,符合现行国家相关标准: 《建筑工程施工验收统一标准》GB50300-2001 《民用建筑电气设计与施工—室外布线》08D800-7 《建筑电气工程施工质量验收规范》GB50303-2002

建筑电气工程设计常用图形和文字符号》00DX001 等电位联结安装》02D501-2 接地装置安装》03D501-4 第二章施工方案 一、施工准备 1. 施工技术准备 全面理解施工图纸,并对施工组织设计进行交底。 2. 主要设备、材料、成品、半成品进场验收主要设备、材料、成品、半成品进行验收是 十分重要的工作,必须认真做好。 检验结论有记录,确保符合GB50303-2002规范的规定才能在施工中运用; 1)采用的设备和器材必须具有国家颁发的生产许可证,3C 认证证书,是否符合国家现行技术标准的合格产品,并有各项合格证书和质量保证证书。设备有铭牌,铭牌为金属材料印制和安装,塑料印制的铭牌不能安装; 2)上述材料如有异议送国家有资质的试验室进行抽样检测,试验室出具检测报 告,确保符合GB50303-2002和相关的技术标准规定方能在施工中运用; 3)经批准的免检产品和认定的名牌产品当进场验收时,一般不做抽样检测。 3. 主要设备、材料、成品、半成品进场验收规定 1)电线电缆符合下列规定 a. 按批次查阅合格证,合格证上有安全许可证编号,按相标准生产的产品有安全认证标志; b. 外观检查:包装完好,抽检的电线绝缘完整无损,厚度均匀,电缆无压扁、扭曲。耐热、阻燃的电线、电缆外护层有明显标识和制造厂标; c. 按制造标准,现场抽样检测绝缘层和圆形线芯的直径;线芯直径误差不大于标称直径的1%; d. 对电线、电缆绝缘性能、导电性能和阻燃性能有异议时,按批抽样送有资质试验室检测。 2)导管符合下列规定:

电气仪表安装工程专项施工方案

目录 一、编制说明 (2) 1.1 编制依据 (2) 1.2 工程概况 (2) 二、施工工艺流程与主要施工方法 (3) 2.1 施工工艺流程 (3) 2.2 主要施工方法 (5) 2.3 主要施工技术措施 (14) 三、质量保证措施 (15) 3.1 质量目标 (15) 3.2质量保证措施 (15) 四、施工机械机具计划及施工作业用料计划 (16) 4.1 施工机械、机具计划 (16) 4.2施工作业用料计划 (18) 五、安全保证措施及文明施工措 (19) 5.1 安全保证措施 (19) 5.2 文明施工措施 (19) 一、编制说明 1.1 编制依据 1.1.1施工图纸 1.1.2现行国家(或行业)、企业施工验收规范与标准 GBJ147-90 《电气装置安装工程高压电器施工及验收规范》 GBJ148-90 《电气装置安装工程电力变压器、油浸电抗器、互感器施工及验收规范》 GB149-90 《电气装置安装工程母线装置施工及验收规范》 GB50150-2006 《电气装置安装工程电气设备交接试验标准》 GB50170-2006 《电气装置安装工程旋转电机施工及验收规范》 GB50171-92 《电气装置安装工程盘、柜及二次回路接线施工验收规范》 GB50168-2006 《电气装置安装工程电缆线路施工及验收规范》 GB254-96 《电气装置安装工程低压电器施工及验收规范》 GB50255-96 《电气装置安装工程电力交流设备施工及验收规范》 GB5170-2006 《电气装置安装工程接地装置施工及验收规范》 GB50256-96 《电气装置安装工程起重机电气装置施工及验收规范》

电气施工技术方案

第一章综合说明 1 主要图集、规范、法律、法规依据 主要图集一览表 1 《利用建筑物金属作防雷及接地装置安装》 主要国家标准规范一览表 《电气装置安装工程电缆线路施工及验收规范》GB50168-2006 2设备安装概况一览表 本工程电源由室外箱变提供 220v/380v低压电源,经一层后 分配至各用电点;消防水泵、消 防风机、消防控制室、消防应急 照明、生活水泵,排污泵等为二

荧光灯或紧凑型荧光灯、LED 走道、楼梯间、电梯前室及主要出入口处设置自带蓄电池供电式

3 工程施工范围 机电工程施工范围包括:待定(界定土建总包和精装修工程范围)。

第二章工程特点、重点分析及对策 根据工程图纸,对本工程特点、重点部分的认识和拟采取的施工对策如下: 1 厂区内有多家在施单位,计划管理是本工程的重点和难点 本工程为公建项目,工期紧、施工作业面小、品质要求高且施工中厂区有多家单位交叉施工。与各承包商积极进行工作界面的协调是保证本工程顺利进行的重点。 施工对策: (1)互通进度计划,联合制定总体进度计划。绘制出现场各施工单位的临时设施及材料堆场的平面位置图。 (2)本工程与室外各种专业管线有多处接驳点,施工过程将需要相互接驳的部位和工序确定,采用列表的形式一一列明,并附总图一张,图中表明上述所有部位和工序,确保按照设计无遗漏并及时做好室内外管道的接驳。 第三章主要施工方案 1预留预埋 1.1电气工程预留预埋 (1)所有配管工程以设计图纸为依据,暗配管应沿最近的路线敷设管路。 (2)管路超过下表长度,应加装接线盒,其位置应便于穿线。 30米 米 (3)暗配电线管路与其它管道最小距离,如下表所示。

电气工程施工方案完整版

电气工程施工方案 HEN system office room 【HEN16H-HENS2AHENS8Q8-HENH1688】

目录 编制说明 1、本方案按照建设单位提供的施工图纸及图纸会审记录进行编制。 2、编制依据为国家规范、标准以及辽宁省地方标准的内容。 3、本方案适用于1、 4、 5、7、8#楼的电气工程施工。 =

一、工程简介 1.工程概况 本工程位于沈阳市皇姑区黄河南大街26号,是由1、4、5、7、8#楼及嘉陵江街一层公建组成的群体工程,其中1#楼为钢筋混凝土剪力墙结构,地下一层、地上十七层,建筑面积13825m2;4#楼为钢筋混凝土剪力墙、短肢剪力墙结构,地下一层、地上最高十七层,建筑面积17661m2;5#、7#、8#楼为短肢剪力墙结构,5#楼建筑面积为7682m2,7#、8#楼建筑面积均为6854m2,;嘉陵江街一层公建为框架结构,建筑面积500 m2;建筑总面积53376 m2 。 2.施工范围 要包括变配电室系统、供电干线系统、电气照明安装系统、防雷及接地安装系统以及智能建筑系统(通信网络、火灾报警及消防联动系统)的施工工作。 3.编制依据 招标文件; 《建筑电气设计技术规范》(JGJ/T16-92) 《高层民用建筑防火设计规范》(GB50045-95,2001版) 《建筑防雷设计规范》(GBJ19-87) 《高层民用建筑设计防火规范》(GB50045-95) 《建筑设计防火规范》(GBJ16-87) 《建筑工程施工质量验收统一标准》(GB50300-2001) 《建筑电气工程施工质量验收规范》(GB50303-2002) 《建筑工程施工质量验收实施细则》(辽宁省地方标准DB21/1234-2003) 各楼号的施工图纸 二、施工准备 建立项目施工组织体系,人员到位,明确分工做好以下方面的准备工作:

电气工程施工方案中英文

电气工程 Electric Works 一、工艺流程图 Technological process Diagram 二、电气安装质量控制点及控制措施 Quality Control Point and Control Measure on Electric Installation 三、关键工序技术及质量控制保证措 Key Working Procedure and Quality Control Guarantee Measure 1、镀锌钢管明敷设 Open Lay of Galvanized Steel Pipe 本工程明敷设钢管均采用了镀锌钢管明敷设工艺。 All open-lay steel pipes in the project adopt the open-lay technology of galvanized steel pipe. (1)工艺流程 Technological process : (2)可上人的吊顶内以及不封闭式竖井通道内的配管为明配管,其管路走向及支架固定均应按明配管要求施工。 The distributing pipe in suspended ceilings that can be entered into and shaft passages that are not closed is open. Both its pipeline direction and support fixture should construct according to

requirements of open distributing pipes. (3)按设计要求用冷煨法把管子煨出所需的弯度,20mm以下管径的管子用手板煨管器,25mm以上管径用液压煨管器(或专用煨管器),煨弯处凹扁度应符合规范规定。 Use the simmering method to simmer pipes with a necessary bend according to design requirements. Pipes that the pipe diameter is less than 20mm may adopt a palm simmer pipe machine. Pipes that the pipe diameter is more than 25mm may use a hydraulic simmer pipe machine (or special simmer pipe machine). The concavity at simmering bends should accord with specifications and regulations. (4)断管采用钢锯或无齿锯,需断切的管子尺寸准确,将管子置于压力钳口中心卡紧,断口平齐。断口处用锉将管口内外锉光,无毛刺,管内铁屑清除干净。 Broken pipes adopt a hacksaw or a saw without teeth. The size of pipe needing to cut should be exact. Put pipes on the center of pressure jaw, and keep fractures even. At fracture, fill the inner or outer of pipe orifice smoothly without any burr. The scrap iron in pipe should be cleaned clearly. (5)管子套丝采用套丝机,根据管子外径及扣距选用相应板牙,将管子用台虎钳或龙门压架钳紧牢固,再把绞板套在管端,均匀用力,不得过猛,随套随浇冷却液。丝扣不乱且干净清晰,管箍上好后,管口应对严,外露丝扣不应过长。(外露丝扣不得超过3扣) The mantle fiber of pipe may adopt a mental fiber machine. Select corresponding dies according to the outer diameter and of pipe the pitch. Clamp the pipes firmly by using a vice or planer pressing pliers. Then cover the capstan on pipe ends. Exert evenly not too strongly, and pour the cooling fluid on it while covering. The clasp is not in disorder and cleaned clearly. After pipes are hoped well, pipe orifices should be aimed at accurately. And the exposed clasp should not be too long. (6)镀锌钢管必须采用通丝管箍连接。不得采用熔焊跨接地线,应在连接处的两端用专用接地卡固定跨接接地线,(镀锌钢管丝扣连接也可以直接用导电膏不采用跨接)如下图所示:Galvanized steel pipes must adopt harness cord pipe hoops to connect. Do not adopt fusion-welding bridge ground wires. Use the special ground card at two ends of joints to fix and bridge the ground wires. The connection of galvanized steel pipes is shown in the following figure. (7)严格按图纸要求敷设管线,坐标与标高准确,固定牢固。管路敷设按规范要求加装接线盒,管箍连接处采用专用接地线卡跨接地线,线管进入盒、箱处,按设计要求预留孔、洞,待稳住盒、箱后再进行下道工序,需加装护口处应及时加装护口。 Lay pipelines strictly according to requirements in drawing. Both coordinates and levels are accurate and the pipelines should be fixed firmly. The pipe lay is asked to add a terminal box according to specification requirements. The joint of pipe hoop adopts special ground wire cards to bridge the ground wire. Spools are put into boxes. And holes and orifices are asked to pre-leave according to design requirements. Only after boxes have been stable, carry out the next working procedure. A protective orifice should be added in time at the position that needs to add. (8)钢管沿墙过沉降缝敷设,按照下图进行敷设: Lay steel pipes through settlement joints along with wall, and carry out laying according to the following figure. (9)管路固定及接地线做法详见下图: Pipeline fixture and ground wire are shown in the following figure.

电气工程总体施工方案

泸天化绿源醇业有限责任公司 年产40万吨甲醇10万吨二甲醚工程 电气工程总体 施工方案 中国化学工程第六建设公司 二○○四年三月三十一日

目录 1 编制说明 2 编制依据 3 工程概况 4 工程特点 5 电气工程施工技术措施 6 施工程序 7 主要分项工程施工方法及技术要求 8 施工进度及劳动力安排 9 主要施工机具计划 10 计量器具选择配备计划 11 质量保证措施 12 安全保证措施

1 编制说明 本施工技术方案针对泸天化绿源醇业有限责任公司年产40万吨甲醇、10万吨二甲醚项目投标片区电气分部工程主要分项工程主要工序编制,编写重点突出施工方法和技术要求。编写目的是让技术人员和电气工人在施工中有章可循,有条不紊,全面达到施工和验收标准,让业主满意。 2 编制依据 《电气装置安装工程电力变压器、油浸电抗器、互感器施工及验收规范》 GBJ148-90 《电气装置安装工程母线装置施工及验收规范》 GBJ149-90 《电气装置安装工程低压电器施工及验收规范》 GBJ50254-96 《电气装置安装工程起重电气装置施工及验收规范》 GB50256-96 《电气设备交接试验标准》 GB50150-91。 《电气装置安装工程爆炸和火灾危险环境电气装置施工及验收规范》 GB50257-96。 《建筑电气工程施工质量验收规范》 GB50303-2002。 《电气装置安装工程电缆线路施工及验收规范》 GB50168-92。 《电气装置安装工程接地装置施工及验收规范》 GB50169-92。 《电气装置安装工程旋转电机施工及验收规范》 GB50170-92。 《电气装置安装工程盘、柜及二次回路结线施工及验收规范》 GB50171-92。 《建设工程施工现场供用电安全规范》 GB50166-92。 《施工现场临时用电安全技术规范》 JGJ46-88。 泸天化年产40万吨甲醇、10万吨二甲醚施工招标文件。 3 工程概况 根据招标文件《5.1装置片区介绍及范围界定》,我公司拟投空分片区和转化片区。查看成达工程公司提供的本工程初步设计文件,空分片区有明确的电气内容说明,转化片区电气施工内容必定有,但工程量可能标在别的装置区。 空分装置的6kW负荷由甲醇变电所6kV系统直接供电,装置内设一6.3/0.4Kv低压

电气配管施工专项技术方案

1. 编制依据本方案编制依据主要以某办公楼室内装修施工图纸及有关规范、图集(见下表)。 1.1 主要施工规范、规程 1.2主要图集 1.3主要标准 我国现行的的安全生产、文明施工、环保及消防等有关规定,以及北京市建筑工程施工现场安全标准管理标准 2. 工程概况 2. 工程概况本工程为室内装修工程,主要涉及装饰工程、给排水工程、通风工程、电气工程、弱电工程,消防工程。我方主要承担地下一层至地上六层,包工包料。 本工程属于室内装修工程,位于山东省烟台市港城东大街XXXXXXXX

3、施工部署 3.1 技术准备 (1)施工前应对图纸审核,了解各部位的管材、盒子选择,做法和技术要求。 (2)隔墙工程配管及吊顶内配管施工应按各道工序进行验收,合格后方可进 行下道工序施工。 (3)做好书面的技术交底和安全交底,并由班组长进行口头交底。 (4)准备好资料用品及检验工具。 3.2 材料准备 (1)各种电气材料已通过验收,满足设计和规范要求,材料进场监理或甲方 验收后合格方可使用。 3.3 劳动力和机具准备 (1)劳动力准备:劳动力的配置根据工程量及施工进度安排进行投入,总体施工人员在30人左右,并根据实际施工进度及时调整以满足施工需要。 (2)主要施工机具:冲击钻、电动手枪钻、电动无齿锯、手电钻、交流电焊机、线坠、钢卷尺、小水桶、钢锯、半圆锉 3.4 施工准备 根据工程实际情况,按施工阶段划分;该时期的施工重点相适应。 4. 施工方法和技术措施 4.1 钢管敷设工程 (1)照明支路吊顶内采用JDG钢管敷设。 (2)墙体内采用JDG钢管敷设。 (3)地面配管采用镀锌钢管敷设 4.1.1 材料准备(主要使用的是镀锌钢管.JDG镀锌钢导管) 4.1.1.1 JDG镀锌钢管、镀锌钢管的材质必须符合设计要求。检测报告、出厂合格证等质量证明文件齐全有效。 4.1.1.2 镀锌钢管壁厚均匀,焊缝均匀,无劈裂、砂眼、棱刺和凹扁现象。镀锌层均匀。 4.1.1.3用游标卡尺检测焊接厚壁钢管,钢管的内外径及壁厚应符合国家标准。 4.1.1.4 锁紧螺母外形完好,丝扣清晰,无翘曲变形等缺陷。 4.1.1.5管箍、护口均应符合要求,并有产品合格证。

电气工程施工方案39628

目录 编制说明 ...................................... 错误!未定义书签。 一、工程简介 .................................. 错误!未定义书签。 1.工程概况 ................................... 错误!未定义书签。 2.施工范围 ................................... 错误!未定义书签。 3.编制依据 ................................... 错误!未定义书签。 二、施工准备 .................................. 错误!未定义书签。 1.技术准备 ................................... 错误!未定义书签。 2.现场准备 ................................... 错误!未定义书签。 3.劳动力准备 ................................. 错误!未定义书签。 4.材料准备 ................................... 错误!未定义书签。 5.施工工机具及检验测量机具的准备 ............. 错误!未定义书签。 三、电气工程施工内容 .......................... 错误!未定义书签。 1. 施工程序 ................................... 错误!未定义书签。 2. 主要施工方法及技术要求 ..................... 错误!未定义书签。 3. 列出技术复核的内容 ......................... 错误!未定义书签。 4. 工程防护内容及方法 ....................... 错误!未定义书签。 编制说明 1、本方案按照建设单位提供的施工图纸及图纸会审记录进行编制。

电气工程施工方案

电气工程施工方案 Ting Bao was revised on January 6, 20021

电气工程 施 工 方 案 一、编制依据 1、百鼎广场电气专业施工图纸和相关设备厂家技术资料 2、《电气装置安装工程母线装置施工及验收规范》 3、《电气装置安装工程电缆线路施工及验收规范》 4、《电气装置安装工程盘、柜及二次回路接线施工及验收规范》 5、《电气装置安装工程接地施工及验收规范》 6、《电气装置安装工程电气设备交接试验标准》 7、《建筑电气工程施工质量验收规范》 8、《施工现场临时用电安全技术规范》 9、《建筑物金属体防雷及接地装置安装》03D501-3 10、《等电位连接安装》02D501-2 11、《接地装置安装》03D501-4 12、《导管配线安装》03D301-3 13、《建筑物防雷设施安装》99D501-1 14、《综合布线工程设计施工图集》02X101-3 15、本公司在多项类似工程中的施工经验。 二、电气工程概况 1、本工程为高层二类商住楼,电气工程主要有高低压变配电系统、照明系 统、防雷接地系统、消防报警与控制系统、楼宇对讲系统、宽带网布线系统、有线电视系统。

消防用电设备、应急照明、疏散照明为二级负荷;其他电力负荷及住宅照明为三级负荷。 2、本工程供电电源由本场区高低压配电室住宅照明、商业照明、公共动 力、备用电源各一路,低压配电系统采用220/380v放射式与树干式相结合的方式,二级负荷采用双电源供电,三级负荷采用单电源供电。 3、建筑物竖向供配电设在电气竖井内。照明配电干线、空调与试验配电干 线采用密集型插接母线在竖井内垂直引上,再由各层插接开关箱引至各层配电箱。由各层照明配电箱配出的照明及插座铜芯塑料线沿回路均采用BV-2.5m㎡托盘敷设,出托盘后穿钢管在吊顶及墙内敷设。 4、照明系统:照明、插座分别由不同的支路供电,照明为单项二线,插座 为单项三线,所有暗敷设穿线导管均采用PVC管,照明线路均采用㎡,导线为2、3根的穿16管,4-6根穿20管,插座导线均采用BV-4m㎡,3根穿20管,5根穿25管,户内普通插座及照明均采用㎡,空调、卫生间、厨房及餐厅插座均采用BV-4m㎡。 5、防雷接地系统:本建筑物按二级防雷设防,采用TN-S接地方式,将设 备保护接地、防雷接地、各种金属管道的等电位接地、弱电系统的工作接地等共用接地装置;要求工频接地电阻不大于l Ω。 6、电缆电视系统:本系统为有线电视分配、分支系统,电视传输、分配干 线在配电竖井内沿弱电线槽敷设,电视用户线穿Ф20PVC管从弱电线槽引出,在墙内暗设至用户插座。终端电坪取64±4DB为设计标准。 三、施工前准备工作 1、技术准备工作 由技术负责人组织参加施工的技工认真熟悉施工图纸及相关设计文件、标准规范,掌握设计意图及设计要求,对图中所选用的电气设备和主要材料进行统计。 做好施工图纸的审查、会审,参加设计交底及图纸会审。施工前技术人员必须详细审图,对照招标文件,提出问题并在图纸会审时落实。然后要根据工程特点编制施土方案,并编排进度计划。根据施工方案提出材料计划,并向施工人员下达详细的技术交底。 2、现场准备工作

电气工程专项施工方案

建筑电气施工实施方案报审表工程名称:和顺家园开发建设项目工程编号: 和顺家园开发建设项目工程 建 筑 电

气 工 程 专 项 施 工 方 案 编制: 审核: 审批: 安徽省观志实业有限公司 二0一七年十一月十五日 和顺家园二期开发建设项目工程,由安徽省信太投资有限公司投资建设,中外建设计与顾问有限公司、黄山市建筑设计研究院设计,江苏宏嘉项目工程管理有限公司监理,安徽省观志实业有限公司承建。 第一章工程概况 和顺家园开发建设项目3#、5#、29-30#、46-50#楼工程位于旌德县城东新区,建筑层数为五、六、十层,总建筑面积为43339.29平方米。结构类型:框剪、框架结构。 一、配电系统

1.本工程施工范围:照明系统;动力系统;综合布线系统;电视系统;防雷接地系统、火灾报警与消防联动系统。 2、供电电源及负荷等级:本工程为地下室应急照明、消防设备、排污泵、机械停车位为一级,其余三级供电负荷。配电系统采用(380/220V)三相四线制,电源由小区配电站采用YJV22-0.6/1KV型电缆套管直埋引至各楼总电表箱。本工程总电表箱设置架空层楼梯间,各户住宅内设分户配电箱。 3、配电方式:由电源进线出柜引至单元电表箱干线均采用YJV22-0.6/1KV型铜芯交流电缆穿管埋地暗敷,埋深不小于0.8m;单元电表箱引至各住户分配电箱采用YJV22-0.6/1KV型铜芯交流电缆穿管沿墙暗敷。照明分支线采用BV-450/750-2.5mm2线穿PVC冷弯阻燃电工管在现浇板或墙内暗敷,BV-2.5mm2导线穿管管径为:2根穿PVC16;3根穿PVC20;4~6根穿PVC25;7~8根穿PVC32。 4、电气设备安装高度及方式:电表箱底边距地1.2m挂墙明装;户配电箱底边距地1.8m暗装,阁楼层箱底距地1.8m暗装;开关底边距地1.4m 暗装;客厅空调插座底边距地0.3m暗装;壁挂空调插座底边距地1.8m暗装;卫生间热水器插座底边距地2.3m暗装;卫生间一般插座底边距地1.4m 暗装;排油烟机插座底边距地2.0m暗装;厨房一般插座底边距地1.2m暗装;其余插座底边距地0.3m暗装;所有安装高度小于1.8m的插座均采用安全插座。有线电视端子箱、寻址箱底边距地1.8m安装;光纤配电箱底边距地1.8m安装;户弱电线底边距地0.5暗装;电话插座底边距地0.3m 暗装;卫生间电话插座底边距地1.2m暗装;电视插座底边距地0.3m暗装;

电气工程施工方案

通州区台湖镇居住用地、托幼用地及公建混合用地(配建“公共租赁住房”)项目-A3-1~3号楼及1#地下车库工程 电 气 工 程 施 工 方 案 编制单位:宿迁华夏基业建筑工程有限公司 编制人:李海昌 编制日期:2013年05月29日

目录 1、编制依据-------------------------------------------------------------------------------------3 2、电气工程施工内容-------------------------------------------------------------------------3 3、施工计划-------------------------------------------------------------------------------------6 4、安装施工部署--------------------------------------------------------------------------------7 5、施工准备--------------------------------------------------------------------------------------8 6、电气施工方法--------------------------------------------------------------------------------8 7、电气工程质量通病与质量控制要点----------------------------------------------------29 8、综合管理措施------------------------------------------------------------------------------40

电气工程专项施工方案

目录 一、工程概况..................................................................... 2.. . 二、编制依据..................................................................... 4.. . 三、施工准备..................................................................... 5.. . 四、电气工程主要施工方法及质量要求................................ 9.. 五、电气安装各分项、检验批工程质量要求及电气通病的预防措施 (14)

一、工程概况 本工程项目占地面积约34000平方米,总建筑面积约136580 万平方米,由4栋29层高层住宅、12栋5层多层住宅、整体地下车库组成。 1、工程名称:华润二十四城二期-1 施工总承包第二标段 2、工程地点:沈阳市经济技术开发区沈海路8 号 3、施工工期: 该工程项目总施工工期为2017 年04 月150 日开工、2019 年06月20 日竣工,其中砌筑工程施工工期为2017年08 月15 日开始、至2018 年6 月1 日结束。 4、工程质量标准:首先,满足施工合同要求,达到国家施工验收规范合格标准;其次,确保至少一个单位工程获得“沈阳市玫瑰杯”;第三,力争“辽宁省建设工程世纪杯(辽宁省优质工程)奖”,争创国家奖项。 5、安全、环境及文明施工标准:(1)执行国家、辽宁省、大连市现行安全生产文明施工、华润公司验评标准,达到“合格”标准。 (2)环境保护达到国家、辽宁省、沈阳市相关法规及规定要求。 6、工程所在地自然环境条件 ①、现场概貌 施工现场自然地坪基本平整。 ②、施工现场自然气候 沈阳属于北温带半湿润的季风性气候,同时受海洋、大陆性气候控制。特点明显,其特征是冬季漫长寒冷,春季干燥多风,夏季炎热多雨,秋季凉爽湿润,春秋季短,冬夏季长。 从搜集到的以往历年气象资料看:沈阳历年平均气温为7?8摄氏度,

专项施工方案--建筑电气工程施工方案

建筑电气工程 施 工 方 案

XX工程公司年月日

1.电气工程概况 1.1 电气工程主要有高低压变配电系统、动力配电系统、照明系统、防雷接地系统、消防报警与控制系统、楼宇自动控制系统、结构化布线系统、电缆电视系统。 1.2 本工程供电电源由本场区l0kV开闭所引来两路l0kV高压电源,经电缆沿托盘直接敷设至地下1层变配电室。高压系统为单母线分段,两路l0kV电源分别供给两台630kVA干式变压器,低压系统为单母线分段运行,由地下1层低压配电室配出的电缆干线均沿电缆桥架明敷至电缆竖井和各供电点。 1.3 建筑物竖向供配电设在电气竖井内。照明配电干线、空调与试验配电干线采用密集型插接母线在竖井内垂直引上,再由各层插接开关箱引至各层配电箱。由各层照明配电箱配出的照明及插座铜芯塑料线沿回路均采用BV- 2.5m㎡托盘敷设,出托盘后穿钢管在吊顶及墙内敷设。 1.4 防雷接地系统:本建筑物按二级防雷设防,采用T N-S接地方式,将设备保护接地、防雷接地、各种金属管道的等电位接地、弱电系统的工作接地等共用接地装置;要求工频接地电阻不大于l Ω。 1.5 消防报警与控制系统:首层消防值班室内设有报警盘、控制盘、广播盘,由中央控制设备引出线路穿过首层楼板至地下1层,沿电缆托盘敷设至电气设备间内,垂直段沿托盘敷设至各层消防端子箱,实现消防报警与联动控制。 1.6 楼宇自动控制系统:中央控制室设在首层消防中心机房内。BAS系统通讯总线和DDC 电源总线均穿钢管敷设至各层现场控制器,由各现场控制器配出的自控线路沿封闭金属线槽,再穿薄壁钢管或直接采用钢管敷设至各被控设备。实现对冷冻水系统、供配电系统、空调机组、新风机组、公共区域照明的监控。 1.7 结构化布线系统:由首层设备向综合布线主配线柜敷设出的干线均采用封闭金属桥架敷设,水平配线用封闭金属桥架在吊顶内敷设再穿薄壁钢管引至各处信息插座,本系

电气工程施工方案237

电气工程 施 工 方 案 一、编制依据 1、百鼎广场电气专业施工图纸和相关设备厂家技术资料 2、《电气装置安装工程母线装置施工及验收规范》

3、《电气装置安装工程电缆线路施工及验收规范》 4、《电气装置安装工程盘、柜及二次回路接线施工及验收规范》 5、《电气装置安装工程接地施工及验收规范》 6、《电气装置安装工程电气设备交接试验标准》 7、《建筑电气工程施工质量验收规范》 8、《施工现场临时用电安全技术规范》 9、《建筑物金属体防雷及接地装置安装》03D501-3 10、《等电位连接安装》02D501-2 11、《接地装置安装》03D501-4 12、《导管配线安装》03D301-3 13、《建筑物防雷设施安装》99D501-1 14、《综合布线工程设计施工图集》02X101-3 15、本公司在多项类似工程中的施工经验。 二、电气工程概况 1、本工程为高层二类商住楼,电气工程主要有高低压变配电系统、照明系统、防雷接地系统、 消防报警与控制系统、楼宇对讲系统、宽带网布线系统、有线电视系统。

消防用电设备、应急照明、疏散照明为二级负荷;其他电力负荷及住宅照明为三级负荷。 2、本工程供电电源由本场区高低压配电室住宅照明、商业照明、公共动力、备用电源各一路, 低压配电系统采用220/380v放射式与树干式相结合的方式,二级负荷采用双电源供电,三级负荷采用单电源供电。 3、建筑物竖向供配电设在电气竖井内。照明配电干线、空调与试验配电干线采用密集型插接母 线在竖井内垂直引上,再由各层插接开关箱引至各层配电箱。由各层照明配电箱配出的照明及插座铜芯塑料线沿回路均采用BV-2.5m㎡托盘敷设,出托盘后穿钢管在吊顶及墙内敷设。 4、照明系统:照明、插座分别由不同的支路供电,照明为单项二线,插座为单项三线,所有暗 敷设穿线导管均采用PVC管,照明线路均采用BV-2.5m㎡,导线为2、3根的穿?16管,4-6根穿?20管,插座导线均采用BV-4m㎡,3根穿?20管,5根穿?25管,户内普通插座及照明均采用BV-2.5m㎡,空调、卫生间、厨房及餐厅插座均采用BV-4m㎡。 5、防雷接地系统:本建筑物按二级防雷设防,采用TN-S接地方式,将设备保护接地、防雷接地、 各种金属管道的等电位接地、弱电系统的工作接地等共用接地装置;要求工频接地电阻不大于l Ω。 6、电缆电视系统:本系统为有线电视分配、分支系统,电视传输、分配干线在配电竖井内沿弱 电线槽敷设,电视用户线穿Ф20PVC管从弱电线槽引出,在墙内暗设至用户插座。终端电坪取64±4DB 为设计标准。 三、施工前准备工作 1、技术准备工作 由技术负责人组织参加施工的技工认真熟悉施工图纸及相关设计文件、标准规范,掌握设计意图及设计要求,对图中所选用的电气设备和主要材料进行统计。 做好施工图纸的审查、会审,参加设计交底及图纸会审。施工前技术人员必须详细审图,对照招标文件,提出问题并在图纸会审时落实。然后要根据工程特点编制施土方案,并编排进度计划。根据施工方案提出材料计划,并向施工人员下达详细的技术交底。 2、现场准备工作 施工道路、施工用水、临电和场地由总承包方统一规划,生产、办公、库房等临时用房由总承包方提供,现场设办公室、库房各一间。因本工程场地比较狭小,所以现场施工技术人员、材料人员需与建设(监理)和土建单位密切配合,做到材料随用随进。 3、按施工作业计划备齐施工用料及施工机具。 4、与设备材料部及质量管理部一起进行工程设备及材料的检验工作,要求设备、材料的规格、型号、数量应与图纸一致,附件、备件、质量合格证及技术文件齐全,同时应符合规范要求,按照要求及时进行施工前的报验,并作好检验记录。