织物疵点检测

DEFECT DETECTION IN REPETITIVE FABRIC PATTERNS

R.Perez

Computer Engineering Technical University of Valencia Ferrandiz y Carbonell no.2

Alcoy,Spain. email:ruperez@disca.upv.es

J.Silvestre

Computer Engineering

Technical University of Valencia

email:jsilves@disca.upv.es

J.Munoz

Instituto Tecnologico Textil

Emilio Sala no.1

Alcoy,Spain

email:jmunoz@aitex.es

ABSTRACT

In this paper a automated analysis system for defect de-tection in the print process of?ocked fabrics with repet-itive patterns is presented.This process represents a less computationally complex method than the detection of any type of pattern in the print process.For this reason,this problem can be solved using a personal computer(PC)in-specting100%of the production that ful?ll the require-ments of repetitive patterns.This system will be extremely useful for companies which produce repetitive pattern tex-tiles in large quantities.The implementation of a prototype system,based on the Fast Fourier Transform,will be de-scribed.

KEY WORDS

Textile Inspection,Fast Fourier Transform

1Introduction

In spite of the advantages that computer vision provides to the fabric inspection process,in the production stage as well as?nal inspection,this technology has had little impact on the textile sector when considering developed systems,research articles and research institute projects. Meier[1]points out that although no electronic system is equal to the human eye,there are disadvantages.These include concentration,reproducibility of the process,es-pecially with the entire width of the fabric,speed and spe-cial functions:analyzing the size,form,con?guration,con-trast and relevancy of the defect to the?nality of the prod-uct.However,the textile industry employs computer vision very little because:

?Visual inspection of irregularities is complex due to the fact that the product is sometimes irregular by na-ture.The textile process can vary signi?cantly and it can still be considered correct.

?Fabric materials are?exible and can easily be dis-torted,which makes it dif?cult to use standard meth-ods for automated inspection.

?The economic cost it is possibly greater in this sec-tor than in others,because of the size of the area to be inspected and the resolution required to detect the defects.For these reasons,the development of systems governed by these restrictions,capable of detecting errors visible to the human eye,are quite expensive.Nevertheless,there have been serious attempts by researchers to introduce these techniques in the textile sector.For example,in regular texture fabrics analysis,Shin[2]develops an algorithm for defect detection and classi?cation based on energy mea-sures and the adaptive mask theorem.Although this needs the design of a classi?er using test data,it is not a gener-ally accepted method(Campbell[3-6])due to the impos-sibility of obtaining representative defect data with all er-ror characteristics.Cohen[7]develops a system based on a Gaussian Markov Random Field(GMRF)model of the correct textile texture,using non-overlapped windows to extract the GMRF parameters and compare it using a clas-si?er,with the correct characteristics of the fabric texture to determine the correctness of the window.Other work on texture defect detection can be seen in papers by Camp-bell[3-6]and Balakrishnan[8],based on Fourier Trans-form and where they also offer an interesting description of the fabric problems,Hoffer[9]uses an Optic Fourier Trans-form(OFT),Lewis[10],develops a Fourier based method using multiresolution decomposition by wavelets,and Es-cofet[11]uses the Fourier Angular Spectra Correlation to detect global defects and Gabor Filters to detect local de-fects.This paper is organized as follow:In section2we explain the problems and their particularities,in section3 we present the developed algorithm and in section4the results and the conclusions are shown.

2Problem description

In the textile industry,the print process is the way in which a particular substance,usually dye,is impregnated on to a fabric in some areas using a perforated cylinder with holes positioned to give the desired design.A cylinder is used for each colour in the process.The most common problem in this process is the obstruction of the cylinder holes by dust, solidi?cation of the dye,etc.so that the resulting design is faulty.In the?ocked fabrics industry,it is normal proce-dure to use this process to make?ocked drawings on fabric bases.The colour of the fabric bases is usually the same as the?ock to be printed,as well as the adhesive used to?x the?ock to the weave.Therefore,although this process of

production is usually slower that the normal fabric printing processes and only works with one colour,it presents a se-rious disadvantage to the inspection of defects by the work-ers.This disadvantage is that all the elements used have the same colour,which makes detection very dif?cult.When considering that up to10,000meters of the same design and colour can be produced,it is easy to see the importance of automatic detection of the printing defects.The system has to detect the defects produced in the print process of the adhesive on the fabric bases,so that later the?ock adheres to the desired areas.The system designed does not require hi-res images since the geometric patterns are not exactly equal.In addition,when the adhesive fails in a small area, the adhesion process masks this so it is imperceptible in the?nished product.Another factor introduced by the im-perfection of the textile geometric designs and what it is tried to avoid in the stamping process when the defect is detected,it will be signalled to the operator,who can clean the cylinder in the area indicated.Thus,the defect is cor-rected and the number of defective meters is minimized. 3Approach

3.1Hardware

For the detection of defects,a colour linear camera of2048 pixels has been used,which provides suf?cient resolution for a fabric analysis of1,60meters.For the illumination system,due to the opacity of the fabric base,a front light system need to be used,that provides an adequate contrast between the fabric and adhesive,obtaining therefore im-ages where the design can be appreciated.

3.2Developed algorithm

The algorithm used is based on the calculation of the fast Fourier Transform(FFT)on windows throughout all the image.To each one of these windows the forward FFT is applied,and then frequencies are?ltered using a mask on the transformed image.Once the image is?ltered,the inverse transform is applied to obtain the?ltered real im-age in which the defects appear as a white or dark spots, as the?ltering process removes the repetitive pattern.In a post process stage,the repetition of these defects is ana-lyzed since those that are repeated in all rapports constitute signi?cant defects for the company.

3.2.1Windowing process

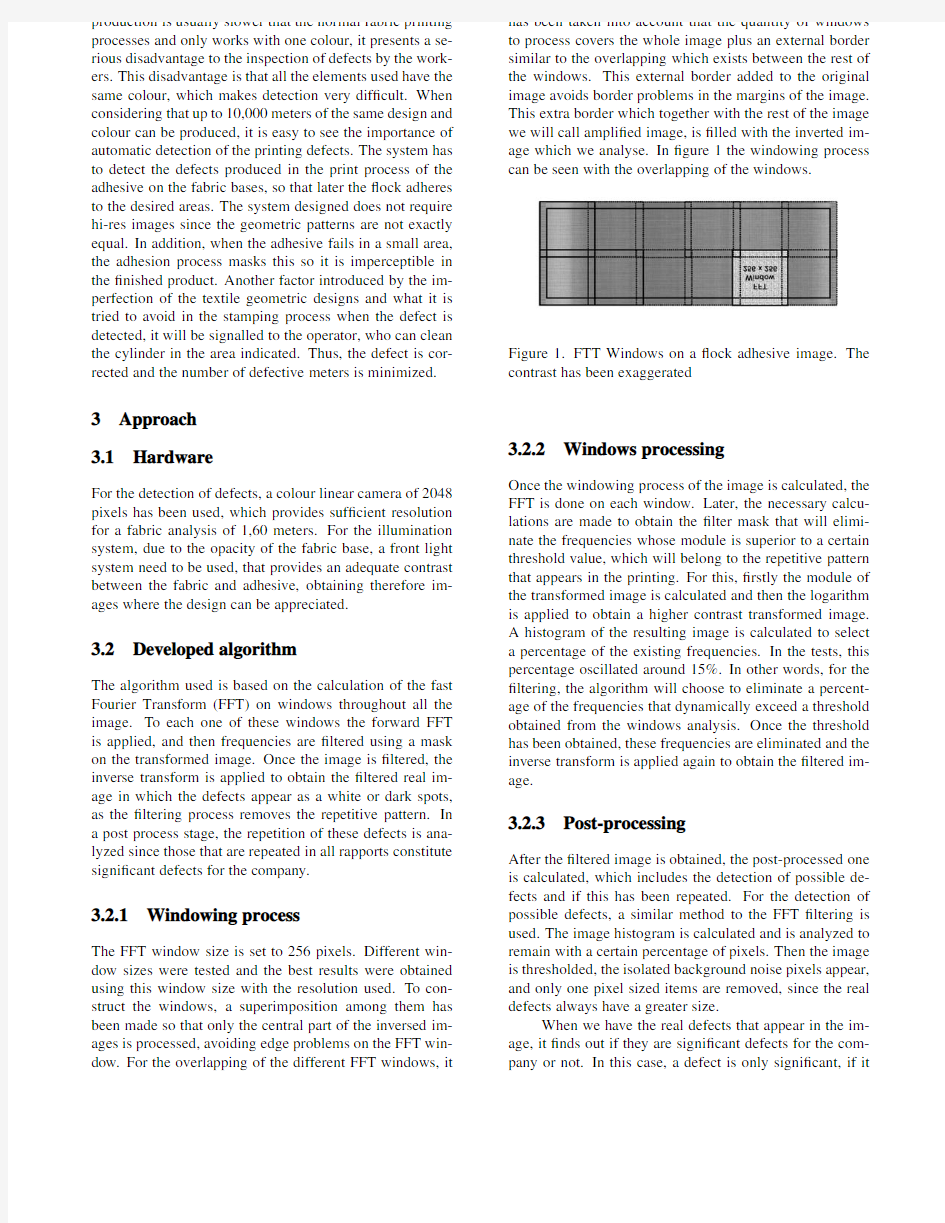

The FFT window size is set to256pixels.Different win-dow sizes were tested and the best results were obtained using this window size with the resolution used.To con-struct the windows,a superimposition among them has been made so that only the central part of the inversed im-ages is processed,avoiding edge problems on the FFT win-dow.For the overlapping of the different FFT windows,it has been taken into account that the quantity of windows to process covers the whole image plus an external border similar to the overlapping which exists between the rest of the windows.This external border added to the original image avoids border problems in the margins of the image. This extra border which together with the rest of the image we will call ampli?ed image,is?lled with the inverted im-age which we analyse.In?gure1the windowing process can be seen with the overlapping of the

windows.

Figure1.FTT Windows on a?ock adhesive image.The contrast has been exaggerated

3.2.2Windows processing

Once the windowing process of the image is calculated,the FFT is done on each https://www.360docs.net/doc/246512154.html,ter,the necessary calcu-lations are made to obtain the?lter mask that will elimi-nate the frequencies whose module is superior to a certain threshold value,which will belong to the repetitive pattern that appears in the printing.For this,?rstly the module of the transformed image is calculated and then the logarithm is applied to obtain a higher contrast transformed image.

A histogram of the resulting image is calculated to select a percentage of the existing frequencies.In the tests,this percentage oscillated around15%.In other words,for the ?ltering,the algorithm will choose to eliminate a percent-age of the frequencies that dynamically exceed a threshold obtained from the windows analysis.Once the threshold has been obtained,these frequencies are eliminated and the inverse transform is applied again to obtain the?ltered im-age.

3.2.3Post-processing

After the?ltered image is obtained,the post-processed one is calculated,which includes the detection of possible de-fects and if this has been repeated.For the detection of possible defects,a similar method to the FFT?ltering is used.The image histogram is calculated and is analyzed to remain with a certain percentage of pixels.Then the image is thresholded,the isolated background noise pixels appear, and only one pixel sized items are removed,since the real defects always have a greater size.

When we have the real defects that appear in the im-age,it?nds out if they are signi?cant defects for the com-pany or not.In this case,a defect is only signi?cant,if it

repeats during all rapports,since these take place by the ob-struction of some of the points of the cylinder injector.If the defect is not repeated,the obstruction has disappeared by itself and it does not make sense to stop production to correct it.For that reason,when we detect a defect,it is analyzed and only if this has already appeared in previous rapport is the defect marked to be signi?cant.If the defect is new,it is stored so that its possible repetition can be ver-i?ed.If the defect doesn’t appear in the following rapports, it will be eliminated because it is not considered signi?cant.

3.2.4Implementation

The inspection system has two different parts:The me-chanical structure and the hardware that are responsible for the correct acquisition of the images of the fabric,and the software application that does all the processing,analysis and possible actions to be taken.The system has to analyze all the fabric,and when some relevant defects are found(as has been commented previously,in the case of the print-ing,the relevant defects are those that take place in each rapport and not in a sporadic form),the machine can make the decision to stop production so that the worker can clean the stamping roller.When the machine starts to analyze the fabric,the program starts a thread to do the acquisition of the images and whenever a new image is acquired,another thread is started to process the frame.This thread analy-ses the image using the technique explained in the previ-ous section and gives back a report with the possible errors found on it.Another problem found,is due to the use of a linear camera that causes due to optical and luminance rea-sons,that the ends of the image always appear darker than the central part.Nevertheless it is a smaller problem since the change of intensity for this reason is?xed and known. To solve this problem,a correction vector is captured from a white image and is stored and used later to correct all the acquisitions.The designed prototype can work as well in colour images,as in black and white images,although the optimal results are obtained normally using colour images. Although the captured image is a colour one,the analysis is made with a black and white transformed image.For the conversion,an algorithm of maximum contrast is used that gives very good results even with the mixtures of dif?cult colours such as blue or black base with black design.In?g-ure2,there is a dark green color design,with the correction and contrast stretch at the bottom.Once the corrected im-age is made,the different windows are calculated to do the FFT and,then?lter it,as has been explained in the previous section.In?gure3,the?ltered result of the whole image can be observed.In the image,a black point is appraised that exactly represents the defect that exists in the design and that the?ltration heightens when eliminating the rest of the repetitive design of the

pattern.

Figure2.Image

Correction

Figure3.FTT Filtered Image

4Results and Conclusions

In the?gure4,the defects detected by the system are shown.There are a lot of repetitive patterns that have been tested correctly by the?ltration algorithm.As can be seen in the images,the proposed algorithm works very well with all the tested designs even with very slight imperfections and strange asymmetric designs.It also has been tested with a wide colour spectra,including colours dif?cult to the human eye such as dark blue adhesive with dark blue weave,and black on black,and the results are good.

5References

[1]R.Meier,J.Uhlmann,R.Leuenberger.El sistema auto-matico de inspeccion para tejidos.Revista de la Industria Textil,Zellweger Uster,375,2000.

[2]Shaw-jyh Shin,I-Shou Tsai,Po-Dong Lee.Feng Chia.Automatic faults detection and recognition for static plain fabrics.I nt.Journal of Clothing Science and Tech-nology.8(1/2),56-65.

[3]J.G Campbell,Fionn Murtagh.Automatic Visual Inspection of Woven Textiles Using a Two-stage Defect Detector.Optical Engineering,37(9),1998,2536-2542.

[4]J.G.Campbell,A.A.Hashim,T.Martin,McGin-nity Thomas,F.Lunney.Flaw Detection in woven tex-tiles by neural network.N eural Networks Conference, Maynooth,1995,92–99.

[5]J.G.Campbell,A.A.Hashim,F.D.Murtagh.Flaw Detection in Woven Textiles using Space-dependet Fourier Transform.Irish Signals and Systems Conference,London-derry,N.Ireland,1997,500-506.

[6]J.G.Campbell, C.Fraley, F.Murtagh, A.E. Raftery.Linear Flaw Detection in woven textiles using

Figure4.Examples of Defect Detection

Model-based Clustering.Irish Machine Vision and Image Processing Conference,Londonderry,N.Ireland,1997, 241-252.

[7]F.S.Cohen,Zhigang Fan,Stephane Attali.Auto-mated Inspection of Textile Fabrics Using Textural Models. IEEE Transactions on Pattern Analysis and Machine Intel-ligence,13(8),1991,803-808.

[8]H.Balakrishnan,S.Venkataraman,S.Jayaraman. FDICS.A Vision-based System for the Identi?cation and Classi?cation of Fabric Defects.Journal of Textile Insti-tute,1998.

[9]Lois M.Hoffer,Franco Francini,B.Tiribilli,G. Longobardi.Neural networks for the optical recognition of defects in cloth.Optical Enginers,35(11),1996,3183-3190.

[10]J.Lewis Dorroty,G.Vachtsevanos,Warren Jasper.Real-Time Fabric Defect Detection and Control in Wearing Processes.National Textile Center Annual Report, Georgia Institute of Technology,North Carolina State Uni-versity,1995,143-152.

[11]https://www.360docs.net/doc/246512154.html,lan,J.Escofet,J.Pladellorens,R. Navarro.Recognition and Inspection of Textile webs us-ing Fourier Analysis and Gabor Filters.VII National Symposium on Pattern Recognition and Image Analysis, Barcelona,Spain,1997,299-304.

布料外观疵点图解及成因分析

GTT大讲堂【148】布料外观疵点图解及成因分析-纱线疵点纱线疵点 简称“纱疵”,即织物纱线本身存在瑕疵,常见的纱疵有粗节、棉结、布开花、条干不匀、云织等等。 粗节(竹节) 外观:织物的经纱或者纬纱存在一小段比正常纱捻度少的粗节。 成因:精纺喂入粗纱时,纤维内密度不均匀,有较小密集的纤维束成纱。

布开花 现象:染色织物布面有极少纤维不上色,或者上色较浅,泛白。 成因:1.棉纤维内含有不着色的死棉纤维;2.纺纱时,一根纱线中混入了其他纤维,如棉纱混入极少的聚酯纤维,染色时没有高温染色或者使用分散性染料,使混入的纤维着色不良。 棉结 现象:布面呈现类似接头大小的(棉)纤维团,且纺入纱中。如将其拔下,纱则有可能断裂。(低等棉纺纱常有此问题。) 成因:原棉纤维中有死棉纤维团,在清花工序中没有清干净。

GTT大讲堂【149】布料外观疵点图解及成因分析-织造疵点(1)织造疵点 织疵主要指在织造过程中,由于织机故障、送纱张力问题或者油渍污染等原因造成影响布面效果的织物疵点。织疵现象多种多样,典型的常见的代表有断纱,稀密路、织造破洞、跳纱、组织错误(错综)、蛛网、纬缩、筘痕、油污纱、纬纱扭结、百足以及各种边疵等等。

1、断经 现象:织物上经纱断掉一根或者多根。 成因:经纱在织造的过程中断裂,自停装置失灵,未将经纱接好而继续织造。 2、断纬 现象:织物中的纬纱断裂,但断开的两端间距较短。

成因:1.纬纱在织造的过程中断裂,但瞬间继续织入,仅缺一小段距离。2.纬纱上有严重的粗结或者飞花,拆除时导致纬纱断裂。 3、双纬与脱纬 现象:单纬织物一个梭口内有两根纬纱织入布内。三根及以上并在一起则称之为“脱纬”。 成因:1、全幅双纬:误将两根纬纱混入一个织口;2、非全幅双纬:边剪设定不当或不够锐利,或断纬后未将纱尾消除。

纺织品名词术语

中华人民共和国国家标准 纺织名词术语 (针织品部分) Textile terms and definitions (Knitgoods) UDC677.6 :001.4 GB5708-85 本标准是对一般针织产品及其性能、试验、疵点名词术语所作的规定。 1产品 1.1针织物 1.1.1纬编针织物weft-knirted fabric 用纬编针织机编织,将纱线由纬向喂入针织机的工作针上,使纱线顺序地弯曲成圈,并相互穿套而形成的圆筒形或平幅形针织物。 1.1.2经编针织物warp-knirted fabric 用经编针织机编织,采用—组或几组经向平行排列的纱线,在经编机的所有工作针上同时进行成圈而形成的平幅形或圆筒形针织物。 1.1.3单面针织物single knit,single jersey 在针织机卜以单针筒或单针床织成的针织物。 1.1.4双面针织物double knit,double jersey 双针筒或双针床针织机织成的针织物。 1.1.5纬平针织物plain knit 采用纬编平针组织编织的针织物。 1.1.6罗纹针织物rib knit 采用罗纹组织编织的针织物。 1.1.7双罗纹针织物interlock fabric 采用双罗纹组织编织的针织物。 1.1.8双反面针织物purl fabric 采用双反面组织的针织物。 1.1.9集圈针织物tuck fabric 采用集圈组织的针织物。 1.1.10起绒针织物rasied knit,knitted fleece 表面起绒,具有绒层或毛茸外观的针织物。 1.1.11长毛绒针织物high pile knitted fabric 纤维毛条或毛纱与地纱一起喂人编织成圈,表面早现较长绒毛的针织物。 1.1.12毛圈针织物terry knitted fabric 由地组织线圈和拉长的沉降弧延展线或衬垫纱线等在表面形成毛圈的针织物。 1.1.13提花针织物jacquard knitted fabric 采用提花组织织成的带有浮线的针织物。 1.1.14丝盖棉针织物 用添纱集圈等组织编织的一种两面由不同纤维的纱线构成的针织物。常以涤纶丝构成其正面,由棉纱

织物疵点检测

DEFECT DETECTION IN REPETITIVE FABRIC PATTERNS R.Perez Computer Engineering Technical University of Valencia Ferrandiz y Carbonell no.2 Alcoy,Spain. email:ruperez@disca.upv.es J.Silvestre Computer Engineering Technical University of Valencia email:jsilves@disca.upv.es J.Munoz Instituto Tecnologico Textil Emilio Sala no.1 Alcoy,Spain email:jmunoz@aitex.es ABSTRACT In this paper a automated analysis system for defect de-tection in the print process of?ocked fabrics with repet-itive patterns is presented.This process represents a less computationally complex method than the detection of any type of pattern in the print process.For this reason,this problem can be solved using a personal computer(PC)in-specting100%of the production that ful?ll the require-ments of repetitive patterns.This system will be extremely useful for companies which produce repetitive pattern tex-tiles in large quantities.The implementation of a prototype system,based on the Fast Fourier Transform,will be de-scribed. KEY WORDS Textile Inspection,Fast Fourier Transform 1Introduction In spite of the advantages that computer vision provides to the fabric inspection process,in the production stage as well as?nal inspection,this technology has had little impact on the textile sector when considering developed systems,research articles and research institute projects. Meier[1]points out that although no electronic system is equal to the human eye,there are disadvantages.These include concentration,reproducibility of the process,es-pecially with the entire width of the fabric,speed and spe-cial functions:analyzing the size,form,con?guration,con-trast and relevancy of the defect to the?nality of the prod-uct.However,the textile industry employs computer vision very little because: ?Visual inspection of irregularities is complex due to the fact that the product is sometimes irregular by na-ture.The textile process can vary signi?cantly and it can still be considered correct. ?Fabric materials are?exible and can easily be dis-torted,which makes it dif?cult to use standard meth-ods for automated inspection. ?The economic cost it is possibly greater in this sec-tor than in others,because of the size of the area to be inspected and the resolution required to detect the defects.For these reasons,the development of systems governed by these restrictions,capable of detecting errors visible to the human eye,are quite expensive.Nevertheless,there have been serious attempts by researchers to introduce these techniques in the textile sector.For example,in regular texture fabrics analysis,Shin[2]develops an algorithm for defect detection and classi?cation based on energy mea-sures and the adaptive mask theorem.Although this needs the design of a classi?er using test data,it is not a gener-ally accepted method(Campbell[3-6])due to the impos-sibility of obtaining representative defect data with all er-ror characteristics.Cohen[7]develops a system based on a Gaussian Markov Random Field(GMRF)model of the correct textile texture,using non-overlapped windows to extract the GMRF parameters and compare it using a clas-si?er,with the correct characteristics of the fabric texture to determine the correctness of the window.Other work on texture defect detection can be seen in papers by Camp-bell[3-6]and Balakrishnan[8],based on Fourier Trans-form and where they also offer an interesting description of the fabric problems,Hoffer[9]uses an Optic Fourier Trans-form(OFT),Lewis[10],develops a Fourier based method using multiresolution decomposition by wavelets,and Es-cofet[11]uses the Fourier Angular Spectra Correlation to detect global defects and Gabor Filters to detect local de-fects.This paper is organized as follow:In section2we explain the problems and their particularities,in section3 we present the developed algorithm and in section4the results and the conclusions are shown. 2Problem description In the textile industry,the print process is the way in which a particular substance,usually dye,is impregnated on to a fabric in some areas using a perforated cylinder with holes positioned to give the desired design.A cylinder is used for each colour in the process.The most common problem in this process is the obstruction of the cylinder holes by dust, solidi?cation of the dye,etc.so that the resulting design is faulty.In the?ocked fabrics industry,it is normal proce-dure to use this process to make?ocked drawings on fabric bases.The colour of the fabric bases is usually the same as the?ock to be printed,as well as the adhesive used to?x the?ock to the weave.Therefore,although this process of

疵点检测系统中疵点检测算法

疵点检测系统中疵点检测算法 1引言 在氟塑料薄膜生产中,薄膜上会出现一些缺陷,称为表面疵点。产生表面疵点有多种原因,比如设备的性能不良、人为操作不当!生产原料在传送过程中被意外污染等。在氟塑料薄膜生产过程中,要经过较多的工序,且每个工序都可能产生一些影响,从而产生疵点。表面疵点会严重地影响塑料薄膜的质量和品质,致使产品的残次品率增加、疵点检测的目的就是在产品生产过程中及时发现这些疵点,通过修复和预防,尽可能降低由疵点导致的产品质量下降,有时也同时完成疵点的分类。 由于疵点种类众多,要找出一种能检验出所有疵点的通用模式识别算法的可能性不大。为了便于本文的讨论,根据氟塑料薄膜表面疵点的特征,并结合常见的疵点类型,将薄膜表面疵点种类简单地划分有机物污染、金属斑点、孔洞三类疵点。 2常见的疵点检测算法 基于机器视觉的疵点检测技术的核心内容是对采集的图像进行分析,将疵点从背景中分离出来"疵点检测的图像分析算法一般有两类"一类是直接对图像的灰度值在空间域进行分析和计算;另一类是通过傅立叶变换!小波变换等算法,先把图像转换到频域,再进行分析和计算畔。 2.1在空间域的疵点检测算法 在空间域进行疵点检测的常用算法中包括灰度匹配法!数学形态法、灰度统计量法、纹理结构模型法。 (1)灰度匹配法:它一般通过将待测产品与无疵点样品进行灰度比较,求出两者灰度的一种度量差,再与设定闽值比较,对待测图像做出判断。这种方法比较简洁,检测速度比较快,适合实时处理。但对图像的质量要求较高,易受噪声的影研句。 (2)数学形态法:该算法首先根据标准无疵点图像的自相关函数计算产品的基本重复单元;然后计算有疵点产品图像像素点的灰度均值及标准差,并根据它们确定产品图像疵点区域与无疵点区域的判别闭值。由己知的无疵点的产品图像得到结构元素。实际检测时,首先将待检产品图像的像素点与该阂值进行逐点比较,对图像进行二值化,然后通过数学形态处理来判断待检产品是否带有疵点并根据疵点的形状确定疵点的类别。这种方法能够判断具体疵点的类别,但由于它要对像素点进行逐点二值化,因而受噪声的影响大,容易引起错误检测。其次,因为这种检测方法的计算步骤多,所以处理速度较慢。 (3)灰度统计量法:这种算法与形态法有些相似,首先根据标准无疵点产品图像的自相关函数计算产品的基本重复单元。然后以基本重复单元为标准窗口大小,计算无疵点产品图像中每幅窗口像素点的平均灰度,并求出这些平均灰度的均值和标准差,并根据公式来确定无疵点窗口和有疵点窗口的判别闭值。这种方法的关键在于选择标准窗口的大小。窗口选择太大,虽然能降低窗口平均灰度的标准差,但是疵点对窗口平均灰度的影响相对减弱,从而造成漏检;另一方面,如果窗口选择偏小,标准差将会增加而使判别闭值范围很大,会引起误检。 (4)纹理结构模型法:通过提取正常纹理中少量特征参数,建立相应的纹理模型,通过分析待检测图像找到异常信息来断定疵点是否存在。首先根据无疵点样品的图像估计该随机场模型参数,并以此为匹配模板。在实际检测时,将待检测图像的模型参数与模板进行对比,通过统计假设法对待检图像做出判断。该方法的最大优点在于采用较少的随机场模型参数表示一幅产品图像,同时又因为其模型参数的估计算法的效率高,从而减少了图像分析的总体计算量。其次由于该方法从图像时域信号统计的角度出发,它对疵点的检测不受疵点类别的限制。这种方法的不足在于仅仅通过随机场模型并不能最大限度地降低图像分析的计算

织物疵点检测实验

织物疵点检测实验 一、实验目的: (1)了解智能织物疵点检测的工业结构和需求 (2)了解织物疵点检测装置结构 (3)熟悉如何检测装置如何检测织物疵点 二、实验要求: (1)进入实验室按照实验室章程操作,不随意触碰正在运行的对身体有伤害的实验设备,注意安全 (2)认真听取实验指导老师的操作介绍及注意事项 (3)观摩织物疵点检测装置 (4)根据检测结果分析布匹疵点位置 三、实验过程: 随着数字集成技术和图像处理技术的飞速发展,机器视觉已经在工业表面检测领域中得到越来越广泛的应用。以计算机视觉来代替人工视觉不仅可以提高检测速度,降低劳动成本,而且通过布匹疵点自动检测系统可以为布匹质量等级的评定,提供双方可信的参考数据,从而有利于布匹贸易的开展。 通常典型的机器视觉系统由以下5部分:光源、镜头、相机、图像采集卡和图像处理软件组成。 选择光源的目的:增强待处理的物体特征及减弱和消除不需要关注的物体和噪声的干扰,获取高品质、高对比度的图像。按照明方式的不同,光源可以分为:直接照明光源、散射照明光源、背光照明光源。条形方式常用的是LED条形光源,条形方式除具备沐光方式的优点外,其安装角度还可以按照需要进行调节。通过调节光线的角度和方向,可以检测到被测物体表面是否有光泽,是否有纹路,也可以检测到表面特征。聚光方式主要是在条形光源上加入一个柱型透镜,把光线汇聚成一条直线,以产生高亮度线光源,线性聚光方式常常配合线阵相机获得高质量的图像。图像采集卡其功能是将图像信号采集到电脑中,以数据文件的形式保存到硬盘上。 线阵相机每次只采集一行,只有把采集的若干行拼接起来才能形成完整的图像。而要完成这一任务就要保证相机的采集速度和布匹运动速度的匹配,如果速度不匹配就会获得失真的图像,更甚者获取不到图像。 根据照度匹配原理,选择LED长条形阵列照明光源,并讨论了光源的正向和背向照明结构;CCD相机和图像采集卡的选择,并详细说明了选择CCD相机应考虑的因素;疵点尺寸的图像测量是不同于以往疵点检测系统的新功能,因此需要对多CCD相机系统进行标定,这里介绍了图像测量原理和CCD相机标定理论,计算出每个相机的空间精确位置和姿态参数,并结合色织物疵点测量精度的要求,通过实验确定出像素相当量。 软件系统: 1、调用bitflow采集卡SDK实现图像的采集 2、VS2010与OpenCV平台的搭建,实现图像的处理 四、实验结果与总结: 该织物疵点检测符合实际工程项目的要求,并且各项指标良好,基本可以投入实际使用。但是,目前的织物疵点自动检测系统主要是针对白坯布,对基于机器视觉和图像处理技术,及宽幅面、高密度色织物的疵点自动检测还有待发展。

面料疵点英语

面料疵点及英语对译 面料疵点及英语对译 弓纬:布面纬向纹路弯曲呈弓形,称为弓纬。Bowing 荷叶边:布边在拉幅时,布边未挂到针链而导致布边有凹型或者月牙型的点。Scallops 门幅布的有效宽度。Fabric Width 门幅小实际布封比要求的布封小。Narrow Width 磨毛痕布面因坯布时已经有针路在磨毛时使针路更加明显。Sand Mark 起毛:织物在实际穿用与洗涤过程中,不断经受摩擦,使织物表面的纤维端露出于织物,在织物表面呈现许多令人讨厌的毛茸,即为起毛。Hair 起球:若这些毛茸在继续穿用中不能及时,脱离互相纠缠在一起,被揉成许多球形小粒,称为起球。Pilling 树脂印过树脂的布在过树脂时产生的印记。Resin Mark 停车痕定型工艺中停机造成,类似色档Stop Mark 纬斜布面纬向纹路与水平方向不一致,形成一定角度的倾斜。Slanting 循环大循环比订单要求的数值大。Repeat Bigger 油污机器上的油或空中飘浮的灰尘污染布面所导致的黑色油点为油污Oil 预缩痕由于预缩调节的张力太松,而导致布在进入橡胶辊之前打槢在经过辊压后形成的预缩痕。Compact Mark 抓毛痕抓毛时出现痕迹。Brush Mark 软油印工艺中用了柔软迹定型过程中泛于布面类似油污Softener

纬斜布面纬向纹路与水平方向不一致,形成一定角度的倾斜。Skewing 错花织布时穿错纱,造成织物花型错误的情况。Pattern Error 错纱换纱时上错纱Missing Yarn 错组织:调试过程中工艺错误,使得织出的坯布组织同要求的不一致Wrong Construction 断拉架LYCRA在生产过程中被拉断。Broken Lycra 断纱生产过程中纱线被拉断,在布面上呈现为沿纬向纹路裂开。Broken Yarn 断针在布面上呈现为沿经向纹路裂开一般在末端形成一个破洞。Broken Needle 反拉架lycra在编织过程中同棉纱的位置翻转,表面形成一段段的横纹效果Reverse Lycra 飞花织布过程中不同颜色的纤维被织进织物中。Flying 飞拉架lycra在编织过程中没有被织针吃到,浮在坯布外面Missing Lycra 飞纱/漏织纱线在编织过程中没有被织针吃到Missing Stitch 黑油针:由于机台供油不足,使得指针在运转中磨损,磨损的金属混在润滑油中,跟随织针的运转污染坯布,形成纵向油针。Dark Oil Needle 横条:在圆筒针织物中出现一些不正常的连续的横间循环。Barre 花针:由于织针未正常成圈,而吃纱造成的纵向疵点Pin Holes坏针在布面上呈现为沿经向纹路裂开一般在末端形成一个破洞。Laddering 黄白纱:原料本身质地不同而形成Yellow White Yarn 黄油针: 由于机台供油不足,使得指针在运转中磨损,磨损的金属混在润滑油中,跟随织针的运转污染坯布,形成纵向油针。Yellow Oil Needle

Q_330502 QR 001-2019婴幼儿及儿童服装

ICS61.020 Y 76 Q/QR 湖州织里启然服饰有限公司企业标准 Q/330502 QR 001—2019 婴幼儿及儿童服装 Garments for infants and children 2019-04-20发布2019-05-01实施湖州织里启然服饰有限公司发布

前言 本标准按照GB/T 1.1-2009给出的规则起草。 本标准由湖州织里启然服饰有限公司提出。 本标准起草单位:湖州织里启然服饰有限公司。 本标准主要起草人:王鹏。 本标准由湖州织里启然服饰有限公司负责解释。 Ⅰ

婴幼儿及儿童服装 1 范围 本标准规定了婴幼儿及儿童服装术语和定义、要求、试验方法、检验规则、包装、储运和标志内容。 本标准适用于以纺织织物、人造革等单种材料或多种材料拼接生产的婴幼儿及儿童服装。 本标准也适用于含絮用纤维、羽绒等填充物的婴幼儿及儿童服装。 2 规范性引用文件 下列文件对于本文件的应用是必不可少的。凡是注日期的引用文件,仅所注日期的版本适用于本文件。凡是不注日期的引用文件,其最新版本(包括所有的修改单)适用于本文件。 GB/T 250 纺织品色牢度试验评定变色用灰色样卡 GB/T 1335.3 服装号型儿童 GB/T 2910(所有部分) 纺织品定量化学分析 GB/T 3917.2 纺织品织物撕破性能第2部分:裤形试样(单缝)撕破强力的测定 GB/T 3920 纺织品色牢度试验耐摩擦色牢度 GB/T 3921-2008 纺织品色牢度试验耐皂洗色牢度 GB/T 3922 纺织品色牢度试验耐汗渍色牢度 GB/T 4802.1 纺织品织物起毛起球性能的测定第 1部分:圆轨迹法 GB/T 4802.3 纺织品织物起毛起球性能的测定第 3部分:起球箱法 GB/T 4841.3 染料染色标准深度色卡2∕1、1∕3、1∕6、1∕12、1∕25 GB/T 5296.4 消费品使用说明第4部分:纺织品和服装 GB/T 5713 纺织品色牢度试验耐水色牢度 GB/T 6529 纺织品调湿和试验用标准大气 GB/T 7573 纺织品水萃取液pH值的测定 GB/T 7742.1-2005 纺织品织物胀破性能第1部分:胀破强力和胀破扩张度的测定液压法 GB/T 8628 纺织品测定尺寸变化的试验中织物试样和服装的准备、标记及测量 GB/T 8629-2017 纺织品试验用家庭洗涤和干燥程序 GB/T 8630 纺织品洗涤和干燥后尺寸变化的测定 GB/T 12705.1 纺织品织物防钻绒性试验方法第 1部分:摩擦法 GB/T 14272 羽绒服装 GB/T 14644 纺织品燃烧性能45°方向燃烧速率的测定 GB/T 15557 服装术语 GB/T 18132 丝绸服装 GB 18383 絮用纤维制品通用技术要求 GB 18401 国家纺织产品基本安全技术规范 GB/T 18886 纺织品色牢度试验耐唾液色牢度 GB/T 19976-2005 纺织品顶破强力的测定钢球法 GB/T 20388 纺织品邻苯二甲酸酯的测定四氢呋喃法 1

79种纺织面料疵点术语大汇总

79种纺织面料疵点术语大汇总 1、横裆疵(Barre) 对针织织物而言,这种缺陷的特点是在织物横列或在织物横向上通常会出现一些不均匀的花纹图案。纱线不均匀、纱线张力不均匀以及纱线具有不同的染料亲和力等都可能是出现这种情况的原因。坏地(Bad Place)-对于那些难以用语言来描述的织物缺陷而言,这是一个十分方便的术语。这个术语通常用来描述那些织物织造受到严重破坏的地方。 2、斜纹疵(Bias)(参考纬斜) 对梭织织物而言,这种缺陷指的是纬纱与经纱发生尺寸偏斜的地方;对针织织物而言,这种情况指的是织物横列与织物纵行发生尺寸偏斜的地方。 3、鸟眼花纹疵(Birdseye Defect) 对针织织物而言,这种情况指的是偶尔无规律出现的与织物设计相反的集圈组织。 4、弓弧(Bow) 对梭织织物而言,这种情况指的是纬纱以弧线方式位于织物的宽度方向上;对针织织物而言,这种情况指的是线圈横列以弧线方式位于织物的宽度方向上。 5、断头疵(Broken End) 这种缺陷指的是经纱断裂后并经过修补的地方,它的常见特点是可以看见织到织物当中的断头。 6、花纹错色疵(Broken Color Pattern) 对梭织织物而言,这种情况指的是花纹的不连续性,在用织布机通丝描绘彩色图案时产生错误或者在纬纱断裂时对织布机进行维修以后对图像填充链的重新设置不正确都可能会导致这种缺陷的产生;对针织织物而言,这种情况是由梭换筒错误而产生的。

7、断纬疵(Broken pick) 这种情况指的是,由于纬纱断裂而导致在织物的部分宽度上缺少纬纱。擦伤疵(Bruise)-(参考边撑疵)-这种情况指的是:由于正在进行编织的纱线或者已经编织完毕的织物受到磨损,从而导致纤维失去方向感并导致织物外观失真。 8、斑点疵(Burl mark) 这是一种由于某些物质过量而导致的变形,这些物质包括粗纺线,废物以及正在用修补工具来去除的飘头纱。 9、吊边疵(Buttonhole selvage) 这是一种织物织边缺陷,更换纬纱之前在织布机梭子上累积起来的过度张力是造成这种缺陷的原因。这种张力往往会限制织边纬纱的正确脱落以及交错,从而产生一种类似于扣眼的瑕疵。 10、擦伤纱(Chafed Yarn) 这种缺陷指的是受到磨损的纱线,纱线受到磨损以后会使纤维失去方向感并令纱线失真。这种缺陷将会影响到纱线的可着色性,并常常会导致径向条花或纬向条痕的产生。 11、碎裂纬纱(Chopped Filling) 这种缺陷是指纬纱方向上产生的不均衡现象,其特点是存在一个明显的或整齐的图案,而该图案是由绘图辊的偏心行为所造成的。 12、破洞疵(Clip mark) 这种缺陷是指织物上未被染上色的地方,这种缺陷的产生是由于夹在织物边缘上的金属小夹子所造成的,这些小夹子是为了避免或修正织物织边在染色时翻折而使用的。 13、粗经疵(Coarse End) 这种情况指的是,有一根经纱的直径要明显大于织物正常经纱的直径。

纺织行业标准用语疵点定义

2.定义: 2.1疵点defects 纺织品上呈现的削弱其质量性能及影响外观的缺陷。 2.2纱疵Yarn defects 纱线上存在的疵点。 2.3织疵woven defects 在织造过程中产生的织物疵点。 2.4经向疵点 warp direction defect 由经纱形成或在织物经向上呈现的疵点。 2.5纬向疵点 weft direction defects 由纬线形成或在织物纬向上呈现的疵点。 2.6边部疵点 selvedge defects 在布边或距布边一定距离内呈现的疵点。 同义词:边疵,布边疵点 2.7整修疵点repaired defects 对织物上疵点经整修后留下痕迹形成的疵点。 2.8染整疵点defects due to dyeing, printing or finishing 染色、印花、整理工艺过程中产生的疵点。 2.9局部性疵点local defects 在织物上所占部位较小或仅在一处,易于计量其尺寸数量的疵点。 2.10散布性疵点spread defects 在织物上分散面积较大,不易计量其尺寸、数量的疵点。 2.11破损性疵点damaging defects 织物经纬纱断裂,组织受到破坏的疵点。 2.12线状(疵点)line 织物上呈现的粗细如线条状的疵点。 2.13条状(疵点)streak 织物上呈现有一定宽度的条、块状疵点。 2.14严重疵点serious defects 在性质程度上对织物外观质量有较大影响的疵点。 3.由纱疵形成的织物疵点 3.1粗节slub 牵伸不良的纱织入,致织物上呈现一根中部较粗、两端呈锥形的纱线,其中部直径数倍于邻近正常纱线。连续的粗节纱片段称为竹节。 同义词:枣核纱 3.2偏细纱fine yarn, thin pick, thin end 织物上一根或数根纱线的细度明显小于邻近纱线。 同义词:细径,细纬 3.3扭结纱cockled yarn 牵伸过程中意外夹入一些纤维或形成扭结或卷曲等原因,使织物上呈现有可拉伸的小粗节纱段3.4裂纱split yarn 纱线受磨损或张力过大,使一根纱线的一部分(如长丝中的一根单丝,双股线中的一股)断裂,织物上呈现一根纱线部分偏细。 同义词:单头 3.5毛丝broken filaments 络筒或织造过程中长丝的单根丝断裂,织物局部或散布性地呈现纤维端突出或茸毛状外观。 3.6亮丝bright yarn 纺丝过程加工不良,如消光剂分布不匀等原因,织物上一根纱线的光泽比邻近的纱线亮。 3.7结头不良ending mark 结头不合规格的纱织入,织物单根经纱或纬纱上有尘污、油污等污迹。 3.8污渍纱soiled yarn

常用试验方法标准名称

常用标准名称一览表 序号检测标准编号(含年号) 1 GB/T2910.1-2009《纺织品定量化学分析第1部分:试验通则》 2 GB/T2910.2-2009《纺织品定量化学分析第2部分:三组分纤维混合物》 3 GB/T2910.3-2009《纺织品定量化学分析第3部分:醋酯纤维与某些其他纤 维的混合物(丙酮法)》 4 GB/T 2910.4-2009《纺织品定量化学分析第4部分:某些蛋白质纤维与某些 其他纤维的混合物(次氯酸盐法)》 5 GB/T 2910.5-2009《纺织品定量化学分析第5部分:粘胶纤维、铜氨纤维或莫代尔纤维与棉的的混合物(锌酸钠法)》 6 GB/T 2910.6-2009《纺织品定量化学分析第6部分:粘胶纤维、某些铜氨纤维、莫代尔纤维或莱赛尔纤维与棉的混合物(甲酸-氯化锌法)》 7 GB/T 2910.7-2009《纺织品定量化学分析第7部分:聚酰胺纤维与某些其 他纤维混合物(甲酸法)》 8 GB/T 2910.8-2009《纺织品定量化学分析第8部分:醋酯纤维与三醋酯纤维 混合物(丙酮法)》 9 GB/T 2910.9-2009《纺织品定量化学分析第9部分:醋酯纤维于三醋酯纤维 混合物(苯甲醇法)》 10 GB/T 2910.10-2009《纺织品定量化学分析第10部分:三醋酯纤维或聚乳酸纤维与某些其他纤维的混合物(二氯甲烷法)》 11 GB/T 2910.11-2009《纺织品定量化学分析第11部分:纤维素纤维与聚酯纤 维的混合物(硫酸法)》 12 GB/T 2910.12-2009《纺织品定量化学分析第12部分:聚丙烯腈纤、某些改性聚丙烯腈纤维、某些含氯纤维或某些弹性纤维与某些其他纤维的混合物(二甲基甲酰胺法)》 13 GB/T 2910.13-2009《纺织品定量化学分析第13部分:某些含氯纤维与其他纤 维的混合物(二硫化碳_/丙酮法)》 14 GB/T 2910.14-2009《纺织品定量化学分析第14部分:醋酯纤维与某些含氯 纤维的混合物(冰乙酸法)》 15 GB/T 2910.15-2009《纺织品定量化学分析第15部分:黄麻与某些动物纤维 的混合物(含氮量法)》 16 GB/T 2910.16-2009《纺织品定量化学分析第16部分:聚丙烯纤维与某些其 他纤维的混合物(二甲苯法)》 17 GB/T 2910.17-2009《纺织品定量化学分析第17部分:含氯纤维(氯乙烯均聚物)与某些其他纤维的混合物(硫酸法)》

纬编针织物常见疵点的原因及其解决措施

纬编针织物常见疵点的原因及其解决措施 目录 1.针织圆机的结构......................................... 错误!未定义书签。 2.常见疵点............................................... 错误!未定义书签。 2.1 针路 (2) 2.1.1 设备方面 (2) 2.1.2 工艺方面 (3) 2.1.3 原料方面 (4) 2.1.4 调机方面控制 (4) 2.1.5 生产方面 (4) 2.1.6 质量控制 (5) 2.2 横纹 (5) 2.3漏针 (5) 2.4 破洞 (6) 2.5 花针 (6) 2.6 油针 (7) 2.7 反拉架 (7) 2.8 紧拉架 (7) 2.9 飞拉架 (7) 3.结论和尚存问题 (8) 参考文献 (9) 致谢 (10)

摘要 本文旨在通过对针织大圆机生产过程中常见疵点的分析、探讨,寻求更好更合理的解决办法,以求达到有利于提高保全的技能和工作效率、产品质量、机器产量和中国纬编针织物的国际竞争力之目的。文中本人通过了解机器运行原理,编织原理、各种仪器工具的使用的研究,提出了解决纬编针织物常见疵点更独到的方法,对其它类似问题有很好的参考价值、启示作用。 关键词:纬编针织布;针路;横纹;漏针;破洞;花针;油针;反拉架;紧拉架;飞拉架;原因及其解决措施

1 针织圆机的结构 要解决问题,那就先对事物有一定的了解和认识。下面就先介绍一下针织大圆机的结构: 纬编针织是将纱线由纬向喂入到针织机的工作针上,使纱线顺序地弯曲成圈并相互串套而形成织物的一种方法。 针织大圆机主要由给纱机构、编织机构、牵拉卷取机构、传动机构和辅助机构组成。(一)给纱机构 其作用是将纱线从筒子上退解下来,不断地输送到编织区域,以使编织能连续进行。针织大圆机的给纱机构有积极式、半积极式和消极式3种类型。目前生产中常采用积极式给纱机构,以固定的速度进行喂纱,控制针织物的线圈长度,使其保持恒定,以改善针织物的质量。 (二)成圈机构 其作用是将喂入的纱线通过成圈机件的运动编织成针织物。成圈机构由织针等多种成圈机件组成,能独自把喂入的纱线形成线圈而编织成针织物的编织机构单元称为成圈系统。纬编机一般都装有较多的成圈系统,成圈系统数越多,机器一转多编织的横列数越多,生产效率就越高。 (三)牵拉卷取机构 其作用是将已形成的针织物从成圈区域引出,并卷成一定形式的卷装,以使编织过程能顺利进行。牵拉卷取量的调节对成圈过程和产品质量有很大的影响,为了使织物密度均匀、门幅一致,牵拉卷取必须连续进行,而且张力稳定。此外,卷取坯布时还要求卷装成形良好。 (四)传动机构 其作用是将动力传送给上述各个机构,使它们协调工作而完成各自的任务。传动机构要求传动平稳、动力消耗小、便于调节、操作安全方便。 (五)辅助装置 其作用是扩大机器的工艺可能性或使机器便于调节和看管,保证编织正常进行,如机器上的花型机构、自动加油装置、清洁除尘装置、各种自停装置等。

纺织品术语

https://www.360docs.net/doc/246512154.html,/?LANG=zh-cn fast colours 不褪色;色泽牢固 punch work 抽绣 embroidery 刺绣品 acetate fibre 醋酯纤维 hemp 大麻 damp proof 防潮 sanforizing, pre-shrunk 防缩 textiles 纺织品 crochet 钩编编织物 gloss, lustre 光泽 synthetic fibre 合成纤维 chemical fibre 化学纤维 jute 黄麻 gunny cloth (bag) 黄麻布(袋)mixture fabric, blend fabric 混纺织物woven fabric 机织织物 spun silk 绢丝 linen 麻织物 woolen fabrics 毛织物(品) cotton textiles 棉纺织品 cotton velvet 棉绒 cotton fabrics 棉织物(品)

non-crushable 耐绉的 viscose fibre 黏胶纤维matching, colour combinations 配色rayon fabrics 人造丝织物 artificial fiber 人造纤维 crewel work 绒线刺绣 mulberry silk 桑蚕丝, 家蚕丝 silk fabrics 丝织物 silk spinning 丝纺 linen cambric 手帕亚麻纱 plain 素色 figured silk 提花丝织物 jacquard 提花织物 applique embroidery 贴花刺绣discolourization 褪色 mesh fabric 网眼织物bondedfibre fabric 无纺织物embroidered fabric 绣花织物 flax 亚麻 linen yarn 亚麻纱 knitting 针织 knitwear 针织品

基于Matlab的织物疵点检测系统

目录 摘要 (1) ABSTRACT (1) 第一章绪论 (2) 第1.1节织物瑕疵检测简介 (2) 第1.2节图像处理技术 (4) 第1.3节本文的主要内容以及章节安排 (6) 第二章基础知识 (7) 第2.1节MATLAB的介绍 (7) 第2.2节图像处理工具箱和小波工具箱 (8) 第三章基于小波变换的织物瑕疵分析 (11) 第3.1节二维小波变换 (11) 第3.2节主要分析流程 (13) 第3.3节基于小波变换的瑕疵检测过程 (14) 第四章总结 (21) 参考文献 (22) 致谢 (23) 附录 (24)

摘要 在纺织品生产中,织物疵点检测是很重要的一个环节。本文在对图像处理技术以及织物瑕疵检测特征值的提取方法一定理解基础上,借助Matlab中的图像处理工具箱和小波分析工具箱,重点分析了织物瑕疵检测的过程。实验表明该方法可以识别简单的织物瑕疵。 关键词:织物瑕疵检测图像处理小波变换 Abstract Fabric defect detection plays an important part in the production process of the fabric. In this paper, on the basis of understanding of image processing technology and the method of character extraction for the fabric defects,the process of fabric defect detection is analyzed with the help of image processing toolbox and wavelet toolbox in Matlab. The experiments show that this method can identify some simple defects in the fabric. Keyword: Fabric defect detection Image processing Wavelet analysis Wavelet transform

织物疵点检测的图像处理技术实验

织物疵点检测的图像处理技术实验 1、实验目的: (1)学习织物疵点检测图像处理技术的工作原理及应用。 (2)了解织物疵点检测的软硬件环境和常见织物疵点的简单分类。 (3)理解各类疵点图像的分割和特征提取等内容。 二、实验过程 众所周知,织物疵点是影响织物品质的主要因素。疵点检测的目的就是在织造完成后,验布过程中及时发现这些已经存在的疵点,通过修复和整理,尽可能降低由织物疵点导致的织物质量下降,有时也可以同时完成织物疵点的分类,用以评价织物的质量。 织物疵点的检测是纺织品检测中最重要的检验项目之一,长期以来,疵点的检测都是由人工视觉完成,也就是检验人员在没有眩光的北面窗旁或日月灯光照明条件下按照自己的经验对织物进行评价,按评等标准对织物进行等级评定。这种方法存在一定的显然缺陷,如劳动强度大、效率低、漏检率高等、受检验人员主观性因素影响大,难以得到准确的检验结果。 随着计算机图像处理技术和神经网络技术的发展,使得基于图像处理和微型计算机平台的织物疵点检测称为可能。此次的参观学习,主要从织物疵点图像的采集、采集的图像预处理和分割、图像的相关分析等方面作以讲解。 (1)织物疵点图像的采集:植物图像的数据获取,包括选择可行的照明(荧光灯或光纤)和图像数字化设备。 (a) 借用目前分辨率较高的数字图像采集设备对织物表面外观进行采 集。 (b) 如何设置光照条件,以保证采样时的光照均匀,从而使采集的数 字图像便于处理。 (2)图像预处理和图像分割:将采集到的图像利用各种图像处理方法进行必要得图像变换,图像增强处理,如将原彩色图像转换为灰色图,并未增强图像对比度进行直方图变换等,以利于后期的图像分析,进一步对图像进行分割、二值化、滤波等操作。 (3)图像分析 (a) 对织物疵点图像进行模式特征提取。 (b) 通过对织物疵点特征分析和进行大量实验,优化处理算法。 三、实验心得体会: 在师兄详细介绍完织物疵点检测系统整个原理及流程后,开始进行