EPA 9056A 离子色谱法检测无机阴离子

9056A - 1

Draft Revision 1September 1999

Pre-release version -- This method has NOT been released by OSW as part of Update IV.

METHOD 9056A

DETERMINATION OF INORGANIC ANIONS BY ION CHROMATOGRAPHY

1.0

SCOPE AND APPLICATION

1.1This method addresses the sequential determination of chloride (Cl G ), fluoride (F G ),bromide (Br G ), nitrate (NO 3G ), nitrite (NO 2G ), phosphate (PO 43G ), and sulfate (SO 42G ) anions in aqueous samples, such as drinking water, waste water, aqueous extracts of solids, and the collection solutions from the bomb combustion of solid waste samples.

1.2The method detection limit (MDL), the minimum concentration of a substance that can be measured and reported with 99% confidence that the value is above zero, varies for anions as a function of sample size. Generally, minimum detectable concentrations are in the range of 0.002-0.02 mg/L for F G , Br G , Cl G , NO 3G -N, NO 2G -N, PO 43G -P, and SO 42G with a 50-μL sample loop.The MDLs for specific anions are given in Table 1. The upper limit of the method is dependent on total anion concentration and may be determined experimentally. Maximum column loading (total anions) should not exceed approximately 500 ppm. Dilution of samples may allow higher concentration samples to be analyzed.

1.3 Analysts should consult the disclaimer statement at the front of the manual and the information in Chapter Two, Sec.

2.1, for guidance on the intended flexibility in the choice of methods, apparatus, materials, reagents, and supplies, and on the responsibilities of the analyst for demonstrating that the techniques employed are appropriate for the analytes of interest, in the matrix of interest, and at the levels of concern. In addition, analysts and data users are advised that, except where explicitly specified in a regulation, the use of SW-846 method is not mandatory in response to Federal testing requirements. The information contained in this method is provided by EPA as guidance to be used by the analyst and the regulated community in making judgments necessary to generate results that meet the data quality objectives for the intended application.2.0

SUMMARY OF THE METHOD

2.1 A small volume of aqueous sample, typically 2 to 3 mL, is injected into an ion chromatograph to flush and fill a constant volume sample loop. The sample is then injected into a flowing stream of carbonate-bicarbonate eluent.

2.2The sample is pumped through two different ion exchange columns, then a suppressor device and into a conductivity detector. The two ion exchange columns, a precolumn or guard column and a separator column, are packed with low-capacity, strongly basic anion exchange resin. Ions are separated into discrete bands based on their affinity for the exchange sites of the resin. The suppressor is an ion exchange-based device that reduces the background conductivity of the eluent to a low or negligible level and also converts the anions in the sample to their more conductive acid form. The separated anions in their acid form are measured using an electrical-conductivity cell. Anions are identified based on their retention times compared to known standards. Quantitation is accomplished by measuring the peak height or area and comparing it to a calibration curve generated from known standards.

3.0DEFINITIONS

Refer to Chapter One and Chapter Three for applicable definitions.

4.0INTERFERENCES

4.1Any species with a retention time similar to that of the desired ion will interfere. Large quantities of ions eluting close to the ion of interest will also result in an interference. Separation can be improved by adjusting the eluent concentration and/or flow rate. Sample dilution and/or the use of the method of standard additions can also be used. For example, high levels of organic acids that may interfere with inorganic anion analysis may be present in industrial wastes. Two common species, formate and acetate, elute between fluoride and chloride.

4.2The water dip or negative peak that elutes near, and can interfere with, the fluoride peak can usually be eliminated by the addition of the equivalent of 1 mL of concentrated eluent (100 times more concentrated than the solution described in Section 7.3) to 100 mL of each standard and sample.

4.3Method interferences may be caused by contaminants in the reagent water, reagents, glassware, and other sample processing apparatus that lead to discrete artifacts or elevated baseline in ion chromatograms.

4.4Samples that contain particles larger than 0.45 μm and reagent solutions that contain particles larger than 0.20 μm require filtration to prevent damage to instrument columns and flow systems. The associated method blanks must also be filtered if any samples or reagents have undergone filtration.

4.5The acetate, formate, and other monovalent organic acids anion elutes early in the chromatographic run and can interfere with fluoride. The retention times of anions may differ when large amounts of acetate are present. Therefore, this method is not recommended for leachates of solid samples where acetate is used for pH adjustment.

5.0SAFETY

5.1The toxicity or carcinogenicity of each reagent used in this method has not been fully established. Each chemical should be regarded as a potential health hazard and exposure should be as low as reasonably achievable. Cautions are included for known extremely hazardous materials or procedures.

5.2Each laboratory is responsible for maintaining a current awareness file of OSHA regulations regarding the safe handling of the chemicals specified in this method. A reference file of Material Safety Data Sheets (MSDS) should be made available to all personnel involved in the chemical analysis. The preparation of a formal safety plan is also advisable.

9056A - 2Draft Revision 1

September 1999 Pre-release version -- This method has NOT been released by OSW as part of Update IV.

9056A - 3

Draft Revision 1September 1999

Pre-release version -- This method has NOT been released by OSW as part of Update IV.

6.0EQUIPMENT AND SUPPLIES

6.1Ion chromatograph, capable of delivering 1 to 5 mL of eluent per minute at a pressure of 1000 to 4000 psi (6.5 to 2

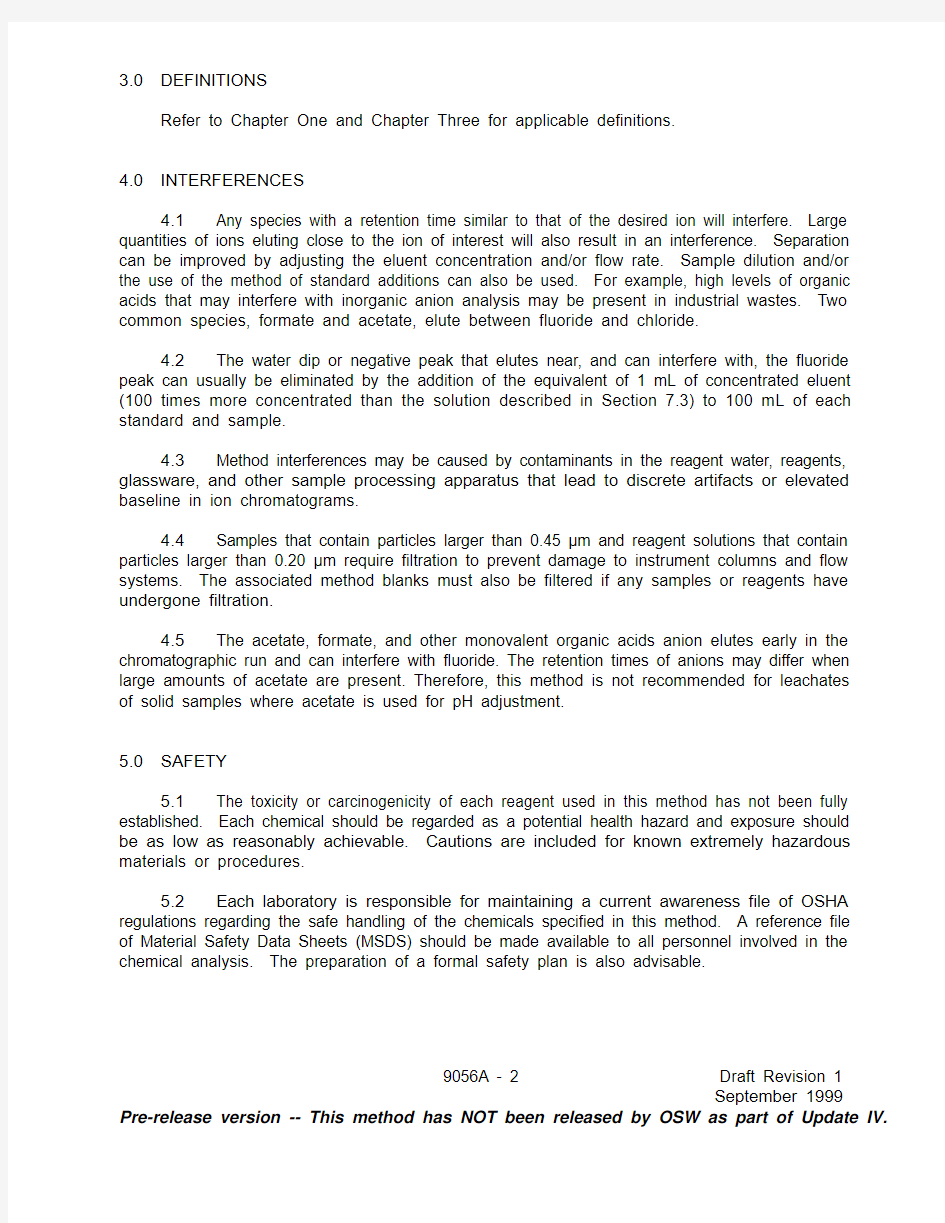

7.5 MPa). The chromatograph shall be equipped with an injection valve, a 25- to 100-μL sample loop, and set up with the following components, as schematically illustrated in Figure 1.

6.1.1Precolumn, a guard column placed before the separator column to protect

the separator column from being fouled by particulates or certain organic constituents (4 x 50 mm, Dionex IonPac AG4A -SC P/N 43175, or equivalent).

6.1.2Separator column (see Figure 2), a column packed with low-capacity

pellicular anion exchange resin that is styrene divinylbenzene-based has been found to be suitable for resolving F G , Br G , Cl G , NO 3G , NO 2G , PO 43G , and SO 42G (4 x 250 mm, Dionex IonPac AS4A-SC P/N 43174, or equivalent).

6.1.3Suppressor, an ion exchange-based device that is capable of converting the

eluent and separated anions to their respective acid forms (Dionex AMMS-II P/N 43074 or ASRS Ultra P/N 53946, or equivalent).

6.1.4Detector, a low-volume, flow-through, temperature-compensated, electrical

conductivity cell (approximately 1.25-μL volume, Dionex CD20, or equivalent) equipped with a meter capable of reading from 0 to 1,000 Siemens/cm on a linear scale.

6.1.5Pump, capable of delivering a constant flow of approximately 1 to 5 mL/min

throughout the test and tolerating a pressure of 1000 to 4000 psi (6.5 to 27.5 MPa).6.2

Syringe, minimum capacity of 1 mL, equipped with a male pressure fitting.

6.3Appropriate chromatographic data and control software to acquire data. Dionex PeakNet was used to record and process the chromatogram shown in Figure 2. Alternatively, an integrator or recorder can be used to integrate the area under the chromatographic peaks. If an integrator is used, the maximum area measurement must be within the linear range of the integrator. The recorder should be compatible with the detector output with a full-scale response time of 2 seconds or less. Systems using an integrator or recorder may not necessarily achieve the same MDLs shown in Table 1.

6.4Analytical balance, capable of weighing to the nearest 0.0001 g.6.5Pipets, Class A volumetric flasks, beakers: assorted sizes.

7.0

REAGENTS AND STANDARDS

7.1Reagent grade chemicals shall be used in all tests. Unless otherwise indicated, it is intended that all reagents shall conform to the specifications of the Committee on Analytical Reagents of the American Chemical Society, where such specifications are available. Other

9056A - 4

Draft Revision 1September 1999

Pre-release version -- This method has NOT been released by OSW as part of Update IV.

grades may be used, provided it is first ascertained that the reagent is of sufficiently high purity to permit its use without lessening the accuracy of the determination.

7.2Reagent water. All references to water in this method refer to reagent water, as defined in Chapter One.

7.3Eluent, 1.7 mM NaHCO 3/1.8 mM Na 2CO 3. Dissolve 0.2856 g of sodium bicarbonate (1.7 mM NaHCO 3) and 0.3816 g of sodium carbonate (1.8 mM Na 2CO 3) in reagent water and dilute to 2 L with reagent water or follow manufacturer’s guidance for the proper eluent for each specific column.

7.4Suppressor regenerant solution (25 mM H 2SO 4), if required. Add 2.8 mL of concentrated sulfuric acid (H 2SO 4) to 4 L of reagent water.

7.5Stock solutions (1,000 mg/L). Certified standards may also be purchased and used as stock solutions.

7.5.1Bromide stock solution (1.00 mL = 1.00 mg Br G ). Dry approximately 2 g of

sodium bromide (NaBr) for 6 hours at 150°C, and cool in a desiccator. Dissolve 1.2877 g of the dried salt in reagent water, and dilute to 1 L with reagent water in a Class A volumetric flask.

7.5.2Chloride stock solution (1.00 mL = 1.00 mg Cl G ). Dry sodium chloride (NaCl)

for 1 hour at 600°C, and cool in a desiccator. Dissolve 1.6484 g of the dry salt in reagent water, and dilute to 1 L with reagent water in a Class A volumetric flask.

7.5.3Fluoride stock solution (1.00 mL = 1.00 mg F G ). Dissolve 2.2100 g of

sodium fluoride (NaF) in reagent water, and dilute to 1 L with reagent water in a Class A volumetric flask. Store in a chemical-resistant glass or polyethylene container.

7.5.4Nitrate stock solution (1.00 mL = 1.00 mg NO 3G ). Dry approximately 2 g of

sodium nitrate (NaNO 3) at 105°C for 24 hours. Dissolve exactly 1.3707 g of the dried salt in reagent water, and dilute to 1 L with reagent water in a Class A volumetric flask.7.5.5Nitrite stock solution (1.00 mL = 1.00 mg NO 2G ). Place approximately 2 g

of sodium nitrate (NaNO 2) in a 125 mL beaker and dry to constant weight (about 24 hours)in a desiccator containing concentrated H 2SO 4. Dissolve 1.4998 g of the dried salt in reagent water, and dilute to 1 L with reagent water in a Class A volumetric flask. Store in a sterilized glass bottle. Refrigerate and prepare monthly.

NOTE: Nitrite is easily oxidized, especially in the presence of moisture, and only fresh

reagents are to be used.NOTE:

Prepare sterile bottles for storing nitrite solutions by heating for 1 hour at 170°C in an air oven.

9056A - 5

Draft Revision 1September 1999

Pre-release version -- This method has NOT been released by OSW as part of Update IV.

7.5.6Phosphate stock solution (1.00 mL = 1.00 mg PO 43G ). Dissolve 1.4330 g

of potassium dihydrogen phosphate (KH 2PO 4) in reagent water, and dilute to 1 L with reagent water in a Class A volumetric flask.

7.5.7Sulfate stock solution (1.00 mL = 1.00 mg SO 42G ). Dissolve 1.4790 g of the

dried salt in reagent water, and dilute to 1 L with reagent water in a Class A volumetric flask.7.6

Anion working solutions

Prepare a blank and at least three different working solutions containing the following combinations of anions. The combination anion solutions must be prepared in Class A volumetric flasks. See Table 2.

7.6.1Prepare the high-range standard solution by combining the volumes of each

anion stock solution specified in Table 2 in a Class A volumetric flask and diluting the mixture to 1 L with reagent water.

7.6.2Prepare the intermediate-range standard solution by diluting 10.0 mL of the

high-range standard solution (see Table 2) to 100 mL with reagent water.

7.6.3Prepare the low-range standard solution by diluting 20.0 mL of the

intermediate-range standard solution (see Table 2) to 100 mL with reagent water.7.7

Stability of standards

Stock solutions are stable for at least 1 month when stored at 4 ± 2E C. Dilute working standards should be prepared weekly, except those that contain nitrite and phosphate, which should be prepared fresh daily. The validity of standards can be confirmed through the analysis of a freshly prepared ICV (Sec. 9.4).8.0

SAMPLE COLLECTION, PRESERVATION, AND STORAGE

8.1All samples must be collected using a sampling plan that addresses the considerations discussed in Chapter Nine of this manual.

8.2Samples should be analyzed within 48 hours of collection. Preserve by refrigeration at 4 ± 2E C.9.0

QUALITY CONTROL

9.1All quality control data should be maintained and available for easy reference and inspection. Refer to Chapter One for additional quality control guidelines.

9.2For each batch of samples processed, method blanks must be carried throughout the entire sample preparation and analytical process according to the frequency described in Chapter One. If the samples are filtered, the associated method blanks must also be filtered.

These blanks will be useful in determining if samples were contaminated during sample preparation or handling. Refer to Chapter One for the proper protocol when analyzing blanks.

9.3 For each batch of samples processed, at least one laboratory control sample must be carried throughout the entire sample preparation and analytical process as described in Chapter One. The laboratory control samples should be spiked with each analyte of interest at the project-specific action level or when lacking project-specific action levels, between the low and midlevel standards. Acceptance criteria should be set at a laboratory-derived limit developed through the use of historical analyses. In the absence of historical data, this limit should be set at ± 20% of the spiked value. In the presence of historical data, ± 20% must still be the limit of maximum deviation to determine acceptability. If the laboratory control sample cannot be considered acceptable, the laboratory control sample must be re-run once, and if still unacceptable, then all samples after the last acceptable laboratory control sample must be reprepped and reanalyzed. Refer to Chapter One for more information.

9.4After initial calibration, the calibration curve must be verified by use of an initial calibration verification (ICV) standard. The ICV standard must be prepared from an independent (second source) material at or near the mid-range of the calibration curve. The acceptance criteria for the ICV standard must be no greater than ± 10% of its true value. If the calibration curve cannot be verified within the specified limits, the cause must be determined and the instrument recalibrated before samples are analyzed. The analysis data for the ICV must be kept on file with the sample analysis data.

9.5The calibration curve must be verified at the end of each analysis batch and/or after every 10 samples by use of a calibration blank and a continuing calibration verification (CCV) standard. The CCV should be made from the same material as the initial calibration standards at or near mid-range. The acceptance criteria for the CCV standard must be ± 10% of its true value and the calibration blank must not contain target analytes above 2-3 times the MDL for the curve to be considered valid. If the calibration cannot be verified within the specified limits, the sample analysis must be discontinued, the cause determined and the instrument recalibrated. All samples following the last acceptable CCV/calibration blank must be reanalyzed. The analysis data for the CCV/calibration blank must be kept on file with the sample analysis data.

9.6Method detection limit (MDL)

MDLs should be established for all analytes using reagent water (blank) fortified at a concentration of approximately 3 times the estimated instrument detection limit. To determine MDLs, take seven replicate aliquots of the fortified reagent water and process through the entire analytical method. Perform all calculations defined in the method and report concentration values in the appropriate units.

9.7Matrix spike/matrix spike duplicates (MS/MSDs)

MS/MSDs are intralaboratory split samples spiked with identical concentrations of target analytes. The spiking occurs prior to sample preparation and analysis. An MS/MSD pair is used to document the bias and precision of a method in a given sample matrix. MS/MSDs are to be analyzed at the frequency of one per analytical batch as described in Chapter One. Refer to the definitions of bias and precision in Chapter One for the proper data reduction protocols. Each

9056A - 6Draft Revision 1

September 1999 Pre-release version -- This method has NOT been released by OSW as part of Update IV.

laboratory should calculate its own acceptance criteria based on its historical data for each matrix type. Refer to Chapter One for guidance.

10.0CALIBRATION AND STANDARDIZATION

10.1Establish ion chromatographic operating parameters equivalent to those indicated in Table 1, or as recommended by the manufacturer.

10.2For each analyte of interest, prepare calibration standards at a minimum of three concentrations and a blank by adding accurately measured volumes of one or more stock standards to a Class A volumetric flask and diluting to volume with reagent water. If the working range exceeds the linear range of the system, a sufficient number of standards must be analyzed to allow an accurate calibration curve to be established. One of the standards should be representative of a concentration near, but above, the method detection limit if the system is operated on an applicable attenuator range. The other standards should correspond to the range of concentrations expected in the sample or should define the working range of the detector. Unless the attenuator range settings are proven to be linear, each setting must be calibrated individually. The calibration curve should be prepared every 12 hours of operation.

10.3Using a fixed injection volume of between 25 to 100 mL (determined by injection loop volume) of each calibration standard, tabulate peak area (preferably) or height responses against the concentration. The results are used to prepare a calibration curve for each analyte. During this procedure, retention times must be recorded.

10.4The working calibration curve must be verified on each working day, or whenever the anion eluent strength is changed, and for every batch of samples, by injection of a CCV standard (Sec. 9.5). If the response or retention time for any analyte varies from the expected (i.e., previous) values by more than ± 10%, the test must be repeated, using fresh calibration standards. If the results are still more than ± 10%, an entirely new calibration curve must be prepared for that analyte.

10.5Nonlinear response can result when the separator column capacity is exceeded (overloading). Maximum column loading (total anions) should not exceed approximately 500 ppm.

11.0PROCEDURE

11.1Sample preparation

When aqueous samples are injected, the water passes rapidly through the columns, and a negative "water dip" is observed that may interfere with the early-eluting fluoride and/or chloride ions. The water dip should not be observed in combustate samples since the collecting solution is a concentrated eluent solution that will be equivalent to the eluent strength when diluted to 100-mL with reagent water according to the bomb combustion procedure. Any dilutions required in analyzing other water samples should be made with the eluent solution. The water dip, if present, may be removed by adding concentrated eluent to all samples and standards to result in a final sample/standard solution that is equivalent to bicarbonate/carbonate concentration of the eluent.

9056A - 7Draft Revision 1

September 1999 Pre-release version -- This method has NOT been released by OSW as part of Update IV.

9056A - 8

Draft Revision 1September 1999

Pre-release version -- This method has NOT been released by OSW as part of Update IV.

When a manual system is used, it is necessary to micropipet concentrated buffer into each sample. The recommended procedures follow:

11.1.1Prepare a 100-mL stock of eluent 100 times normal concentration by

dissolving 1.428 g NaHCO 3 and 1.908 g Na 2CO 3 in 100-mL reagent water or use the manufacturer’s specified eluent. Cover or seal the volumetric flask .

11.1.2Pipet 5 mL of each sample into a clean polystyrene micro-beaker.

Micropipet 50 mL of the concentrated buffer into the beaker and stir well.

11.1.3Dilute the samples with eluent, if necessary, to concentrations within the

linear range of the calibration.11.2

Sample analysis

11.2.1Start the flow of regenerant through the suppressor device, if required.

Alternatively, apply the appropriate current to the ASRS immediately after starting the eluent pump.11.2.2

Set up the recorder range for maximum sensitivity and any additional ranges

needed.

11.2.3Begin to pump the eluent through the columns. After a stable baseline is

obtained (approximately 30 minutes), inject a midrange standard. If the peak area or height deviates by more than ± 10% from that of the previous run, prepare fresh standards.11.2.4Begin to inject standards starting with the lowest concentration standard and

increasing in concentration. Calculate the regression parameters for the initial standard curve. Compare these values with those obtained in the past. If they exceed the control limits, stop the analysis and identify and correct the problem.

11.2.5Inject an ICV standard. Calculate the concentration from the calibration

curve and compare the known value. If the ± 10% control limits are exceeded, stop the analysis until the problem is found. Recalibration is necessary.

11.2.6When an acceptable value has been obtained for the ICV standard, begin

to inject the samples.

11.2.7Load and inject a fixed amount of well-mixed sample. Flush the injection

loop thoroughly (with at least 5x the loop volume), using each new sample. Use the same size loop for all standards and samples. Record the resulting peak size in area or peak height units. An automated constant volume injection system may also be used.

11.2.8The width of the retention time window used to make identifications should

be based on measurements of actual retention time variations of standards over the course of a day. Three times the standard deviation of a retention time may be used to calculate a suggested window size for a compound. However, the experience of the analyst should weigh heavily in the interpretation of chromatograms.

9056A - 9

Draft Revision 1September 1999

Pre-release version -- This method has NOT been released by OSW as part of Update IV.

y i 'mx i %b

x j '

(y j &b)m

11.2.9If the response for the peak exceeds the working range of the system, dilute

the sample with an appropriate amount of reagent water or eluent and reanalyze.11.2.10If the resulting chromatogram fails to produce adequate resolution, or if

identification of specific anions is questionable, spike the sample with an appropriate amount of standard and reanalyze.

12.0DATA ANALYSIS AND CALCULATIONS

12.1Prepare separate calibration curves for each anion of interest by plotting the peak areas or peak heights of the standards against the concentration values. Compute the concentration of each analyte in the sample by comparing the sample peak response with the standard curve. Appropriate chromatography data analysis software may be used to perform the functions listed in 12.3 and 12.4.

12.2Many systems will automatically calculate the sample results, but if your system does not, then the enter the calibration standard concentrations and peak heights from the integrator or recorder into a calculator with linear least squares capabilities.

12.3Calculate the slope (m) and the intercept (b). The slope and intercept define a relationship between the concentration and instrument response of the form:

where:

y i =predicted instrument response m =response slope

x i =concentration of standard i b

=

intercept

Rearrangement of the equation above yields the concentration that corresponds to an

instrument response:

where:

x j =calculated concentration for a sample y j =

actual instrument response for a sample

and m and b are the calculated slope and intercept from the calibration equation.

12.4Enter the sample peak area or height into the calculator, and calculate the sample concentration in milligrams per liter.

13.0METHOD PERFORMANCE

13.1Examples of single-operator accuracy and precision values for reagent, drinking, and surface water, and mixed domestic and industrial wastewater are listed in Table 3. See EPA Method 300.0 for examples of multiple laboratory determinations of bias for the analytes using an IonPac AS4A column, bicarbonate/carbonate eluent, AMMS suppressor and conductivity detection (see Reference 1).

13.2Combustate samples

Tables 4 and 5 are based on 41 data points obtained by six laboratories who each analyzed four used crankcase oils and three fuel oil blends with crankcase in duplicate. The oil samples were combusted using Method 5050. A data point represents one duplicate analysis of a sample. One data point was judged to be an outlier and was not included in the results.

14.0POLLUTION PREVENTION

14.1Pollution prevention encompasses any technique that reduces or eliminates the quantity and/or toxicity of waste at the point of generation. Numerous opportunities for pollution prevention exist in laboratory operation. The EPA has established a preferred hierarchy of environmental management techniques that places pollution prevention as the management option of first choice. Whenever feasible, laboratory personnel should use pollution prevention techniques to address their waste generation. When wastes cannot be feasiblely reduced at the source, the Agency recommends recycling as the next best option.

14.2The quantity of the chemicals purchased should be based on expected usage during its shelf life and disposal cost of unused material. Actual reagent preparation volumes should reflect anticipated usage and reagent stability.

14.3For information about pollution prevention that may be applicable to laboratories and research institutions consult Less is Better: Laboratory Chemical management for Waste Reduction available from the American Chemical Society, 1155 16th Street, NW, Washington D.C. 20036, (202) 872-4477.

15.0WASTE MANAGEMENT

The Environmental Protection Agency requires that laboratory waste management practices be conducted consistent with all applicable rules and regulations. The Agency urges laboratories to protect the air, water, and land by minimizing and controlling all releases from hoods and bench operations, complying with the letter and spirit of any sewer discharge permits and regulations, and by complying with all solid and hazardous waste regulations, particularly the hazardous waste identification rules and land disposal restrictions. For further information on waste management, consult The Waste Management Manual for Laboratory Personnel available from the American Chemical Society.

9056A - 10Draft Revision 1

September 1999 Pre-release version -- This method has NOT been released by OSW as part of Update IV.

16.0REFERENCES

1.Environmental Protection Agency, Environmental Monitoring Systems Laboratory, Office of

Research and Development, USEPA Method 300.0,"Determination of Inorganic Anions by Ion Chromatography," EPA-600/R-93-100, August 1993.

2.Annual Book of ASTM Standards, Volume 11.01 Water, "Test Method for Anions in Water

by Chemically-Suppressed Ion Chromatography," D 4327-97, 1998.

3.Standard Methods for the Examination of Water and Wastewater, Method 4110,

"Determination of Anions by Ion Chromatography," 18th Edition of Standard Methods, 1992.

4.Dionex, DX-500 System Operation and Maintenance Manual, Dionex Corp., Sunnyvale, CA

94086, 1996.

5. A. Gaskill, E.D. Estes, D.L. Hardison, and L.E. Myers, “Validation of Methods for Determining

Chlorine in Used Oils and Oil Fuels,” prepared for U.S. Environmental Protection Agency Office of Solid Waste, EPA Contract No. 68-01-7075, WA 80, July 1988.

17.0TABLES, DIAGRAMS, FLOW CHARTS AND VALIDATION DATA

The pages to follow contain tables and figures referenced within the text.

9056A - 11Draft Revision 1

September 1999 Pre-release version -- This method has NOT been released by OSW as part of Update IV.

CHROMATOGRAPHIC CONDITIONS AND METHOD DETECTION

LIMITS IN REAGENT WATER

Analyte Retention Time (min)a Method Detection Limit (mg/L)

Fluoride 1.20.005

Chloride 1.70.015

Nitrite-N 2.00.004

Nitrate-N 3.20.002

o-Phosphate-P 5.40.003

Sulfate 6.90.020

a The retention time given for each anion is based on the equipment and analytical conditions described in the method and summarized below. Use of other analytical columns or different eluent concentrations will effect retention times accordingly.

Data are taken from Reference 1 and are provided for illustrative purposes only.

Chromatographic Conditions:

Columns As specified in Secs. 4.1.1 through 4.1.3

Detector As specified in Sec. 4.1.4

Eluent As specified in Sec. 5.3

Sample loop50 μL

Pump Flow rate 2.0 mL/min

Concentration of Mixed Standard (mg/L):

Fluoride 2.0

Chloride 3.0

Nitrite-N 2.0

Nitrate-N 5.0

o-Phosphate-P 2.0

Sulfate15.0

9056A - 12Draft Revision 1

September 1999 Pre-release version -- This method has NOT been released by OSW as part of Update IV.

9056A - 13

Draft Revision 1September 1999

Pre-release version -- This method has NOT been released by OSW as part of Update IV.

PREPARATION OF STANDARD SOLUTIONS FOR INSTRUMENT CALIBRATION

Analyte Volume of Stock Solution (in mL) used to prepare the High-Range Standard 1

Concentration of Standard in mg/L

High-Range Standard Intermediat e-Range Standard

Low-Range Standard Fluoride (F G )1010 1.00.2Chloride (Cl G )1010 1.00.2Nitrite (NO 2G )2020 2.00.4Phosphate (PO 43G )5050 5.0 1.0Bromide (Br G )1010 1.00.2Nitrate (NO 3G )3030 3.00.6Sulfate (SO 42G )

100

100

10.0

2.0

1

The volumes of each stock solution (1.00 mL = 1.00 mg) that are added together in a Class A volumetric flask and diluted to 1 L to prepare the high-range calibration standard (refer to Sec.7.5).

The intermediate-range standard is prepared by diluting a volume of the high-range standard, as described in Sec. 7.6.2.

The low-range standard is prepared by diluting a volume of the intermediate-range standard, as described in Sec. 7.6.3.

SINGLE-OPERATOR ACCURACY AND PRECISION

Analyte Sample Type Spike (mg/L)Mean Recovery (%)Std. Dev. (mg/L) Chloride RW0.05097.70.0047

DW10.098.20.289

SW 1.0105.00.139

WW7.582.70.445 Fluoride RW0.24103.10.0009

DW9.387.70.075

SW0.5074.00.0038

WW 1.092.00.011 Nitrate-N RW0.10100.90.0041

DW31.0100.70.356

SW0.50100.00.0058

WW 4.094.30.058

Nitrite-N RW0.1097.70.0014

DW19.6103.30.150

SW0.5188.20.0053

WW0.52100.00.018

o-Phosphate-P RW0.50100.40.019

DE45.7102.50.386

SW0.5194.10.020

WW 4.097.30.04

Sulfate RW 1.02102.10.066

DW98.5104.3 1.475

SW10.0111.60.709

WW12.5134.90.466

All data are taken from Reference 1 and are based on the analyses of seven replicates.

RW=Reagent water SW=Surface water

DW=Drinking water WW=Wastewater

9056A - 14Draft Revision 1

September 1999 Pre-release version -- This method has NOT been released by OSW as part of Update IV.

REPEATABILITY AND REPRODUCIBILITY FOR CHLORINE IN

USED OILS BY BOMB OXIDATION AND ION CHROMATOGRAPHY

Average Value, μg/g Repeatability, μg/g Reproducibility, μg/g

500467941

1,0006611,331

1,5008091,631

2,0009351,883

2,5001,0452,105

3,0001,1452,306

All data are taken from Reference 5 and are provided for illustrative purposes only.

TABLE 5

RECOVERY AND BIAS DATA FOR CHLORINE IN USED OILS BY

BOMB OXIDATION AND ION CHROMATOGRAPHY

Amount Expected (μg/g)Amount Found (μg/g)Bias (μg/g)Bias (%)

320567247+77

480773293+61

9201,050130+14

1,4981,694196+13

1,5271,772245+16

3,0293,026-30

3,0452,745-300-10 All data are taken from Reference 5 and are provided for illustrative purposes only.

9056A - 15Draft Revision 1

September 1999 Pre-release version -- This method has NOT been released by OSW as part of Update IV.

9056A - 16Draft Revision 1

September 1999

Pre-release version -- This method has NOT been released by OSW as part of Update IV.

9056A - 17

Draft Revision 1September 1999

Pre-release version -- This method has NOT been released by OSW as part of Update IV.

0.0

5.0

-2.0

10.0

uS

8.0

1.0

2.0

3.0

4.0

6.0

7.0

Minutes

S u l f a t e

o -P h o s p h a t e -P

N i t r a t e -N

B r o m i d e N i t r i t e -N

C h l o r i d e F l u o r i d e

FIGURE 2

EXAMPLE ANION PROFILE

This figure is provided for illustrative purposes only.

METHOD 9056A

DETERMINATION OF INORGANIC ANIONS BY ION CHROMATOGRAPHY

9056A - 18Draft Revision 1

September 1999 Pre-release version -- This method has NOT been released by OSW as part of Update IV.

离子色谱法测定土壤提取液中的无机阴离子

离子色谱法测定土壤提取液中的无机阴离子 谢春生a赵杰b徐新华a郝志伟c a浙江大学环境工程研究所,杭州,310027,xiechsh@https://www.360docs.net/doc/a717514167.html, b浙江理工大学生命科学学院,杭州 310018, c瑞士万通中国有限公司,上海,200335,sh.haozw@https://www.360docs.net/doc/a717514167.html, 摘要:离子色谱法是利用离子交换的分离原理,进行离子测定的液相色谱法。该方法灵敏度高,准确性高,稳定性好,检测限低,样品预处理简单,操作简单迅速,能多种离子同时测定。本文采用离子色谱法对土壤提取液中的F-,Cl-,NO2-, NO3-, HPO42-和SO42-等无机阴离子进行分析。样品经过IC-RP预处理小柱过滤后,通过万通的A Supp 4型阴离子分离柱进行测试,1.8mM碳酸钠/1.7mM碳酸氢钠淋洗液,流速为1.0ml/min,进样量40μl。实验结果令人满意。 关键词:离子色谱;土壤提取液;无机阴离子 1 前言 土壤农化分析工作在提高农业生产上具有极其重要的作用,它为土壤分类、土地资源开发利用、土壤改良、合理施肥等提供依据。因此,使用先进科学的现代分析仪器,探讨新的测定手段,以加快分析工作速度,提高分析结果的精密度和准确度至关重要。土壤中可溶性无机阴离子以F- , Cl- , NO2-,NO3-, HPO42-和SO42-最为常见,其含量与土壤的性质和外来因素有关,其分析工作在农业生产上具有重要作用,能为土壤分类、土地资源开发利用、土壤污染分析、土壤改良和合理施肥等提供依据.传统的分析方法操作技术水平要求较高,操作步骤繁琐,药品和试剂消耗量大,不利于快速分析。离子色谱法操作简便、快速,可使多种离子同时分离测定,已广泛用于医学研究、常规化学分析检测等方面,但在土壤中无机阴离子的分析方面还较为少见。因此,本文采用离子色谱测试土壤提取液中6种常见阴离子的含量,以探索快速、准确地测定土壤中无机阴离子含量的方法。 2 实验部分 2.1 仪器及试剂 Metrohm-792 Basic 型离子色谱仪(瑞士万通)配有电导检测器、化学抑制器、低脉冲串联式双活塞往复泵、双通道蠕动泵、数据采集/处理软件等。标准样:F-,Cl-,NO2-, NO3-, HPO42-和SO42-均按标准方法配制成1000mg/L储备液备用。所有药剂均为分析纯,溶液均用电阻率大于18M?超纯水配制。 2.2 色谱条件 色谱柱:Metrosep A Supp 4 250 型阴离子分析柱(250×4mm),Metrosep A Supp 4/5 Guard 保护柱(50×4mm);流动相:1.8mmol/L碳酸钠+1.7mmol/L碳酸氢钠淋洗液,50mM 硫酸抑制器再生液,进样体积:40μL,流速:1.0 mL/min。 2.3 分析步骤 2.3.1 样品制备 称取通过20目筛子的风干土样5.0g(精确到0.001g)于100 mL离心管中,加入50ml 超纯水,塞紧瓶塞,在25℃恒温振荡器上振荡16h。振荡时间到后,在4000rmp下离心15分钟,取上清液。用0.45μm的滤膜过滤上清液,经此处理后的样品再进行下一步的测试。 2.3.2 样品前处理 测试前,须采样IC-RP预处理小柱对制备好的土壤提取液进行预处理。在使用 RP 柱前,需按以下步骤对其进行活化后方可处理样品: (1)用 5 mL 甲醇活化 RP 小柱,推动速度每分钟不超过 3 mL; (2)用 10 mL 去离子水冲洗 RP 小柱,推动速度每分钟不超过 3 mL; (3)将小柱平放 20 分钟; (4)将 5 mL 样品缓慢推入小柱,推动速度每分钟不超过 3 mL,弃去前 3 mL; 收集2 mL经IC-RP预处理后的样品直接进样。

采用离子色谱法对黄酒中氨基酸的比较研究doc-省级科研计

采用离子色谱法对黄酒中氨基酸的比较研究 诸葛庆,李博斌,刘兴泉,郑云峰 (国家黄酒产品质量监督检测中心绍兴312071) 摘要:准确测定黄酒中的氨基酸对研究黄酒的营养价值和黄酒风味具有重要的意义,本研究采用了阴离子交换色谱法-积分脉冲安培检测法测定了江西、绍兴、福建三地黄酒中的氨基酸。分析结果显示,绍兴黄酒、福建黄酒的氨基酸总量较高,平均含量分别是3946.56mg/L、3726.80 mg/L,江西黄酒氨基酸含量为1634.33mg/L,每种黄酒的呈味氨基酸以甜味氨基酸和苦味氨基酸为主,它们占80%左右。 关键词:阴离子交换色谱法;积分脉冲安培检测;氨基酸;黄酒 黄酒是我国的民族特产,黄酒是以稻米、黍米、玉米、小米、小麦等粮食为主要原料,经蒸煮、糖化、发酵、压榨、过滤、贮存、勾兑等工艺生产的酿造酒。黄酒酒精度低、耗粮较少、富含多种氨基酸、蛋白质、维生素和对人体有益的矿物元素,营养丰富[1]。黄酒中含有多种多量的氨基酸,黄酒中的氨基酸主要是曲霉菌的酸性蛋白霉和酸性羧肽酶对蒸煮后的原料米中的蛋白质起作用而产生的,是黄酒中的主要成分之一,不仅是黄酒的营养成分,也是黄酒的风味物质或风味的前驱体,对黄酒的风味起着重要作用[2,3]。氨基酸具有鲜、甜、苦、涩等多种味感,赋予了黄酒丰富的味觉层次,使黄酒具有鲜美、醇和、浓郁、柔润、协调和多滋多味的特征[4]。 黄酒中的呈味氨基酸与黄酒的风味有着很大的联系,因此准确的对黄酒中的氨基酸进行定性和定量分析是非常有必要的。但是氨基酸种类繁多、性质接近,氨基酸分析是色谱界公认的难题。现在常用的方法有离子交换色谱法,基于反相色谱分离、柱前衍生、荧光或紫外检测的高效液相法,阴离子交换分离直接安培法检测的离子色谱法,衍生化气相色谱法和毛细管电泳法,这些方法在检测氨基酸方面还存在一定的不足。本研究所用的高效阴离子交换色谱-积分脉冲安培检测法(HPAEC-IPAD)是一种新的氨基酸分析方法[5]。此方法是基于氨基酸分子中的羧基在强碱性介质中可以形成阴离子,而氨基酸分子中的氨基在强碱性介质中通过施加一定的电位,可在贵金属(金、铂)电极表面发生氧化反应,从而实现氨基酸的阴离子交换色谱分离和积分脉冲安培检测[6,7,8]。 1 实验部分 1.1仪器和试剂

离子色谱法测定水中四种阴离子

龙源期刊网 https://www.360docs.net/doc/a717514167.html, 离子色谱法测定水中四种阴离子 作者:刘松欢林仰锋 来源:《南北桥》2017年第24期 【摘要】目的通过离子色谱法测定水中四种阴离子。方法 ICS-900型离子色谱仪(美国DIONEX),选用Ionpac AS19分离柱,Ionpac AG22保护柱,流速1.0mL/min,流速等度。结论该方法操作简单,省时省力,分离效果好,重现性好,符合国家标准要求。 【关键词】离子色谱法阴离子 中图分类号:G4 文献标识码:A DOI:10.3969/j.issn.1672-0407.2017.24.204 前言 近年来饮用水标准不断提高,离子色谱法(Ion Chromatography )是美国人SMALL1972 年发明的,是高效液相色谱(HPLC)的一种,是主要用来分离极性和部分弱极性化合物的一种分离技术,是色谱技术在离子型物质检测领域的一种突破[1]。本文采用近年来发展起来的广泛应用于分析化学和生物医学领域的高效、快速新型分离技术离子色谱法,来测定GB5749-2006生活饮用水卫生标准中的常规必检项目:氟化物,氯化物,硝酸盐,硫酸根这四种阴离子。 一、原理与材料 1.1 原理 根据分离柱对各种阴离子的亲和力不同,从而使样品中各种待测阴离子随淋洗液进入离子交换系统之后分离开来,已分离的阴离子流经阳离子交换柱或抑制器系统转换成具高电导度的强酸,淋洗液则转变为弱电导度的碳酸。电导检测器测量电导率之后以相对保留时間定性,峰面积定量[2]。 1.2 仪器 ICS-900型离子色谱仪(美国DIONEX); 淋洗液自动发生器(KOH); AERS 300 4mm阴离子抑制器; 分离柱:Ionpac Dionex AS19;

离子类高效液相色谱法

离子类高效液相色谱法 1308102-19 彭陈 摘要:离子色谱是高效液相色谱的一种,是分析阴离子和阳离子的一种液相色谱方法。 离子色谱的分离机理主要是离子交换。分离方式有3种:离子交换色谱,离子排斥色谱和离子对色谱。其中离子交换色谱用低容量的离子交换树脂,分离机理主要是离子交换;离子排斥色谱用高容量的树脂,分离机理主要是离子排斥;离子对色谱用不含离子交换基团的多孔树脂,分离机理主要是基于吸附和离子对的形成。 一,离子对色谱 离子对色谱法是将一种(或多种)与溶质分子电荷相反的离子(称为对离子或反离子)加到流动相或固定相中,使其与溶质离子结合形成疏水型离子对化合物,从而控制溶质离子的保留行为。 在色谱分离过程中,流动相中待分离的有机离子A+(也可以是带负电子的离子)与固定相或流动相中带相反电荷的对离子B-结合,形成离子对化合物A+B-,然后在两相间进行分配: 若固定相为有机相,流动相为水溶液,就构成反相离子对色谱,此时A= 的分布系数B-为: 当流动相的pH值、离子强度、有机改性剂的类型、浓度及温度保持恒定时,k'与对离子的浓度[B- ]w成正比。因此通过调节对离子的浓度,就可改变被分离样品离子的保留时间Tr。

离子对色谱法,特别是反相离子对色谱法解决了以往难以分离混合物的分离问题,诸如酸、碱和离子、非离子的混合物,特别是一些生化试样如核酸、核苷、儿茶酚胺、生物碱以及药物等的分离。另外,还可以借助离子对的生成给试样引入紫外吸收或发荧光的基团,以提高检测的灵敏度。 二,离子交换色谱法以及离子色谱法 (1)离子交换色谱法 离子交换色谱利用被分离组分与固定相之间发生离子交换的能力差异来实现分离。离子交换色谱的固定相一般为离子交换树脂,树脂分子结构中存在许多可以电离的活性中心,待分离组分中的离子会与这些活性中心发生离子交换,形成离子交换平衡,从而在流动相与固定相之间形成分配,固定相的固有离子与待分离组分中的离子之间相互争夺固定相中的离子交换中心,并随着流动相的运动而运动,最终实现分离。 离子交换色谱的固定相是交换剂,根据交换剂性质可分为: 阳离子交换剂和阴离子交换剂。 交换剂由固定的离子基团和可交换的平衡离子组成。当流动相带着组分离子通过离子交换柱时,组分离子与交换剂上可交换的平衡离子进行可逆交换,最后达到交换平衡,阴阳离子的交换平衡可表示为: 阳离子交换:R+Y-+ X-= R+X-+ Y- 阴离子交换:R-Y++ X+= R-X++ Y+ R+、R-—为交换剂上的固定离子基团,如RSO3-或RNH3+; Y+、Y-—为可交换的平衡离子,可以是H+、Na+或OH-、Cl-等 X+、X-—为组分离子。 组分离子对固定离子基团的亲和力强,分配系数大,其保留时间长;反之,分配系数小,其保留时间短;因此:离子交换色谱:是根据不同组分离子对固定离子基团的亲和力的差别而达到分离的目的。

离子色谱法测水中阴离子

离子色谱法测水中阴离子 指导老师:郭文英 实验人:王壮 同组实验:余晓波 实验时间:2016.3.21 一. 实验目的 1. 掌握离子色谱法分析的基本原理。 2. 掌握常见阴离子的测定方法。 3. 掌握离子色谱的定性和定量分析方法 二.实验原理 离子色谱法中使用的固定相是离子交换树脂。离子交换树脂上分布有固定的带电荷的基团和能离解的离子。当样品加入离子交换树脂后,用适当的溶液洗脱,样品离子即与树脂上能离解的离子进行交换,并且连续进行可逆交换分配,最后达到 平衡。不同阴离子(32,,,F Cl NO NO ---- 等)与阴离子树脂之间亲和力不同,其在 交换柱上的保留时间不同,从而达到分离的目的。根据离子色谱峰的峰高或峰面积可对样品中的阴离子进行定性和定量分析。离子色谱法应用电导检测器。 三.仪器与试剂 仪器:离子色谱仪;阴离子分析色谱柱;阴离子分析色谱保护柱;超声波发生器;真空过滤装置;注射器 试剂:20ppm 、30ppm 、40ppm 、50ppm Cl -和3NO -标准溶液、未知样。 五.实验内容 1. 打开电脑,打开power ,后打开IC 软件,等power 灯不闪后,就可以使用了。 2. 按下列条件设置仪器参数:淋洗液流量为0.8mL/min ;数据采集时间为10min ,设置完后扫基线。 3. 阴离子的定性分析:分别吸取0.5mL 各浓度的标准溶液,进样,记录保留时间 4. 测定未知水样。取0.5mL 未知样按同样实验进样,记录保留时间。

表1. 不同浓度F-保留时间和出峰面积 表2.不同浓度Cl-保留时间和出峰面积 表3. 不同浓度 NO-保留时间和出峰面积 3 对不同浓度的标准样品所测得的保留时间和出峰面积绘制标准工作曲线:

固定污染源废气 氟化氢的测定 离子色谱法 (暂行)(HJ688-2013)

主题:氟化氢检测(监测)方法指导书第 A 版第 0 次修订颁布日期:2015年10月01日 氟化氢检测(监测)方法指导书 (方法标准号:HJ688-2013) 编制: 审核: 批准: 批准日期: 修改记录表 序号对应章节号修改前内容修改后内容修改人批准人批准日期

主题:氟化氢检测(监测)方法指导书第 A 版第 0 次修订颁布日期:2015年10月01日 1方法原理 本方法采用加热的采样管连续从固定污染源采集废气样品,经加热的过滤器滤除颗粒物,废气样品进入冷却的碱性吸收液,气态氟化物被吸收生成氟离子。经离子色谱仪分离检测,保留时间定性,响应值定量。 2适用范围 本标准规定了测定固定污染源废气中氟化氢的离子色谱法。 本标准适用于固定污染源废气中气态氟化物的测定,以氟化氢浓度表示,不能测定碳氟 化物,如氟利昂。 当采样体积120L,定容体积200ml 时,检出限为0.03mg/m 3 ,测定下限为0.12mg/m 3 ; 定容体积500ml 时,检出限为0.08mg/m 3 ,测定下限为0.32mg/m 3 。 3仪器及试剂 3.1 试剂和材料 除非另有说明,分析时均使用符合国家标准的分析纯试剂;水,GB/T 6682,二级。 3.1.1氢氧化钾(KOH)。 3.1.2无水碳酸钠(Na2CO3)。 3.1.3氟化钠(NaF),优级纯:在110℃下干燥2h,于干燥器中保存。 3.1.4吸收液 3.1. 4.1氢氧化钾溶液:c(KOH) = 0.1mol/L。称取 5.6g 氢氧化钾(3.1.1),溶解于水,稀释至1000ml。 3.1. 4.2氢氧化钾-碳酸钠溶液:c(KOH) = 0.006mol/L,c(Na2CO3) = 0.008mol/L。称取0.33g 氢氧化钾(3.1.1) 和0.85g 无水碳酸钠(3.1.2),溶解于水,稀释至1000ml。 3.1.5 淋洗液 3.1.5.1氢氧化钾溶液:c(KOH) = 0.030mol/L。称取1.7g 氢氧化钾(3.1.1),溶解于水,稀释至1000ml。 3.1.5.2 氢氧化钾-碳酸钠溶液:c(KOH) = 0.0018mol/L,c(Na2CO3) = 0.0024mol/L。称取0.1g 氢氧化钾(3.1.1)

人教版化学高二选修6第三单元实验3-1几种无机离子的检验同步练习B卷

人教版化学高二选修6第三单元实验3-1几种无机离子的检验同步练习B卷 姓名:________ 班级:________ 成绩:________ 一、选择题 (共20题;共40分) 1. (2分)某澄清溶液,可能含有NH4+、Na+、Cl﹣、CO32﹣、I﹣中的一种或几种,现做如下实验: ①通入足量氯气,溶液变为棕黄色,滴加淀粉溶液后溶液显蓝色 ②加入BaCl2有白色沉淀生成,再加入足量盐酸后,沉淀完全溶解,并有气体生成 ③用铂丝蘸取少量溶液做焰色反应实验,火焰的颜色呈黄色 ④加入NaOH溶液并加热,没有任何现象 下列关于该澄清溶液的说法中错误的是() A . 一定含有I﹣ B . 一定含有CO32﹣ C . 一定含有NH4+ D . 一定含有Na+ 【考点】 2. (2分) (2016高一上·大连期中) 对于某些离子的检验及结论一定正确的是() A . 加入碳酸钠溶液产生白色沉淀,再加盐酸白色沉淀消失,一定有Ba2+ B . 加入稀盐酸后产生无色无味的气体,将气体通入澄清石灰水,溶液变浑浊,原溶液一定含有CO32﹣ C . 加入硝酸银溶液有白色沉淀产生,一定有Cl﹣ D . 向某溶液中加入盐酸,无明显现象,再加入氯化钡溶液有白色沉淀产生,一定有SO42﹣ 【考点】 3. (2分) (2018高二下·台州期中) 某溶液中只可能含有下列离子中的几种(不考虑溶液中含有的较少的H+和OH-):Na+、NH4+、SO42-、CO32-、NO3-。取200 mL该溶液,分为两等份分别做下列实验。实验1:第一份加入足量的烧碱并加热,产生的气体在标准状况下为224 mL。实验2:第二份先加入足量的盐酸,无现象,再加足量的BaCl2溶液,得固体2.33g。下列说法正确的是() A . 该溶液中可能含有Na+ B . 该溶液中肯定含有NH4+、SO42-、CO32-、NO3- C . 该溶液中一定不含NO3- D . 该溶液中一定含Na+ ,且c(Na+) ≥ 0.1 mol·L-1 【考点】

离子色谱法测定有机溶剂中痕量阴离子

离子色谱法测定有机溶剂中痕量阴离子* 叶明立朱岩**郭莹莹 (浙江大学西溪校区化学系杭州310028) 摘要:采用阴离子交换分离,化学抑制模式,对甲醇、乙腈、异丙醇等有机溶剂中的阴离子进行测定。各有机溶剂稀释一倍直接进样可以测定Cl—、NO3—、SO42—,在所采取的色谱条件下,三种阴离子都具有很好 的线性和较低的检测限,甲醇中三种离子的检测限分别是:1.06、3.23、4.88ug/L,乙腈中分别是:1.41、 7.07、16.47ug/L,异丙醇中分别是:1.22、8.11、25.65ug/L。比较采用自动再生循环模式,利用化学抑 制模式的离子色谱法是一种检测有机物中阴离子的高效,准确的方法。 关键词:离子色谱有机溶剂阴离子 1.引言: 常规测定有机溶剂中阴离子的方法多数是根据离子的物理化学特性进行的,一般是采用比色法和浊度法。实验需要将大量的样品进行蒸发分馏,然后对于其中的每种阴离子分别用比色和浊度法进行分析测定[1-2]。但是采用这些方法不仅费时,而且测定结果往往不精确,特别是不能对有机溶剂中痕量阴离子进行测定。而离子色谱对于测定有机溶剂中的阴离子具有很高的灵敏度和较低的检测限,但是对于测定有机溶剂,往往存在一定的基体效应,因此Edward Kaiser采用基体消除技术对样品进行预处理,但该技术难度较大而且对仪器的要求也很高,仪器设备复杂[3-4]。 本文采用离子色谱外加酸化学抑制方法避免了有机溶剂的基体效应,仪器设备简单,方法简便,可以准确快速的对分析纯有机溶剂中的痕量阴离子进行测定。 2.实验部分 2.1仪器及试剂 仪器:Dionex 500离子色谱仪;GP50梯度泵;EG40淋洗液发生器;ED40电化学检测器;Dionex ASRS-ULTRA(2mm)自再生抑制器;Dionex Peak5.2色谱工作站(美国Dionex公司)。 色谱柱:Dionex AS9-HC保护柱;Dionex AS9-HC分离柱;Dionex AS17保护柱;Dionex AS17分离柱(均为2mm) 试剂:甲醇、乙腈、异丙醇均为分析纯。F—、,Cl—、NO3—、SO42—贮备液均购自上海市计量测试技术研究所,使用时稀释至所需浓度的标准使用液。溶液都用18.3MΩ.cm的二次去离子水配制。 2.2 样品处理 分别将甲醇、乙腈、异丙醇稀释1倍,直接进样。 2.3 色谱条件 淋洗液:采用淋洗液发生器产生的高纯KOH溶液;流速:0.25 ml/min;进样量:25μL 3.结果与讨论 3.1采用碳酸钠淋洗液系统对阴离子进行测定 3.1.1采用9mmol/l碳酸钠作为淋洗液,抑制器自再生模式(包括外加水和自循环,抑制电流50mA),AG9-HC保护柱+AS9-HC分离柱对有机溶剂中的阴离子进行测定。直接将用2.2方法处理的甲醇样品(稀释一倍)进行进样,测定结果见图1。 *国家和浙江省留学基金资助项目 **通信联系人

离子色谱法测定水果中氟离子

离子色谱法测定水果中氟离子 王雨,李静 戴安中国有限公司应用研究中心, 北京,100085,wangyu@https://www.360docs.net/doc/a717514167.html, 摘要:本文使用IonPac AS15中高疏水性高容量阴离子交换色谱柱,使氟离子与高浓度有机酸高效分离,配合大体积进样方式,成功分析了水果样品中的痕量氟离子。氟离子标准曲线线性关系良好,相关系数为99.94%,氟离子的最低检出限为1.8μg/L。该方法前处理简单,分离效果好,灵敏度高,基体干扰小,方法高效准确。 关键词:氟离子;离子色谱;水果; 氟是人类生命活动所必需的微量元素之一,但氟对人体健康的作用取决于剂量,摄入氟过多或过少都会给人体健康带来不利的影响。由于人体对氟含量极为敏感,因此氟的安全范围比其他微量元素窄得多[1]。适量的氟可以促进人体骨骼和牙齿的钙化,增强骨骼的强度。但是长期摄人过量氟化物会引起氟中毒,如由于氟摄入过多可引起牙齿、骨骼等组织的病理改变,也可引起肾脏、肝脏等器官的组织病变等。世界上大多数国家均制定了人体每日氟摄入量标准。世界卫生组(WHO)规定,人均每天适宜的氟摄人量为2.5~4.0 mg[2]。国标GB4809-84 《食品中氟允许量标准》 对多种食品中氟的含量有限制要求[3]。 本文利用离子色谱梯度淋洗的方法,成功分析了多种水果中的氟离子含量,通过IonPac AS15高效阴离子交换色谱柱分离,有效避免了样品中大量有机酸对氟离子测定干扰,该方法前处理简单,分析速度快,灵敏度高,分析干扰少,结果准确可靠。 1、实验部分 1.1仪器与试剂 仪器:ICS-3000型离子色谱仪(Dionex,美国) 试剂和样品:氟离子标准溶液(1000mg/L);甲醇(色谱纯,百灵威公司);超纯水(Millipore,电阻率为18.2MΩ/cm);OnGuard RP(1.0cc)前处理柱;0.22μm尼龙滤膜;市售水果。 1.2 色谱条件 色谱柱:IonPac AS15阴离子交换分析柱,250*4mm;IonPac AG15保护柱,50*4mm 淋洗液:KOH,0-17 min 3 mM, 17.1-27 min 60 mM , 27.1-31 min 3 mM; 淋洗液流速:1.2ml/min; 抑制器:ASRS 300型抑制器4mm,外接水抑制模式,抑制电流为150mA; 进样量:200μL;https://www.360docs.net/doc/a717514167.html,/Shop/product.asp?id=15599&cid=&s=&page=2 1.3 溶液配制

实验3-1几种无机离子的检验 (2)

“铁哥儿俩”——《铁盐和亚铁盐的转化》学案 广安友谊中学 唐灵欣 学习目标:掌握铁盐和亚铁盐的转化方法,了解在生活中的应用。 自主实验探究 请同学们运用氧化还原反应......的相关理论,选择恰当.. 的试剂,实现铁盐和亚铁盐之间的转化。 探究一:Fe 2+转化为Fe 3+ 实验结论:Fe 可以被 (填写化学式) (“氧化”或“还原”) 成Fe 3+ 。 探究二: Fe 3+转化为Fe 2+ 实验结论:Fe 可以被 (填写化学式) (“氧化”或“还原”) 成Fe 2+ 。 生活中的化学 缺铁性贫血.....可以通过药物治疗,比如“速力菲”是一种常见的补血药,请阅读该药品的使用说明书。 【药品名称】琥珀酸亚铁片 【成 分】本品每片含亚铁0.1克 【性 状】本品为薄膜衣片,除去薄膜衣后显暗黄色。 【药物相互作用】维生素C 与本品同服,有利于本品吸收 思考:1、贫血补的是几价铁?

2、补铁药表面薄膜 ..衣.的作用是什么? 3、补血剂为何要搭配维C一起服用? 4、根据说明书,某液态 ..补铁产品 ....(含FeSO4)放置很久,为确定是否还能继续服用。请选择合适的试剂设计实验检验: ①该药物中铁元素是否变质? 2+ 归纳整合建模 深度思考:要实现铁盐和亚铁盐的转化,除了探究 ..的试剂,还可以加入哪些 .....提供 ..实验一、二 物质呢?把你能想到的物质补充到下面的空格中。 () Fe2+Fe3+ () 巩固拓展应用 【魔术揭秘——茶水的秘密】 资料卡片: 1、茶水中含有鞣酸。 2、鞣酸和铁离子生成的鞣酸铁 .......。 ...呈.黑色 ..,鞣酸亚铁呈无色 3、维生素C具有较强的还原性。维生素C能把难以吸收利用的三价铁还原成二价铁,促进人体对二价铁的吸收,有助于治疗缺铁性贫血。 我的猜想:茶水变色的秘密是和之间的转化。 课后DIY 印刷电路板的制作 1、将电路板有铜的一面全部涂上石蜡; 2、用刻刀刻出国旗图案和文字; 3、将电路板在氯化铁溶液中浸泡一段时间; 4、用清水冲洗电路板,并将石蜡清除。 你能说出其中的化学原理吗?请用恰当的离子方程式表达出来。

离子色谱法测定水中常见阴离子教学要求(精)

项目三景观湖水质监测 任务8离子色谱法测定水中常见阴离子 单元教学要求 一、教学目标 该项目是环境监测工作的核心技能之一。通过实施该项目使得学习者进一步巩固前面所学知识,在进行校园景观湖水质监测中,增强对《环境监测》方面的基本方法和监测点位的选择设计,提高学习者调查和动手实验能力。同时根据监测结果,找出污染因子,了解水质现状及其变化趋势,为学院后勤管理部门提供可靠依据。 1. 知识目标 (1)理解离子交换色谱分析的基本原理; (2)掌握离子色谱仪的基本组成和操作方法; (3)掌握离子色谱法测定水中常见阴离子的测试方法。 2. 技能目标 (1)根据相关规范、标准,选择水中常见阴离子的测定方法; (2)能根据离子色谱分析方法,制订水中常见阴离子的监测方案; (3)能依据标准方法,完成常见阴离子等水样预处理及测定; (4)正确处理数据表达结果,并能进行初步质量评价工作; (5)能够根据分析情况,采取一定质量控制措施。 3. 素质目标 (1)培养学生认真负责的工作态度; (2)提高学生的团队合作精神; (3)培养分析问题、解决问题的能力。 二、教学条件 (1)主讲教师:有相关专业的学历背景,有从事环境监测工作岗位的经历,最好有熟练的用离子色谱仪操作经验;并经过高职教育教学的培训,能胜任“教学练做”一体化的教学模式。 (2)教学材料:正式出版的高职类环境监测规划教材、离子色谱法测定水样中阴离子的国家标准测定方法及工学结合特色明显的案例。 (3)实验实训设备条件:学习场地、教学设施设备要适应“教、学、练、做”项目化的要求,配置一定的多媒体、仿真、实训场地。实验仪器及实验试剂符合国标规定。

离子色谱法及液相色谱法(附答案)

离子色谱法及液相色谱法(附答案) 一、填空题 1. 离子交换色谱主要用于有机和无机_____、_____离子的分离。答案:阴阳 2. 离子排斥色谱主要用于_____酸、_____酸和_____的分离。答案:有机无机弱醇类 3. 离子对色谱主要用于表面活性的_____离子、_____离子和_____络合物的分离。答案:阴阳金属 4. 离子色谱分析样品时,样品中离子价数越高,保留时间_____,离子半径越大,保留时间_____。 答案:越长越长 5. 在离子色谱分析中,为了缩短分析时间,可通过改变分离柱的容量、淋洗液强度和_____,以及在淋洗液中加入有机改进剂和用梯度淋洗技术来实现。答案:流速 6. 高效液相色谱紫外检测器属于_____型检测器,只适用于检测那些_____的物质。答案:选择能吸收紫外光二、判断题 1. 离子色谱(IC)是高效液相色谱(HPLC)的一种。( )答案:正确 2.离子色谱的分离方式有3种,即高效离子交换色谱(HPIC)、离子排斥色谱(HPIEC)和离子对色谱(MPIC)。它们的分离机理是相同的。( )答案:错误正确答案为:它们的分离机理是不同的。 3. 离子色谱分析中,其淋洗液的流速和被测离子的保留时间之间存在一种反比的关系。( 答案:正确4.当改变离子色谱淋洗液的流速时,待测离子的洗脱顺序将会发生改变。( 答案:错误 正确答案为:待测离子的洗脱顺序不会改变。 5. 离子色谱分析阳离子和阴离子的分离机理、抑制原理是相似的。( 答案:正确 6. 离子色谱分析中,水负峰的位置由分离柱的性质和淋洗液的流速决定,流速的改变可改变水负峰的位置和被测离子的保留时间。( 答案:正确 7. 离子色谱分析中,水负峰的位置由分离柱的性质和淋洗液的流速决定,流速的改变可改变水负峰的位置和被测离子的保留时间。(答案:正确 8. 离子色谱分析中,淋洗液浓度的改变只影响被测离子的保留时间,而不影响水负峰的位置。(答案:正确 9. 离子色谱中的梯度淋洗与气相色谱中的程序升温相似,梯度淋洗一般只在含氢氧根离子或甲基磺酸根的淋洗液中采用抑制电导检测时才能实现。( 答案:正确 10. 高效离子色谱用低容量的离子交换树脂。( 答案:正确 11. 离子排斥色谱(HPICE)用高容量的离子交换树脂。( 答案:正确 12. 色谱柱的分离度表示在一定的分离条件下两个组分在某个色谱柱上分离的好坏。( 答案:正确 13. 高效液相色谱梯度洗脱中的低压梯度又称内梯度,高压梯度又称外梯度。( 答案:错误 正确答案为:低压梯度又称外梯度,高压梯度又称内梯度。 14. 在正相键合液相色谱法中,固定相是极性的,流动相是非极性溶剂。( 答案:正确 15. 在正相键合液相色谱法中,流动相极性变小,色谱保留时间延长。( 答案:正确

离子交换与离子交换色谱

仲恺农业工程学院Array论文题目:离子交换与离子交换色谱 论文作者:陈维权万辉 作者学号:201111014228 201111014229 所在院系:化学化工学院 专业班级:应用化学112班 指导老师:刘展眉

离子交换与离子交换色谱 摘要 本文对离子交换与离子交换色谱技术进行了综述。简要介绍了离子交换剂的作用原理;重点系统的论述了有机离子交换技术和无机离子交换技术的研究进展。并展望了有机离子交换技术和无机离子交换技术的发展方向。 关键词 离子交换色谱离子交换剂有机离子交换无机离子交换 Abstract This article by ion-exchange chromatography and ion exchange technologies for review. Brief description of the action principle of ion exchanger; key system deals with organic and inorganic ion-exchange technology of ion-exchange technology advances. And the prospect of organic ion exchange technology and development trend of inorganic ion-exchange technology. Keywords Ion Exchange Color spectrum Ion exchanger Organic ion exchange Inorganic ion exchanger 引言 随着科学技术的发展,现代分析化学的分析对象越来越复杂,待检测组分含量越来越复杂,待检测组分含量越来越低,在地球和宇宙科学、环境科学、生命科学、材料科学以及医学和考古学中,经常要求检测μg∕g,nm∕g,pg∕g甚至更低含量的组分。目前虽然有许多灵敏度和选择性很高的仪器分析方法,但在分析实践中,常常由于存在基体效应以及其他各种干扰而难以得到准确的结果,因此在分离富集仍然是分析方法中不可缺少的重要环节。 回顾化学的发展历史便可以发现:化学的发展离不开分离富集。元素周期表中的各个元素的发现,经典的化学分离和提纯方法都曾经起着重要作用。从二十世纪开始,各种天然放射性元素的逐个发现,人工放射性元素的获得,原子核裂变现象的最终确认,几乎都离不开各种化学分离技术。今年来生命科学的许多重要成就,也都与分离科学有着紧密联系。在大多数分析实验中,对复杂物料的分析或痕量、超痕量分析一般均采用样品制备-分解-分离富集-测定-数据处理的分析流程,也就是说,分离富集是分析流程中必不可少,而且往往是相当困难而又关键的环节。从分析仪器的研制和发展趋势看,分离富集技术与测量技术紧密结合是仪器分析的必然趋势。目前最有成效的是气相色谱仪、高效液相色谱仪、离子色谱仪以及测汞仪等,它们都是集分离-

离子色谱法测定水中无机阴离子材料与方法

离子色谱法测定水中无机阴离子材料与方法 目的:应用离子色谱法同时检测黄河水中6种无机阴离子(F-,Cl-,NO2-,NO3-,HPO42-,SO42-)的含量,研究并优化检测条件。方法:采集流经兰州市西固区、安宁区、七里河区和城关区连续3天的黄河水样,利用瑞士万通882型离子色谱仪进行检测,观察兰州市四个不同行政区黄河水中6种无机阴离子含量。色谱条件为:分离柱为A Supp 4-250阴离子分析柱,保护柱为Metrosep A Supp 4/5 Guard,以0.0018mol/LNa2CO3和0.0017mol/LNaHCO3为淋洗液,以0.05mol/LH2SO4溶液为再生液,泵的流速为1.0ml/min。结果:每种离子的相关系数r均大于0.999,F-,Cl-,NO2-,NO3-,HPO42-和SO42-检出限分别为0.02 mg/L、0.02 mg/L、0.03 mg/L、0.08 mg/L、0.12 mg/L和0.09 mg/L,相对标准偏差均小于5%,加标回收率在96.58%-103.00%之间,实验条件良好;经检测发现连续3天兰州不同区段黄河水中6种阴离子指标均符合地表水环境质量标准(GB3838-2002)和生活饮用水卫生标准(GB5749-2006)。结论:离子色谱法检测黄河水中无机阴离子灵敏度高,准确度好,方便高效;黄河水兰州段水中6种无机阴离子含量安全稳定。 关键字;离子色谱、阴离子、黄河水、加标回收 黄河,起自青海,流经兰州,是兰州人民的“母亲河”。兰州的饮用水、生活用水、工业用水和农业灌溉都离不开黄河,因此黄河水的水质安全应得到足够的重视。天然水中含有一定量的氟化物、氯化物、硝酸盐、硫酸盐等无机物质,其含量主要受地质条件的影响,各地有所不同。同一区域水体内其含量是相对稳定的,然而,当水中这些物质含量突然增高时,表明水体有可能受到人畜粪便、生活污水、工业废水或农作物肥料等污染。 水中无机阴离子的含量是否正常与人类生活有着密切的关系[1],F-、Cl-、NO2-、NO3-、HPO42-和SO42-6种离子含量的检测对水质安全意义重大。目前,上述离子常规的检测手段有分光光度法,电极法等,但这些方法一般不能同时检测多种离子,并且大多数运用了化学分析的方法[2]。自1977年离子色谱法应用于水处理领域以来,经过几十年来科学技术领域的进步,高效分离柱、温度补偿的电化学检测器等一系列辅助系统技术的融入,使得离子色谱法的稳定性和灵敏度均得到了迅速提高,应用领域也不断拓展,在环境监测方面得到普遍应用,对于无机

离子色谱法测定水中的阴离子

实验五离子色谱法测定水中的阴离子 环境工程李婷婷2110921109 一、实验目的 1、了解离子色谱分析的基本原理及操作方法; 2、掌握离子色谱法的定性和定量分析方法。 二、实验原理 离子色谱(Ion Chromatography,IC)是色谱法的一个分支,离子色谱法(IC)是利用被分离物质在离子交换树脂(固定相)上交换能力的不同,从而连续对共存多种阴离子或阳离子进行分离、定性和定量的方法。 阴阳离子的交换方程可以表示为: 阴离子交换:R+Y-+X-=R+X-+Y- 阳离子交换:R-Y++X+=R-X++Y+ 其中:R+,R-为固定相上的离子交换基团; Y+,Y-为可交换的平衡离子,例如H+,Na+或OH-,Cl-; X+ ,X-为组分离子。 如下图所示:

IC仪器主要测定流程:

测定步骤: (1)进样:水样待测离子首先与分离柱的离子交换树脂之间直接进行离子交换(即被保留在分离柱上); (2)淋洗:如用NaOH作淋洗液分析样品中的F-、Cl-和SO42-等,保留在分离柱上的阴离子即被淋洗液中的OH-基置换并从分离柱上被洗脱。对树脂亲和力弱的待分析离子(如F-)则先于对树脂亲和力强的待分析离子(如 SO42- )被依次洗脱; (3)阻留:淋出液经过抑制柱,将来自淋洗液的背景电导抑制到最小(即去除NaOH),这样当待测离子离开抑制柱进入电导池时就有较大的可准确测量的电导信号。 (4)测定:根据依次进入电导检测器的待测离子电导率差异,可进行定量测定。 三、实验步骤 1、过滤:用0.45μm过滤膜过滤。 目的是:去除样品中所包含的,有可能损坏仪器或者影响色谱柱/抑制器性能的成分——有机大分子;去除有可能干扰目标离子测定的成分。 2、进样: 手动进样。用针管吸取1mL水样推进进样口。 注意:水样不要交叉污染,清洗针管 3、分析水样: 自动分析水中的氟离子、氯离子、硝酸根离子、亚硝酸根离子、磷酸根离子、硫酸根离子。

基体消除-离子色谱法分析复杂基体中的阴阳离子

基体消除-离子色谱法分析复杂基体中的阴阳离子 (瑞士万通中国技术支援中心, 中国上海, 200053) 摘 要:准确而方便快捷的样品预处理是目前分析化学研究的难题之一,它制约着相关学科如环境科学和生谱;阴离子;阳离子 谱(IC )从二十世纪七十年代问世至今得到了迅猛的发展,被认为是各种离子化 合物等性能。但是实际是目前分析化学的瓶颈,它制约着相关学科如环境科学和生命科学的发展,是分括过滤、超滤、固相萃取、渗析、稀释、预浓缩等。英蓝基体消除技术结合Metrohm 812+833装置,分析了甘油样品中的K +,IPA 、 H 2O 型离子色谱仪(瑞士万通)配有电导检测器、化学抑制器、低脉冲串联式双活钠、碳酸 孙郑冬 命科学的发展,是分析化学研究的热点。对于大量复杂基体的样品,离子色谱可以采用合适的方法,通过预处理后再用离子色谱法进行分析,但如果预处理方法不合适,经常会导致不稳定的基线、畸形的色谱峰、较差的分离效率,甚至根本无法进行色谱分析,同时色谱柱的寿命也会大大缩短。合适的预处理方法可大大提高复杂基体样品测定结果的准确性、提高分析方法的灵敏度。采用Metrohm 812+833英蓝基体消除装置,分析了含甘油样品中的K +,以及IPA(异丙醇)、H 2O 2 31%、NH 3·H 2O 2%、NMP中的F -、Cl -、NO 3-、PO 4-、SO 42-等阴离子,并获得满意的测定结果。 关键词:英蓝技术;基体消除;离子色1. 前言 离子色最有效的分析方法之一[1]。 IC 特别适用于多组分无机和有机阴阳离子的快速、同时测定。对大多数应用而言,IC 的显著特点是:选择性强、测定范围广、灵敏度高。 可通过分析标准溶液,论证现代IC 的色谱分离度、同时性、灵敏度和速度应用中,通常面临的是真实样品。样品组分可能差别很大,多数情况下都需要通过复杂的样品制备过程,才能进行IC 分析。如待测组分的浓度太高、样品必须先稀释,然后才能进样;检测系统的灵敏度不够高,待测离子需先预浓缩后才能定量分析;样品中待测离子浓度相差几个数量级;存在信号重叠引起干扰的物质;存在对分离柱产生不可逆转影响的物质;以及含颗粒、固体、气体样品的测定等。所以,样品的前处理至关重要[2~4]。 2. 英蓝技术 样品前处理析化学研究的难点和热点问题之一。由于样品数量极多,且分析物含量越来越低、基体越来越复杂,迫切要求发展高通量、高选择性、高效率的在线样品前处理技术。因此,开展这方面的研究具有极为重要的意义。近年来,自动化的样品前处理技术,尤其是在线样品前处理技术,正越来越受到分析界的关注。 实践中已广泛应用的样品前处理技术包所有这些技术的共同点是:通常用手工来完成。但是,手工样品制备不仅费时,而且精确度和准确度差,分析成本高。为此,瑞士万通开发了离子色谱样品直接进样连续处理分析技术(Metrohm Inline Sample Preparation, MISP )。实现了全自动的样品渗析、样品超滤、样品稀释、和样品基体消除。为最优化离子色谱样品制备带来了不可估量的潜力。分析费用大为降低,同时分析结果的质量显著改善。从而使离子色谱作为重要分析手段的领域得到了持续的扩展。 本文使用2 31%、NH 3 2%、NMP 中的F -、Cl -、NO 3-、PO 4-、SO 42-等阴离子,获得满意的测定结果。 3. 实验部分 3.1 仪器及试剂Metrohm-761 塞往复泵、812六通定量阀、833双通道蠕动泵、数据采集/处理软件等。 标准样:F -、Cl -、NO 3-、PO 4-、SO 42- (国家标准物质研究中心)。硝酸钾、碳酸

第七节 离子交换色谱

第七节离子交换色谱 离子交换色谱(ion-exchange chromatography,IEC)是发展最早的色谱技术之一。20世纪30年代人工合成离子交换树脂的出现对于离子交换技术的发展具有重要意义,基于苯乙烯-二乙烯苯的离子交换树脂至今仍是最广泛使用的一类离子交换树脂。但它并不十分适合对生物大分子如蛋白质、核酸、多糖等的分离,因为:①树脂交联度太大而颗粒内网孔较小,蛋白质分子无法进颗粒内部,只能吸附在表面,造成有效交换容量很小;②树脂表面电荷密度过大,使蛋白质在其上吸附得过于牢固,必须用较极端的条件才能洗脱,而这样的条件往往易造成蛋白质变性;③树脂的骨架具疏水性,一旦与蛋白质之间发生疏水相互作用,也容易造成蛋白质变性失活。 20世纪50年代中期,Sober和Peterson合成了羧甲基(CM-)纤维素和二乙氨乙基(DEAE-)纤维素,这是两种亲水性和大孔型离子交换剂。其亲水性减少了离子交换剂与蛋白质之间静电作用以外的作用力,而大孔型结构使蛋白质能进人网孔内部从而大大提高了有效交 换容量,而纤维素上较少的离子基团有利于蛋白质的洗脱,因此这两种离子交换剂得到了极为广泛的应用。此后,多种色谱介质特别是颗粒型介质被开发和合成,包括交联葡聚糖凝胶、交联琼脂糖、聚丙烯酞胺以及一些人工合成的亲水性聚合物等,以这些介质为骨架结合上带电基团衍生而成的离子交换剂也层出不穷,极大地推动了离子交换技术在生化分离中的发展和应用。 一、离子交换色谱相关理论 (一)基本原理 离子交换色谱分离生物分子的基础是待分离物质在特定条件下与离子交换剂带相反电荷因而能够与之竞争结合,而不同的分子在此条件下带电荷的种类、数量及电荷的分布不同,表现出与离子交换剂在结合强度上的差异,在离子交换色谱时按结合力由弱到强的顺序被洗脱下来而得以分离。离子交换色谱的原理和一般步骤如图6.7-1所示。

离子色谱分析

离子色谱分析 科室:姓名:得分: 一、填空题(每题4分,共20分) 1、离子色谱可分为、和三种不同分离方式。 答案:高效离子色谱离子排斥色谱流动相色谱 2、离子色谱系统由、、、、和 等部分组成。 答案:淋洗液存贮器输液泵进样阀分离柱抑制柱检测器数据处理机(或记录仪) 3、各种类型的离子交换剂都是通过其功能基所结合的离子与外界同电荷的其它离子间发生或作用达到分离物质的目的。 答案:取代络合 4、1975年Small等人用型阳离子交换树脂作为离子色谱的分离柱。答案:低容量薄壳 5、为防止输液系统堵塞,水样作离子色谱分析前,必须先行处理后方可进样。 答案:稀释和过滤 二、选择题(每题4分,共20分) 1、离子色谱柱上,下列常见阴离子的保留时间从小到大排列正确的是。 A、F-,Cl-,Br-,I- B、I-,Br-,Cl-,F- C、F-,Cl-, I-,Br- D、Cl-, I-,Br-, F- 答:A 2、对离子色谱下面说法正确的是。 A、配制淋洗液所用的水必须是蒸馏水,且用0.45微米的微孔滤膜过滤 B、离子色谱分析的原理是离子交换原理 C、分析酸雨阴离子时,抑制柱的作用主要是把阴离子转变成相应的酸 D、电导检测器对温度的变化不敏感

答:B 3、高效离子色谱的分离机理属于下列哪一种?。 A、离子排斥 B、离子交换 C、吸附和离子对形成 答案:B 4、离子色谱的淋洗液浓度提高时,一价和二价离子的保留时间的变化是。 A、缩短 B、延长 答:A 5、以下三种离子色谱抑制柱,哪一种柱容量大?。 A、树脂填充抑制柱 B、纤维抑制柱 C、微膜型抑制柱 答:C 三、判断题(每题4分,共20分) 1、高效离子色谱用低容量的离子交换树脂。() 答案(√×) 2、流动相离子色谱(MPIC)用不含离子交换基团的多孔树脂。() 答案(√) 3、离子色谱用的中等强度碳酸盐淋洗液对高亲和力离子的分辨率低。()答案(×) 4、作离子色谱分析用纤维抑制柱时,如淋洗液浓度相同,增加流速,背景电导会减小。() 答案(×) 5、增加进样量可提高离子色谱的灵敏度。() 答案(√) 四、问答题(每题4分,共20分) 1、离子色谱具有哪些优点? 答:快速、灵敏、选择性好、可同时分析多种离子。 2、影响单柱阴离子色谱保留时间的因素有哪些? 答:分离柱树脂交换的容量;淋洗液浓度;淋洗液pH